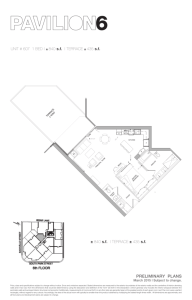

CHAPTER 3 : DESIGN

advertisement