Document 11847948

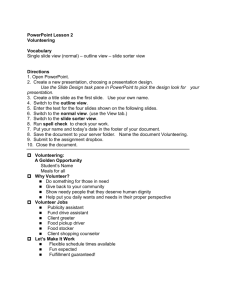

advertisement

Immediate response is the key to capturing customer commitment in today’s highly competitive environment. Integrating automated processes to achieve more centralized warehousing is a means of achieving this goal. GBI offers the solutions necessary to accomplish these goals while simultaneously providing attractive returns on your investment in the near term and continuous savings thereafter. Our philosophy has always been to place the customer first. Whether it is in the area of software customization, customer technical support, or addressing specific customer needs, we are there when you need us. Our courteous customer service engineers provide unparalleled 24/7/365 support. Here we present an overview of what GBI has to offer. We encourage you to contact us to discuss your specific requirements and explore the solutions that are appropriate for you. To stay competitive: You not only need to provide your customers with quality products but with quality service as well. This translates to faster delivery and better tracking of customer orders. Coincident with this endeavor your company will achieve: "High Speed" Tilt Tray Sorter • Quicker response - as shown on this CD, DVD, Video Tape and Cassette Application • Lower operating costs • Higher accuracy • Fewer charge-backs due to late delivery • Increased storage space • Faster inventory turns Some of the Applications we offer sortation for include: • Order Fulfillment Centers • Returns Processing • Bulk Mail Center Sortation; w/weigh in motion & complete manifesting "Multiple Divert Chute Sorter reduces sorter footprint" - as shown in this Jewelry Application sorting small boxes and polybags • Material Handling of any product smaller than a Bread Basket; including packaging such as "polybags" Some of the Industries and Products we build sorters for include: • Retailers, Distributors, and Wholesalers related to: - Book Publishing - Entertainment; CD’s, DVD’s, Cassettes, and Video Tapes - Jewelry Industry; Boxes or Polybags - Apparel; Hanging or Flat - Pharmaceuticals - Direct Mail & Catalog Houses - Other Industries and Products such as; Optical, Sunglasses and PhotoFinishing Large Accumulation Sorter - as shown on this Small Package and Sunglass Application The Tilt Tray Sorter will simultaneously sort irregularly shaped products from small, lightweight polybags to larger boxes weighing up to 25 lbs. The tilt tray mechanisms and chutes are adapted at time of manufacture to handle the weight and size product for each given application. All our sorters are built in modules to allow fast and easy expansion with minimum interruption of work flow. The sorter is designed to provide high reliability and require minimal maintenance. Benefits • Automatically and reliably sort individually packaged and barcoded products • Simultaneously sort mixed shapes of small boxes and items in polybags • Greatly reduce labor costs associated with manual sortation and verification • Greatly reduce the time needed to assemble individual product by order or other criteria The Tilt Tray Sorter - provides a cost effective • Expand the sort window and viable alternative to pick-to-light systems • Recover more warehouse space Load Section Automatic, Semi-Automatic and Manual Mode Options (see Additional Options for more details) "Racetrack" or Oval Sorter Layout - with automatic takeaway and dual load sections Common Features Straight In-Line Sorter Layout • Fast sort rates of up to 12,000 trays per hour • High accuracy rates • Modular construction • Ease of use • Low maintenance • Long life and reliable operation • User friendly Windows ® software interface • Sorts barcoded or non-barcoded products • Cross platform integration support BULK MAIL CENTER (BMC) SORTER - an offshoot of the tilt tray sorter is GBI’s Bulk Mail Center Sorter used to separate packages by postal code for manifesting. This sorter is built to scan and weigh the packages and communicate all pertinent information to our proprietary manifesting system. GBI’s Manifest System is a Windows ® based tracking and reporting system that creates documents in the same format that the shippers use. The system prices and manifests packages for shipments with UPS, FedEX, the US Postal Service (USPS) and other carriers. Print & Apply “on the fly” Here we present an Entertainment Tilt Tray Sorter specifically designed to handle products such as; CD's, DVD's, Video Tapes, and Cassettes. This Sorter features Print & Apply Label Applicators, Automatic Induction, and Stacking Chutes for uniform products – used for applications such as; Order Fulfillment, Returns and Loose Receipts Processing. GBI’s Print & Apply “on-the-fly” feature will independently and uniquely label each product while it is being sorted according to customer specified rules. As little as two label-printer-applicators are mounted along the tray path with the combined capability of labeling product at the maximum sort rate of 200 trays per minute. A third printer is recommended to share the load equally with the others and to provide redundancy. GBI’s unique orientation design transfers the automatically inducted product from the first belt (tray) to a second by tilting the product onto the second belt (tray). This transfer reorients the product to an upright position. The product is then conveyed passed the