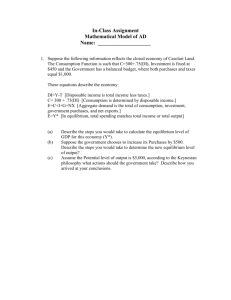

‘Using disposable single-use systems for high volume manufacturing’ Gerald Kierans

advertisement

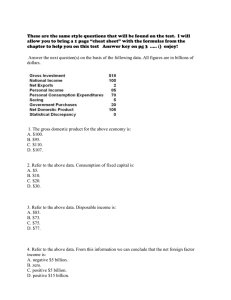

‘Using disposable single-use systems for high volume manufacturing’ Gerald Kierans Director, Technical Services - Pfizer Global Supply May 22th, 2014 Disposable Single Use Technologies Overview Established as part of bio-manufacturing tool-kit Promises high productivity, multi-product production in clean, contained systems Demands of high volume cGMP manufacturing require further industrialisation of the available technologies. 1 Content Pfizer Global Supply, Grange Castle – Background The Evolution of Disposable Technology for Biotech The Challenges – ‘the Opportunities’ Understand your Supply Chain What could the Future look like ? 2 High Volume Biopharmaceutical Manufacturing Pfizer Global Supply Grange Castle Site, Dublin Over 900 FTEs ‘3 Factories in 1’ : Mammalian Cell Culture Conjugation/Pegylation Parenterals Filling 3 The Commercial Products We Supply Commercial cGMP Context Large, existing highly automated stainless steel plant Typically using disposable single use systems to debottleneck facility, rather than as the fundamental design principle. Disposable single use technology are a very significant cost => implications for fully disposable strategy? Our context High Volume Manufacture = Zero Tolerance for Defects 5 Content Pfizer Global Supply, Grange Castle – Background The Evolution of Disposable Technology for Biotech The Challenges – ‘the Opportunities’ Understand your Supply Chain What could the Future look like ? 6 Single Use Technology Evolution Traditional plasma fractionation & vaccine manufacturing Recombinant human insulin Recombinant DNA technology SINGLE-USE DISPOSABLE TECH EVOLUTION 1970s Approval of leading biotech products Commercial biotech start-ups 1980s Cell culture capacity crunch 1990s CMOs adopt disposables Pandemic virus response drives rapid capacity solutions 2000s Tube welding Early adopters of hospital bag technology for solution storage Cell culture titre increases Proliferation of major new biotech facilities around globe 2010s Aseptic connectors Initial ‘Plastic Factory’ concepts γ - capsule filters Vendors produce ‘standard’ disposable System designs Single-use sensor technology 77 Single Use Technology Benefits Contained, Dedicated Fluid Paths Lower Capex Single Use Technologies Proposed Benefits Increased Plant Production Time Pre-Sterilised Components Reduced Engineering Complexity Near ‘Off-the-Shelf’ designs 8 Disposables - Success & Future Potential Plastic Plants have moved from Paper to Reality Semi-auto system designs Enabling ‘disruptive’ facility designs 9 Content Pfizer Global Supply, Grange Castle – Background The Evolution of Disposable Technology for Biotech The Challenges – ‘the Opportunities’ Understand your Supply Chain What could the Future look like ? 10 Issues to be addressed ….. Polymer assemblies can be fragile and potentially leak / break Leak from aseptic sampler Tie-wrap connection between different tubing types - leak only evident under back-pressure 11 Issues to be addressed ….. Many engineering Polymers are weakened by Gamma-irradiation eg. PTFE Ideally looking for Cheap Accurate Clean Robust Gamma Irradiatable Instrumentation at multiple scales Limited availability of robust, gamma-irradiatable sensor technology Some components coming from Medical Device technology Generally do a lot of testing off-line – more intervention Limited scalability of current instrumentation Difficult to design standardised SU systems if key components do not exist yet. One strategy – do as much as possible off-line or tube-weld on what you want (Not an optimal strategy for high volume manufacturing) 12 Issues to be addressed ….. What is an acceptable level of particles ? Swab of internal particles from disposable components Polycarbonate alien particle found in a product sample bag cGMP requirement for zero contaminants Various different particles identified – some are constituent materials of the assembly Sometimes they are not ! Regular disconnect between vendor particle specification and GMP quality requirement. 