Stochastic Modeling of a Concrete Mixture Plant with Preventive Maintenance

advertisement

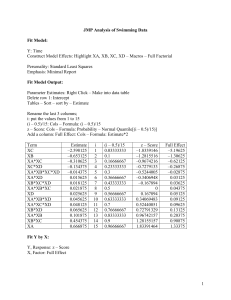

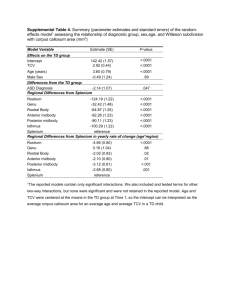

Available at http://pvamu.edu/aam Appl. Appl. Math. ISSN: 1932-9466 Applications and Applied Mathematics: An International Journal (AAM) Vol. 9, Issue 1 (June 2014), pp. 13-27 Stochastic Modeling of a Concrete Mixture Plant with Preventive Maintenance Ashish Kumar and Monika Saini Department of Mathematics Manipal University Jaipur Jaipur-303007, Raj (India) S.C. Malik Department of Statistics M.D. University Rohtak-124001, Haryana (India) akbrk@rediffmail.com Received: November 26, 2013; Accepted: February 6, 2014 Abstract In this paper, a stochastic model for concrete mixture plant with Preventive Maintenance (PM) is analyzed in detail by using a supplementary variable technique. In a concrete mixture plant eight subsystems are arranged in a series. The system goes under PM after a maximum operation time and work as new after PM. The time to failure of each subsystem follows a negative exponential distribution while PM and repair time distributions are taken as arbitrary. A sufficient repair facility is provided to the system for conducting PM and repair of the system. Repair, maintenance and switch devices are perfect. All random variables are statistically independent. Various measures of system effectiveness such as reliability, mean time to system failure (MTSF), are derived using a supplementary variable technique. The numerical results for reliability and availability are obtained for particular values of various parameters and costs. Keywords: Concrete Mixture Plant; Reliability; Availability; Preventive Maintenance and Supplementary Variable Technique MSC 2010 No.: 90B25, 60K10 13 14 Gurju Awgichew et. al 1. Introduction Concrete mixture plants are widely used to produce various kinds of concrete including quaking concrete and hard concrete, suitable for large or medium scale building works, road and bridge works and precast concrete plants, etc. Basically, such plants are designed for the production of all types of concrete, mixed cements, cold regenerations and inertisations of materials mixed with resin additives. Due to the complexity of modern concrete mixture systems, which involve high risks, the concept of reliability has become a very important factor in the overall system design. While dealing with reliability-based design of machines and structures, we can study the relative importance of mechanical and structural failures from the point of view of loss of human lives. Reliability analysis of such a system helps us to obtain the necessary information about the control of various parameters. Arekar et al. (2012), Kharoufeh et al. (2010), Proctor and Singh (1976), Shakuntla et al. (2011), Malik (2008) and Uematsu and Nishida (1987) have analyzed single-unit systems under a common assumption that the unit works continuously till failure without undergoing PM. The continued operation of the systems may reduce performance and reliability of the system. Therefore, PM of the unit is necessary after a specific period of time at any stage of operation to improve the reliability and availability of the system because the cost to repair the system after its failure is greater than the cost of maintaining the system before its failure. Thus, the method of preventive maintenance can be adopted to improve the reliability and profit of system. The concept of preventive maintenance has been used by many researchers such as Malik and Nandal (2010), Kumar et al. (2012) and Kumar and Malik (2012) while analyzing the redundant systems with maximum operation time. It is also interesting to note that not much work related to the reliability modeling of the concrete mixture plant subject to preventive maintenance has been reported so far