RE/ER RCH DOTE 74 MULTISPAN LOGGING OF OLD-GROWTH TIMBER IN SOUTHWEST OREGON

advertisement

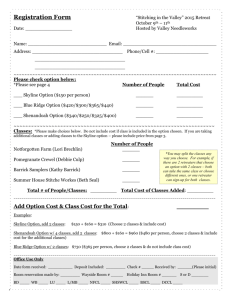

sD Lc 4 0717 C,of2 V0 7 cr !1-f FOREIT REIEARCH LA TORY RE/ER RCH DOTE 74 MULTISPAN LOGGING OF OLD-GROWTH TIMBER IN SOUTHWEST OREGON DAVID H. LYSNE STEPHEN E. ARMITAGE ABSTRACT Multispan yarding systems have not been widely used for harvesting timber in southwest Oregon. In this case study a 6-acre stated of old-growth timber considered typical of southwest Oregon was clearcut with a multispan skyline system using one support per road and a live skyline. One single-tree and one double-tree support system were used. Each required approximately 4 hours to rig completely. Net production averaged 25 Mbf per day while logging over either type of support. The carriage passed a 7.5° deviation from span alignment in the double-tree support system but not a 12.25° deviation in the single-tree system. Support-line tensions measured in the single-tree system exceeded predicted tensions. Support-line tensions measured during inhaul were greatest when the carriage was immediately uphill from the jack and were lowest when the carriage crossed the jack. INTRODUCTION In 1982 the Medford District, USDI Bureau of Land Management (BLM) identified a 6-acre area of old-growth timber near Azalea, Oregon in need of a regeneration harvest. One-end log suspension was required to protect fragile soils and ensure successful reforestation. Multispan logging was planned because convex terrain precluded singlespan logging and other options, including additional road construction, were not economical. The area was set up as a demonstration project because it was considered typical of other possible multispan logging sites and because multispan logging is a relatively new concept in southwest Oregon. The timber sale was clearcut in June 1982. We used the sale as a case study of multispan logging and obtained data on support-line tensions and support rigging times. During the study, we measured production for portions of 2 days, Including 35 turns on two skyline roads. We also observed logging with non-aligned skyline spans and the use of a live skyline while logging over intermediate supports. CHARACTERISTICS OF THE LOGGING OPERATION STAND CHARACTERISTICS The upper ground slopes of the 6-acre demonstration area averaged 30 percent and SEPTEMBER 1983 the lower slopes 60 percent. A complete cruise of the demonstration area indicated it contained an average of 40.5 merchantable trees per acre and an average net volume of OREGON STATE UNIVERSITY, SCHOOL OF FORESTRY CORVALLIS, OR 97331-5704 503-753-9166 31.8 Mbf per acre. The average tree was 28 inches diameter at breast height (d.b.h.) and contained 1.1 Mbf, gross volume. The largest trees were 64 inches d.b.h. anchor point was being rigged. When the final skyline anchor point was ready, yarding was interrupted briefly while the skyline was moved to the final anchor point. These techniques maintained an acceptable level of pro- ductivity and allowed an analysis of span deviations from alignment. A single-tree sup- LOGGING A fan-shaped setting with two skyline roads was used to yard logs uphill towards the yarder on the haul road. Logs were unhooked, decked and loaded on a lower step landing. For each skyline road the skyline was tied to a convenient temporary anchor point below the single support system, the support system was rigged and the skyline was raised and tensioned in the jack. This procedure allowed yarding to begin while the final skyline port system and a double-tree support system were rigged (Figs. 1 and 2). Looking downhill from the landing, the jack in the double-tree support system (Fig. 1) hung closer to the right-hand support tree because the skyline angled to the right below the jack. When the skyline was elevated sufficiently to ensure that a log would be partially suspended, the horizontal force a TO THIRD TAILHOLO 60 1 326.25° -GUYLINE TO FIRST TAILHOLD 315.5° TO SECOND TAILHOLD 2 40 0 327° -SUPPORT LINE 30 10 \ TAILHOLD 320° ` SUPPORT TREE SUPPORT/ LINE 0 SUPPORT LINE SUPPORT TREE 10 20 SKYLINE Z 20 _SUPPORT TREE 10 0 324.5 ° TO SECOND 30 20 50 skyline TO FIRST TAILHOLD TOP VIEW 50 40 70 the hand tree. -GUYLINE STUMP TOP VIEW 80 by exerted caused the jack to drift toward the right- 30 0 I GUYLINE I PLAN VIEW n 10 20 RIGGING GUYLINE 30 II 317 ° BLOCK f 0 0 U' 70 PLAN VIE 30 60 20 50 -TO GUYLINE ANCHOR 40 0 x w x 10 0 30 LINE 60 50 40 30 20 20 10 0 10 20 30 40 50 60 70 80 DISTANCE FROM SKYLINE (ft) 10 ANCHOR 0 80 70 60 50 40 30 r 1 20 10 10 20 30 40 50 60 FIGURE 2. DISTANCE FROM SKYLINE (ft) SYSTEM. THE DOUBLE-TREE SUPPORT JACK HAS BEEN ENLARGED TO SHOW FIGURE 1. SINGLE-TREE SUPPORT SYSTEM. JACK HAS BEEN ENLARGED TO DETAIL. DETAIL. THE SHOW OR LOGGING EQUIPMENT AND PERSONNEL Specifications are All equipment used in the demonstration was either shop-fabricated or significantly modified, commercially available equipment. loggers. The yarding crew was composed of a hooktender, a rigging slinger, a choker setter, a chaser, and a yarder operator. given in Table 1. The equipment was unique, but similar to equipment preferred by American