13 Issues to be addressed ….. Highly complex assemblies Outsourced aseptic and material control Typically custom designed Manually assembled Infrequent, low volume batch runs 14 Issues to be addressed ….. Polymer assemblies can be fragile and potentially leak / break Limited availability of robust, gamma-irradiatable sensor technology What is the acceptable level of particles ? Low volume, manual production runs Outsourced aseptic and material control ‘What about L&E ?’ …and cost ! 15 Content Pfizer Global Supply, Grange Castle – Background The Evolution of Disposable Technology for Biotech The Challenges – ‘the Opportunities’ Understand your Supply Chain What could the Future look like ? 16 Impact of Material Variability – A Cautionary Tale ... Cell culture performance issues for a number of years impacting certain cell lines at a number of companies using a specific type of disposable bioreactor. ‘What about L&E ?’ Industry initiative through BPOG to address issue. A leachate has been identified which is breakdown product of a common polymer antioxidant. Additional cell culture issues have been observed using other single use materials; however the mechanism is not necessarily understood. Bis(2,4-di-tert-butylphenyl) phosphate (CAS 21150-89-0) bDtBPP – ‘the Two-Arm Bandit’ Identification of a Leachable Compound Detrimental to Cell Growth in Single-Use Bioprocess Containers - PDA Journal of Pharmaceutical Science and Technology March/April 2013 vol. 67 no. 2 123-134 Matthew Hammond, Heather Nunn, Gary Rogers, Hans Lee, Anatolia-Liliana Marghitoiu, Lourdes Perez, Yasser Nashed-Samuel, Carl Anderson, Michael Vandiver and Sally Kline Strategy for Selecting Disposable Bags for Cell Culture Media Applications Based on a Root-Cause Investigation Joseph Wood, Ekta Mahajan, Masaru Shiratori `Biotechnology Progress DOI 10.1002/btpr.1802 17 Know Your Supply Chain Antioxidants Slip Agents Lubricants Thermal & Mechanical Stress Thermal & Mechanical Stress Polymer Resin Compounding Film Extrusion Potential Mechanical Stress thru Handling Bag Manufacture Components Connectology Tubing Capsule Filters Aseptic Connectors Sensors Sub-assemblies Tube Weld Tie-Wrap Mouldings Hose-barbs Assembly Irradiation Stress Gamma Irradiation Potential Mechanical Stress thru Handling Delivery & Storage Potential to impact Quality at multiple nodes across a long supply chain 18 Content Pfizer Global Supply, Grange Castle – Background The Evolution of Disposable Technology for Biotech The Challenges – ‘the Opportunities’ Understand your Supply Chain What could the Future look like ? 19 Disposable System Engineering Huge investment by Vendors and Pharma Engineering functions How reliable and proven are these solutions for high volume manufacturing? Requires upfront investment off the ‘critical path’ 20 Plastic Mab Factory of the Future Monoclonals continue to be the largest pipeline of prospective biological drug candidates for the future. Generally standardised production concepts – similar unit operations across industry ‘Higher cell culture titres enabling 100kgs production per year in 100Ls bioreactors’ Disposable rocking or STR reactors Harvest by Depth Filter Virus Removal Filtration by Capsules Capture by Chromatography Formulation by UFDF Polishing by Flow-thru Membrane Absorber Sterile Capsule Filtration & Biobag Storage ‘Continuous production paradigms may enable a further step change in COGs’ Goal : New capital plants could avoid SIP/CIP/scale complexity 21 The Takeaway Single use disposable technology promises additional potential to shape the future of bio-manufacturing. We all need to step up in terms of our application knowledge. Vendors End-Users We need to share our challenges and probably the solutions. 22 Discussion