in the literature of reliability. Most of the authors discussed the system possessing Markovian properties. The system having non-Markovian property can be converted into a system having Markovian nature by introducing a new variable called a supplementary variable. Initially, Cox (1955) used the supplementary variable in analyzing a non-Markovian system and presented a systematic solution of reliability and availability of that system using the supplementary variable technique. Gaver (1963) studied a parallel redundant system with constant failure and arbitrary repair rates. Since then several authors have studied the reliability of the various systems using supplementary variable technique. Singh and Dayal (1991) used supplementary variable technique for problem formulation. Alfa and Rao (2000) discussed the supplementary variable technique in stochastic models. The concrete mixture plant with preventive maintenance has not been discussed so far even though it plays an important role in our daily life and development of the infrastructure. The assumption of constant failure, maintenance and repair rates may not be practical in any industry. Keeping this in view, in the present study, we have considered eight-subsystems of the concrete mixture plant with constant failure and arbitrary repair rates of the subsystems and discussed the reliability modeling of concrete mixture plant with preventive maintenance using supplementary variable technique. An attempt has also been made to discuss the availability of this plant with respect to different failure and repair rates. AAM: Intern. J., Vol. 9, Issue 1 (June 2014) 15 The paper has been organized as follows: Section 1 is introductory in nature. In Section 2, a summary of the system and various notations of the subsystems are presented. The basic assumptions, on which the present analysis is based, are also discussed in Section 2. The mathematical formulation and solution of the differential-difference equation of Concrete mixture plant developed using the supplementary variable technique, (assuming constant failure and variable repair rates) presented in Section 3. Certain conclusions drawn from this analysis are also discussed in the Section 4. 2. System Description, Notations and Assumptions Concrete mixing plants are widely used to produce various kinds of concrete including quaking concrete and hard concrete suitable for large or medium scale building works, road and bridge works and precast concrete plants, etc. A concrete plant, also known as a batch plant, is a device that combines various ingredients to form concrete. Some of these inputs include sand, water, aggregate, fly ash, potash and cement. A concrete plant can have a variety of parts such as a dosing system, mixer feeding belt conveyor, main chassis superstructure, mixing system, cement silo, screw conveyor, electrical control system and insulated control cabinet. In this paper, we consider concrete mixing plant consisting of eight sub-systems namely, a dosing system, mixer feeding belt conveyor, main chassis superstructure, mixing system, cement silo, screw conveyor, electrical control system and insulated control cabinet. The complete description of the systems and their notations required in the mathematical formulation are as follows: 2.1. System Description 2.1.1. Sub-system A (Dosing system) It is a storehouse of the aggregates which are controlled by cylinders of two material discharging hoppers. The size of the two doors is different. The size of the material doors can be adjusted. 2.1.2. Sub-system B (Mixer feeding belt conveyor) It is a double surface ladder fence. It is jointing with main tower in such a way that it avoids the shaking of the main tower making the exact weighing. 2.1.3. Sub-system C (Main chassis superstructure) It is built from color steel sandwich board. Its main functioning is heat preservation and heat insulation. It is equipped with dust catcher to avoid pollution. 