Chabot College March 1993 Replaced Fall 2010

advertisement

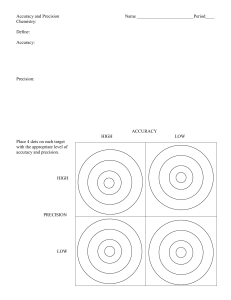

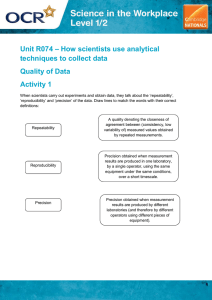

Chabot College March 1993 Replaced Fall 2010 Course Outline for Machine Tool Technology 63A INDIVIDUAL PROJECTS Catalog Description: 63A – Individual Projects (May be repeated 3 times) 2 units Design, development, and fabrication of selected projects for the machine tool technology major to develop special entry level job skills. Corequisite: Any Machine Tool Technology course. 6 hours laboratory. [Typical contact hours: 105] Expected Outcomes for Students: Upon completion of the course, the student should be able to: 1. 2. 3. 4. 5. use precision measuring tools, such as the vernier caliper and height gauge; set up and do basic bench operations, such as filing, sawing, and threading; perform basic drill press, bandsaw, lathe, and vertical milling operations; make precision layouts on the surface plate using precision layout tools; apply basic mathematical formulae for calculating correct speeds, feeds, and data required for precision part layout. Course Content 1. This is a laboratory course only. Students are assigned selected projects to develop special skills required for entry-level jobs in industry. Methods of Presentation: Laboratory projects; demonstrations; visual aids; field trips Methods of Evaluating Student Progress: Quality and quantity of project work completed; ability to use good mechanical judgment; ability to follow instructions; homework assignments; midterm and final examination Textbook(s) (Typical): The textbook(s) will be the same as the books the student uses for his or her regular Machine Tool Technology class. Special Student Materials: Approved safety glasses; scientific calculator with trigonometric functions; padlock with two keys or a combination lock mk mach63A.out 3/93; 9/30/94