printers where the labels are applied. Once the label is applied the product is repositioned to lie flat on the tray for conveyance to its designated sort destination. Automatic Induction Unit The automatic feeders are used to receive the product and automatically induce them onto the sorter. CD's, cassettes, videotapes or DVD's are loaded in stacks onto each auto-feeder. Each feeder may be adjusted using two quick release clamps for the size product to be loaded. Product is oriented for disposition to the vision system scanner which is specifically designed to scan entertainment products. Below - Print & Apply Section Shows product being labeled in an upright position. Above - Transfer Section GBI’s unique orientation design allows for a greater range of product forms and sizes to be simultaneously sorted & labeled. Chute Sensors & Status Displays Each chute may be equipped with a chute sensor to detect product either when it passes or has accumulated. The sensor may be used to verify that product has been sorted accurately or to indicate that product is backing up in the chute. Upon detecting an accumulation the sorter controls will suspend the effected chute to prevent any other product from entering the chute. Chute blocked beacons may also be provided to illuminate when this condition occurs to alert personnel to empty the chute. Upon clearing the sensor, by removing product, the chute automatically reverts back to a normal condition and the chute blocked beacon is turned off. GBI utilizes a third party label printer applicator and integrates it to work in concert with the sorter system. Labels may be unique and are printed on demand as required on an item-by-item basis. Accumulation Section for odd shaped products Stacking Accumulation Chutes Two Entertainment Sorters - featuring Autoloaders, Print & Apply, Stacking and Accumulation Chutes - shown with incoming and take away conveyors. GBI offers a combination stacking and accumulation chute. Products of uniform size may be sorted directly to the stacking chute while other sizes and shapes are sorted above to an accumulation chute. The diverter that diverts the product may be "active" in that the sorter controls actively position it to sort to either chute, or passive, where by an operator positions the chute manually. When the diverter is manually set, uniform product is sorted first to the stacking chute then manually repositioned to sort to the accumulation section when ready to sort other sizes and shapes. Each chute has a Lexan door to visually monitor the stacking process and to provide access for product removal. Stacking Chutes for uniform shaped products This High Density Carrier Sorter provides a new level of cost/performance not previously available. Working at speeds of up to 10,000 packages per hour the sorter maintains an accuracy guaranteed at 99.99% with verification. Packages are conveyed in clear LexanTM carriers which are shifted to interior and exterior bins. This cost effective alternative to manual sortation may be used to sort small packages, and envelopes. Automatic Loader (Synchro-Loader) This closeup shows verification sensors - verifies that the product made it into the prescribed drop at the precise moment expected. (See Additional Options for more details on this sensor) Features • Modular construction • High density chute arrangement This sorter has evolved through several • Autoloading capable generations. There are over 50 carrier based sorters in use around the world in • Multiple configurations companies such as Wal-Mart, Qualex (a • Custom software integration Kodak company), and Deluxe Check • Built-in verification Printers. The first one delivered over • Low maintenance eighteen years ago is still operating at • High reliability full capacity today. Many of these sorters • High accuracy 99.99% Simple Solution Sorter – shown with Automatic Loader Option are operated six to seven days a week The Synchro-Loader enables automatic loading of the product into the sorter, and maximum throughput is achievable. See Sorter-Lite for additional information. and up to 22 hours per day. GBI's new compact addition to our line of "Carrier / Bomb-Bay Style", Simple Solution Sorters, is the economical Sorter-Lite, combining the best features of our full sized sorters. The Sorter-Lite was specifically designed for the smaller warehouse and photofinishing labs that could benefit from this technology, but either didn’t have the space for a sorter or the volume to justify the return on investment. Some of the products that are ideally suited for this sorter include optical products, pharmaceutical products, and photofinishing envelopes. GBI combines the best features of the time-tested Simple Solution Sorter with the proven technology of the Advance Solution Vision Systems Outbound & Inbound Sorting - using a single machine GBI's Vision System may be added to the front-end of this sorter to recognize and record inbound products for sortation by process (in photofinishing) or by other criteria (other industries). Sorter-Lite Benefits & Features • • • • • • • • • • • The Sorter-Lite Sorter utilizes the same proven technology, ruggedness, and software as GBI's full size sorters. Automatic Induction is standard using our proven Synchro-Loader. The Optional Vision Inspection Module may be added to recognize and/or record inbound & outbound product. Interfaces