Maria Melissa B. Quemada

advertisement

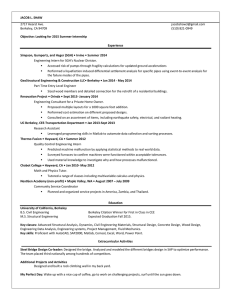

Maria Melissa B. Quemada mbquemada@gmail.com EDUCATION University of California, Berkeley CA B.S. Chemical Engineering Chabot Community College, Hayward CA A.S. Chemistry EXPERIENCE Thermionics Metal Processing, Inc.(TMPI), Hayward, CA Process Engineer/Lab Manager, Jan 2008 – Present Design and develop cleaning processes that will improve performance, lifetime, and integrity of materials used for equipment in different industries Head engineering and facility projects that improve efficiency and reduce operational costs Manage and maintain precious metals recycling program Monitor and control chemistry of different chemical baths Phoenix Biosystem, Inc., Pleasanton, CA Research Intern, May – Sept 2007 Design biosensors that measures glucose response (in vitro) in a continuous flow and single-used systems Characterize biosensors using Cyclic Voltammetry and Chronoamperometry to measure glucose response Optimized preparation and design of biosensor to yield a broader response range and lower sensitivity for glucose response Lawrence Berkeley National Laboratory (LBNL), Berkeley, CA Research Intern, June 2006 – May 2007 Generated coal ash coated with ferric hydroxide (ARUBA-patent pending) for removing arsenic from ground waters in Bangladesh, India and California Investigated the temperature dependence of arsenic removal capacity of new technology Optimized the preparation of media by investigating the role of sodium hydroxide in its process chemistry Tested ARUBA media for arsenic removal capacity using Arsenic Quick TestTM field kit University of California, Santa Barbara, Santa Barbara, CA Research Intern (Internships in Nanosystems Science, Engr., and Tech.), June – Aug 2005 Electrochemically deposited platinum (Pt) through commercially available nafion membrane on carbon cloth using state of the art equipment Fabricated and tested performance of a small-scale fuel cell using experimentally created substrate Characterized the deposited Pt using Cyclic Voltammetry and Scanning Electron Microscope PROJECTS Energy-saving Project Project Lead Project Cost: $9,000 Estimated Savings/year: ~$11,000 in operational cost Worked with PG&E to improve energy efficiency of the plant 1 of 2 Plant Equipment Projects Project Lead Aboytes Bead-blast machine o Total Project Cost: ~$45,000 o Estimated Savings/year: $10,000 in consumables o Acquired an efficient and larger bead-blast machine to improve performance and accommodate larger materials that needed roughening and cleaning CLS-700T/Liquilaz 200 – Liquid particle counter o Total Project Cost: ~$45,000 o Acquired tool that can quantify number of particles in Deionized (DI) water and other corrosive chemicals o Used to monitor and control DI final rinse tanks Process Development/Process Control Lead Engineer Worked with different Silicon Valley companies in developing cleaning processes Maintain process documents and laboratory control charts Collaborate with Quality Manager in controlling and improving quality of product Set-up QA/QC criteria Perform Internal audits Chemical Process Design Class – UC BERKELEY Leader of Team Designed optimization of Poly(lactic) acid (PLA) plant production using simulation, Superpro™ Reduced unit production cost from $5/kg of material produced to $1.59/kg of material produced Supervise and led the group for the 3rd optimization design Currently in the top 25% of class of approximately 20 people COMPUTER SKILLS MS Word, MS Excel, PowerPoint, Superpro™ LANGUAGES English and Tagalog 2 of 2