2.1.4. Sub-system D (Mixing system) In a mixing system various materials such as cement, sand or gravel, and water are combines in a homogenous manner to form concrete. A typical concrete mixer uses a revolving drum to mix the components. 2.1.5. Sub-system E (Cement silo) It is used to store dry, bulk cement. Gurju Awgichew et. al 16 2.1.6. Sub-system F (Screw conveyor) It is a duct along which material is conveyed by the rotational action of a spiral vane which lies along the length of the duct. 2.1.7. Sub-system G (Electrical control system) It is a collection of electronic devices that manage commands, directs or regulates the behavior of the whole concrete plant. 2.1.8. Sub-system H (Insulated control cabinet) In this cabin, electronic devices, fittings, sockets and switches exist. 2.2. Notations A, B, C, D, E, F, G and H, indicate that the sub-system is working in full capacity. a, b, c, d, e, f, g and h, indicate the failed state of the sub-system. αi, denotes the constant failure rate of the units, where i = 1,2, …, 8. αm, denotes the constant transition rate of the system. ( ) ( ) ( ) ( denotes the probability that at time t the system is in good state. ) ( ( ) ( ) denote the repair rate of the unit and probability density function, respectively, for the elapsed repair time ‘x’, where i = 1, 2, …, 8. denotes the probability that at time t the system is in failed state the elapsed repair time lies in the interval ( x, x ), where i 1,2, ,8. ) denotes the probability that at time t the system is under PM, the elapsed PM time is ‘y’. ( ) denote the preventive maintenance rate of the unit and probability density function, for the elapsed maintenance time ‘y’, respectively. Laplace transform of ( ) AAM: Intern. J., Vol. 9, Issue 1 (June 2014) ( ) ( ) , 17 [ ∫ ( ) ( ) [ ∫ ( ) ( ) ] ] denotes the definite integral from 0 to x. Dosing system Mixer feeding belt conveyor Main chassis superstructure Mixing system Cement silo Screw conveyor Electrical control system Insulated control cabinet Figure 1: System Formulation 2.3. Assumptions (i) Repair and failure rates are independent of each other and their unit is taken as per day. (ii) Failure and repair rates of the subsystems are taken respectively as constant and variable. (iii) Performance wise, a repaired unit is as good as new one for a specified duration. (iv) Sufficient repair facilities are provided. (v) Service of the subsystem includes repair and/or replacement. (vi) Switch devices, repairs and preventive maintenances are perfect. (vii) The distribution of preventive maintenance is considered as arbitrary. Gurju Awgichew et. al 18 3. Formulation and Solution of Mathematical Model By probability considerations and continuity arguments, we obtain the following differencedifferential equations governing the behavior of the system: 8 8 P ( t ) [ P ( x , t ) ( x ) dx ] Pm ( y, t ) 9 ( y )dy. i m 0 i i t i 1 i 1 0 0 (1) i ( x ) Pi ( x, t ) 0, where i 1,2,...,8. t x (2) 9 ( x ) Pm ( y, t ) 0. t y (3) The boundary and initial conditions to be satisfied are given below Boundary Conditions: Pi (0, t ) i P0 (t ), where i 1,2,...,8, (4) Pm (0, t ) m P0 (t ). (5) Pi (0) 1, when i 0, (6) Initial Conditions: Pi (0) 0, when i 0. By taking LT of equations (1)-(5) and using in (6), we get 8 8 s P ( s ) 1 P ( x , s ) ( x ) dx i m 0 i i P9 ( y, s) 9 ( y )dy. i 1 0 i 1 0 (7) s i ( x ) Pi ( x, s ) 0, where i 1,2,...,8 x (8) s 9 ( y ) Pm ( y, s ) 0. y (9) Pi (0, s) i P0 ( s), where i 1,2,...,8. (10) Pm (0, s) m P0 ( s). (11) Now, integrating equation (8) and further using in equation (10), we get AAM: Intern. J., Vol. 9, Issue 1 (June 2014) 19 (12) x [ sx i ( x ) dx ] Pi ( x, s ) Pi (0, s ) e 0 , where i 1,2,...,8. Integrating equation (9) and further using equation (11), we