w smmm WtMMi 4 fUSlS

Ft(MM WSELIVW MQU QfL PEISS w

WtMMi SKIM® BilS®

4 fUSlS a^bmit^ea to ig partial tvOStVms&k of tii© rd(|ulremeat8 for tit©

insfiE o? smmm

xs&B&vmt

ij\iyii>:^!*iT>,^wr»' 1 w=«if^i?^aBSSgw;. .m,^ .IT; i^,.ic£»»i^^.<asrea2gfeisw?^in-*«»-Bs>W'v-^.'..,7'. .»'

Assediate Professor of Foods aad Bdttfitioa la Cb*£@e of Major

■

»i« > »-'i»Miiii if > rr fr-fr-f-r i ^ n ii- ji'f mi-li; i-, i in- i nrr HTK jr

■

-m «

■

,.

O&aissaii of Soliool Gfadaate Qoonlttee

^UJ^t^J^»^^''^'l

^

^*^-^

!

ir i

* »

J ia*-i»,'iirli-i l

',«-,i.-ii,if».iy teas, Ora^uate Sohool

AGIMOWLSBGEMEIT

Tlie author iKrishes to express to Dr. Andrea C.

Overman her deep appreoiation for the suggestion of this probleia, for directins the research aad for valuaMe assistance in the preparation of the maauscript.

To Dr. Margaret L. fiaeke s

the author wishes to estpress her gratitude for advice and assistance in the preparation of the manuscript.

The author wishes to express her appreeiatioa to the Traders Oil Mill Co., Proflo Division, of fort

Worth, ferns, who donated the peanut granules and

Proflo

?

the edible cottonseed flouri and to the A, Eo

Staley Manufacturing Goc of Secatur, Illinois, from whom the Lo-^fat Soy flour was received,

fABLB OF COMOTTS

Historical Backgromai. ,..*

♦

.

Mothot of Manufactus'lag Flours <,

♦

,» * * *

.*».

Eaaeifiity of Fats. ......*.,«.„

Methods used in the Deteralnatioa of

'RonolAity* «•««•**••»•

Factors isflueueiag the ©©Telopmont of

Raneidity* .»••..,.•«« f ©ateraess of Fastry » » • « ., * .«

♦

*.*

* •

* «

OSAPTIS I3U PQfBPOSB OF IMS UPmBffiMf • . . . • ,

I

B

8

19

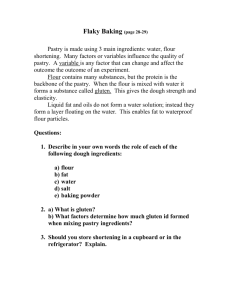

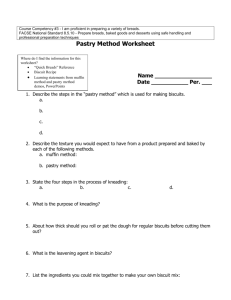

Procefimr© for Pastry

♦

Xagredi^nts* * . *

I'ontfijla. .

# #

♦ ♦

•- « « •

« « « o

Solliago

♦

» •

» * iDivlslosi of samples!.

InCiibatlou of saaples*

Soleetioa of Bamplm for estraetlosu

Frooeiure for pastrf aises ,

Procedure for Extractijtg- Fat »

♦ ferozifi® laiSber BGt©rsainatioa*

Method o .

Reagents -.

» 0

* *

* * * # •

• > * a •

Staadardlgatiom of Sodloa Shlosttlphate o •

• it e » e o

* <•

* •

» »

• *

GIAFT1R I¥.. RESULTS Mm BtSCBSSIOH .... g0

80

SO

21 si

8S

34

24

25

8S

26

26

2?

2?

28

CHiffTIR ?. SiMI^RY MB COMGLIISIOIS «. » .. *

BXBIiXOQEAFKSTt *..«••**«*«.•.. iUPPMDXXa «..*.... * « «

34

36

MST

of Trntm m® Ficsytss

Tmm z

TX

III

I?

Page

Effect on ttnifo^ait^r of Alffereat metliods

of sampling pastry as shovm hf p©rosi4a atmbeff of e^feradted fat

-—Plain, baked gas try.

41 flB,%& Pastrj, Ba^eft —* F©3posi4© muabes'S 48 of fat ©ztracted from pastry stored at 50 o

0

PXaia Pastry, Mix •»-* Peroxide nuabors of 4S fat extr&ated from mia: stored at SO"

3

^

Peaaiit Pastry, Baked —» Peroxide oaafeers of 44 fat extracted trom pastry stored at

■

V n

TO

mx

IX fXOISS

PeaBttt Pastry, Mi% »*- Peroxide aundbers of 45 fat extracted from mix stored at 50 o e

Soybean Pastty, Baked *-* Peroxide auabers 46 of fat extracted from pastry stored at. m

0

Q

Soybean Pastry, lix *-*• Peroxide nuabers of 47 fat extracted from pastry .stored at

50%

Cottonseed Pastry* Baked -*- Peroxide trnmbers m of fat extracted from pastry stored at 50

@

C

Oottonseed Pastry,- Mix *-*» Peroxide mambsrg of fat extracted from pastry stored at 50 o

€!

49

Influence of soy, peanut and cottonseed

fioors oa the tenderness of toalcea pastry

50

Th& effect of soy, peanut and cottonseed flours on development of rancidity in baked pastry stored at 50 0

Pago

51

msf m TABLES m® mmmB {oomimm)

WWME Pag©

II The ©ffeot of sQtf* peaauU aad eotto&seefi §2

flours on d©felopm©at of ^aacidit^ im ram pastrsr aises stored at SO*^

Kg mUGSLDASST WWmT OF WtBIM FLQUBS msBivm mm OIL PBISS omEB m ewmw mT-GmTAwma IOOB MUTHIIS

ZWTRQWQMQM

The p*oblem of ranoldity la fats aaS ia stored fooda eoataiaiag fat is of major isportanoe ia tike food lafiustty m&. ia tka iiome.

Ia the i&veatlgat&oa of faetors that way iaflaoae® tli© (aevelopmeat of taaeiditf, laaola imrk has h®m doae on the use of antioxidant inaterSal3« T&ese stadies tove dealt aost frequeatly witii t&e effeet of aatio^ldaat gafe* stances when added to t&e fat itself, gmh matoyials not to inhibit oxidatioa of tM fat.

In this group of sahstances are fount som© aatorallr oeeav* ring materials» as gua guaiae or wheat iera coEe@atrate

9 and many e&emieal compounds •

Thoogh a&ieh attention lias been given to the problaa of fat raneidity and laany materials have beoa studied aa to their antioxidaat effect,, very little triork has been done on the inhibition of rancidity ia prepared food mis©s and in cooked food produets.

Baked foods present speeial probieas sinee rancidity develops very rapidly in the fat present in such foods.

2

The present study was primarily concerned xirith the

©ffect on fat rancidity of several oil press cakes which were iaeorpomted in food aliases and in baked food products.

The PVBBS cakes studied we2*e peanut, soy and oottoa. Xt it cotild be demonstrated that oil press cakes, usually regarded as simple by-products of the oil mamfaetaririg

Industry, ©re effective inhibitors of fat rancidity t both in prepared mixes aad la baked foods, then a new aad valuable use would be suggested for these materials,

A second purpose of this study was to collect infos*'- nation regarding th© method to be used fo* accelerating the development of rancidity In the food oiztured*

Although the Soybean has been used by Oriental

races as food for eenturles, its introduction to ^meri* cans did not occur until 1804, At first it was used only as a food for cattle, during the first ftorld War the oil extracted from soybeans was used by hoiaemkers as a source ©f fat* t& the second World War soybeans found widespread use as human food. Soy flour was used for fortifying various cereal products, cakes, breads,,

muffins, soups, and other products used by the army.