to your WMS or host system. Full tracking capability with numerous standard and custom reporting capability. Easily configurable sort set-up using mouse clicks. Flexible drop assignment and configuration. Drops may be temporarily suspended or forced closed. Sort Rate up to 10,000 sorts per hour. Optional Oversize Station for including larger non-sortable items in the data sent to the host. Modular construction enables easy expansion. Reduced Cost & Size The Sorter-Lite is a mechanically scaled down version of the larger Simple Solution Carrier Sorter, while retaining all the functionality. The result is a high density sort configuration in a smaller overall footprint and a lower equipment cost. Package Configuration This sorter is available with 3.5", 5.25", or 7.0" chute centers and 1.5 or 3.0 inch wide carrier openings according to accumulation or product requirements. This sorter accommodates packages up to 2.8 inches thick, 6.75 inches wide and 13 inches high. Synchro-Loader Features • • • • • Gently handles your product Increases accuracy & speed Provides positive induction displacement Greater loading efficiency Handles a wide range of product sizes - including 35mm & Pano packages (in photofinishing) Top View - above Sorter-Lite with Synchro-Loader Side View - below Common Features GBI offers our Paperless Pick/Put-to-Light System as an economical alternative to manual picking or placing of product for lower volume operations. It is designed to electronically assist sorting personnel in pulling (pick) or placing (put) SKU’s to meet order requirements. In a "pick-to-light" application the operator would scan the order and the quantity to be picked is displayed on the "display module" at the bin location. In a "put-to-light" application the product is pulled from the carton and placed with the order in the appropriate quantities as indicated by the "display module". Once the pick/pull is completed, the operator presses the "send" button on the display module and the data is electronically transmitted resulting in real-time order and parts tracking. • Windows® graphical user interface • Seamless integration with existing Warehouse Management Systems and Conveyor Control Systems • Modular design for growth • Open database connectivity for easy creation of reports, charts and graphs utilizing off the shelf software as MS Excel® and MS Access® Optional GBI Reports: - Personnel Requirement Report - Replenishment Analysis Report - Traffic Monitor Display - Order Tracking Report - Personnel Performance Report - Productivity Report Pick / Put-to-Light Display Module The Pick/Put-to-Light display module as shown below is used for high volume picks or puts and has a number readout, a "send" button, and increment/decrement buttons. Display Module Increment Push Button This multi-colored light indicates additional status information and quantities that exceed two digits. Paperless Pick / Put System System Benefits • Sorting and picking productivity is greatly increased over manual picks • Substantially reduced interpretation errors since orders are bar code scanned and not read • Sortation accuracy is greatly increased due to directed picks • Better order and parts tracking • User can easily create custom reports or statistical analysis charts and graphs Decrement Push Button Two Digit LED Display Pick/Put Complete SEND Button Each Module may be removed easily and snapped back into place without the use of tools. The units are wired with quick release ribbon connectors. Options • Row and Column Lights – used as an alternative or in addition to the AlphaNumeric Display Unit to specify the location of the directed pick/put. • Alpha-Numeric Display Unit – used in conjunction with an individual Display Module - for displaying location coordinates. • Zone Beacon – identifies zone or flow racks that have product to be picked or placed - when a zone consists of multiple flow racks. Scanner - accepts numerous pairs of input devices including barcode scanners in various orientations and RF devices. The GBI Hanging Garment Sorter is the result of our collaboration with various experts within the garment industry, combined with our engineering expertise, and 18 years of sortation experience. Numerous installations of GBI’s Hanging Garment Sortation System are in various facilities throughout the world. We encourage you to contact us to discuss your specific sortation requirements. Operator Control Panel - gives operators direct control to route product as needed Hanging Garment Demonstration Layout - systems are designed to meet customer specifications Singulator - separates product for proper sortation Pneumatically Activated Diverts System Benefits • Windows ® graphical user interface • Seamless integration with existing Warehouse Management Systems and Conveyor Control Systems • Full tracking capability within the plant to locate and expedite order deficiencies Features • Detail reporting by garment • Sort rates starting at 7,000/hr. • Equipment monitoring • Modular design • Pneumatic diverts • State of the art C++ software • Generous use of sensors & controls Product Accumulation Conveyor - used for accumulation of product based on any given criteria Drag Link Conveyor - allows accumulation of garments and singular conveyance when released Delicate or Fragile Product Handling Chutes and Status Displays GBI recognizes that no two installations