get (13) y [ sy 9 ( x) dy ] Pm ( y, s) Pm (0, s) e 0 . By using equations (12-13) in equation (7), we get 8 8 s i m P0 ( s) 1 [i P0 ( s) Si ( s)] m P0 ( s) S9 ( s). i 1 i 1 (14) 8 s i (1 Si ( s )) P0 ( s ) 0 . i 1 (15) [s m (1 S9 (s))]P0 (s) 0. (16) P0 ( s ) (17) 1 , T ( s) where 8 T ( s) s i (1 Si ( s )) m (1 S9 ( s )) . i 1 (18) Now, the Laplace Transformation of the probability that the system is in the failed state is given by P1( s ) P1( x, s )dx 1 P0 ( s ) 0 1 S1( s) A ( s) 1 1 , s T ( s) (19) where A1 ( s) 1 S1 ( s) . s Similarly Pi ( s ) Pi ( x, s)dx i P0 ( s ) 0 1 Si ( s) A ( s) 1 i . s T (s) (20) where Ai ( s) 1 Si ( s) , i 2,3,4,5,6,7,8. s Pm ( s ) Pm ( x, s)dx m P0 ( s ) 0 1 S9 ( s) A ( s) m m . s T ( s) where Am ( s) 1 Sm ( s ) . s (21) Gurju Awgichew et. al 20 It is worth noting that 8 Pi ( s ) Pm ( s ) i 0 1 . s (22) Evaluation of Laplace transforms of up and down state probabilities The Laplace transforms of the probabilities that the system is in up (i.e., good) and down (i.e., failed) state at time ‘‘t’’ are as follows Pup ( s ) P0 ( s ) 1 , T ( s) 8 Pdown ( s ) Pi ( s ) Pm ( s ) i 1 8 Ai ( s ) Am ( s ) i 1 . (23) T ( s) Steady-State Probabilities Using Abel’s Lemma in Laplace transforms, viz. lim sZ ( s) lim Z (t ) Z (say ) s0 t Provided the limit on the right hand side exists, the following time independent probabilities have been obtained. Pup 1 , 8 [1 i Si' (0) m S9' (0)] i 1 8 i Si' (0) i 1 Pdown 8 [1 i Si' (0) m S9' (0)] i 1 (24) . Reliability Indices In order to obtain system reliability, consider repair rates (i.e., ( ) ) equal to zero. Using the method similar to that in section 2, the differential–difference equations are: 8 t i m P0 (t ) 0. i 1 Theorem 1. The reliability of the system is given by (25) AAM: Intern. J., Vol. 9, Issue 1 (June 2014) 21 8 R(t ) e ( i m )t i 1 (26) . Proof: The proof of the Theorem 1 is given in the appendix. Corollary 1. The mean time to system failure (MTSF) is: MTSF 1 8 i i 1 . (27) m Proof: ∫ Calculating ( ) implies the result ‘*’ given in the appendix. Special Case (Availability) When repair rates follows exponential time distribution. Setting S9 ( s) m s m and i , where i , i=1, 2, 3, ..., 8, are constant repair rates. Putting these values in equation s i (17), we get Si ( s ) 8 s ( s m ) ( s i ) i 1 8 ( s i )( s m ) i 1 . 8 8 8 s j ( s m ) ( s i ) s m ( s i ) j 1 i j ,i 1 i m,i 1 (28) 4. Numerical Analysis Table-1: Effect of failure rate ( 1 ) on Reliability (R(t)) Time α2 α3 α4 α5 α6 α7 1 2 3 4 5 6 7 8 9 10 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 α8 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 αm .04 .04 .04 .04 .04 .04 .04 .04 .04 .04 R(t) for α1=.001 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 R(t) for α1=.005 0.874328 0.764449 0.668379 0.584382 0.510942 0.44673 0.390589 0.341503 0.298585 0.261061 R(t) for α1=.05 0.835855 0.698654 0.583973 0.488117 0.407995 0.341025 0.285047 0.238258 0.199149 0.16646 Gurju Awgichew et. al 22 Table 2. Effect of failure rate ( 2 ) on Reliability (R(t)) Time α1 α3 α4 α5 1 2 3 4 5 6 7 8 9 10 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 α6 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 α7 α8 αm 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 R(t) for α2=.002 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 .04 .04 .04 .04 .04 .04 .04 .04 .04 .04 R(t) for α2=.008 0.872581 0.761397 0.664381 0.579726 0.505858 0.441402 0.385159 0.336082 0.293259 0.255892 R(t) for α2=.08 0.811963 0.659285 0.535315 0.434656 0.352925 0.286562 0.232678 0.188926 0.153401 0.124556 Table 3. Effect of failure rate ( 3 ) on Reliability (R(t)) Time α1 α2 α4 α5 1 2 3 4 5 6 7 8 9 10 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 α6 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 α7 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 α8 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 