(Lager, 1945) (26).

The first attempts to proctac© a satlsfaotory floov from soybeana mat with failare* These taethods either ji@lde# a product high in fat whiph feeeaaa s-ameici. ^o^f rapidly t or the qaiality of the beatt had toeea destroy^ during proeedding* the first eueeeeetul soyi>ea& flour fieiis produced toy St. Itosglo B»og@ilar of Tieaaa* This flour was pleaaa&t in tlxvot, the aiitritiire value aM

@ood q,uaiities tier© prosertea aad it was fo«aa to have

©xeeilent keeping qualities, Sim©© this time Gemany has <IOEe store thaa aay other eoontsy to developing methods of manufadturiss m& asing soyhean flour. tfQVX**, l©'g9.J La@@r

?

1945) (11| 2©},

The intiroduotien of ©ottoaseea meal as tmrnaa f ooa was in 1676*. It was not widely used exeept ia speeial diets tiAere a low staroh eonteait was needed* The pfe« sen©© of the toxio sahatanee, goasypolj made it neeessaxy to develop a method of processing in which the press cake ooald fee used safely for stook feeding and as flour for tittffian food* (MCffeth, 1940} (51)« f©anmts have been groim in Aneriea sines colonial days^, but only became of eomereial importance about 60 years ago. from the beginning of the peanut crashing industry the pjpess cafee has been accepted as an excel- lent protein supplement in the feeding of farm animals.

4

Qnltf in reedOLt jeara lias the ^soeXlence of the peaimt press ca&® ^e©a ©stablialied as hmms. food, JSafiy attempts to produce an acceptable fioar p^odact met with failure due to the lack of proper equipaont and teehnlqaes, Ja

1939 the eottosisead oil-iailliag co^aay wMieh had suoeess* fully ovasooae the same difficulties ia the prodactios of cottonseed flour undertools the development of m aeeeptabie pe®nut floux*. (fayae

9 tMQ; Asohaiij 1939)

(3S| l)» Peaaut tXoax is used ppiaeigally in ooabimatios

ndth wheat flour la mffitts, breads, amd oookies,. ajad la diabetic diets as a means of vedaoing the eaffeohydrate valui® aad improving the proteia ©onteat. (Aseham,, 1936)

BotfhQm m& peanut flours have heen fouat to eoafer desirahie oharaeteristics upon eertein cereal products. lohns and Finis® {1921) (21)$ Stella? and Bailey (1938)

(40)| Bohn and Favor (1945) (6) found that the use of

5 per cent to SO per cent soybean flour in bread dough increased the ahsorption quality

■ of the wheat flour and produced a much slower rate of staling of the ftreacL

^rohns ^and Finlss (1920) (20) added ireamut flour'to bread and produced a palata&l© loaf rich in water soiu» bie vitamins, and containing a protein aistar© adequate for normal gro^/th in vats. Bread made with a 4© per cent proportion of peanut flour yielded a loaf with a slight

deo:r©ase ia white&ese of tie cxmib and small deoreas® ia volwue* Oookies, biseaita, muff ins« g^lddl© caicos, aad waffles gaf© satisfacto^sr products usi&g §0 p©r cent pea* nut flour. t@f*©TTO, 19451 national i^au&t Oooneili 1942)

(let 35),

Soyj, feaaut,. aad eottoaseed flours are fe^pyodtxets of oil aaaufacttsfe. Certaia preeaations ar© ©ss^atiai for th® psodadtion of edible flours that woald fee itt- necessary if oil. aanafaouujre were the only ©oasideratioa.

She metHods ^sed for the manufactiare of edible press calces agree ia general for' the diff©remt seeds, but' wy differ slightly ia details^ She method of xaaaufaeturiag eottoxxseed flour ma.^ %Q easily adapted to soybean aad peaaat, (IteSgath, 1940; Bttrlison, 1936) (51? 7). The steps ili the process ares

1

#

6lean» ©speeiallF selected eesds are used,

.§

♦

Stills and feeraels are separated*

$» Eeraels are rolled, then- cooked at tea^eratmr© approsimatelr that of tooilijag tvater. Water may or may aot "be added depending oa the type of eottonseede used,

4.. Oil-is expressed W the hydraulic or espalier process* The meal which is left contains

6 onlf a small pe^eeatag© of oil, aad is th® press 6a&e«

5* Fres® eake Is eooled ©at stored foy §0. &a^a before gri&ding«

6, The press oak© is ground aiM the finer meal is separated tvcm the eoarser groaad poftioa by tteeJEfcanleal m^aas •

7, F^orn a tea of eottenseeds, ^00 pounds, of edible flour mf he produeed*.

^ertaiE eUanges taJtee plae© duriag tlie eoo&ing proeeaa i^kea eottenseed Is eooteed, the pretein separates and eoasiUates asd binds gossfpolj oausing lorn of its tosi© properties• {Ly&nn, lollaad, and Sal©

9

1944$ oioett^

1^1) (89| S6)

0 fia^iai eookiag of soytoeans, tie enzymes, liposddase and lipase are inaotivated* (Balls., ^atelrod aad Ireis,

19431 Simmer aad freasl^r^. 1943) (9$ 41) •

Oooidns of peanuts results in the pepti^atioB of the sdtrogemous oenstituents tvhile ear© oust be taken to preareat the deiaatiiratioa of proteia, CFoataia®, aaaaels asid irking, 1944; Papie,, 1948) USj 38),

Some recent discoveries suggest aeif uses for these various flours» such as* the addition of sojrbean ©r peaaut flours to inereaae protein value of foodstuffs i

ms© la teeat to deeree^id rat© of staling^ asd adfiitioa to milk ptoduets to laMliit ra&eiaitjr of ^uttevtat.

(liaamanj 19445 fayat,. 1942; Paya® and stua?t, 19441

Sola amd Jtevor* 1945|- illllaasoa.*. 1944) (85| 38} 39 j 6 5

42),

Xa addition to the special propefties tfeat haw® maS© ties© flours d68i?able Sot food niaaafactore tlie press ealsea lia^© le@a 3iio\m to possess -aQtlosidaat aoti- vitjr wfeea aaded to fat^o Slctoe^g (1940) (9) foaad tfeat t&e adiltloa of ssaXX qmaatiti^s of aa aatio^idant frae- tioa (XeGithls) fTom so^eaas ia^vo^ed tHe stalllitf of

oils aaS fats*.

Mmk@t, ^1938j 3L04B) (SSj 34J suggasts t&at ra&oldity in Xard wm.f be lablbited by the additiom of ©of or oefeal floaffd.

These obserratiims iadleate that the flosrs m&f

k®f® am aatiOEidaat ©ffeet.ishem jLnoorporated is food mis.es«. laaeldlty is a oonditjloa deirelopiag is fats aad baked goods eo&tainiag fat in which defixtite off flairofs and odots a^e cieteotecu -.Bailer (1945} (to) declares that this pheaoaeaoa does not involve &mm ^umtities of

8 roneId fat, bat that o&lj afeoat 0*1 p©r c©at of the fat wa.f actually <leeoapos® to fo^m tine eompouads respcmsifele to® its rancid flavor aad odor,

S,ea (1939) sayso

9 ffee most Importaat, and from a ecientiflo point of ¥iew tk® &m% iaterestias form of ramcidity is tbat produood W the aetloa of osygea of the air on the fat*® (29<»—>p« ft).

