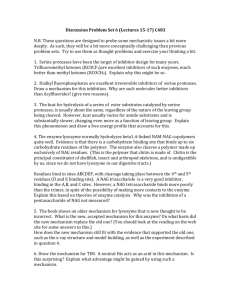

AN ABSTRACT OF THE DISSERTATION OF

advertisement