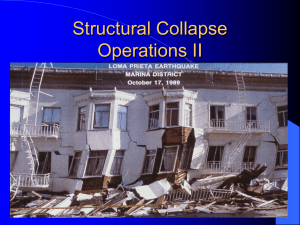

Field Guide for Building Stabilization and Shoring Techniques BIPS 08 / October 2011

advertisement