INSTITUTE FOR SHOCK PHYSICS Laser-Shock Spall Experiments in Aluminum II:

advertisement

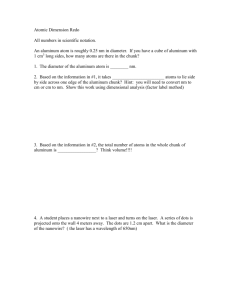

Laser-Shock Spall Experiments in Aluminum II: INSTITUTE FOR SHOCK Interface Measurements Thomas M. Bersano,* Illinois Wesleyan University Institute for Shock Physics Objectives • Examine tensile fracture in aluminum alloys at short time scales (10-8 s) • Role of PMMA backing material window -Changing the tensile pulse characteristics • Determine agreement of spall plane prediction with microstructural evidence PMMA Backing t3 a) Spall plane t2 Target and Laser Characteristics Real Time Measurements • 1064nm wavelength laser beam • 6061-T6 or 1100-H14 aluminum targets approximately 110 m thick • PMMA with vapor deposited Al mirror Δt b) Pullback Vel. Target Interface Velocity Impactor • Velocity Profiles (Left) • Stress-Velocity Plots (Top) • Soundspeed and Spall Plane Distance (Bottom) t1 Spall Plane Distance Time t1 t2 t3 Fig 1: a) Plane waves traveling through both the flyer and the target collide causing the material to experience tension. b) Pullback velocity indicates tensile loading has occurred. This velocity difference is used to calculate stress data. 1 Laser-Shock Spall Experiments • Laser vaporizes the chromium layer, launching the flyer • Flyer impact creates stress pulse in the material • Tension Occurs! • Spall occurs as material is “torn apart” Soda-lime substrate Laser 1064nm 15 ns FWHM Brass Spacer PMMA Window ~ 220 m VISAR Fig 3 : A simplified diagram of the VISAR system. Laser Interferometertry Chromium 2 • Laser light reflects off a moving surface • Reflected light splits and travels through two legs of the same length • Etalons slow one leg of light creating a time difference τ • Analyzing light intensity at the detectors gives Δu, a change in velocity Deposited Al Mirror (< 1 m) Al Flyer (~54 m) PHYSICS 6061 Al Target Fig 2: A diagram of the target set-up. References [1] X. Chen, J.R. Asay, S.K. Dwivedi, D.P. Field, “Spall behavior of aluminum with varying microstructures.” J. Appl. Phys. 99 (2006). [2] D.H. Dolan, “Foundations of VISAR analysis.” Sandia National Laboratories Report. (2006) Post Shock Data • Targets polished to clean non-spall markings • Viewed by optical microscopy • Only two samples showed any sign of spall • 1100-H14 did not show tensile fracture Aluminum Aluminum Aluminum Δt Spall Plane Indicates Thickness Alloy Soundspeed Peaks Distance Spall? (μm) (μm/ns) (ns) (μm) 103 6061-T6 6.372 18.5 59 YES 114 6061-T6 6.372 25.4 81 YES 116 6061-T6 6.372 21.4 68 YES 102 6061-T6 6.372 18.3 58 YES 117 1100-H14 6.494 26.0 84 YES 145 1100-H14 6.494 27.7 90 YES Fig 8: Two 6061-T6 targets at 20x magnification. (Top) After polishing this target doesn’t show any sign of spall. (Bottom) There is an evident spall plane across the middle of the target. Conclusions • Laser-shock induced tensile damage possible with a PMMA backing • Post shock data for aluminum, backed with PMMA, are inconsistent • Better polishing and greater magnification are needed to inspect for tensile fracture * Advised by Yoshi Toyoda and Y. M. Gupta