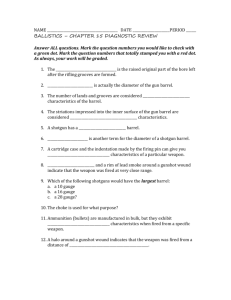

SMALL ARMS CHAPTER 3

advertisement