Chabot College Fall 2012 – BMW Chassis Dynamics

advertisement

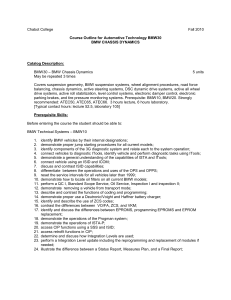

Chabot College Fall 2012 Course Outline for Automotive Technology BMW30 BMW CHASSIS DYNAMICS Catalog Description: 30 – BMW Chassis Dynamics 5 units Covers suspension geometry, BMW suspension systems, wheel alignment procedures, road force balancing, chassis dynamics, active steering systems, DSC dynamic drive systems, active all wheel drive systems, active roll stabilization, level control systems, electronic damper control, electronic parking brakes, and tire pressure monitoring systems. Prerequisite: BMW10, BMW20. Strongly recommend: ATEC 4, ATEC 5. 3 hours lecture, 6 hours laboratory. [Typical contact hours: lecture 52.5, laboratory 105] Prerequisite Skills: Before entering the course the student should be able to: BMW Technical Systems – BMW10 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. identify BMW vehicles by their internal designations; demonstrate proper jump starting procedures for all current models; identify components of the 3G diagnostic system and relate each to the system operation; connect vehicles to diagnostic ITools, identify vehicle and perform diagnostic tasks using ITools; demonstrate a general understanding of the capabilities of ISTA and ITools; connect vehicle using an ISID and ICOM; discuss and contrast ISID capabilities; differentiate between the operations and uses of the OPS and OPPS; reset the service intervals for all vehicles later than 1999; demonstrate how to locate oil filters on all current BMW models; perform a QC I, Standard Scope Service, Oil Service, Inspection I and inspection II; demonstrate removing a vehicle from transport mode; describe and contrast the functions of coding and programming; demonstrate proper use a Deutronic/Voight and Haffner battery charger; identify and describe the use of ZCS codes; contrast the differences between VO/FA, ZCS, and VKM; identify and discuss the differences between EPROMS, programming EPROMS and EPROM replacement; demonstrate the operations of the Progman system; demonstrate the operations of ISTA-P; access CIP functions using a SSS and ISID; access retrofit functions in CIP; determine and discuss how Integration Levels are used; perform a Integration Level update including the reprogramming and replacement of modules if needed; illustrate the difference between a Status Report, Measures Plan, and a Final Report; chart the structure and function of PuMA; interpret how FASTA is used in BMW dealerships; outline and discuss the differences between PuMA and Teile Clearing; demonstrate proper procedure to perform a DEF service; outline and discuss Hybrid safety; outline a repair order and follow procedures in order to properly facilitate warranty claims; demonstrate the ability to use BMW's information systems (SIB, SBT, TIS, PuMA, ETM, EPC); demonstrate and discuss details of the BMW Center network operations including ISID, ISIS, ICOM, printer, SSS, and online update capabilities. Chabot College Course Outline for BMW30, Page 2 Fall 2012 BMW Body Electronics – BMW20 1. distinguish the differences between different types of connectors and identify which tool to use for their repair; 2. demonstrate the ability to diagnose a parasitic draw; 3. perform repair on BMW wiring harnesses and connectors to BMW standards; 4. identify and install the proper Breakout Box and V Cables for the purpose of testing; 5. demonstrate the ability to properly use a relay testing tool; 6. demonstrate a clear ability to break down a Test Plan on ISID; 7. demonstrate proper use of Diagnostic Chart; 8. analyze, isolate, perform the repair, verify the repair and document the 3 Cs for purposes of warranty compensation; 9. diagnose an open circuit; 10. diagnose a high resistance in a circuit; 11. diagnose a failed ground; 12. diagnose a low voltage condition; 13. diagnose a short to ground; 14. compare the differences between EWS systems; 15. demonstrate an understanding of EWS components and locations; 16. diagnose a failed input to the EWS; 17. demonstrate the ability to diagnose a failed key and or FZD Module; 18. demonstrate the ability to activate keys, bar keys and synchronize the EWS module; 19. demonstrate a clear ability to differentiate between AC and DC signals; 20. demonstrate a clear ability to differentiate between Inductive, Magnetoresistive, Angle Pulse and Hall Effect sensors; 21. demonstrate a clear ability to interpret a Potentiometers; 22. demonstrate a clear ability to interpret a Transistors; 23. demonstrate the ability display signals on an oscilloscope; 24. demonstrate the ability to charge a battery; 25. demonstrate proper use of Midtronics Tester; 26. recognize a failed battery, the cause, and properly document cases for purposes of warranty