Milli-Kelvin Cryo-Cooler Development at the Mullard Space

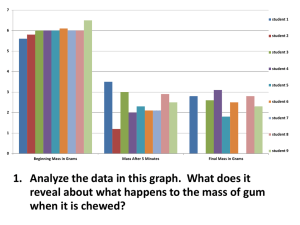

advertisement

UCL DEPARTMENT OF SPACE AND CLIMATE PHYSICS MULLARD SPACE SCIENCE LABORATORY Milli-Kelvin Cryo-Cooler Development at the Mullard Space Science laboratory – I. Hepburn, J. Bartlett, G. Hardy Engineering Model (2002-2008) 44 kg IXO Development (2008 -) <10kg Milli-Kelvin Cryo-Cooler Development (2010 -) <2 kg 1 Further information • Bartlett et. al. Cryogenics 50 (2010) 582-590 “Improved performance of an engineering model cryogen free double adiabatic demagnetisation refrigerator” • Bartlett et. al. Cryogenics 50 (2010) 647-652 “Thermal characterisation of a tungsten magnetoresistive heat switch” 2 Engineering model - 50 mK ADR cooler • ESA Contract to Astrium (Stevenage) in association with MSSL in 2002. – Develop and qualify 50 mK ADR cooler. • Base temperature < 30 mK – To be able to be pre-cooled by 4 K J-T (Planck cooler) – To have high level magnetic shielding to protect spacecraft and X-ray detectors on cold finger Formal transfer of system to ESA June 2008. (System has stayed at MSSL on loan for continued component development) 3 50 mK EM ADR DGG stage CPA stage 4 K or lower interface Cold finger/detector stage DGG magnet DGG magnet booster coils CPA magnet booster coils CPA magnet cancellation coils DGG magnet cancellation coils 4 Construction and qualification Modular construction to enable sub-systems to be used in future systems. key sub-systems qualified • Kevlar suspension system • Low current superconducting magnets • Heat switches 5 Kevlar suspension Kevlar suspends cooling parts of the ADR • 6 kg suspended mass • Kevlar tensioned to 720 N • Passed vibration qualification • Test system has remained strung since March 2004 (6.5 years) with no change. 6 Superconducting magnets Low current to magnetic field superconducting magnets (0.79 Amps per Tesla) – Low current to minimize Joule heating in leads – Minimize electrical power required Magnetic field lines Magnet coil layout Magnet system on vibration table 7 Heat switches • Required to extract heat during magnetisation phase of ADR cycle • Provide thermal isolation during cold phase. • Superconducting heat switch qualified for use at the milliKelvin end of ADR Superconducting switch connected to cold finger 8 Modelling Mathematical thermal model developed during project. – Model agrees very well with real system – Model incorporates low temperature heat flow (i.e. Thermal boundary resistance) – Model includes • • • • All heat loads. Base temperature. Hold time at required temperature. Recycle times – Model used to investigate performance of future systems e.g IXO and milli-Kelvin cryo-cooler 9 System mass breakdown Sub-system Assembly component Paramagnetic including Complete CPA and DGG assembly including cold finger cold finger Magnet CPA mass 0.25 kg DGG mass 0.9 kg Magnet assembly (of which 11.196 kg is Mass (kg) 5.526 24.080 superconducting wire) 60% magnet mass due to cancellation coils and associated former structure Magnetic shielding Focal plane magnetic shield (passive shield) 12.9 Heat switches Gas switch 0.127 Superconducting lead switch 0.097 Miscellaneous ADR parts 1.942 Miscellaneous Sub total 44.672 10 As delivered performance (2008) • System kept at 4 K for just over 1 year (cooled by a 4 K pulse tube cooler). – No change during the year long operation • Base temperature: 25 mK – Limited by thermal boundary resistance inside pill • Recycle time: 15 hours (Required 4 hours) – Limited by superconducting heat switch – Limited by maximum heat load to envisaged 4 K J-T cooler (peak load < 5 mW) • Hold time at 50 mK with 1 µW: 10 hours (Required 24 hours) – Limited by heat load from superconducting lead heat switch • Hold time at 30 mK: 2.2 hours • Thermal stability at 50 mK: ± 8 µK – Limited by thermometer readout electronics 11 Improvements & new systems • • • EM system on loan to MSSL for continued technology development (e.g. heat switches) Mathematical thermal model identified main area affecting performance - Superconducting heat switch. New heat switch developed – magnetoresistive (MR) heat switch – solid state switch – Qualification project just started. – Improvement in performance demonstrated with lab MR switch. • Purity of material not high enough to obtain full performance. • With required purity, performance will exceed requirement. New switch in EM ADR 12 IXO development (X-ray micro-calorimeter spectrometer.) • IXO reduction in stray magnetic field enables reduced magnet coils significant mass saving (2 magnet coils rather then 10). • No cold finger enables splitting of cooler stages and thus optimization. significant mass saving. • Can use existing Kevlar suspension system as EM system. • Same cooling stages as EM system. • Magnet wire/manufacture same as EM system. • Same heat switches as EM system (2 K operation) or with MR heat switch for 4 K operation. 13 IXO Magnet design •Same wire as used in ESA system (can run at 4 K or below) •FEA magnet design performed •FEA thermal investigation performed •FEA mechanical investigation performed with Ariane 5 vibration loads. Only 2 coils required rather then 10 for the EM system Magnet design robust Magnet field lines 14 IXO system model performance and masses Interface Temperature 2K 2K 4K S/C Switch + Gas Switch MR Switch + Gas Switch MR Switch + Gas Switch CPA mass 750 grams 500 grams 750 grams CPA 50 mK hold time 31 hours with 2 µW load (+parasitic) 32 hours with 2 31 hours with 2 µW load µW load (+parasitic) (+parasitic) DGG mass 1000 grams 900 grams 1000 grams DGG stabilised temperature (ADR 1st stage temperature) 0.6 K with 7µW load (+parasitic) 0.6 K with 7 µW load (+parasitic) 0.6 K with 7µW load (+parasitic) Re-cycle time 9 hours <6 hours <6 hours Pill stage mass (including structure) 2 350 grams 2000 grams 2350 grams Magnet mass 7094 grams 7094 grams 7094 grams Heat switch mass ~250 grams ~500 grams ~500 grams Total mass 9694 grams 9594 grams 9950 grams 15 Milli-Kelvin cryocooler • Development started on a ground based milli-Kelvin cryo-cooler. – Provide continuous cooling from 4 K down to 50100 mK from a 4 K cryo-cooler. – Based on multi-stage ADR units – 2 year project started in July 2010 with £0.5M funding from EPSRC (Engineering and Physical Sciences Research Council, UK). – Cooler using technology developed as part of the EM ADR cooler and IXO development (e.g. Magnets and MR switch) Easier to transfer to flight system 16 Milli-Kelvin cryo-cooler Project time scales • PDR – January 2011 • CDR – May 2011 • Testing – end of 2011 Projected mass ≤ 2 kg for mK cryocooler module. mK cryo-cooler module Cryo Mech pulse tube cooler 4 K cryo-cooler interface Cold surface 50-100 mK base temperature. Module made from multiple ADR stages. Therefore temperature settable over range 50-100mK ≤ T< 4K. 17 Summary • On-going 50 mK cooler programme builds on existing technology development – ESA EM ADR – Heat switch development • Application to missions like IXO and the cryogenic spectrometer instrument with significant mass saving from original system. • New generation of ground based cooler providing continuous mK temperatures in a very low mass system in development. – Adaptable for use in space since largely using technology/components from EM / IXO development 18