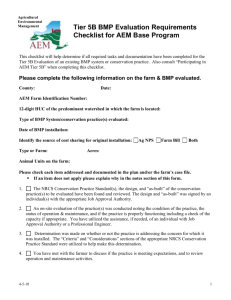

A F W C

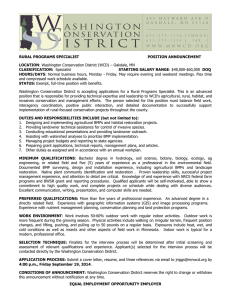

advertisement