She initial step in the oseidatioa of fats is the additiom of ospgoa. at or near the doabl© ^oad of a fatty aoid ehala to' form unstable compomads Isaecan a^ peroxides.

(Bailey, i§45| (aK

H. r IS

I !

II

-•e.= c--+'o d

^ -e— c-

A-i fats such aa lard,, which are relatively high In eleie sold ©oateat end low in linoleie aoitj will be* eoae raacid after the afesorptioa. of less ©sqfgea t&as fats la which the amount of th®se acids ore ^©^©^sed*

The rate at which oxygen is absorbed % fat is markedly aeoelerated by heat,, ©^osure to light, particularly ultravioletj end the preeenee of certain aetal®o (Siag,

Bosohen asd im$A» 1933; BoeHa aai tfillians, 1945) tSS|

§)., the eouree of oxidation folioss two phases:

1* Initial ptaase Of iMttetioa pe^iot* ©selta*

tioa durisg this pha.B® proeeeds felativeXjr sloiirlsr aad at a more or

IBBB aaifoEm fato-.

^ fl

seeond pfcasd. fl&ea tbe iatottioa pevloA is

©aded, o^idatioa takes plaoe at a grdajbly ae«9ldrated rateo fli@ f©imt -at i^liiefe t&a saaple smells aa<i tastes raaei^ odlaeMts witli tk# ^eglimi^ ©f the seeoud pMBe»

(Bailey

♦

1945? Ml&e, Mattiloni Loasdiieott^, 1945) m m>

«m@ fflo^© tiigM^ «ataratftft a^lual fats mto jtyfiro* g#aat©d oil® viHese oasatavated aelda ooaaist iafgelf of dl©ie &oid we rolati^i^ little aiterea £a fM'ror aat od©^ durlag tli© e&wlf phase, Ozuset ef raaeiditF in ©ueh fats is botb suddea and defiaite,^ (BaiXesr* 1945#*^o

45) fa).

?ai?ious met&ods kate bees, developed for tesfciag ta&eidity ia fats aad ia prodaets wade witls fat* BaMid

o&om asjd flavor mar be detexml&ed otsaaolepticall^,

Of ^asoiditir oaf ^© deteapalned toy chemical anetliods. Of the <5fe©ffiical methods foa? deteanaining the degree of

: ostdatioa the test tor fat p.eroxldes Is asost seasltii?©. fat peroxides a^e iateymediate pyeduets formed

m dttfiag oxidatioa of tlie fat* Th®&® pe^osi4@s deeooipose rapiily to form otjto? products whicl @ire ^©spoaslfele for flavoFS aad odors*, Thoy are eatiaiated bjr their ability to release iodiae from potassium iodide {Kt) la glacial acetic acid {<H^€QQK)« fko peposide tralue of a fat is a aeasttr© of its content of reactive osygea la millimols of pefoxide or ailli@ttti^aients of 02$@$& pm 1000 graffls of fat., (Lea, If39j Sailey, 2.94S) (2Vf

/ / oHg - o f KI > o^, * @ ^ as.

OH OK

?-?

L

■ f f ,

R(v H0 * OH :*E 4 SIS' »i*'H$ - CH;*8- 4 ' Xg

1

2

t »i>Sg0

3

> ^aX 4 SV^

0

*

!Pbe length of time required for many fats to become rancid uitdefr normal conditions is comparatiireiy great* for t&ig reason accelerated testa &ave been introduced and are now frequently used. These tests make us© of relatively high temperatures to increase the rate of oxidation, { Beadle, 1946) (4K the Sohaal oven test is a method mfcing use of

slapi© laeuljatioa of tlie sample ia aa ovea at 6©%.

(Ballejr» 1945) (2), a© test was a©^©lop®d to profid© a aeaaa ©f 3?atiS;g t&e'FeXatlve stability of various sborteniags aad as am fades: to t&eir k^epiag quail ties«

IJI tlte tost ie^reloped hf Sehaal S0 gran samples were plaeei in bea&eys covered witfe wateli (glasses < fh® saaples were smelled dally* ia the i&omlag t

for faaeit odbfs^ f&e oad of t&e IMutetioE period was oar&ed by tine deirelopment of a raneld odoy and darkenizig of the saaple,.

Peroxide foraatioa viag used In ©oaaeotion with the orsaaoleptie tests to follow the dewioimeat of ?aneld£ty.

Oertaio liadtatloas exist ia the me of a method for detesmlxting yaaeidity bf oiigaaoleptie meaast

1« ^evsonal eiraluatloii of the point at whteh ra&eid odors ooear. Banoidity ia fats with short iaduetien periods ia easier to deteet* the longer iMaotiom periods latvodttee aere dlffleulties sl&ee the sample ehaztges feat little from day to day* the m& of the todaetioa period is haM to determine

■ with mmvmtf*

8. 9O1OP ohaages to i&dleate e»d point nay be eoafaeingo Some fat darfeeas toward the end of its iaduotioa period* but ia som© eases the oolor of the fat beoomes lighter.

u

The St?Jift

4 s stabllitr test is oae ia ngthieh the sample is aerated by bubbliag ©sygen tteougli the liquid fat mhile 4t la held at a eoastant ten^e^atare of -Q©

0

© ©a a water hath* |Si&g» Rosehen m& Jrroto, 1933J (34)« Shis test ie-Biaialy ased for deteraialag stability of fats aad oils* and has not heen adapted for us© with toaJsed ot pt®pa.®®& foods. Most of the data ffeperted ia the foiiow- iag papers mm obtalaed lay means of this test*

ThB appeara&ee of Tasoiditsr aay he aeeelerated 02? inhibited* the preseooe of certain metallio salts or aiaute traces of eeftaia metals hafe a oatalytie effect upon the osidatioa of fats. OoppeJ' has heem fouM to be the most active* Beeause of this,, eopper shoold aot be used ia any of the atenslls in whieh fats ate pfooess^

In a&ditioa to the aeeeieratins ©ffeet of metals, it is well established that two other faetors a^e of prime laportaae© ia affecting the dgvelojniQ&t of 3?suaei-

: dity. The eaEposore of fats to light* partioulaffly ultra- violet raysj, as well aa holdi&g fats at high temperatures will accelerate the appearanee of ta&eidity. (Eing, losehea and Irwis, 1953s Boebm and Williams, 1934} (83i 5).

13 the t@f@l©pm©at of ra&olaity tm.f he Inhlbltdd Uy dtoriise a fat at low tenpefatcures a^d proteetiag it from light* She iceepixig quality aay be greatly improved fey tli© aMitioa of aati03Cidaat aabstaaoes*

She Biamifaetarers of ooasiereial fats and oils weff© the flvst to fe©eome interested in maierials whieh if added'to their products would delay the appearance of rancidity* Sine© aaimsl fat eontalna oaly small amounts of aatmral antiexldante a annfeer of JBaterials haire been studied as to their effect in proloaging the Iseepiag

Quality of lard aad other aalaal fats,, m antifioxidant selected for this purpose should t lo lathibit effective inhibitory aetioa*

3. 1© easily soluble la fat,

3. JDapart mo foreign flavor^ odor, or color on long storage*

4< Exhibit ao harmful physiological effect*

5,, SscJiibit no eita&ges when heated,

6.. possess ability to retard raacidity is. bated goods prepared from the fats treated, with it.

