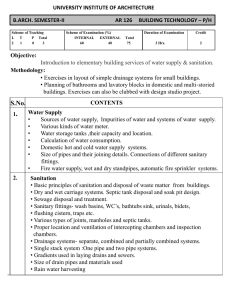

GREENING FEDERAL FACILITIES An Energy, Environmental, and Economic Resource Guide SECOND EDITION

advertisement