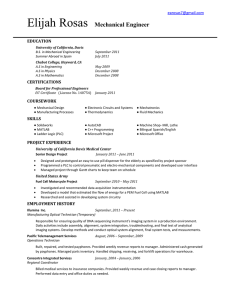

Elijah Rosas Mechanical Engineer EDUCATION

advertisement

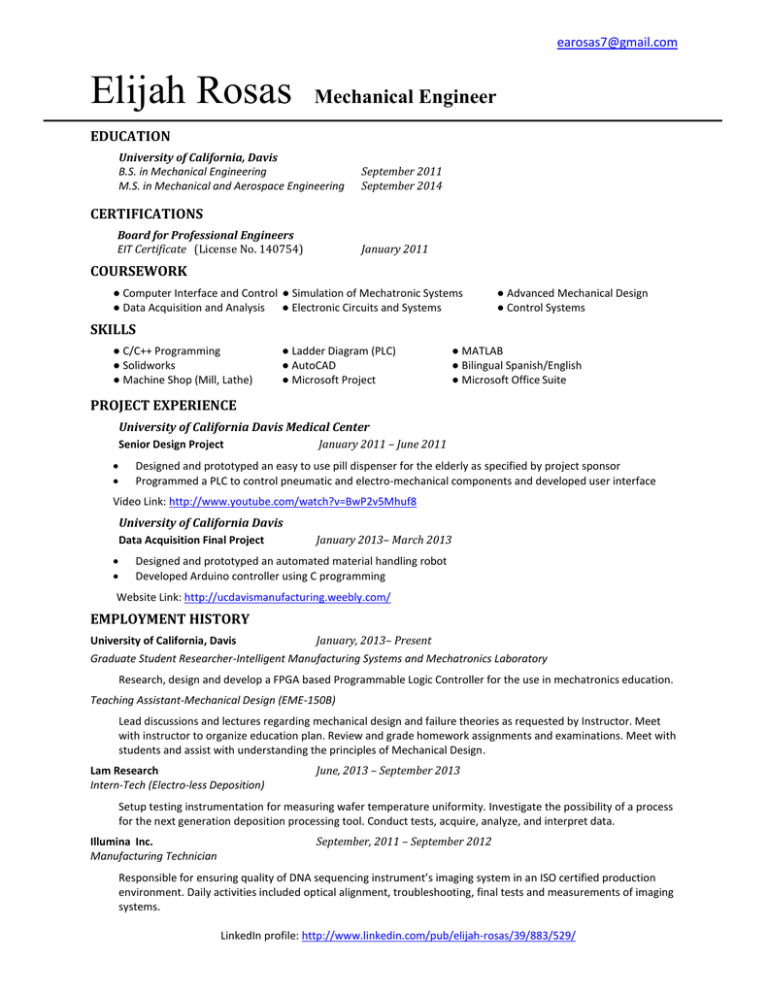

earosas7@gmail.com Elijah Rosas Mechanical Engineer EDUCATION University of California, Davis B.S. in Mechanical Engineering M.S. in Mechanical and Aerospace Engineering September 2011 September 2014 CERTIFICATIONS Board for Professional Engineers EIT Certificate (License No. 140754) January 2011 COURSEWORK ● Computer Interface and Control ● Simulation of Mechatronic Systems ● Data Acquisition and Analysis ● Electronic Circuits and Systems ● Advanced Mechanical Design ● Control Systems SKILLS ● C/C++ Programming ● Solidworks ● Machine Shop (Mill, Lathe) ● Ladder Diagram (PLC) ● AutoCAD ● Microsoft Project ● MATLAB ● Bilingual Spanish/English ● Microsoft Office Suite PROJECT EXPERIENCE University of California Davis Medical Center Senior Design Project January 2011 – June 2011 Designed and prototyped an easy to use pill dispenser for the elderly as specified by project sponsor Programmed a PLC to control pneumatic and electro-mechanical components and developed user interface Video Link: http://www.youtube.com/watch?v=BwP2v5Mhuf8 University of California Davis Data Acquisition Final Project January 2013– March 2013 Designed and prototyped an automated material handling robot Developed Arduino controller using C programming Website Link: http://ucdavismanufacturing.weebly.com/ EMPLOYMENT HISTORY University of California, Davis January, 2013– Present Graduate Student Researcher-Intelligent Manufacturing Systems and Mechatronics Laboratory Research, design and develop a FPGA based Programmable Logic Controller for the use in mechatronics education. Teaching Assistant-Mechanical Design (EME-150B) Lead discussions and lectures regarding mechanical design and failure theories as requested by Instructor. Meet with instructor to organize education plan. Review and grade homework assignments and examinations. Meet with students and assist with understanding the principles of Mechanical Design. Lam Research Intern-Tech (Electro-less Deposition) June, 2013 – September 2013 Setup testing instrumentation for measuring wafer temperature uniformity. Investigate the possibility of a process for the next generation deposition processing tool. Conduct tests, acquire, analyze, and interpret data. Illumina Inc. Manufacturing Technician September, 2011 – September 2012 Responsible for ensuring quality of DNA sequencing instrument’s imaging system in an ISO certified production environment. Daily activities included optical alignment, troubleshooting, final tests and measurements of imaging systems. LinkedIn profile: http://www.linkedin.com/pub/elijah-rosas/39/883/529/