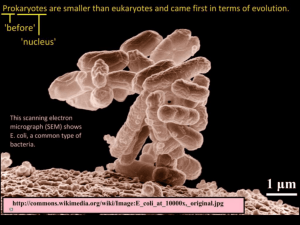

Distributing a metabolic pathway among a microbial Please share

advertisement