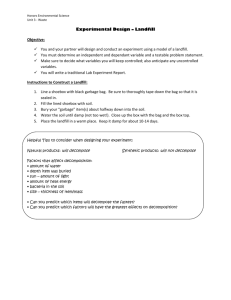

CANCELLED SOLID WASTE DISPOSAL UNIFIED FACILITIES CRITERIA (UFC)

advertisement