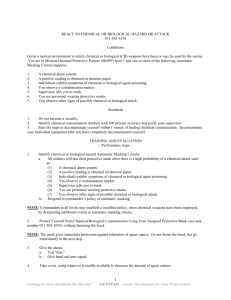

Chapter 16 CHEMICAL DEFENSE EQUIPMENT

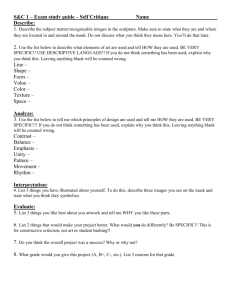

advertisement