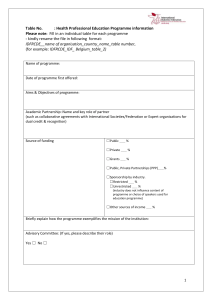

Risk-Based Commissioning & Qualification Benchmarking Educational Track #1

advertisement

Risk-Based Commissioning & Qualification Benchmarking Educational Track #1 Agenda Part 1 (8:30 – 10:00) • ISPE Baseline® Guide Volume 5: Commissioning & Qualification vs. ASTM E2500 – Mr. Robert Chew • Overview of C&Q approaches – Abbott, Lilly, Pfizer Break – Vendor areas open Part 2 (10:30 – Noon) • Panel Q&A Wrap-up (10:00 – 10:30) ISPE Baseline Guide Volume 5: Commissioning and Qualification, vs. ASTM E2500 Robert E. Chew, PE President, Commissioning Agents, Inc. My Background in Subject • Official trainer for ISPE Baseline Commissioning and Qualification Guide • Member of team that wrote ASTM E2500 Key Points to Compare • • • • • Terminology Qualification practices Focusing the effort Roles and responsibilities Managing changes during the project Terminology • C&Q Baseline guide • Commissioning • Qualification • ASTM E2500 • Verification Qualification Practices • C&Q Baseline Guide • “To meet the demands of the regulators” • ASTM E2500 • Not mentioned Focusing the Effort • C&Q Baseline Guide • Impact assessments • Direct impact systems and critical components • V-model • ASTM E2500 • Risk assessment -> critical aspects Roles and Responsibilities • C&Q Baseline Guide • Quality pre and post approves protocols; quality control role • ASTM E2500 • Quality involved in process requirements, risk assessments, critical aspects, and acceptance and release • Subject matter experts used throughout Managing Change • C&Q Baseline Guide • QA pre-approved change control implemented at start of IQ/OQ • ASTM E2500 • QA pre-approved change control implemented at start of manufacture of product for distribution Common Elements • • • • • • Good engineering practices Planning Requirements definition Engineering design reviews Project change management Documented inspections and testing Risk-Based Commissioning & Qualification Approach Abbott Laboratories Global Pharmaceutical Operations Steve Connelly Overview Where Abbott Is Today C&Q Approach Commissioning & Qualification Activities How We Manage Cost Lessons Learned Where Abbott is Today Risk Based Maturity Model* *Adapted from 2007 ISPE Tampa Conference Presentation Commissioning & Qualification Approach C&Q Approach: • Application of ISPE Baseline® Guide Volume 5: Commissioning & Qualification (last 2 years) • Little to no implementation of ASTM E2500-07* • Level 3 (Risk-based Maturity Model) Implementation: • Corporate policies support Science & Quality Risk Management and includes Good Engineering Practice (GEP) reference • Training ( RBA, GEP, ECM. Commissioning, Risk Assessments) • Tools and Templates • Discretion of the Validation Review Board (VRB) *ASTM E2500-07: A Standard Guide for the Specification, Design, & Verification of Pharmaceutical and Biopharmaceutical Manufacturing Systems and Equipment START User Requirements Direct Impact Systems VCR Submitted w/Assessment Report and Rationale Functional Design Evaluate Risk/ Impact Assessment Does system directly impact product quality? Yes No Science & Quality Risk Management Qualification Process Flow Design Qualification Does system support a direct impact system? No Impact Systems Commissioning Plan Indirect Impact Systems Yes VCR Submitted w/Assessment Report and Rationale No VCR Submitted w/Assessment Report and Rationale Commissioning Plan Pre-Qualification Engineering tests / FAT as applicable Engineering tests / FAT as applicable Process Complete VCR Closed Yes Installation Qualification No System have operational functions? Yes Operational Qualification Support of CPPs tested in PV? No Performance Qualification Good Engineering Practices Formal acknowledgement of GEP in corporate policy Divisional GEP guideline consists of minimum requirements Additional divisional guidelines are in development for lifecycle management – Calibration – Maintenance – Engineering change management Training to aid site support (implementation) Requirements Based On Impact Category Three methods: –ISPE-Style System* Impact Assessment Questionnaire –Risk Assessment with any standard method (FMEA, HAZOP, etc.) –Technical Evaluation by SMEs •Documented and VRB approved •Determining impact to identifying critical elements Quality Risk Control –Risk Assessment (i.e. FMEA, etc) used to enable: •Qualification focus on critical functions and/or components •Leverage limited commissioning testing (FAT/SAT) and •Eliminate some redundant activities (i.e. alarms, etc) *System = equipment, facility, utility Commissioning When supporting Qualification, Commissioning must include or address: • Engineering Change Management (ECM) – After point commissioning data intended to support Qualification • Testing – Methods described in sufficient detail for repeatability – Documentation confirms critical elements met criteria – Acceptance criteria documented prior to execution – Criteria based on