are alike. Each customer has special requirements for their product accumulation. GBI will design and build chute arrangements to meet these requirements. Status displays at the chutes are used to inform personnel around the sorter about the status for each drop. Custom designed chutes are used in conjunction with "chute full beacons" to handle delicate or fragile products as shown in this book application. Here are a few examples of chutes designed for specific applications, such as; large quantity or small quantity accumulation, stacking chutes for uniform products, high density multiple divert chutes used to reduce the sorter footprint, and chutes designed to handle delicate or fragile products. This close-up shows the Chute Full Beacons that are used to indicate when a chute is approaching full capacity or when full capacity is reached. Chute Status Terminals Non-uniform product accumulation section of chute Large Quantity Accumulation Chutes Small Quantity Chute Guides – shown sorting to totes Stack Uniform Products - for quick packing while diverting other shapes and sizes into a separate accumulation section of the chute - as shown in this CD, DVD, Cassette and Video Tape application. High Density Chutes This high density chute arrangement reduces sorter footprint by utilizing a multiple divert for each tray tilt, as shown in this jewelry application. Tri-color light is used to indicate additional status information. SEND Button This close-up shows the Tilt Tray Mechanism simultaneously sorting polybags and boxes. Drop Status Display - individual modules that display the remaining or accumulating counts. Notification is given for chute full, low count and limit reached. The SEND button may be used to initiate the electronic transfer of chute contents data. GBI will design a sortation system to meet your specifications for speed, package handling, and sorter configuration. These are examples of Additional Options that you can add to your sortation system. We encourage you to contact us to discuss your specific requirements and explore the solutions that are appropriate for your operation. Adjustable Guides Semi-Automatic Induction Units This option is used for inducting fast sorters with products of varying sizes or for manually entered UPC’s or SKU’s. Manual Mode Product Identification • Identifies bar code unreadable or non-barcoded products • Allows operator to hand scan or key-in SKU • Terminal displays the quantity to be deducted • Operator places one product per tray • Sorter detects the presence of product on trays and assigns manually entered SKU to each tray • Displayed counter is decremented and the manually input SKU is associated to the product Drop Verification • Additional sensors destinations (chutes) are added to the sort • Sorting accuracy is guaranteed to 99.99% with verification • Verifies that the product made it into the prescribed drop at the precise moment expected Automatic Induction Units This option may be used whenever package sizes are uniform. The auto-loaders may be easily adjusted to fit the product size. The operator places groups of products into the auto-loading units and activates it to load product onto the passing trays as shown in this CD/DVD application. This option enables the high speed Tilt Tray Sorter to achieve maximum throughput. After-Sort Package Sensor Array Label Applicators - Print & Apply “on-the-fly” More Optional Features • Provides additional protection in the event that a product was not deployed to the designated drop • GBI’s unique orientation design allows for a greater range of product forms and sizes to be simultaneously sorted & labeled • Chute Status Indicators • Error message is posted to screen and recorded in database • Sort count is automatically adjusted and product need only be re-induced onto the sorter • Applies custom and unique labels to sorted products • Beacons & Displays • Drop Status Displays • May be used for UPC pricing with barcode or other informational purpose See Entertainment Sorter for additional information on this feature. See Chute Types & Status Displays for details on these Options. GBI currently provides two types of tray mechanisms. Integration • User friendly graphical screens and controls • Intelligent and informative messages on the state of the sort. Light Capacity Tray Mechanism – 5 lb. Weight Capacity Conveys packages weighing up to 5 lbs., and is used primarily for small items such as jewelry, pharmaceuticals, check boxes, cosmetics, bags or parcels. • Built in safeguards report or intervene to protect the integrity of the sort or the maintenance of the equipment • Communications link with your existing warehouse management system and ties in all aspects of the production or distribution process for a seamless flow of data • Trip lever is positively guided throughout the sorter to help ensure a level tray position, allowing the tray to only tilt at the designated location. • Trays are righted to a level position before leaving the designated drop chute resulting in increased accuracy. • Tilt mechanism contains only two moving parts and is attached to the belt by four screws making it easy to replace, if needed. Software Safeguards Safeguards are in place to monitor equipment function, display warnings and errors, and to act when necessary to protect the operators, equipment or the integrity of the sort. Medium Capacity