Automatic temperature monitoring: What are the potential benefits?

advertisement

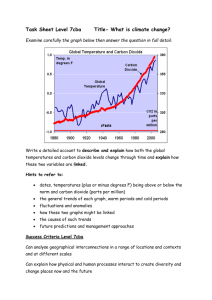

Automatic temperature monitoring: What are the potential benefits? Jeffery Bewley, Graduate Research Assistant, Purdue University, for Progressive Dairyman In recent years, a number of products have been developed to automate the process of recording temperature in cattle. The majority of these systems are designed to record milk temperatures or reticular temperatures. Milk temperatures are recorded in-line while the animal is milking, while reticular temperatures are recorded using a bolus equipped with a temperature monitoring device. As an example, the MaGiiX™ Cattle Temperature Monitoring System (CTMS, MaGiiX Inc., Post Falls, ID) utilizes radio frequency identification (RFID) technology within a rumen bolus, a panel reader placed at a parlor entrance or exit, and a software package to collect, analyze, and view data. Other examples of temperature recording systems include the TekVet™ System (COLT Technologies LLC, Salt Lake City, UT), the CowTemp™ telemetric system (Innotek, Inc., Garrett, IN), the CorTemp™ (HQ Inc., Palmetto, FL) temperature/heart rate monitoring system, the ETD Bolus™ system (CowTek Inc., Brule, NE), and the Bio-Thermo™ (Digital Angel Corp., South St. Paul, MN). These and other similar technologies have been described in the literature and are commercially available, or may be soon.Automatic temperature recording has tremendous potential for incorporation into a dairy’s information management systems. Body temperature has been described as the “single most useful measurable parameter and a sensitive indicator of the PROGRESSIVE DAIRYMAN reactions of the animal to physicoenvironmental factors, disease processes, and physiologic functions such as nutrition, lactation, and reproduction” (Nakamura et al., 1983). Although the value of changes in temperature to animal monitoring is clear, inherent difficulties exist in monitoring temperatures. Body temperatures vary between cows, within a day, and with varying environmental conditions. Consequently, monitoring temperatures using strict cut-offs (i.e., examine all cows with temperatures greater than 103°F) is not a very effective way of monitoring temperature. Alternatively, monitoring temperatures by establishing an individual animal’s temperature baseline, factoring in diurnal (within day) and environment variations would likely prove advantageous. Many factors influence body temperature, including overall health, environment, ambient temperature, activity level, estrus, pregnancy status, eating and drinking behavior, and excitement (Hewitt, 1921, Lefcourt et al., 1999). Perhaps the largest potential benefit of employing an automatic temperature monitoring system on a dairy would be in early detection of cases of diseases, illnesses, or disorders that plague the dairy industry (Maatje et al., 1987). For many diseases, an increase in temperature is an early physiological response (Bitman et al., 1984, Hicks et al., 2001, Piccione and Refinetti, 2003, Schlunsen et al., 1987). Theoretically, the economic impact of decreasing death loss or minimizing the effect of disease on productivity through early detection is quite large. Of particular interest is the potential during the cow’s transition period, defined as the three weeks before to the three weeks after calving. Metabolic disorders, such as ketosis, retained placenta, and milk fever; and digestive disorders, such as displaced abomasums, indigestion, traumatic gastritis, acidosis, and bloat, represent tremendous losses to the dairy industry. In recent years, intensive fresh cow management programs have been established based upon using electronic thermometers to detect fever (Aalseth, 2005). Attempts have been made to use milk temperature as a predictor of mastitis. A large temperature rise (>1.0°C) is typically associated with clinical mastitis, and may even be observed before clinical symptoms are evident (Fordham et al., 1988). Detecting increases in temperature at estrus has been suggested as a strategy for estrus detection. Temperatures generally increase corresponding with estrus. Limitations with regard to the magnitude and duration of this temperature increase may present challenges in using temperature increases to identify estrus. Temperature monitoring systems have been proposed as a tool to use in management of the negative effects of heat stress. Generally, body temperatures are highly correlated with ambient conditions (Fordham et al., 1988, Spiers et al., 2001). A better understanding of the patterns of body temperature under varying scenarios may be useful in determining management strategies during heat stress (Al-Haidary et al., 2001). Data from telemetric temperature monitors could be fed into an immediate feedback loop designed to keep an animal in its thermoneutral zone (Lacey et al., 2000). Continuous measurements of temperature could prove useful in evaluation of cooling and heat abatement strategies by providing a more accurate indication of cow response to these efforts. Automatic temperature monitoring systems may also be used in identifying the onset of calving (Aoki et al., 2005, Nielsen et al., 2001, Wrenn et al., 1958).Body temperature has been demonstrated to drop between eight to 48 hours before calving. The ability to predict calving time would be useful in assisting difficult births. Consequently, calf mortality rates may decrease and reproductive function of the dam could improve. We have a great deal to learn about how to best incorporate automatic temperature recording systems into daily management schemes. Research needs to be conducted to determine the variation in temperature with large numbers of high-producing dairy cows. Utilizing the large volumes of data available from these systems will allow us to examine how changes in temperature affect physiological changes we are interested in identifying (i.e. health, mastitis, estrus, heat stress). How changes in temperature correlate with these events is essential to understanding how to utilize automatic temperature recording systems. Computer algorithms need to be developed to improve the detection of true outliers. In turn, the dairy manager will be able to focus efforts on examining animals that have experienced a real physiological change that is causing a change in temperature. Lastly, research needs to be conducted to determine the profitability of investing in these systems. PD PROGRESSIVE DAIRYMAN Reprinted from February 2006 PO Box 585 • Jerome, ID 83338-0585 • 208.324.7513 or 800.320.1424 • Fax 208.324.1133