Safety Showers Article 1.26.2010

advertisement

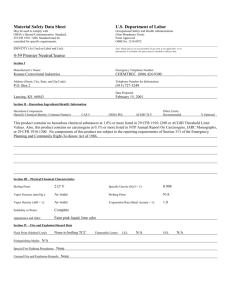

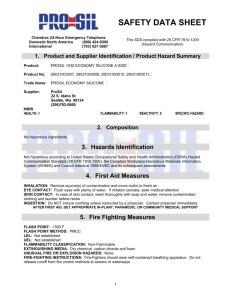

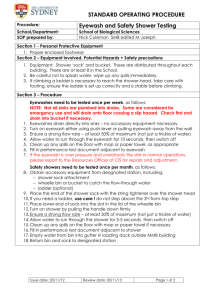

Safety Showers Article 1.26.2010 Written by Jerry Schwartz from HEMCO Corp. in Independence, MO The Protection Program Work environments often include the use of chemicals ether hazardous or caustic, or other irritants that workers may come in contact with. If you are in-charge of an organizations Safety procedures or an employee concerned with on the job Safety, you need to be informed for the rules and regulations for Safety Showers, Eyewash stations, and Drench Showers. The employee benefits from a safer work environment, knowledge that if an accident occurs equipment is at ready to care for the situation, and in the event of an accident less time lost form work. The Employer benefits from better employee morale, meeting of government regulations, and reducing cost associated with an accident. Having a Safety program can be very beneficial, but it involves work and planning. The Safety program needs to include but is not limited to, written Safety procedures to ensure that all national and local government polices are being followed. MSDS data sheets are required for many chemicals in the workplace. An appointed person who monitors the equipment, and checks to see that it is properly maintained, and in working order. Employee training for both new employees and annual training updates for current employees. And in the case of an accident, a follow-up investigation of the situation, and report on changes that may prevent the same accident from reoccurring. The Work Environment, ANSI standards specify that Emergency equipment must be installed within ten seconds walking time from the location of the hazard. Equipment must be installed at the same level as the hazard, and the path-way to the equipment must be straight and free of obstructions. The exception being in cases in which workers handle strong caustics or acids where the after-math of a spill could be serious to the injured party, in cases such as these the safety equipment should be installed with immediate access from the work area. In Laboratory settings Emergency equipment is often installed in hallways or corridors outside of the lab. In these situations it is good to install combination Drench hoses/ Eyewash units near lab sinks, to provide for immediate response. The Americans with disabilities act requires that all employers provide accessible workplaces for all employees. In some cases workplaces may require barrier free Safety Showers and Eyewash stations that are designed to provide access to handicapped persons. Emergency Equipment should be easy to identify by the use of high visibility signage. The area near the Emergency equipment needs to be well lighted. The water that is delivered by the Emergency equipment should be tepid (lukewarm), and from an uninterruptible water supply. In most cases this means that both hot and cold water must be supplied. For Eyewash stations the water needs to have a low velocity flow, to rinse the eyes and face of the injured worker, without causing harm. Drench hose units, may be used as a supplement to, but not instead of Eyewash units. Drench units are most useful in situations where the worker is in a prone or lying down position and the affected body area is inaccessible to either the Eyewash or the Safety Shower. Familiarity and Usage Employees must be trained in the location and proper usage of Safety equipment. A written Response plan should be followed, in an accident situation workers need to know how to assist the injured worker, and who to call if necessary. In the event of an Emergency, the area affected should be rinsed down for at least 15 minutes, insuring that all containments have been thoroughly rinsed away. Where floor drains are the means of removal, it is important that they also be properly maintained. Emergency Showers can deliver a very high volume of water. Floor drains that are blocked it could cause a flooding situation and damage near by assets. If the activation of an Emergency Shower creates a pool of water, it could be a potential slip hazard. Safety Showers Article 1.26.2010 After the activation of an Emergency Shower or Eyewash, the water exiting may contain hazardous materials that cannot be introduced into a sanitary sewer system, because of environmental concerns. In these cases it is necessary to drain the contents of the Emergency equipment to a containment tank. Showers can be equipped with an optional pump and tank to keep waste water from leaking into outside sources. Using the Equipment Use of Emergency Shower, step into the Shower stall, pull down on the actuator, the water will be dispensed from the Shower head. Use of Eyewashes, place eyes in close proximately to spray heads, activate the valve actuator, tepid water will be dispensed to rinse the affected area. Use of the Drench hose, remove the unit from the holder, activate the unit by using the valve actuator and rinse the affected area, when finished place the Drench hose back into holder. Safety Equipment must be maintained on a regular basis. It is recommended that each device is activated on a weekly basis, to ensure that it is in proper working order. Yearly inspections should also be conducted to insure compliance with standards. Technology Involved The Emergency Shower Booth should be constructed of molded seamless fiberglass which adds to strength, lowers the risk of leakage, and is resistant to chemicals. Non-skid treads are located on the floor to lower the risk of slips and falls. An air curtain will reduce the amount of waste water that is leaked to the surrounding area. Optional alarm sounds when the Emergency equipment is activated, to alert others that an accident has occurred. The Alarms are particularly necessary in remote areas where one worker may be located away from others. Alarms can also send a signal to a monitoring station. Proper maintenance and use of Safety equipment is important, by following all applicable standards, having a Safety procedure in place, and training employees, your work environment will be on its way to being a safer place. References: ANSI 117.1-1-1992, ANSI Z358.1, ANSI 535.1, ANSI Z358.1-2004, Guardian ANSI Z358.1-2004 Compliance Checklist OSHA 29 CFR 1910.15, OSHA 29 CFR 1910.178, OSHA 29 CFR 1910.261, OSHA 29 CFR 1910.268, OSHA 29 CFR 1910.94, OSHA 29 CFR 1910.111, OSHA 29 CFR 1910.151. The Americans with Disabilities Act (ADA)