West Coast TABLE 1. LOGGING EQUIPMENT SPECIFICATIONS. Equipment) Specifications Yarder (Made of spare parts assembled by logger) Undercarriage Tracked Tower 46-foot-high, lattice construction Engine 892-T Detroit diesel, approximately 430 hp Weight 85,000 pounds fully rigged Skyline 1,400 ft. of 1 1/4-in. wire rope2 Main line 1,400 ft. of 7/8-In. wire rope2 3,000 ft. of 5/8-in. wire rope2 1,600 ft. of 7/16-in. wire rope H au lback Tag line Interlock Drums were not interlocked Not water-cooled Brakes Carriage (Modified large model Christy) Weight T ruck 1,000 pounds Not required because carriage was open-sided Jack (Handmade) Weight 130 pounds, including support-line block 'AII equipment supplied by the logger, Bud Van Norman, President, Mt. Reuben Logging, Incorporated, P.O. Box 370, Glendale, Oregon 97442. 2Additional line could have been spooled on the drums. Line lengths given are spooled lengths used during the demonstration. RESULTS AND DISCUSSION USE OF A LIVE SKYLINE FOR MULTISPAN LOGGING was used during the yarding of this sale. The Skyline length is usually fixed for a given multispan setting (Binkley and Sessions 1978, Nickerson 1980, Fodge 1981). The stretched skyline is assumed to flow over the jack and on the jack. into the located. span in which the carriage is However, a live skyline, which was lengthened or shortened within a yarding cycle as needed, skyline always flowed easily over the jack and through a clip used to keep the skyline No wear was observed on the skyline after yarding was completed. Fresh paint in the downhill side of the jack's skyline groove was evident after logging. However, there was wear on the sides of the skyline groove; the groove sides can be worn by the carriage sheaves If skyline spans are not aligned. 3 Therefore, the wear on the downhill end of the jack was apparently caused by deviations from span alignment (Figs. and 2) rather 1 than by the live skyline. live skyline can often increase the load capacity of multispan settings. The skyline A can be lengthened to increase deflection when terrain permits, and shortened (if the yarder has enough horsepower to retension the skyline while inhauling) when the load nears a terrain point that limits skyline length. Use of a live skyline reduces skyline tensions, and thus might reduce the impact that sudden shock loadings have on the skyline and on the yarder, both during lateral yarding and inhauling. Use of a live skyline might also permit easier unhooking at the landing. DEVIATION FROM SPAN ALIGNMENT A deviation from span alignment is the horizontal angle created when a span deviates from the line projected by an adjacent span. The deviations from span alignment observed in the demonstration project are shown in Figures 1 and 2. Field crews are usually advised to lay out straight multispan settings (Kellogg 1981) because little is known about the effects of even slight deviations in span alignment. Fodge (1981) identified two modes of failure associated with non-aligned spans in doubletree support systems; neither occurred in the demonstration project's double-tree system. However, a failure due to deviations from span alignment did occur in the demonstration project's single-tree support system; that failure is described at the end of this section. Fodge's first mode of failure is that the support jack or the skyline can swing over and hit a support tree when the approaching carriage is midspan in the span below the support. This failure did not occur in the demonstration project's double-tree system. The carriage passed easily over spans with a 7.50 deviation from alignment. The skyline chord slopes for these two spans were -42 horizontal forces pushed the support jack to the right (Fig. 2). However, when the carriage was near the jack, the angles between the support line and an imaginary horizontal line on both sides of the jack became approximately equal, and the jack became nearly centered between the support trees. Fodge's second mode of failure is caused by a main line rubbing against a support tree: the rubbing can increase the risk that the support tree will buckle, or can create enough friction to restrict lateral yarding or gravity outhaul of the carriage. This failure did not occur in the demonstration project's double-tree system. The main line in the demonstration system lay on the ground at the terrain break; therefore, all of the main line's horizontal force on the support tree was directed to the base of the support tree and did not buckle the tree. Also, the main line rubbed the ground near the support tree's base, rather than rubbing the tree itself; thus the deviation from span alignment did not cause any observable additional restriction of lateral yarding or of gravity outhaul. However, Fodge's second failure mode could occur if the main line no longer lay on the ground, but instead became sufficiently elevated to cause the failure; this situation could develop if long, straight slopes are logged with intermediate supports whose spans deviate from alignment. The demonstration project's single-tree support system did fail in one situation caused by deviations from span alignment. The failure