7*. Be available la qtuaBtity amd be ©eoaomieal,

(Kiggins aad BXaols, 1944) (18),

u

MM effiolent aatiosidaat mast feave a hy&go^l gwomp uncombiaed and attached directly to aa aroaatto ring, flue antioxidaat cosapounds found ia iregetalble oils are pte&olie In nature amd depead for their aetlHtjr on free tif&TOTS^l groups. (Olcotty 1941} (39) <, JLard con- tains only small quantities of the phenolic type of anti- oxidantso

Certain synthetic antiossidaats ha're been used in lard but tbei? us© has beeia diaeoistinued because of the undesirable flavor aM odor t mad because they are too unstable ©r toxic for use ia edible products* (Bailey»

1945) i2U

Some acids ha^e been found to delay the appearance of rancidity. Most of tbe effective acids act onlf in the presenee of pbenolic type compoimdB» fhef are designated as ©yaergists.

Materials which oeeur naturally in ooanection with foods ha^e received most of the attention for stabilise ins fatty foods j since such substances are umliisely to have toxic effects, Some pfeosphatides behave as syner- gists, Pwifiea lecithin has been shorn t© contain no antiosidaat properties*. Gephalia, though similar in cheeaieal struetur® to the inactive lecithin exerts an inhibiting effect on the development of rancidity. Its

i&MMtisg action is probably to® to tba pfeospiiorie acid*

The sam© s^oup is preseat but is bound in leoit&ixu

H

I

I B fi

I

N

0 . /

H

Leolthls f

SMCUOQOC »!« cepiialim

Mito&eiX and Bluek (1954) (38) asd HilaiteH m&

Paal (1939) (19) fotmd the phoapholiplds of oottoaseea and com oil to be more potent ia their aatlozidant effect than tware those of sofbeasi*

Oae importaat class of naturally ©©earring a&ti* oscldaats consists of the toaopherols • fheir presejsee has beea deiBonstrated ia some vegetable oils where they undoubtedly act as the chief aatiostidaats. Three different tocopherols have beea isolated and are design

3.6 aated as aj B» aad f toooplae^ol*

0H

3 |

S

S

(CHg) 0H^S g l

3

d{0H

2

)g CKCCHg), a^ToeoFliarQl

Altliougia tooopherole at© thought to ^e tte ohjLef antioxidants of veget&M© otXs t

others mzintj, ©om© of wbieli Have beea identified,! Qtos'timax^f},$^xiiMme t

aa oxidation pvoduot of toeopherel* aad gossfpol are aati* oscldant mat ©rials wMofe kaTe" feeea ideatif led* Seeaae and ri^e bran oils a^e imusualXF stable aXtbough the toooplietoi oonte&t ©f thes^ oils is mot partiooXarlf iiigiio jt is believed tlwit they ©ostaia antloxidaats

mom poteat tkm toeopherol^ probablsr sesamol in the

3©same oil. (Bailey, 1945f OolufflMe, 194gj Bove^ 1944)

{g| 15i 1?).

Small cpaatities of soybeaa or oat flour o^ fuae- tioas of eoybean ha'tfe boea added to layd as a meaas of retardtag vaneldlty. (li&iehe?* 1935$ Dahlo aad neleoh t

2.941} (SBj 8.),

If

/

&&%©!

m<$. Smm&tlin

(1945) (14) eompaafsfi tbe teMey* aess of pastries made with fife different

typ.es

of soy flour, f&er f@im& that SOF flour eontainizig only 5 to IS pea? eeat of fat ptofeoed aoi

1

© teM©i? pastry tiaan did full- fat flours,

The

atttltOTs felt that the laerease of tesderaess of the past^2f ©ad^ from extYadted fScare eontai&ing S- per

cent

amd 15 per eettt fat was due to the fat prese&t la thse floors*

fkw

fouM.

a mo significaat 4iffereaoes la the

mem.

lbx s

©a&iag strengthe of pastriea giad© with the esW traoted soy floors contaiBiag. S per oettt ©r 15 per eent fat aad the pastries

la

the third series made with the defatted flour aad eoyfeeaa oil eqaivaloats

whm

the total fat In the pastries was ooastaat. In ooiapariiig a soy flour of the espeller type cojatalni&g 5 per ce&t fat with extracted type soy flours, it was fomad that the pastries made with the expeller floor were aieh sore teader thah with the extracted fioar of either the 5 per eeat or the

15 per eaxt fat coateat or efea thaa pastries aiad© tsdth the fall fat soy flour oOBtaittia§ 2S per eeat fat."

From these results the authors eoseluded that "this dif- fereaee

in

teaderaess aaist have beea eaused

W

some fac- tor other thaa the fat in the differeat types of floor**

U4*.#p« 871, sn)

^

IS

OBAPXgR II

FU1POSB. OF tm KPERBHif fM work of Hil&Uch aad Paul (1939) (19), Daiile and lels©a (1941) (8) aad otliei's Ms Aenonstrated the effeetiYeness of goy, dottoa aad p©aaut fimirs, or eertain of tteir fraotloas, a® iahlls^tors of fat ©si- datioa, Thfiise fiadiiigs suggested tho possibility tMt tli© f^urs might Hav© axitiosldant effect in prepared foods.

Shis eacperiaeat was desigaeds

1* To eoapai"© flouva from ttee© oil press caises as tor

(a) Tbelr ©ffoet ©a the Aevelopment of raaeidity la ftaleed pastry aad pastry miares *

lb) Theif effeot oa the t©adera®ss of the pastry•

2, To o&taia iaformatloa regardiag the method for aoceleratioa of reacidity*

(a) To detormiae Aether dlvisioa of samples for iaeiabatioa ^etweem a few large or maay small coataiaers would iaflaenoe ooasisteaoy of results*

(&) 'So $,et<®T®Xne v^ietheF an immhatog teiiperatus'© of S0®@ (lag

0

!) tsoold be- Buff ioiestlj Mgh to aacelerate the appearance of raaeldity witMu a reasonable period of time, yet not liig& ^siougii %o obseure tbe possible differemces between the experlsiental flours,. if

SSPSRBISEITAL PR0CSS9HE

Baked pastry waa prepared* using a dtanOorAised foraaia ®md teolmlque. The pastry ^aa tMem e^uaMea aa<& distributed between tlte Jars In wMeft it was to be stored* Xhese jars of pastry^ as weil as Jars of raw pastry mis wore stored at 10%.

Samples of both pastry a&d sAx were removed at iaterirala. The fat was extracted, BM- peroxide siumbers of tue fat ¥#«sr@ determined^

Xagrediettta

The iagredieuts used were all-purpose pateat w&eat tlour* salt f

lard^ soy^ eottonaeed, amd peaaut flours.

All iagredtents wiere secured in qaaEtities .sufficient to sor^e for the eatire experiment* Stietilled tratter was used in ma&lag the pastry*

Sbe ^heat flour m& lard were stored at 0%. trntil needed, ©a the day preeedi&g the am on t?hieh tbe pastry or ffiis was to be prepared, the weighed ingredients were plaeed in an incubator whieh s^intaiaed a tenpera*- o ture of 25 G. IMring tbis holding period the

SI teoperatitte of all iagfedieats feeeame adjusted to S5

0

0.

