UNIFIED FACILITIES CRITERIA (UFC) ASSESSMENT OF EXISTING FACILITIES FOR USE IN MILITARY OPERATIONS

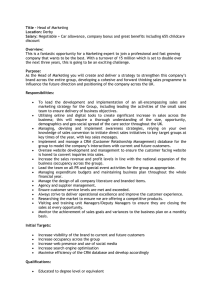

advertisement