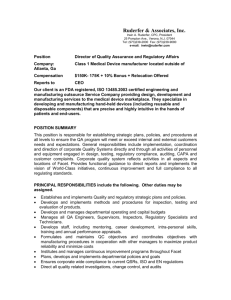

AMER EL-HAGE

advertisement

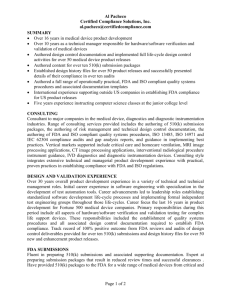

AMER EL-HAGE 2101 Manzanita Ave. Menlo Park, CA 94025 415-314-9267 amer@beestonengineering.com SKILLS /SPECIAL QUALIFICATIONS: Product development of scientific instruments; technical consulting in mechanical design, fluid handling, plastic injection molding, micro-devices, test and qualification and transfer to manufacturing. Has excellent applicable knowledge of FDA, ISO, UL and CE regulations for instrument development. TECHNICAL EXPERTISE: Program Management, Product Development, Quality Engineering, Computer Aided Drafting (Pro/E, SolidWorks), Design Controls, Metrology/Calibration, Process Optimization, Risk Analysis, Failure Mode Effect and Criticality Analysis (FMECA), Failure Analysis (FA), Root Cause Analysis, Environmental and Reliability Studies, Statistical Process Control (SPC), Development Lifecycle/ Quality Programs, GMP/ISO 9000/ISO13485/CE/ FDA Quality System Regulation (QSR), Medical Device Directive (MDD) WORK EXPERIENCE: 2004 -Present 2000-2004 1991- 2000 1987- 1991 Beeston Engineering Consulting, Menlo Park, CA Principal Consultant Assignments for medical device, bio-analytical, and life science fields to develop instruments, product designs, and the manufacturing quality strategies for release to manufacturing by: Assisting with development and implementation of product design systems and validation programs. Developing procedures related to instrument design, verification and transfer to manufacturing. Conducting assessments of programs to determine compliance with ISO, CE and FDA regulations. Molecular Devices Corp, Sunnyvale, CA Director, Engineering Responsible for the transfer of technology and release to manufacturing of MDC first automated High Throughput Electrophysiology product. Developed and lead the product release project for a High Efficiency image detector system. Coordinated concepts and design reviews, verification, reliability and life testing of new products Developed and released an updated MDC Product Development Process for ISO Design Control. LJL BioSystems, Sunnyvale, CA Senior Director, Engineering Programs Responsible for contract product project development which includes conceptualization, specifications, budget, schedule and resource allocation Identified and hired technical resources needed to build the R&D department Developed the verification and validation plans and directed the outsourcing of technical projects, product reliability, and UL compliance Directed project managers in qualified methods to develop achievable project development plans Supervised and coordinated the intellectual property (IP) portfolio of the company for three years Co-authored the company product development process to conform with ISO 9001 quality system, and FDA/GMP compliance Varian Associates, Walnut Creek, CA Sr. Mechanical Engineer Principal mechanical engineer for an automated micro-sampler to Varian main Gas Chromatography (GC) instrument product. Product is still in production. Designed and tested new detector and high temperature injectors’ for lower cost systems, and analyzed new generation high temperature ovens. Developed a novel electronic MEMS gas flow controller to replace manual flow controllers. Amer El-Hage 1982 - 1987 Developed and applied accelerated concurrent processes for development of engineering projects. Beckman Instruments, Palo Alto, CA Product Engineer Mechanical engineer and fluid dispensing designer on two bimolecular instruments; a new DNA synthesizer, and a Vapor Phase Protein Sequencer with a micro-autosampler. Engineered Beckman Instrument first Laboratory robot "Biomek 1000" Photometric reader, micro dispense tool, and developed consumables for product extension. Responsible for successful transfer to manufacturing of a High Performance Liquid Chromatography (HPLC) system Executed a cost reduction program which resulted in more than $750K of documented savings through new designs, second sources, and innovative assembly methods. TRAINING (selected): 2004 2001 2001 2000 2000 1999 1997 1994 1993 1992 1991 1990 1989 SolidWorks basic user’s training - GEI technology Project Management - Cadence Management Corporation Micro-fluidics & micro-fabrication technologies – Small Talk conference course Advanced management training - American Management Association CCD Devices and Fluorescence Spectroscopy – SPIE course Micro-machined sensors basics - (Sensors Expo Course) Software Validation (QSR) - SPIE Managing Multiple Projects - (Skillpath Seminars) Pro/E user’s training - Parametric Engineering Design control / FDA compliance - Stockwell Design for Manufacturing (DFM) – IBM Industrial Consulting Basic Project Management - American Management Association (AMA) Statistical process Control (SPC) PROFESSIONAL AFFILIATIONS: Chair - American Society of Mechanical Engineers (ASME), Santa Clara Valley Section; Co-Chair Microplate Standards Development Group Society of Bimolecular Sciences (SBS); Society of Optical Engineering (SPIE); Member of SMEI Microfludics MEMS International Standards Task force, and Association of Laboratory Association (ALA); Laboratory Robotics Interest Group (LRIG) -Bay area PUBLICATIONS: El-Hage, Chinn, “Vapor Surface Modification of Consumables used in Drug discovery” – Presentation at ImTECH, Conference South San Francisco, May 2005 El-Hage, et al. “Development of a Second Generation Low Volume Microplate Matched to the Confocal Optical Properties of Analyst AD and HT “– Presentation SBS Conference Vancouver, September 2000 El-Hage, et al. “An Automation-Friendly, "Industrial Strength" Solution to Fluorescence, Fluorescence Polarization, TRF Detection Needs in HTS”- Lab Automation 1998 El-Hage, et al. “Rapid Instrument Development”, IVD magazine full article, August 1996 - - PATENTS: 13 US patents, and 2 international LANGUAGES: English, Arabic, sufficient French, and Spanish. EDUCATION: M.Sc. Mechanical Engineering, University of California, Berkeley, California, 1980 B.Sc. Agricultural Engineering, Ohio State University, Columbus, Ohio, 1978 Page 2 of 2