LESS THAN ONE IN A QUADRILLION—A TEST METHOD FOR MEASURING

advertisement

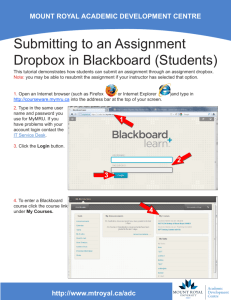

TECHNICAL ARTICLE Snehal Prabhu and Ian Beavers Analog Devices, Inc. | Share on Twitter LESS THAN ONE IN A QUADRILLION—A TEST METHOD FOR MEASURING ADC CONVERSION ERROR RATE | Share on LinkedIn |Email Abstract To err is human. But what claims can be made about your system’s analog-to-digital converter (ADC)? We will review the extent of our conversion error rate (CER) testing and analysis of high speed ADCs. The ADC CER measurement process may take weeks or months to complete depending upon the sample rate and the target limit required. Often, testing beyond the first error rate occurrence is needed for a high confidence level (CL) (Redd, 2000). For those systems that require a low conversion error rate, it takes this kind of detailed attention and effort to quantify. When we get done with it all, the error rate can be established with high confidence— better than <10–15. Many real-world high speed sampling systems, such as electrical test and measurement equipment, vital systems health monitoring, radar, and electronic warfare countermeasures cannot tolerate a high rate of ADC conversion errors. These systems are looking for an extremely rare or small signal across a wide spectrum of noise. False alert triggers in these systems can cause system failure. Therefore, it is important to be able to quantify the frequency and magnitude of a high speed ADC conversion error rate. CER vs. BER At the onset, let’s separate two distinct differences in error rate description. Conversion error rate (CER) is typically a result of the ADC making an incorrect decision about an analog voltage sample and, therefore, its respective digital code compared to the full-scale range of the converter input. The bit error rate (BER) of an ADC could also describe a similar error. But, for the purposes of our discussion here, we define BER as purely a digitally received error of otherwise correctly converted code data. In such a case, the correct ADC digital output fails to be properly received in a downstream logic device such as an FPGA or ASIC. The degree to which the code is in error and its frequency of occurrence is what we will discuss in the remainder of this article. The ADC conversion error may be difficult to glean by simply reading a technical parameter off a data sheet. You can certainly get some kind of estimation about the conversion error rate with a single number on a converter data sheet. But what exactly does the number quantify? You cannot tell what size sample excursion is considered to qualify as an error and are not able to identify the confidence level in either the test measurement or simulation. The definition of an “error” must be bounded in the magnitude for which the frequency of occurrence is known. Visit analog.com Error Sources There are several error sources, both internal and external to the ADC, that can play a role in conversion errors. External sources include system power supply glitches, ground bounce, abnormally large clock jitter, and potentially erroneous control commands. ADC data sheet recommendations and applications notes will typically outline the best system layout practices to circumvent these external issues. Internal sources to the ADC can mainly be attributed to metastability (Beavers, 2014), or residual processing handoffs between stages in the analog domain, and output timing errors in the digital and physical layer domain. These challenges must be analyzed by the ADC design team during the development of the component. Ideal ADC Transfer Function Actual ADC Transfer Function Digital Output Code Digital Output Code Analog Input Analog Input Figure 1. An ideal ADC sample has a single digital output for each bit of analog resolution across the full scale (left). An example of real-world ADC output behavior (right) shows some ambiguity related to internal and external noise. A metastable condition in a bank of comparators can occur when the comparator reference voltage is precisely equal to, or extremely close to, the voltage to be compared (Kester, 2006). The closer in magnitude the compared voltage is to its reference, the longer in time it takes for the comparator to make a complete decision. In the case where the delta voltage between the two is very small or zero, the comparator may not have enough time to resolve a final decision as to whether the voltage is