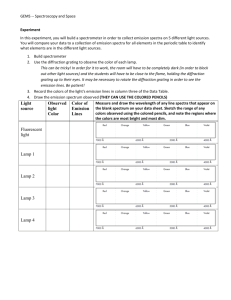

Fluorolog -3 Operation Manual

advertisement