αm 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 .04 .04 .04 .04 .04 .04 .04 .04 .04 .04 R(t) for α3=.003 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 R(t) for α3=.009 0.872581 0.761397 0.664381 0.579726 0.505858 0.441402 0.385159 0.336082 0.293259 0.255892 R(t) for α4=.004 R(t) for α4=.007 R(t) for α3=.06 0.829195 0.687564 0.570125 0.472745 0.391997 0.325042 0.269523 0.223487 0.185315 0.153662 Table 4. Effect of failure rate ( 4 ) on reliability (R(t)) Time α1 α2 1 2 3 4 5 6 7 8 9 10 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 α3 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 α5 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 α6 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 α7 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 α8 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 αm .04 .04 .04 .04 .04 .04 .04 .04 .04 .04 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 0.875202 0.765979 0.670387 0.586724 0.513503 0.449419 0.393332 0.344246 0.301285 0.263685 R(t) for α4=.07 0.821766 0.675299 0.554937 0.456028 0.374749 0.307955 0.253067 0.207962 0.170896 0.140436 AAM: Intern. J., Vol. 9, Issue 1 (June 2014) 23 T Table 5. Effect of failure rate ( 5 ) on reliability (R(t)) Time α1 α2 α3 α4 α6 1 2 3 4 5 6 7 8 9 10 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 α7 α8 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 αm .04 .04 .04 .04 .04 .04 .04 .04 .04 .04 R(t) for α5=.05 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 R(t) for α5=.09 0.843412 0.711343 0.599955 0.506009 0.426774 0.359946 0.303583 0.256046 0.215952 0.182136 R(t) for α5=.15 0.794295 0.630905 0.501125 0.398041 0.316162 0.251126 0.199468 0.158437 0.125846 0.099959 R(t) for α6=.03 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 R(t) for α6=.093 0.824235 0.679363 0.559954 0.461534 0.380412 0.313549 0.258438 0.213013 0.175573 0.144713 R(t) for α6=.12 0.802278 0.64365 0.516386 0.414285 0.332372 0.266655 0.213931 0.171632 0.137697 0.110471 R(t) for α7=.0001 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 R(t) for α7=.003 0.87529 0.766133 0.670588 0.586959 0.51376 0.449689 0.393608 0.344521 0.301556 0.263949 R(t) for α7=.012 0.867448 0.752466 0.652725 0.566204 0.491153 0.426049 0.369576 0.320588 0.278093 0.241231 T Table 6. Effect of failure rate ( 6 ) on reliability (R(t)) T Time α1 α2 α3 α4 α5 1 2 3 4 5 6 7 8 9 10 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 α7 α8 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 .04 .04 .04 .04 .04 .04 .04 .04 .04 .04 α8 αm 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 0.0002 .04 .04 .04 .04 .04 .04 .04 .04 .04 .04 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 αm Table 7. Effect of failure rate ( 7 ) on reliability (R(t)) Time α1 α2 1 2 3 4 5 6 7 8 9 10 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 α3 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 α4 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 α5 α6 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 Gurju Awgichew et. al 24 T Table 8. Effect of failure rate ( 8 ) on reliability (R(t)) Time α1 α2 1 2 3 4 5 6 7 8 9 10 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 α3 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 α4 α5 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 α6 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 α7 αm 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 .04 .04 .04 .04 .04 .04 .04 .04 .04 .04 R(t) for α8=.0002 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 R(t) for α8=.004 0.874503 0.764755 0.66878 0.58485 0.511453 0.447267 0.391136 0.342049 0.299123 0.261584 R(t) for α8=.122 0.777167 0.603989 0.4694 0.364802 0.283512 0.220336 0.171238 0.133081 0.103426 0.080379 .0002 .0002 .0002 .0002 .0002 .0002 .0002 .0002 .0002 .0002 R(t) for αm=.04 0.877832 0.770589 