Forsftila flae basic pastry forxauia used was that developed by l.©we,

9

Held on * and Baohanan (19S9) (£8).

Basic fotuml&i

Wheat flouT g76 o

0 graaa

La^d 110.0 gyasj©

Salt 6*0 grains ffetar ^0*0 ml

For tbe soy, dottoaseed aad peanut series, 10 -pet ceat hj weiglit of eaeb of t&ese flour's was substituted for t?lieat fiou^- ia the basic fovmula* Mo otheg ©liaages were made, f&e fOBsulas used for the yaw mixes were ideatical to tftose. used for the balsed pastries t

with the exeeptioa that water was omitted from the mixes*

Mixing the dough was mixed usiag a modificatioa of the method described by %&m, lelson aa.d luehaaan ^1938)

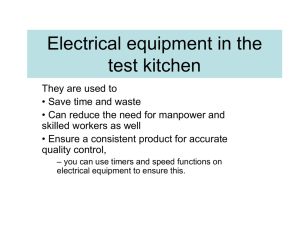

(a8)» A aaehine method tot missisg was eiagloyed. The e^uipmeat ©oasisted of a Hobai?t litcheaAid* Model ©, its 3 quart Mixing bowl aad pastry knife.

The standardized technique used for eonMaiag ingredients followed this pattern{ The flour and salt

wwe sifted oace and then sifted into the mlsiag bowl*

The l©3?d was then added • These ingvedieate were mixed for th3»e© minates at slow speed, without stopping the isachine, th# misture was se^aped dom with a spatula at i§, ^ s

and Si miaates. At the ead of three aimttea the maehia© ims stopped, the mixture §saia scraped doim aad the water added. Mixi&g at slow speed was tfesn ootttlaaed for £0 aeooade.

Att®T wising f the dou^h was turned omt onto a board.

It was then Kaeeded Into a ball with 10 aotloas of the hand, Th® ball of dough was eut iato six strips. The two outer strips were discarded leaving the four center strips to be rolled. tolling

Somiediately after' the dough was- mixed and cut into strips. It was rolled between steel cleats, 1/8 of an inch in height, fo prevent the dough sticking to the rolling pin and board it was rolled between two pieces of was paper. fhe upper piece of paper was then resoved. A rectangular steel cutter measuring 1& by Sf inches was used to cut the pastry into wafers of uniform size* The superfluous dough was trimmed away eround the edges of the wafers and the trimmings discarded. The pastry

2S wafers xmr® then transferred with a sdaiiium of laaadliag to a tin baking sheet* This was aocomplished by invert- ing over the feakimg sheet the lower strip of was paper to whioh the wafers afiherred. By brushia^ a haad iightiy over the paper enough pressure was exerted to cause the wafers to cliag to the bateiiag sheet. The was paper was thea peeled off. fhe wafers were prickM to aiaimiEe blistering.

The instromeat used for prickiag was a small bloclc of wood carrying a aumber of evenly spaced sharp steel points.

Baking

A despatch electric ovea was ased to bake the pastry iflafers,: fhe heat was thermostatieally controlled and cheeked by thermometer<». The bafel&g sheet was placed as nearly as possible in the center of the oven to help in- sure uniform bailing conditions * The pastry was baked for

SO xaiautes at 180 o

€«> {SS©

0

F,)

0

A stopwatch was used for timing the baking period, and the ovea temperatore was accurately .controlled.

After removal from the QTren* the pastry wafers were transferred to wire calse racks where they were allowed to cool for one hour, the breaking strength was then determined by means of the Bailey Shortoaeter,.

24

Mvisioa of samples

All pastyy wafers were rolled to crsambs aBd t&or* owgljlsr mixed* For one part of the experiment the pastry eruuabs were divided equally amoBg many sajall jars. In a second part of the esperimeat, the pastry crumbs were

SlYMed equally araong foar large jars«. lECiibatioa of samples fhe jars of pastry erim^s were placed in an incubat- or which aaiataiaed a temperature of .50

o

@. & OoBS

0

^. as measured by a thermometer placed ia the center of the top shelf<, ©ke temperature -rariations at different points in the oven were; from the bottom shelf to the top shelf, l^7

0

G

% and frosa the front to back of each shelf, O.JJOO-. to ©*8

0

0*

In the second part of the experiiaent when each com* bined lot of pastry or mia: iras divided among four large jars, the jars were placet from front to back on the center shelves of the incubator•

Selection of samples for extraction

At suitable intervals, samples of pastry or mix were removed from the incubator for extraction of the fat.

'In the first part of the experiment, when the pastry was held in many sraall containers, two saspies of pastry

25 aafi two of ais were picked at roaaom. These two sup- posedly were representative of the whole* in the seoo&A pa^t of the ©^perimeat trfiea each lot of p^gtyy of mis ims ai-riaei ^gmallF among four large

Jarsj samples were feaoved from all fouf Jars at each ineufeation period studied* ?hese four sas^les were reproseBtativ© of the lAole.

Procedure for raw pastry raises

Xhe procedure for aoiabining the raw pastry raizes was Meatical to that used for the baked pastry except that water was oaitteSo fh© different lots of raw mis were distributed amoag Jars in the same ©ay as the baked pastry. Incuba- tion aad selection of samples for estractioa were done in the same way as for the ba&ed pastry.

wmmi&mmm

™

®

MM

The fat was extracted from the pastry samples with petroleum ether using Soxhlet eirtractors, The erfcractioE was stopped at the end of eight hours. Excess petroleua ether was removed by distillation fro® the fat sauple.

Drying of the extracted fat v>ras completed under a 25-50, inch VBL&axm at §0

O

0. for sis to eight hours.

86

igtffli Mugs mmm^mm

of the ndtliod &©trel©p@a l>jr I»©a (1939) (2?)* Th® steps .in tbe fieteaaiaatioa w®i>© aa folloii's:

I# SaqpXe wa© ii?©i@i3i©a (1*000 gram plus or Bims 0 a

0§ g3?am) imt© aaber glass test tttl>©o Duplicate fie* temiaations were mat® oa to&h sai^l© ©f fat* g.* App^osiaatdlF I &vm of powdered potassiiM iodliie was added.

So SO xal glaoial acetic aeid amd ohlorofoann mist* taret (2J1 W trolame) mm added.

4= fhe test tuab© eontainiiog t&e above fixture was' plaeed ioaediately in a b@ak as

,

of boiling «ate?»" amd to^at©d ©aractlF 1 aiautt©, A stopweitoJa vms used. Gar© was taken ©o misstar© did not foa®

5, Mixtmr© YMUI tinea poured into SO ml water ia 100 '

6o ffei© ^r^© lodia© was then titrated with standard* iaed sodium thiosulfat© 0*02 Sf until near ®ad poiat*

?

♦

Appvoziaatelsr 2 ml iadioator stared solution

■

©as added.

8o The mixture nas titrated until eolorless.

9* Perosid© number* formulas a<& poroxid© p©r iOQO @ fat *

jm IfagSgOg.) (Bognality)

'weight'' ©f' "fat'm "irams

Peroalde nioib®r is ©stressed tks ailliequivalents of perosid® per 1000 grains of fat

39

E@a@eatg pot&ssiaii lodate vefere&oe standard* 0»02 H*

0.71S4 g potiassiam iodat© per lltei

1

.