above or below the reference. As the conversion time expires for the sample, the comparator outputs may be left in a metastable third state instead of clearly deciding a valid logic output of 1 or 0 (Kester, 2006). This indecision will ripple through the ADC and can cause a conversion error. A Comparator Output (VIN > Reference) Valid “1” B Small +VIN Output C ~Zero +VIN Undefinable State (Metastable) ~Zero –VIN Valid “0” Small –VIN Output Large –VIN Large +VIN Valid Data A Valid Valid Data B Data C Time Figure 2. An ideal ADC sample has a single digital output for each bit of analog resolution across the full scale (left). An example of real-world ADC output behavior (right) shows some ambiguity related to internal and external noise. Less Than One in a Quadrillion—A Test Method For Measuring ADC Conversion Error Rate In pipeline ADC architectures, additional potential sources of conversion errors are those at the points of the interstage boundary handoff where a residual voltage is passed from one stage to the next. For example, if an uncorrected gain matching error occurs between two stages, then the handoff of the residual voltage can have an error in the subsequent stages. Additionally, a glitch in the residue DAC that sends a voltage to the next ADC stage can also cause an unexpected disruption error in the later processing (Kester, 2006). Inherent to all ADCs is a thermal noise component present in any passive component that determines the absolute noise floor of the ADC processing (Brannon, 2003). All these potential sources of error must be vetted and quantified during a thorough characterization of the ADC to ensure that there are not any gaps in the execution of the converter. The integral nonlinearity (INL) of the ADC is the transfer function across the full-scale ADC input range of the actual samples code relative to the ideal output (Kester, 2005). This information is also typically specified and plotted in an ADC data sheet. The maximum deviation to the ideal code is typically noted as some number of least significant bits (LSB). An example INL plot can be seen below. Although it represents some amount of absolute error, INL will typically only account for about 0 to 3 codes in most high speed ADCs that are 16 bits or less in resolution. It will not be a principal contributor to the actual converter error rate. 1.0 0.8 0.6 Input Referred Noise— Ideal 14-Bit ADC 1 0.2 0 –0.2 –0.4 –0.6 –0.8 –1.0 Codes Figure 4. An example measured INL curve across all ADC codes shows about ±1 LSB or ±1 code of maximum error compared to an ideal sample, essentially negligible to an ADC conversion error. 0.1 Test Method 0.01 0.001 0.0001 0.00001 N – 11 N – 10 N–9 N–8 N–7 N–6 N–5 N–4 N–3 N–2 N–1 N N+1 N+2 N+3 N+4 N+5 N+6 N+7 N+8 N+9 N + 10 N + 11 0.000001 ADC Output Code 10 INL (LSB) Input referred noise is one inherent component of ADC conversion imperfection that is inclusive of the thermal noise seen at the ADC input. It is often quantified using a histogram of digital output codes, given an open or floating ADC input. This is typically noted and shown within an ADC datasheet. The plots below show an example of the magnitude of this noise, which in this case is [N] ± 11. 10 ~±1 LSB 0.4 Noise Components Histogram Count (Log—Millions) Input Referred Noise— Actual 14-Bit ADC 1 0.1 0.01 0.001 0.0001 0.00001 0.000001 N – 11 N – 10 N–9 N–8 N–7 N–6 N–5 N–4 N–3 N–2 N–1 N N+1 N+2 N+3 N+4 N+5 N+6 N+7 N+8 N+9 N + 10 N + 11 2 Histogram Count (Log—Millions) ADC Output Code Figure 3. With an open or floating input, an ideal ADC will sample a single midscale offset code as shown in the histogram on the left. An actual ADC will have input referred noise that should exhibit a Gaussian shape curved histogram in log scale on the right. A test method for long-term CER detection can use a very low ADC input frequency relative to the clock rate. The slope of the sine wave can be approximated to be roughly a straight line between any adjacent two sample points. Analogously, a frequency input that is slightly higher than the sample rate will alias as a low frequency. For this case, there is a predictable ideal solution whereby each adjacent sample can be within ±1 code from the previous sample. The input signal frequency and the encode sample clock frequency need to be locked in a predictable phase alignment. If this phase is not held constant, then the alignment will walk out of phase and the measured data will not be