0.676448 0.593808 0.521263 0.457582 0.40168 0.352607 0.30953 0.271715 R(t) for αm=.12 0.810341 0.656653 0.532113 0.431193 0.349413 0.283144 0.229443 0.185927 0.150664 0.12209 R(t) for αm=.32 0.663451 0.440167 0.29203 0.193747 0.128542 0.085281 0.05658 0.037538 0.024905 0.016523 T Table 9. Effect of Transition rate ( m ) on reliability (R(t)) Time α1 α2 1 2 3 4 5 6 7 8 9 10 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.002 α3 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 0.003 α4 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 0.004 α5 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 α6 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 α7 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 α8 AAM: Intern. J., Vol. 9, Issue 1 (June 2014) 25 Table-10: Availability of Concrete Mixture Plant w.r.t. failure rate (α1). Set 1: α2=.002, α3=.003, α4=.004, α5=.05, α6=.03, α7=.0001, α8=.0002, αm=.04, β1=.05, β2=.9, β3=.3, β4=.59, β5=.9, β6=.98, β7=.7, β8=.9, βm=1.2 α1 In set 1 In set 1 In set 1 In set 1 In set 1 In set 1 In set 1 Replace Replace Replace Replace Replace Replace Replace Set 1 α4=.004 α7=.0001 α2=.002 α3=.003 α5=.05 by α6=.03 by α8=.0002 by by by α2=.07 by α3=.05 α5=.5 α6=.3 by α8=.02 α2=.04 α7=.005 0.001 0.876526 0.822082 0.770692 0.832026 0.609434 0.706026 0.87118 0.859943 0.002 0.874992 0.820733 0.769506 0.830644 0.608692 0.705031 0.869665 0.858466 0.003 0.873463 0.819388 0.768324 0.829266 0.607951 0.704038 0.868155 0.856995 0.004 0.87194 0.818047 0.767145 0.827893 0.607213 0.703048 0.86665 0.855529 0.005 0.870422 0.816711 0.76597 0.826525 0.606477 0.702061 0.865151 0.854067 0.006 0.868909 0.815379 0.764798 0.825161 0.605742 0.701076 0.863656 0.852611 0.007 0.867402 0.814051 0.76363 0.823801 0.605009 0.700095 0.862167 0.851159 0.008 0.8659 0.812728 0.762465 0.822446 0.604278 0.699116 0.860683 0.849713 0.009 0.864403 0.811409 0.761305 0.821096 0.603548 0.69814 0.859204 0.848271 0.01 0.862911 0.810095 0.760147 0.819749 0.602821 0.697166 0.85773 0.846835 In set 1 Replace αm=.04 by αm=.19 0.789972 0.788726 0.787483 0.786245 0.785011 0.78378 0.782553 0.781331 0.780111 0.778896 Table-11: Availability of Concrete Mixture Plant w.r.t. repair rate (β1). Set 2: α1=.001,α2=.002, α3=.003, α4=.004, α5=.05, α6=.03, α7=.0001, α8=.0002, αm=.04, β2=.9, β3=.3, β4=.59, β5=.9, β6=.98, β7=.7, β8=.9, βm=1.2 β1 In set 2 In set 2 In set 2 In set 2 In set 2 In set 2 In set 2 Replace Replace Replace Replace Replace Replace Replace Set 2 β2=.9 by β3=.3 by β4=.59 by β5=.9 by β6=.98 by β7=.7 by β8=.9 by β2=1.9 β3=1.3 β4=1.42 β5=2.5 β6=2.3 β7=1.7 β8=1.9 0.01 0.870422 0.871309 0.876289 0.873435 0.89822 0.883939 0.870486 0.870511 0.02 0.874227 0.875121 0.880145 0.877266 0.902273 0.887863 0.874291 0.874316 0.03 0.875502 0.8764 0.881438 0.87855 0.903631 0.889179 0.875567 0.875592 0.04 0.876142 0.87704 0.882086 0.879194 0.904312 0.889839 0.876206 0.876231 0.05 0.876526 0.877425 0.882476 0.879581 0.904721 0.890235 0.87659 0.876615 0.06 0.876782 0.877682 0.882735 0.879839 0.904994 0.890499 0.876846 0.876872 0.07 0.876965 0.877865 0.882921 0.880023 0.905189 0.890688 0.877029 0.877055 0.08 0.877102 0.878003 0.88306 0.880161 0.905336 0.890829 0.877167 0.877192 0.09 0.877209 0.87811 0.883168 0.880269 0.90545 0.89094 0.877274 0.877299 0.1 0.877294 0.878196 0.883255 0.880355 0.905541 0.891028 0.877359 0.877385 In set 2 Replace βm=1.2 by βm=2.2 0.882055 0.885962 0.887272 0.887929 0.888323 0.888586 0.888774 0.888915 0.889025 0.889113 5. Conclusion The results and system reliability are shown in Tables (1-10) which indicates that the reliability of the system decreases with the increase of failure rates ( i ) and transition rate m w.r.t. time and for fixed values of other parameters. Also, it is analyzed that there are sudden jumps in the values of reliability function and over a long period of time the system