Sodium thiosulpiULte 0*OS K, (approsdaately)

5»6 g sodltam thiooalpiiate per liter.

Acetic aeld and oiniorof©m nizto^e 2 parts glacial aeetic acidj, I. part oldorofesm "bf

Stareli solatioa

■

1. 3 solafele starch per 100 mi water.

Hsfdroc&loric aoidj ooncentrated

50 per cent potassima l©did@ golatloa

50 g potadslttm l©did© la 100 oil wat©r. potassloia iodide in pondered ©r erjrstaX form.

Standardisation of so&itm tiliosalpliatd

3., £S«00 ml potassium lodate solution, 0.02 B, was rtta into a 100 mi igrlenmeyar flask

2. 10 mi potaseima iodide solution was added.

So S ml eonteatrated hydroehlorio a©ld was added»

4o Fro© iodia© was titrated with approximately

0.03 $ ^oiiiculi.-thibsalphate until a light straw color* then 5 ml starch solution was addod* Starch solution was freshly prepared.

5. The laist&re was tl&en titrated ant 11 colorless.

8. Foxmilai (ml of potassium iodate)s|H of potas- sium iodate) * {ml of sodium thiosulp&atels

(W of sodium thi©sulphate)*

9. friplioate determinations were m&e,, and each calculated separately. She results were then averaged.

2#

vwmB. iv

lEs^ifs m msmsstoM

Znfo^Biatioa was obtained as to the most desiralJl© method for sampllag ttie ineutoated pastapy^ As meatioaei iiader "Sxparlstental prooddiira

M

oae lot of pastry was distributed among amay small Jaics. &£t©3? laeabation t

- samples ¥#<ai»e selected at raadea for ttietraetios of the fat aM dete^mlaatioja of the peroxide nuiabers* Another lot of pastry tms divided equally among foar lasg© 4ars*

Uaeh %iMB that pastry «as remoired for asalysis of the fat f a senile tras tafeou from-. each of these jars« la the foliowiag disoussioa the first osthod is deaig&ated as Test 1, the second method is ^esigaated as test 11.

Data ohtaiated W saapllag at random fro® auiaeroiis small containers (Test 1) are eonpared tvith those ob* tained by saoaplihg from four large eoatalaers {feat 11) in Table Z*

Differences between duplicate samples froa Test I are MO greater than ^ariatioas amoBg quadruplicate sables in test II. On the other hand* a comparison of the day to day results shoiss considerable fluctuation among the averages fro® Test I. Ho tread is apparent, asad iio ©ur?e could be plotted from these data.

29

A su3?¥© for development of raneiditr In larS twuld be expeoted to allow a short iadaetioa period followed tf a mpid iaGfeas© in peroxide a-aslsero This type of oar¥e tiras oTbtaiaed vthen averages from Test II were plotted, as s&ora hj the curve for plain pastry

In Figmi?© I, Siaee these averages represent a cross seetioa of the changes takiag place in the eatir© lot of pastrsri the method ot saspliag followed In Test 11 should give the aore aceorate picture»

Mo definite ©splaaatios has yet ^eea focted as to the reasos why all" samples do sot become rancid at the same time when all conditions are apparently ttnifora? lr?bank and CfcmM, (104a). (10) workiag with butter samples, found that when samples were spaced far apart in the oven they varied more as to the rate of axidation thaaif closely grouped in the center of the oven,

"66.5 per cent of the samples on the bottom shelf crai- dized more rapidly than those on the top shelf*

5

* '(10-*- p# 806)

♦ n

9eoreasitie the sise of sa^)l© or increasing surface area markedly affected the rate of oxidation."

(10—--p* 207) o Standardization ©f the sise of sample and size of eontaiaes?, as well as the arrangement in the oven ms found to be necessary for reliable results, la the present study, differences in peroxide

30 auxabers of ^upiieat© or quadruplioate samples mj kave h&en due to tempefatiir© lariat ions within the incmbator.

A tefflperatm^© of §0

0 e» (123%*) was foond to fe© satisfactory for acceieratiag the davelo^&e&t of faacldity in pastiy saiipl@s. It was bigb ©aomgli to spe@i up tho appeaffanc© ©f 3?aiioidlt2r» yet low ©Bough to allow sas&X* ing at coa^eaiaat intervals. f ihe tasting of nearly all saaples ?ms complete la approximately two months* fhomgh some saiaples dli not becoae raaciS up to nine month© of storage, 'this was aot fooM to be an inoonvenieatly long holding peipiod.

A tmperature of ©0

0 a» (103%.). is but slightly higher than that of a hot mm&* day. Bomaer tempera- tmm abound 100%* in the shade are ootmaoiL in many parts of the Qovrnttfo ¥ea&*?at«K?ds lomv than, les^p. woald be preferable for stmdyins the development of rancidity, siaoe these would approach aofe elosely normal holding conditions*, However, a lower inenbation teoperatore woald aot be feasible for laboratory use.

The effect of soy, peanut and cottonseed flours on the development of rancidity ia baked pastry and pastry misses is Bhoim in fables II through IS. and by figures % and %%*

It is evident that oxidation of the fat ia plain

31 a&& peaaixt ^aked pastry followed a very gimilai

1

eourse.

Both the plaia baited pastry aad the baked pastry ©oa-

taibisg peaatit flour became raaoid witiiia 1? days. The paaaut flour prsse&t in the baked pastry exerted very little if aay aatioxida&t effect, fhe last samples of pea.2Mit mis to be analysed were removed from the immbator after 4© days* They showed no evideaee of beeomiag rahoid at that time* the plain ais showed no Increase in perox- ide aumber up to the sixtieth day of ineubatios, bat rancidity developed between the sixtieth and seventy^ fifth day*

On the other hand,, soybean flour was shown to be a good entioxlda&t, and cottonseed flour an esoellent anti«* osidant both in the baked pastry and in the raw aiKes.

Th® baked pastry containing soy flour did not become raneid up to 39 days of incubation. The raw soy sals became rancid after nine months, fhe baked pastry con- taining cottonseed flour showed no sign of becoming rancid up to 86 days of storage, and the raw mis showed no increase in peroxide number up to nine months•

The effectiveness of soy and cottonseed flours in delaying the appearance of rancidity is doubtless due to their content of antioxidants of different kinds. It is known that cottonseed 'flour contains gossypol and tocopherols as well as other antiozidaat substances as

yet aot identified, Gossypolj n&et&ep in its free of feoimd form, has beea s^owa to fee a very powerful anti- oxidanto (Hilditoli aad vwil, 1939) (19), Qleatt (1941)

(S7) reported that a water soluble aatiosiidaat also is present in cottonseed* Soybeaa flour is tenam to eoa* tain tocopMerols aad lecitkin,

Peaaut flour xaay eoataia. tocopfeerols. Inaamuch as tbe peaaut flour did sot delay rancidity ia baked pastry, it may be assumed that aatioxidaat substances were present in vewy assail aaounts or were readily ostidissed, fhe -lard used for preparing the pastries and mixes had a peroxide number of S..

1

?. In every ease,, the fat estraeted from the freshly baked pastry had peroxide numbers lower than that of the unused lard, fhe same observation wag made in regard to fat extracted from the dry mixes* Peroxide numbers x?ere found to be loTirer than

8,7 in every fat sample from the plain mix through 60 days of incubation, from the peanut mix through 40 days, from the soy bean six through 114 days and from the cotton- seed mix through 270 days..