useful. Thus, in order to calculate the ideal conversion, sample(N + 1) – sample(N) should be a code difference in magnitude of no more than 1. Sources of small predictable conversion errors inherent in all ADCs include integral nonlinearity, input noise, clock jitter, and quantization noise. All of these noise contributors can be added cumulatively to obtain a worst-case limit whereby, if exceeded, an error would be considered from two adjacent conversion samples. A 16-bit ADC will have 24 or 16× the number of output codes as that of a 12-bit converter. Therefore, this expanded resolution will have an impact on the number of codes used for a limit to test the conversion error rate. All else being equal, a 16-bit ADC will have a limit that is 16× wider than that of a 12-bit ADC. An internal built-in-self-test (BIST) within the ADC can be used to establish an error threshold based on thermal noise, clock jitter, and other system nonlinearity. Particular samples can be flagged within the ADC core when an error limit is exceeded with its corresponding sample count and error magnitude. One of the main benefits of using an internal BIST is that it isolates the error origin within the ADC core itself, which excludes those errors due to received bit errors exclusively in the digital data transmission output. Once the error threshold is established, then a full system measurement involving the ADC plus the link plus the FPGA or ASIC is performed to determine the complete component CER. 10 10–1 10–2 10–3 10–4 10–5 10–6 10–7 10–8 10–9 10–10 10–11 10–12 10–13 10–14 10–15 10–16 10–17 ADC Error vs. “X” Sigma of Normal Thermal Noise Distribution 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 Sigma of Normal Thermal Phase Figure 5. The conversion error rate of an ADC vs. its thermal noise is typically only available through transistor level circuit simulations. An example plot for a 12-bit ADC is shown above where a thermal noise sigma of 8 must be tolerated to achieve a CER of 10–15. Let’s examine how we calculate the thermal noise contribution (Brannon, 2003). SNR = 20log(VSIGNAL/VNOISE) VNOISE = VSIGNAL × 10^(–SNR/20) To find the rms noise of an ADC, we must scale the VFULLSCALE: VNOISE = (VFULLSCALE /(2 × √(2) × 10^(–SNR/20) Calculating the thermal noise limit of the AD9625, a 12-bit, 2.6 GSPS ADC designed for a full-scale range (FSR) of 1.1 V, with an SNR of 55 at 2.508 MHz aliased input frequency using the following equations. Thermal noise limit = 8 sigma × VINpp × 10 × (SNR/20)/2√(2) = 3.39 mV ~ ±12 codes. In this case, an 8 sigma distribution of only the thermal noise alone can contribute up to ±12 codes to a 10–15 error limit. This should be tested against the total input referred noise measurement of the ADC. Keep in mind that the input referred noise from a data sheet may not be based on a large enough sample size for 10–15 testing. The input referred noise will encompass all internal noise sources, including thermal noise. In order to define the limit to possibly cover all the sources of the noise, including the test equipment, we use the internal BIST to measure the error magnitude distribution. Using an internal BIST within the AD9625 running at 2.5 GSPS and an aliased AIN frequency of 80 kHz close to the full scale of an ADC under nominal supply and temperature conditions, CER measurements were performed over a period of 20 days. Let’s suppose that all of the ADC processing of an analog voltage to a digital representation is ideal. The digital data still needs to be precisely transmitted and received at the next stage of processing in an FPGA or ASIC downstream in the signal chain. Digital snafus at this stage are typically defined by the term bit errors or a bit error rate. However, comprehensive characterization of the data eye diagram output from an ADC at the end of the PCB trace can be directly measured and compared against the JESD204B receiver mask for a very good understanding of the output quality (Farrelly, Loberg 2013).1 In order to establish a CER of 10–15, one quadrillion samples, within 1 sigma at 2.6 GSPS, we need to run this test continuously for 4.6 days. In order to establish a higher confidence level with a larger sigma, this test needs to be run even longer2. The testing requires a very stable test environment with clean supply sources. Any nonsuppressed glitch on the voltage supply to the converter under test will result in erroneous measurements and the testing will need to