Document 11875265

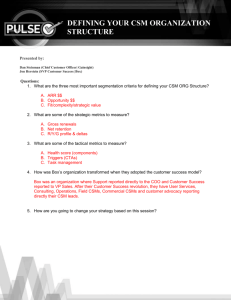

advertisement