These lower peroxide values may have been due to reducing substances in the food mixtures which acted upon peroxides ia the fat, or they may have been due to sub- stances extracted with the fat, which were capable of reducing iodine in the iodometric method of analysis used*

35

Tfce effect of soy, peasmt aad cottonseed flours on teMerBess of baked pastry is shown in fable X. Averages of tsreakiag strengtii deterainatlons show that plain pastry was someiAat more tender than the others. The pastfles in v/Meh soy^ peaaut or oottonseed floiir had been used differed bat little from eaoh other*

The pastries in i?Moh soy, peaaat and eottoassed flosirs were used were aeeeptabl© in eolor, flavor and texture«

■ r i'he pastries made with soy or pearnat flour were slightly creassy or yellow in ^oloro i'he flours added a slightly nutty flavor to the pastry. Th® oottoneeed pastry was slightly darker .in oolor than th© others*

A smaller percentage of cottonseed flour would have given a lighter colored product* The flavor was not unpleasant, but. in the opinion of the author, was not as pleasing as that from ..soy or peanut flour.

As rancidity developed in the pastry and mixes,, definite color changes were noted in the extracted fat.

The fat.extracted from the fresh pastry had a light yellow tint*

-

This color was due to the carotene from the unbleaehed flour, AS rancidity progressed the yellow tint of the fat gradually faded to colorless.

A definite color change was noted In the extracted fat from the sample of cottonseed aiss that had been

33a incubated for ftine montlis* Mhen incubation vma first started a faint yellow tint was characteristic of the fat, but a distinct orange-red color was present in t&e fat extracted from the sample that had been held for this long period of time. This may have been due to the formation of toeoquinones, caused by the oxidation of the tocopii^l?ols that are present in the cottonseed flour*

The toeoquinones exhibit a red color,, (Oolumbic, 1943;

Bailey, 1945) (15? g).

34

©EAPOT ? th® ®tim%'iv®mB8 of so^s l»®&»t aad eottoasaed tlouf in €©Xajing ranoidltF la balsea pastry aai paster mizes has bis^a stufiiedo

BakeS padtrjr aad djpy mixes we?© m@4$ usiag a standasttlared fomaala* aat atanaasdleod taehnl^e* fh®

BOfp p96jaa% aat dottoas@e4 flours wef© dabatitutei for

10 per $eat ^j welg&t of wheat flour la the formula, fja© pastel- asd alses were stored ia glass Jars at a @OB- etant te©peratm#e of 90o

$* Peroxide auabers were deteni- imeft at i&tarvaXs oa fat extracted from a assies of eaola kiM- to test for tba deTrelopmeat of raaeiaitj^

Ferosslcle numbers of fat esstraotad from aeuoples nkiQh feat Iseea ltteut»atad for the same length of time were fouod to be sore ualf orm wkem the pastrf was in a few $ars of the same slse tluui wkea atorea in raaay jars of .small alse*

& teaperatmr© of 5® o

0o was fooiad to be eatlsfaetor? for a study of tfels tjrpe.

Sottoaseet flour eserted the greatest aatiosldaat

©ffe©t s

aad goytoeam was good» but peanut flour appeared to have ao anttOKidant value. Pastry In nhieh peanut

flour h@.& b&6& iaoovporated imB almost iaentieal to plain pas toy la the speed tsith tshi&h raaaldity developed*

. Sa every sas© the S^j mlses kept ^ettes

4 tkm the correspoBdiag foatoa past^*

Pastries la tnhleh S©F» peaaut or eottomseed flour had been used differed ver^ little from eaeh other la teaderaese* hut la eaeH ^ase were lese teade^ thaa the plala feaked past^jr*

MBhmmmm

li MGhaMj, L©ah. Peaimt seal foot traime m& uses.

©eoygia Bsgparimeat station Bull* X9S t

Beo« 195©. lip. luteraeiaaee F«m7 IncTTltew York, 1945.=, TfSp.

3* Bails, A* S., toal^ot, B* aufi Eela, M» w» Soybean llpossiaase^ *r. Bi©X, 0h«9u Mg^491»304^ 1943*

4* Beaftle*' B

0

Wo ProBl©®© in the eiraluatlbn -of fat tttafeility* '©11 ama Soa© ||;i 33*3S

4

1946

♦

5* Boetey !

■

« and Williams., B* Sbe prevention of autosidatii?© reunolsity in fats ©md oils. Phasm*

J* jmi 3.63*4* X9434

6-» B^lm-j, 8^. f-« amd ?avor

4

1* So 9oya flour as a feread

. ingredient.* Oeveai ^Jaemo- S|: 396~31X.» 1945,,

^o Bu^Xison,, W. l,o lEhe sof^as®.. A plant imigrai&t maJteea good-, lad* aad sng* Ohem* B|s ^sa-V??., 193$..

8* BabXa t

0.» B-. aad Helson, B« H. AAtioa^fgenio fractioss of oat aad so^a feeaa fious?.* f., Dairy Solo S4t • g9«3ft, X941.

"":

9* Bieiib«rg t

Joseph. Sor lecithin aids indtsst??.*

SOjb©am ©igest Jj 8., jran» 194So

XOi? Bvirbank. F, CU and Ooald* I. 4* Ihe o^en aad a©ra« tiom a®t&oas as aeaas of aeeeleratinis fat oxidation. Oil amd Soap |j|5 80S^@09.» X94S..

William ii©M<^2mTM7ri9ll7Tip.«

IS* filer, £.. 0*e s

Ja&ttil, K* to and Longeneeker, H* B«

Olianges oocurring'in fat aatoxidation« Oil and Soap SSi 196*201, 194§.

13„ foataiae,, T« ©«,. Sasnels, 0* amd irviag, 0, w.

Properties of peamt ®eal

0

Xnfiaenee of process^

im% faotors. Xnd« and Bng. Otaea*, 36 i #25*^37,

g?

14. CtebgLt 6* ana SsiadsrilSf 0, f®M©3ra@ss of pastries

maM. with a&ffereat aor flours* Oil aa& soap

|gj 8^1*272* 1945*

3.5• Golaqft&Q, Oal^ia* totloisiaaats aM atttosidatioa f3?©m

7969tabXe fats* £* ABL« C^0m„ Soo« 642 S33?*S340,

X0

O

©s-w^, SBiily> Is© of peaxutt floay is bakiag*. food

%«saaro£L !£.; 23*41, 1946, •

17. Eair@j> B# I.* Gossfpol as a carote&e**proteetl&g aatioiidaBt, la DIVQ aiad in tritvo* ^T. Biol.

18. Higgia^s, J, W« aad Blaekp H. 0* A preliminaiy com* pa^lsoii of the stabilizing ©ffeet of several jredd&tly proposed antioadOants for ©dibie fats ant oils. Oil ami Soap g^t .877*d79

#

1944.

19o HiMitola,. 'T*.' f. aad Paul, 3* Ota&laa oa tlie aatu^t of aatiosqrgeas presant in nataral fats* tf* fh<e proportions aad prop©rti<©s of antioa^senlo ooj^onads in various estraotad seed eakes* ^c

BOQ, Oliagu lad* 68s 21*24, 1959*

SOo 0"oimE., 0» G, and Finks, A* J.. file natritiva -ralua of peanut flour as a sapplament to x^Jheat fiomr*

SI. jTohns,, C» 0* aad Finks,, A* 3* Kutritiv© valme of go^ibeaia flour aa a smpplament to wheat flour*

m. 3** f byslology H? 455*461, 1921.