claims; 27. diagnose and repair a failed charging system; 28. demonstrate the ability to graph bus signals using the IMIB; 29. interpret the Power Management functions and operation on various BMW models; 30. outline the procedure to monitor sleep mode and closed circuit current monitoring using the IMIB; 31. demonstrate a clear understanding of the I.P.O. principal; 32. demonstrate competent use of a DVOM and an understanding of Ohm's Law; 33. demonstrate the ability to use BMW's information systems (S.I.B, T.R.I, TIS, Puma, ETM, EPC); 34. outline the operation of electrical BUS systems used on BMW Vehicles; 35. collect and interpret oscilloscope patterns on electrical BUS systems; 36. determine BUS communication using an ISID; 37. develop the ability to troubleshoot electrical BUS system. Expected Outcomes for Students: Upon completion of the course the student should be able to: 1. 2. 3. 4. 5. 6. 7. 8. interpret BMW suspension geometry; demonstrate the replacement of a front strut; demonstrate the replacement of a rear shock; demonstrate how to perform a wheel alignment; demonstrate how to dismount and mount runflat tires; demonstrate balancing tires; compare and contrast between RDC and RDW; reinitialize FTM systems on all current vehicles; Chabot College Course Outline for BMW30, Page 3 Fall 2012 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. evaluate and compile a failed FTM system; demonstrate wheel bearing replacement (Press Type); demonstrate removal and replace of an axle shaft; interpret neutral, over and understeer; interpret "Sport" functions of steering; compare and contrast EPS functions on E85 and E89; compare and contrast basic and active steering operations; research and compile initialization procedures on AFS vehicles; compare and contrast DBC, MBC, CBC, DBS, DBC, ASC, ADB, EBV, MSR, MBC, HDC and ICM operation; compare and contrast DSC8+ and DSC X; demonstrate a brake reline; demonstrate how to replace parking brake shoes; demonstrate how to reset ASZE parking brake; demonstrate a brake flush; demonstrate recalibration of a DSC System; interpret a failed wheel speed sensor; compare and contrast longitudinal and vertical dynamics; interpret an xDrive fault; illustrate ARS operation; evaluate and adjust ride height; illustrate VDM operation; interpret an input fault to the ICM; compare and contrast EMF systems (E65,E70,E89); demonstrate EMF cables replacement; demonstrate an EMF run in procedure; demonstrate removal and Installation of a driveshaft on an E70; demonstrate removal and installation of an xDrive transfer case; interpret and outline the I.P.O. principal; demonstrate the use of BMW's information systems (S.I.B, T.R.I, TIS, Puma, ETM, EPC). Course Content, Lecture: 1. Suspension geometry a. alignment angles 2. BMW suspension systems a. front axle b. rear axle 3. Wheel alignment procedures 4. Road force balancing a. tire balancing b. run out c. radial force variation d. vibration diagnosis 5. Chassis dynamics a. vehicle dynamics b. chassis forces 6. Active steering a. variable ratio b. vehicle interfaces c. diagnosis 7. Electric power steering a. configurations b. vehicle interfaces c. diagnosis 8. Dynamic driving systems a. dynamic stability control (DSC) systems Chabot College Course Outline for BMW30, Page 4 Fall 2012 b. vehicle interfaces 9. DSC with xDrive 10. Dynamic drive a. dynamic drive ARS systems b. vehicle interfaces 11. Level control systems a. air suspension systems 12. Damper control systems a. electronic damper control systems – continuous (EDC-K) 13. EMF parking brake 14. Tire pressure monitoring systems Course Content, Laboratory: Laboratory Content mirrors the subjects listed in “Corse Content, Lecture” with the inclusion of skill based exercises. Examples: 1. Practical lab projects for developing skills necessary to diagnose suspension systems using alignment angles to ensure proper vehicle handling and control. 2. Lab projects covering skills to evaluate BMW suspension systems. 3. Demonstrate the capability to perform 4 wheel alignments on BMW vehicles. Methods of Presentation: 1. 2. 3. 4. 5. Lecture Demonstration Guest speakers Laboratory Field trips Assignments and Methods of Evaluating Student Progress: 1. Typical Assignments a. Read section on DSC in BMW Training Manual before class session b. Identify major assignment principles and discuss application to vehicles operation c. practice and demonstrate operation of DSC 2. Methods of Evaluating Student Progress a. Homework assignment b. Class participation c. Quizzes d. Performance of laboratory task list and projects e. Midterm examination f. Final examination Textbook(s) (Typical): BMW Chassis Dynamics, Updated continually by BMW to latest version Special Student Materials: 1. Safety Glasses 2. Shop/safety clothing KWS09282011