Tray Mechanism – 25 lb. Weight Capacity Conveys packages weighing up to 25 lbs., and is used primarily for larger packages, or items such as books, groceries, clothing, and parcels. Tracking Software • Over center design locks the tray level to help prevent a forced tilt due to uneven weight distribution. Tracking information is available for remote examination by network or modem to assist in diagnosing irregularities or for generating productivity or other analysis reports. • Weight is supported directly to the frame for stable product transport. • Tilt mechanism contains only six moving parts and is attached to the belt by four screws making it easy to replace, if needed. Sorter Control Boards • GBI’s proprietary node control boards work in concert with the sorter software to track the product and trip the mechanisms Common Features • Confirmations and cancel notifications are communicated to the sorter computer by the node controllers as a check on the sort • Low maintenance and high reliability • Node boards are standard issue for the tilt tray and carrier family of sorters • Trays can handle packages of varying sizes and types within design limits • Low maintenance requirements • Conveyed items are positively transported for better handling accuracy • Long life • Tray material is specially coated metal chosen for the product conveyed • Quiet operation Remote access software and modem are supplied with each sorter computer. GBI has built an outstanding reputation in small package sortation for the Material Handling Industry. We design, fabricate and install custom solutions that integrate with your existing system to meet both current and anticipated needs. Our focus is on automation in the area of distribution, returns processing, and order fulfillment to help reduce labor costs, increase efficiency and accuracy, while providing a rapid return on investment. GBI has also established itself as the largest supplier of sorting equipment in the PhotoFinishing Industry in North America. GBI Milestones 1967 – GBI was founded by two engineers, Lloyd Gordon and Robert Bledsoe 1980 – Founders are replaced by the team of Steve Gordon as President, and Maurice Rochman as Vice President 1994 – A majority interest of GBI is purchased by it’s employees, and a new era begins with Maurice Rochman as President, and Mark Wolkenfeld as Vice President 1995 – GBI becomes the largest producer of photographic pricing terminals in the world 1996 – GBI installs first Tilt Tray Sorter with manifesting 1997 – Windows-based Sortation System and Vision System Sorter introduced Quality and Reliability We pride ourselves on the quality and reliability of our products. We maintain a full staff of electrical, mechanical, and software engineers utilizing the latest software languages and tools available today. Our customers report that even with continuous 24 hour use on a seven day basis, maintenance is minimal and life span is long. The first GBI sorter ever delivered is still operating today after 18 years, at the same capacity as it was the day it was delivered. Accurate and reliable small package sortation for time critical applications is our business. 1998 – First Medium Capacity Tray Mechanism (up to 25 lbs.) is installed 1999 – First CD Sorter with automatic induction and stacking chutes is installed 1999 – GBI installs new smart module Pick–To–Light System 2000 – GBI relocates to a new 52,000 sq. ft. facility 2000 – GBI installs first complete hanging garment sorter 2001 – GBI introduced new economical Synchro-Loader for automatic induction for Carrier Sorter 2002 – GBI develops unique label Print & Apply “on-the-fly” for handling a greater range of product forms and sizes 2003 – GBI introduces the Sorter-Lite Carrier-Style Sorter Customer Commitment GBI’s philosophy has always been to place the customer first. Whether it is in the area of software customization, customer technical support, or addressing specific customer needs, we are there when you need us. Our courteous customer service engineers provide unparalleled 24/7/365 support. Employee Owned "ESOP" In 1994, the majority interest of GBI Data and Sorting Systems was purchased by its employees, becoming an ESOP (Employee Stock Ownership Plan) Company. All the employees now have a stake in the success of GBI and are totally committed throughout the entire product life cycle – from initial specification to post-installation support. Offices Today GBI assembles its systems in a newly renovated 52,000 sq. ft. complex in Deerfield Beach, Florida. This move was necessitated due to the rapid growth in both sales and personnel, which now includes more than 60 engineering, production, sales and administration employees. With the expected growth in sales the company plans to add another 25 employees over the next one to two years. Shipping & Receiving Given the Opportunity GBI will sort out the details to create an efficient sortation system for your business. You’ll be surprised at how quickly everything Manufacturing 1143 West Newport Center Drive • Deerfield Beach, FL 33442 USA • www.gbisorters.com • e-mail: info@gbisorters.com • Phone (954) 596-5000 ext. 231 • Fax (954) 596-5015 P r i n t e d b y S u p e r C o l o r, I n c . 1 - 8 0 0 - 3 3 0 - 1 1 2 5 Phone: (954) 596-5000 ext. 231 Fax: (954) 596-5015 1143 W. Newport Center Drive Deerfield Beach, FL 33442 USA e-mail: info@gbisorters.com