Containment Level 3 Facility GMO and Non- GMO

advertisement

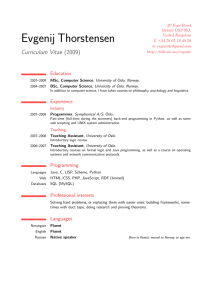

Containment Level 3 Facility GMO and Non- GMO Containment Level 1 CL-1 Containment Level 1 (CL-1) CL-1 is suitable for work with agents in Hazard group 1. Although defined as unlikely to cause disease by infection, some agents in this group are nevertheless hazardous in other ways (i.e. they are allergenic or toxigenic) and adequate control measures must be in place. Laboratory personnel must receive suitable and sufficient information, instruction and training in the procedures to be conducted in the laboratory. ¬ Most requirements are procedural – see supporting document • Physical requirement – Area where work is being carried out must remained closed 29.05.2016 University of Oslo 2 Containment Level 2 CL-2 Containment Level 2 (CL-2) CL-2 is suitable for work with agents in Hazard group 2. Laboratory personnel must receive suitable and sufficient information, instruction and training in working safely with biological agents in this hazard group. A high standard of supervision of the work should be maintained. In addition to the measures described for CL-1: ¬ If the laboratory is mechanically ventilated, it must be maintained at an air pressure negative to atmosphere while work is in progress. ¬ An inward flow of air must be maintained while work is in progress. ¬ Work & storage surfaces must be impervious to water, easy to clean & resistant to acids, solvents & disinfectants. 29.05.2016 University of Oslo 3 Containment Level 3 CL-3 Containment Level 3 (CL-3) CL-3 is suitable for work with agents in Hazard group 3. Laboratory personnel must receive suitable and sufficient information, instruction and training in working safely with agents in this hazard group. A high standard of supervision of the work should be maintained. A list must be kept of employees engaged in work with biological agents in Hazard group 3 indicating the type of work done and, where known, the agent(s) to which they are exposed. This must include, as appropriate, a record of exposure (e.g. resulting from accidents and incidents). In addition to the measures described for CL-1 and CL-2: ¬ The facility should be separated from other activities in the building ¬ The laboratory door should be closed when work is in progress and locked when the room is unoccupied. A biohazard sign should be posted at the entry to the laboratory. 29.05.2016 University of Oslo 4 Containment Level 3 CL-3 Containment Level 3 (CL-3) (continued) ¬ The facility must exhaust through a HEPA filter or equivalent ¬ The laboratory must be sealable to permit decontamination. ¬ There must be an observation window or an alternative (e.g. CCTV) so that ¬ occupants can be seen. A CL-3 facility must be maintained at an air pressure negative to atmosphere. ¬ This should be achieved by one of the following methods:a) extracting the laboratory air through independent ducting to the outside air through a HEPA filter (or equivalent); b) extracting the laboratory air to the outside air with a fan and HEPA filter (or equivalent) 29.05.2016 University of Oslo 5 Containment Level 3 CL-3 Containment Level 3 (CL-3) (continued) ¬ In laboratories with a mechanical air supply system, the supply and extract airflows should be interlocked to prevent positive pressurisation of the room in the event of a failure of the extract fan. The ventilation system should also incorporate a means of preventing reverse airflows. Summary Weiss can supply equipment for a facility that will enable licencing to containment standards ¬ However this will need to be backed up by safe working procedures to achieve a safe licenced facility. 29.05.2016 University of Oslo 6 Rothamstead CAT 3 facility 29.05.2016 University of Oslo 7 Rothamstead CAT 3 facility Containment area: ¬ Total area of 428 sqm ¬ Large room with 4 growth rooms , two tiered with 24 sqm of growth area, two ¬ ¬ ¬ ¬ ¬ 29.05.2016 with trolleys with 9.75sqm of growth area. UV water treatment system Wet Laboratory Dry Laboratory Autoclave room Entrance lobby and Air Shower University of Oslo 8 Rothamstead CAT 3 facility 29.05.2016 University of Oslo 9 Rothamstead CAT 3 facility Building Envelope ¬ Containment facility is part of a much larger structure but physically separate. ¬ All six elements of the structure have been carefully constructed to provide a hermetic solution. • Kingspan roofing system for thermal and sealing purposes. • All plasterboards surfaces are double skinned- each skin being taped and sealed • Joints/interfaces between elements are fitted with PVC coving that is mechanically fixed and mastic sealed. • Number of penetrations is kept to a minimum • Floor is sheet vinyl punctured only by drains of growth rooms and sump to which drains are fed. 29.05.2016 University of Oslo 10 Rothamstead CAT 3 facility 29.05.2016 University of Oslo 11 Rothamstead CAT 3 facility 29.05.2016 University of Oslo 12 Rothamstead CAT 3 facility Building Envelope ¬ Swipe carded door entry. - Both outer door and inner lobby door. ¬ Outer Lobby - Monitoring equipment and signing in book. - Coats and safe storage (lockers) ¬ Air shower installed - Interlocked doors , timed air shower - Designed to remove loose particles, pollen and Insects - Traps inside shower to monitor insect load. SOP to monitor and fumigate if required. - Separate goods air shower ¬ Inner Lobby - Held at -5 Pa relative to air shower and outer lobby. - Main are, including labs kept at -15 Pa relative to inner lobby 29.05.2016 University of Oslo 13 Rothamstead CAT 3 facility 29.05.2016 University of Oslo 14 Engineering Solution The Growth Rooms ¬ There are 4 growth rooms that provide the highest level of containment. - Integral air locks. - mechanically sealed box with sealant gunned into the joints. - totally pressure tight apart from the functional openings. ¬ The fresh air inlet. - Connected to an external weatherproof louvre via sealed ductwork. - Gas tight dampers for filter maintenance and fumigation - EU4 filter with integral pressure sensing - A VAV damper to maintain room negative pressure - Supply fan - Back draught prevention damper - Power Failure protection – to ensure pressure differential is maintained - Supply air diffuser and integrated insect screen 29.05.2016 University of Oslo 15 29.05.2016 University of Oslo 16 Rothamstead CAT 3 facility The Growth Rooms ¬ The Exhaust Air Outlet. - Connected to an external weatherproof louvre via sealed ductwork. - Gas tight dampers for filter maintenance and fumigation. - Filter section comprising pre filter, an H13 HEPA filter, an insect screen and integral pressure sensing. - Exhaust fan with speed control governed by room negative pressure. ¬ Negative Pressure Regime. - Growth room lobby - 15 Pa to main room. - Growth room – 15 Pa to growth room lobby (-45 Pa to outside) 29.05.2016 University of Oslo 17 29.05.2016 University of Oslo 18 Engineering Solution The Growth Rooms ¬ The Growth Room Lobby. - Door to main growth room from lobby has face to face seals on three sides and wiper seal on bottom. - Door to main room has face to face seals on all four edges. - Door to growth room has EU filter. - Door interlocked to outside main room door. - Infra-red operated tap. ¬ Main Growth Room. - Adjustable air flows. - Noise levels less than 70 db - Temperatures adjustable in range 10 to 30°C, Uniformity + 1°C - Light level achievable up to 500 µmol m2 sec1 - Occupancy Sensor 29.05.2016 University of Oslo 19 Rothamstead CAT 3 facility 29.05.2016 University of Oslo 20 Weiss Technik UK Limited Units 37-38 Loughborough Technology Centre Epinal Way Loughborough Leicestershire LE11 3GE United Kingdom Phone +44 1509 631590 Fax +44 1509 211133 www.weiss-uk.com