8a <> ^osraert M. T» ©ad IteX&tsrre* ?• B. The ovaa test as saa index of keeping qpaiity* Oil aad Soap 158

164-186 j, 19S8«

BSo Kiag, A* B«» Bosoben^E* L«. and Inwia, w. B« ffea aeoaleratins effect of a@tal@ oa tie development of peroxides in oils aad fats. Oil and Soap 10t

MtemZOV, 19SS.

E4* Sins* A* S*, Hosafcen. B« I., and Irvdn, W* H. An aaaalarated stability test naaiag tbe peroxide valae m an index. Oil a»d soap ^0? 103*109,

1933*

m g5» glBBmsa* Olate H; Nutritive value, of soF¥eaB.s

e

So^b©aa Bigeet Jtr-G* 10> !$.«. Oct. 1944*

26* lasery Mldved* ^g Psefgl Soybean. Me$raw«5iU

Oo# Inc. Hear'"Xoric;,

=

l^fe'V 'SS'^p*

8?

#

Lea, 0* H. Sss®|l4&-lEJMlia4aM* ®®®& invest!^ gatioa special repoftj BaT^o; ' Shea* 3Publ« 0©*,

Haw Tork* 1999.

■

330$«

£8«' iLaw©^- BelXa* Helsoa, F* label ai^i Baoluman* J* H.

'Hue p&yslcal aafi dfeeiaioal oharQ^teristlos of lards m&' otshar fats ia relation to their attlinary value. I* Shortanias ^alm© la pastry aaA eaofelea* lg,rioultms?©.l' Sa^arioaat StatlOBf--

Iowa State Coliage, teeSj: Xocsa. Raaaarclt Ball.

84S, 0et» 1038,

S@. Lfmm, 0* M*, HollaMj B* R« aad 8al6» f * ffocassiag oottoas^od- meal* 4 meuaikfa^tiiriiig method for

©iiainetifis toxic qualities^ Xud» asid Sii§

0

Chaai* 36: 188*190, 19*4*

30* fitettll^ I0 4* i&tios&fia&ta* S^me^gista.,,: and Pro* oxidaats., Oommittae oa Flood Reaaaroh.

Daterioratloa of fata 'and oils* Amf Senrlce

fovQ^B Office of q. M» CkHHera^t Kov. 1945^ p. .

90*98*

51<« McHSafcfc, 0* lo Oottosseed as a source of a aew typ® of flour* Pro©, Cotton Reaeareh Oongraaa it

380 Kitetiell,. 1* S. aad Blacle, B* O, stabilisation of fate aad fatty foods* lad., aad l&g* Oham*

^ 50*58, 1943,

S3. SftLsher*. Sld&ajr. OereaXs a»d s©eda ia&ibit raaeidit^ in lard, food luduatries li 167*16©, 1935,

S4* ISsslier, SidaeF* 9. S* Patent #8,883,806, May IE,

1943.

35* MatioBal Faaaut GQVUMSII, lac Peanuts, their food

Taiue aad int eras ting recipes, ^aagphlet

Published from Atlanta, Georgia, 1948*

39

36. OJLcott, H* S. Solvestt extract ion of ©ottoaseed oil*

If feet ©f eoolsiag ou jrield* IM° ant Sngo Cli©m

D

^34 611*015i 1941.

37. Olcottj H. s. AatlosMaats for edible fats aadt oils. Oil and Soap JB* ^^-SOa 1941«

384 Papie, Boa. S. Itevelopisosit, Hm&uf&etur® sad utiliza* tl<m of peamut flow*, e&ea asd Sag. Hews 801

U75-1174, 1948, *~~

S9* Payae> P. 3* aM Stuart, L* S. Food uses fo* soy- beans*, sor^©am,Digest.fs 10*19, ©©e* 1944.

40P Stellet^ W» E,. aE€ Bailey, C#.H» Tfe© relatloa of flomr st^engt&j soy flpur aaa teaperature of storage to the stallns of bread, cereal

mm. Zg? 391-401, 1938.

41. Sonae?; E* 3* aiid Tressler^ 0. E

0

Llpoifi oaldas©

4n sofl3©aa meals, lad* aad Eng* OMem. §Sj

931^1943.

43* Willlaiiasoa t

M, B. Beta^dation of f$b amtozidatlon

in dried allies* Food Heseareb 9:J 298-308, 1944.

JPBOTXX

Eafele ¥2* S01BE&S I'ASfgT"

0

, B&MSt —* Poroadde a-ara^ers

00

" of fat

© ext^aetea tmm pastry storet at §0 G.*

Bays of laembatios

0

4 f

11

14

1?

SO

24 gE m

1

. s*§

6»S

10.3

3.4

5*5 a.8

§*4

§

♦

0

4*4

5*0

6«S

5*5

4*1

3*e

4*4

5*B

S.g

4-e

S.l

GoataiaQ3? jmiafe©i

>

XI III

•*• —

5*1

5*2

4*0

4*2

S*g

5*7

5*S

14 *&

M*S

10 per eejfti Soy flo^p?

' Milliegoivaleats SO pey 1000 yearns fat

I?

**-

4*7

9*2

B*9

4.3

4*3

5*3

5*4

4*7

7*3 '

^ 4^erag§

5*5

5*7

7.6

3*6

4*4 a.9

5*4

5*1

7*1

7*:$

m oa tJU© tea^ssraesB of &&&©& pastry.

I

II

III i?

>'

¥J fll „ fill

'ii

I ii ill

AF©.3?age

4 e

? a.?

3*3

4*1

W*0

$,,@

9*9

»

♦

*

,i i.iiiM>i,>

, .„.„

6*3

14#j»

X4»8 n*8 is* a

•11*4 • • 3,3* 6

U»?

15 «! is* a is.s

13.0 i6 a

9*S

10* $

U»5

10,6

X8»8

3.g*3

12,8

,,,„,.

■ r

,

1844

... n, .. n*f ia.*@

13 • 8

8.#.§

10*7

12 « 8

B*.6

12*4

12 #8

12.4

12*8

1.0*2

10*8

MMCbeW

0

A?@.x»®g.©8 Of 14 i® 18 imf©^0 pei

8

lot o* 10 ^er sent of s©j s

peanat os? ©©$toas©©d flims? 3iaTbst4i»mt@d fw wheat flow

51

80

Peanut

60

£

0 o o o

LU

: 40

Pfain

UJ a

>< o

£ 20

■

Larc,

G J l

Soy

9

Co ttonseed o

>« _ « * a e

" e

^- •

^9

20 40 60 SO IOO

DAYS

FIGURE-I

The effect of soy, peanut and cottonseed flours on development of rancidity in baKcd pastry stored at

50° C.

5E

80

<£

UJ

ID s

D

Z

UJ o

<

8 o

60

P/wn MH J'oy Mix

.

Lard ftzanut Mix 1 onto '. r.a X • • y

1 " ' " o 80

FIGURE -I

* c e ^^

/ Cottonseed Mix

•

160

DAYS

240

The effect of soy, peanut, and cottonseed floors on development of rancidity m raw paitry mixes stored at

50° C.

320