provided detailed information about a previously unrecognized problem associated with deviations from span alignment. The failure occurred in a span that deviated 12.25° from alignment and that had chord slopes of -39 and -46 percent. When the carriage was a significant distances from the jack, the jack slanted and bisected the vertical and horizontal aspects of the skyline chords. The skyline remained seated in the jack. However, as the carriage approaching came closer to the jack, the weight of the carriage and logs forced the jack back to a vertical position, the skyline fell off the jack's downhill arm and the carriage stopped. percent and -71 percent. When the skyline was unloaded, or was loaded and the carriage was A jack with a deeper skyline groove might of a span) from the support, the skyline's 1D1stance at which bisection occurred varied with each turn and depended on log weights, skyline pretension and other factors. located a significant distance (more than 1/4 have retained the skyline. 4 SUPPORT-LINE TENSIONS Accurate predictions of support-line tensions are required for support system design. We measured support-line tensions in the singletree support system for turns of known weight (Table 2) to compare predicted tensions with measured tensions. The data were collected from the single-tree support system that had a deviation from span alignment of 0.75° and chord slopes of -39 and -59 percent. The data are a subsample of tensions measured during 4 days and represent turns for which log weights were measured and total turn weight calculated. Total turn weights are not correlated with support-line tensions because the skyline length varied with each turn. peaked as a loaded carriage crossed the jack slowly, a situation that simulated a static analysis. Our study was based on actual operations rather than on a simulation of a static analysis, and produced much higher carriage speeds than did the Peters-Aulerich study. The highest carriage speeds encoun- tered in our study caused the support-line tension to peak after the carriage crossed the jack. TABLE 2. SINGLE-TREE SUPPORT-LINE TENSIONS. Totals As the loaded carriage came from the tailhold uphill toward the jack, the support-line tension increased slowly until the carriage was a few feet downhill from the jack. At that carriage location the skyline became very steep between the carriage and the jack, the carriage speed decreased and the supportline tension increased to a high point (Table column 2). The carriage thereafter suddenly ascended the skyline and appeared to hop across the jack. Because the carriage crossed the jack very rapidly after accelerating upward, relatively little turn weight transferred to the jack and the support-line 2, turn weight (kips) Line Tensions at Carriage Locations (kips) Downhill Crossing Uphill from jack the jack from jack 10.1 14.3 8.7 13.1 -- 16.1 6.1 5.3 5.0 13.5 13.3 -9.7 13.7 13.7 6.9 6.8 13.3 15.5 8.5 13.5 17.3 -- Avg. 6:7 13.8 9.0 llncludes carriage, jack and logs. 13.8 14.7 tension decreased accordingly (Table 2, column 3). As soon as the carriage was uphill from the jack, the skyline slack from the lower span flowed rapidly over the jack from the lower span to the upper span, the upper span sagged and the carriage dropped into the sag. When all of the skyline slack from the lower span transferred to the upper span, the skyline tightened, catching the falling carriage, and the support-line tension surged to its highest point (Table 2, column 4). Our measurements produced some unexpected results. Not only did the maximum tension occur at an unexpected location, but the tension was greater than we expected. A static analysis of support-line tension predicts that the highest tension will occur as the carriage crosses the jack (Fodge 1981). Peters and Aulerich,2 using a recording tensiometer, found that support-line tension 2Peters, P.A., and D.E. Aulerich. 1977. Timber harvesting using an intermediate sented at the support system. Unpublished paper premeeting, American Society of winter Agricultural Engineers, Chicago, Illinois, December. We were interested in comparing predicted support-tensions with measured tensions using information commonly available to timber sale planners. We predicted support-line tensions by using equations of static equilibrium; measurements of support-line angles; carriage, jack and average turn weights, and measurements of the vertical force which the skyline pretension exerts on the jack in twoand three-dimensional analyses. The constant skyline pretension used in the calculations was obtained from a standard multispan payload analysis (Nickerson 1980) that estimated the standing skyline pretension required to obtain the minimum design carriage clearance for the turn of average weight. The two- dimensional analysis yielded an average predicted support-line tension of 10.8 kips and the three-dimensional analysis yielded a predicted tension of 12.9 kips. A computer program that estimates jack loading for various carriage positions (Nickerson 1980) estimates the average support-line tensions at 11.0 kips in a two-dimensional analysis 5 alternately serviced the yarder