restart all over again. An FPGA counter can be used to track the instances where the magnitude difference between two adjacent samples in time exceeds the threshold limit, counting that sample as a conversion error. The counter must keep a cumulative total of errors throughout the duration of the testing. To ensure that the system is working as expected, the magnitude of the error vs. ideal should also be logged in a histogram plot. The time needed for the test will be based upon the sample rate, the desired tested conversion error rate, and the confidence level desired. A CER of <10–15 with a 95% confidence level requires at least 14 days of continuous testing. An estimation of the CER can be done by extrapolating beyond measured values with a lower confidence level (Redd, 2000). Since measuring an ADC’s CER can be a time consuming exercise, you may be wondering if it is possible to extrapolate beyond known measured results. The good news is that yes, this can be done. However, there are always trade-offs in this approach, so caveat lector may be in order. As we continue to make an educated mathematical estimation of what the error rate would be, had we tested for it with near certainty, we approach ever diminishing confidence levels in our estimation.3 For example, it may not be all that useful to know an error rate of 10–18, if we are less than 1% confident in our answer. The error threshold for conversion may sum cumulatively to 4 or 5 least significant bits for any given sample. It may be slightly more or less depending upon the ADC resolution, system performance, and the application’s error rate requirements. When this error band is used to compare against the ideal value, a sample that exceeds this limit will be counted as a conversion error. The error band for an ADC can be tested by adjusting the threshold and monitoring typical performance data. The final test limit used is the root mean squared sum of the imperfections, which is usually dominated by the ADC thermal noise. The tested data histogram of sampled values vs. the ideal resembles that of a Poisson distribution, which is a discrete distribution. The major difference between a Poisson and a binomial distribution is that the Poisson does not have a fixed number of trials. Instead, it uses the fixed interval of time or space in which the number of successes is recorded, which is analogous to the CER test method described. Any recorded sample that is beyond the calculated error limit from ideal is identified as a bona fide code error. Code Histogram Count (Log) Conversion Error Rate Due to Thermal Noise Visit analog.com Calculated Error Limit Absolute Value of ADC Sampled Code vs. Ideal Figure 6. By taking a long-term histogram of ADC samples compared to the ideal output code, we can detect any excursion beyond the calculated limit. The histogram resembles that of a Poisson distribution. Systems Now that we understand the CER for a single converter, we can compute the error rate for an advanced synchronous system of many converters. Many system engineers ask what the cumulative ADC conversion error rate will be within a large complex system that uses a multitude of ADCs. 3 4 Less Than One in a Quadrillion—A Test Method For Measuring ADC Conversion Error Rate Therefore, a secondary consideration for advanced multisignal acquisition systems is to identify the conversion error rate across not one, but an array of converters. This may sound like a daunting task at the onset. Fortunately, after the CER is measured or computed for a single ADC, extrapolating this rate to multiple ADCs is not too terribly difficult. The function then becomes a probability expansion equation, based on the number of converters used in the system. First, we find the probability that a single converter will not exhibit an error. This is only slightly less than 1 by the value of the error rate, (1 – CERSINGLE). Second, this probability is then multiplied by itself for each ADC in the system, (1 – CERSINGLE)#ADCs. Finally, we can find the rate that an error will occur in the system by subtracting this value from 1. We get the following equation: CERMULTIPLE = 1 – (1 – CERSINGLE)#ADCs Let’s consider a system using 99 ADCs with a single ADC CER of 10–15. 