becomes less and less reliable. Table 10, shows that are availability of the system decreases with the increase of the failure rate ( 1 ). Table 11, shows the behavior of steady state availability with respect to repair rate ( 1 ) and observed that availability of the system increase with the increases of the repair rate and preventive maintenance rate. Gurju Awgichew et. al 26 REFERENCES Cox, D.R. (1955). Analysis of Non Markovian stochastic processes by the inclusion of Supplementary variables, Proc. Comb. Phill. Soc., Vol. 51, pp. 433–441. Gaver, D.P. (1963). Time to failure and availability of parallel system with repair, IEEE T. Reliab. R-12, pp.30–38. Proctor, C.L., Singh, B. (1976). A repairable 3- state device, IEEE Trans. Reliab., R-25, pp. 210- 211. Uematsu, K, Nishida, T. (1987). One-unit system with a failure rate depending upon the degree of repair, Mathematica Japonica,Vol. 32, No.1, pp.139-147. Singh,J., Dayal,B. (1991). A 1-out of-N: G system with common cause failure and critical human errors, Microelectron Reliab. Vol.31, pp.101–104. Alfa, A.S., Rao, T.S.S. (2000). Supplementary variable technique in stochastic models, Probab. Eng. Inform. Sci. Vol.14, pp. 203–218. Malik, S.C. (2008): Reliability modeling and profit analysis of a single-unit system with inspection by a server who appears and disappears randomly, Journal of Pure and Applied Mathematika Sciences, Vol. LXVII, No. 1-2, pp. 135-146. Kharoufeh, J.P., Solo, C.J. and Ulukus, M.Y. (2010). Semi-Markov models for degradationbased reliability, IIE Transactions. Vol. 42, pp. 599–612. Malik, S. C. and Nandal, P. (2010). Cost- Analysis of Stochastic Models with Priority to Repair Over Preventive Maintenance Subject to Maximum Operation Time, Edited Book, Learning Manual on Modeling, Optimization and Their Applications, Excel India Publishers, pp.165-178. Shakuntla S., Lal, A.K., Bhatia, S.S. and Singh, J. (2011). Reliability analysis of polytube industry using supplementary variable technique, Applied Mathematics and Computation, Vol.218, pp. 3981-3992. Arekar, K., Ailawadi, S. and Jain, R. (2012). Reliability modeling for wear out failure period of a single unit system, Journal of Statistical and Econometric Methods, Vol.1 (1), pp. 3341. Kumar, A., Malik, S. C. (2012). Stochastic Modeling of a Computer System with Priority to PM over S/W Replacement Subject to Maximum Operation and Repair Times. International Journal of Computer Applications, Vol.43 (3), pp. 27-34. Kumar, A., Malik, S.C. and Barak, M.S. (2012). Reliability Modeling of a Computer System with Independent H/W and S/W Failures Subject to Maximum Operation and Repair Times, International Journal of Mathematical Achieves, Vol.3, No. 7, pp.2622-2630. APPENDIX Derivation of Equations (1)-(3) Assuming failure rates of the system are constant and repair rates are variable. By applying supplementary variable technique, we develop the following differential difference equations ) associated with the state transition diagram (fig. 1) of the system at time( ) and ( 8 8 i 1 i 1 0 0 P0 (t t ) P0 (t )[1 i m ] [ Pi (t ) i ( x)dxt ] Pm (t ) m ( x)dxt o(t ). AAM: Intern. J., Vol. 9, Issue 1 (June 2014) 27 Pi (t t , x x) Pi (t , x)[1 i ( x)x] o(t , x) where i 1,2,...,8. Pm (t t , y y) Pm (t , y)[1 m ( y)y] o(t , y). Proof of Theorem 1: Taking Laplace transform of (25) and using (6) we get 8 ( s i m ) P0 (s) 1 i 1 Using the initial conditions, the solution can be written as P0 ( s) R( s) 1 8 s i i 1 , m 1 8 s i i 1 , m Taking inverse Laplace transform, we get (*) 8 R(t ) e ( i m )t i 1 . aBCDEFGH P1(x,t) ABCDEFGh P8(x,t) AbCDEFGH P2(x,t) α2 β8(x) α8 α1 β1(x) β2(x) ABCDEFgH P7(x,t) ABCDEfGH P6(x,t) α7 β7(x) β6(x) α6 α3 ABCDEFGH P0(t) β3(x) αm β5(x) α5 βm(y ) ABCDeFGH P5(x,t) ABcDEFGH P3(x,t) α4 β4(x) ABCdEFGH P4(x,t) abcdefgh Pm(x,t) Operative State Figure 2. State transition Diagram Failed State