and operated the yarder to manipulate the straw and 13.2 kips in a three-dimensional analy- for dures for predicting support-line tensions, line and haulback line used in rigging. The demonstration project rigging time indicates that a hooktender and a choker setter using sis. The procedures we used, common proceoverestimated the tensions measured when the carriage crossed the jack and underestimated the tensions measured when the carriage was near the jack. INTERMEDIATE SUPPORT RIDGING TIME LOGGING PRODUCTION Each support system required 4 hours to rig, including raising the skyline. This was the first time that the logger who participated in this demonstration project had a power or hand-operated winch could rig similar supports in 3 hours, a reasonable amount of time for the size of lines used. either used standing trees to rig supports. On one previous occasion the logger hung his jack from a line that was perpendicular to the skyline and anchored to opposing ridgelines, a system described briefly by Pearce and Stenzel (1972). The rigging crew for the demonstration project consisted of the hooktender, rigging slinger, and choker setter. The yarder opera- The 191 Mbf of merchantable timber (the volume determined by the pre-sale cruise) was logged in 15 days, for an average production of 12.7 Mbf per day. The 15 days included time spent on equipment rigging and dismantling, which delayed production and -- because timber sale volume was low -- had an exaggerated effect on the production average. The logger estimated his net production while logging at 25 Mbf per day, based on scaled truck loads. A subsample of 35 turns from skyline settings taken over a 2-day period, excluding scheduled delays, yielded a net production of 5.5 Mbf per hour. both SUMMARY Multispan logging with a live skyline and one-end log suspension was used successfully to log old-growth timber in a area where convex terrain precluded the use of single span systems and where roading was not economical. No problems were encountered in yarding over a 7.5° deviation from span alignment, but the carriage failed to pass a 12.25° deviation from span alignment. Measured support-line tensions exceeded pre- dicted tensions for carriage locations immediately uphill from the jack during loaded inhaul and were less than predicted tensions as the carriage crossed the jack. CONVERSION TABLE 1 acre = 0.4047 hectare 1 foot (ft.) = 0.3048 meter (m) 1 inch (in.) = 2.54 centimeters (cm) 1 pound = 0.4536 kilogram horsepower (hp) = 745.7 watt (W) 1 1 kip = 4.448 kiloNewton 6 LITERATURE CITED BINKLEY, V.W., and J. SESSIONS. 1978. Chain and board handbook for skyline tension Service, and deflection. National Forest USDA System, Forest Pacific Northwest Region, Portland, Oregon. 193 p. FODGE, F.W. 1981. Engineering analysis of forces created in two tree intermediate supports during multispan logging. Master of Forestry Paper, School of Forestry, Oregon State University, Corvallis, 70 p. Research Laboratory, Oregon State University, Corvallis. Research Bulletin 36. 15 p. D.B. 1980. Skyline payload analysis using a desktop computer. USDA Forest Service, National Forest System, Division of Region, Northwest Pacific Oregon. Portland, Management, Timber RG-TM-012-1980. 136 p. NICKERSON, PEARCE, J.K., and G. STENZEL. 1972. KELLOGG, L.D. 1981. Machines and techniques for skyline yarding of small wood. Forest P. 280 in: Logging and pulpwood production. The Ronald Press Company, New York. The Authors Acknowledgements David Lysne is an assistant professor in the Department of Forest Engineering, School of Forestry, Oregon State University; at the time of this study, he was Harvesting Specialist for the Southwest Oregon Forestry Intensified Research Program (FIR). Stephen Armitage is the Forest Manager for the Butte Falls Resource Area, Medford District, Bureau of Land Management; at the time of this study, he was Area Engineer for the Glendale Resource Area, Medford District, BLM. The authors wish to thank Mr. Bud Van Norman, President of Mt. Reuben Logging, Disclaimer The mention of trade names or commercial pro- ducts in this publication does not constitute Incorporated, whose enthusiasm for new logging techniques made this multispan timber sale a success. FIR is a cooperative research and technology State Oregon among effort transfer Land of Bureau USDI University, the Management, USDA Forest Service, and southwest Oregon counties and timber industries. FIR is designed to help foresters solve complex forest management problems in southwest Oregon. This study was conducted as a cooperative project between FIR and the Medford District, Bureau of Land Management. endorsement or recommendation for use. As an affirmative action institution that complies with Section 504 of the Rehabilitation Act of 1973, Oregon State University supports equal educational and employment opportunity without regard to age, sex, race, creed, national origin, handicap, marital status, or religion. 7 FOREST RESEARCH LABORATORY SCHOOL OF FORESTRY OREGON STATE UNIVERSITY CORVALLIS, OR 87331-5704 ADDRESS CORRECTION REQUESTED NorvP of i O g. us. Pa5leoe PAID COrvalile, OR 97331 Permit No. 200