1 – CERSINGLE = 0.999999999999999 References Beavers, Ian. “Demystifying the Conversion Error Rate of High Speed ADCs.” EDN, 2014. Brannon, Brad. “Analyzing ADC Noise Impacts on Wireless System Performance.” EE Times, 2003. Farrelly, Frank and Chris Loberg. “Faster JESD204B Standard Presents Verification Challenge.” Electronic Design, 2013. Kester, Walt. “MT-011: Find Those Elusive Sparkle Codes and Metastable States.” Tutorial MT-011, Analog Devices, Inc., 2006. Kester, Walt. “MT-004: The Good, the Bad, and the Ugly Aspects of ADC Input Noise—Is No Noise Good Noise?” Tutorial MT-004, Analog Devices, Inc., October 2005. Redd, Justin. “Calculating Statistical Confidence Levels for Error Probability Estimates.” Lightwave, 2000. Redd, Justin. “Explaining Those BER Testing Mysteries.” Lightwave Online, 2004. CERMULTIPLE = 1 – (0.999999999999999)99 = 9.8999999999995149000000000799095 × 10–14 (~about 10–13) We can see that the CERMULTIPLE value is now nearly 100× greater than the CERSINGLE of 10–15. We can glean from this that essentially the conversion error rate of a system with 99 ADCs scales proportionately to the CER of a single ADC based upon the quantity of ADCs in the system. It is fundamentally higher than that of a single ADC and is limited both by the conversion error rate of a single ADC and the quantity of converters used within the system. Therefore, we can establish that a system composed of many ADCs may significantly impair the overall conversion error rate compared to that a single ADC. Ugalde, Jeffrey and Ian Beavers. “Designing JESD204B Converter Systems for Low BER.” EDN, 2014. Wolaver, Dan H. “Measure Error Rates Quickly and Accurately.” Electronic Design, 1995. Endnotes 1 While not discussed in detail within this article, the quality of the digital data eye at the ADC receiver, and therefore the BER of the digital link, is attributable to many factors including pre-emphasis, PCB material, intersymbol interference, and the trace length. 2 To examine the confidence level of CER testing in more detail, reference (Redd, 2000) and (Beavers, 2014). 3 Extrapolation of known data can be done at the expense of the confidence level. 10–7 ADC CERMULTIPLE vs. # ADCs 10–8 10–9 10–10 CERMULTIPLE 10–11 10–12 About the Authors 10–13 Snehal Prabhu has been a product development engineer in the High Speed Converter Group at Analog Devices since 2012. He holds a master’s degree in electrical engineering from Arizona State University and a B.S in electronics and telecommunications from Goa University, India. 10 –14 10–15 10–16 1 10 100 System ADC Count 1k 10k Figure 7. The CER of a system using multiple converters proportionately scales the single CER by the ADC count. Pinpointing ADC conversion errors can be challenging, but achievable. The first step is to identify what magnitude a conversion error looks like in a system. Then, a set of appropriate bounded error limits needs to be identified that includes the nonlinear benign sources of expected ADC operation. Finally, specific measurement algorithms can achieve most or all of the testing. Extrapolation of the measurements can target beyond the boundaries of the testing for additional approximation. Ian Beavers [Ian.Beavers@analog.com] is a product engineering manager for the Automation Energy and Sensors team at Analog Devices (Greensboro, NC). He has worked for the company since 1999. Ian has over 19 years of experience in the semiconductor industry. Ian earned a bachelor’s degree in electrical engineering from North Carolina State University and an M.B.A. from the University of North Carolina at Greensboro. Online Support Community Engage with the Analog Devices technology experts in our online support community. Ask your tough design questions, browse FAQs, or join a conversation. ez.analog.com Analog Devices, Inc. Worldwide Headquarters Analog Devices, Inc. Europe Headquarters Analog Devices, Inc. Japan Headquarters Analog Devices, Inc. Asia Pacific Headquarters Analog Devices, Inc. One Technology Way P.O. Box 9106 Norwood, MA 02062-9106 U.S.A. Tel: 781.329.4700 (800.262.5643, U.S.A. only) Fax: 781.461.3113 Analog Devices, Inc. Wilhelm-Wagenfeld-Str. 6 80807 Munich Germany Tel: 49.89.76903.0 Fax: 49.89.76903.157 Analog Devices, KK New Pier Takeshiba South Tower Building 1-16-1 Kaigan, Minato-ku, Tokyo, 105-6891 Japan Tel: 813.5402.8200 Fax: 813.5402.1064 Analog Devices 5F, Sandhill Plaza 2290 Zuchongzhi Road Zhangjiang Hi-Tech Park Pudong New District Shanghai, China 201203 Tel: 86.21.2320.8000 Fax: 86.21.2320.8222 ©2016 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners. Ahead of What’s Possible is a trademark of Analog Devices. TA14171-0-3/16 analog.com