User Requirements – Documentation of observed results Commissioning & Qualification (C&Q) Plans typically contain run rules for project Qualification – Equipment User requirements • Product and Process User Requirement (PURS) • General User Requirements (GURS) Commissioning (in support of qualification) • Test it once (or one set of multiple test repetitions, where appropriate); document it correctly • Primarily installation activities, operational testing leveraged in some instances (VRB discretion);compile, summarize test results for VRB approval Qualification • When approved, commissioning reports complete the IQ/OQ phase of Qualification with no additional “protocol” testing Qualification – Software (APC/HMI/DCS) Categorization (based on product quality impact) • Managing control issues for critical elements • Supplier Assessments for direct impact systems only • VRB discretion with technical advisory from Subject Matter Expert Holistic Approach • Integrated Qualification document (IOQ for equipment/controls; as applicable) • APC specific qualification requirements – Traceability matrix = Design Qualifications (DQ) – Commissioning = Qualification except critical items Qualification – Facilities Indirect Impact Facilities - Commission – Design and construction conforming to GEP – Abbott Engineering Standards Direct Impact Facilities – Commission/Qualify – Meet quality specifications (i.e. Aseptic facility, etc) – Design and construction conforming to GEP – Abbott Engineering Standards Qualification – HVAC Categorization • Interdependent with facility quality attributes – For example: Continuous monitoring for critical environmental aspects; therefore facility and HVAC can be Indirect Impact (HVAC controls would then be qualified) – For example: Temperature, RH, and room pressure differentials typically critical elements which are monitored and recorded continuously, alarming when parameters exceed specifications; VRB discretion as to qualify Qualification – Utilities Impact Categories - Typically critical or non-critical Utility systems typically not big source of Validation Change Request (VCR) sources Only regulatory requirement concern is typically Potable Water feed to purification – Purpose of pretreatment usually to preserve life of purification equipment rather than direct impact of water quality How We Manage Cost… $ In 2007, reviewed C&Q costs for several capital projects to: – Establish a baseline – Compare costs for the “traditional, validate everything” C&Q approach versus the risk-based C&Q approach $ Cost comparisons across projects difficult because – Inconsistent reporting and project scope varies widely $ Drive cost reporting model for capital projects needed to: – Address scope differences, track additional parameters: Number of Qualification Protocols per project Number of Qualified Systems Total Number of Systems – Three parameters documented in C&Q Plan How We Manage Cost… Commissioning & Qualification Cost Tracking Details • Monthly Capital Project Status Reports are used to track costs and progress • There is a wide variation in the tracking systems used by the engineers for the project costs • Most project engineers / project managers use spreadsheets of their own design to track costs How We Manage Cost… Opportunities Identified for Consistent Reporting Engineering/Commissioning/Qualification costs categorized below Activities not linear, categorization to clarify “gray” areas of cost reporting ENGINEERING FEP 1-3 User Requirements Functional Specification (Draft) Preliminary Design Detailed Design Construction Loop Tuning Equipment Installation/Alignment COMMISSIONING Risk Assessment Failure Mode Effect Analysis I/O checkout Calibration Functional Specification (Revisions) Factory Acceptance Testing Startup Trouble Shooting Sequence Testing As-Builts (Non Qualified Systems) QUALIFICATION (CERTIFICATION) Validation Plan Design Qualification Equipment Installation Qualification Equipment Operational Qualification Computer Hardware Installation Qualification Computer Software Installation Qualification Controller Modification Qualification HVAC Installation/Operational Qualification Utility Installation Qualification Process Qualification Validated Drawings Samples/Testing Cleaning/Passivation Inspections Engineering Work Orders / Contracts Defines appropriate cost “bucket” for consistency across projects Lessons Learned Risk-Based C&Q is an iterative process (one tiny step at a time) Corporate & divisional policies in place, tools developed, although success for various sites, concern about corporate & regulatory audits Sites want to maintain autonomy with guidance; common elements, not same approach (i.e. all engineers comply however variations due to specialty) Application: Site readiness tools - identifying opportunities for closing gaps Lessons Learned Listen, Speak, Deliver. Communication is key. Quality may wonder: What if engineering doesn’t do its job?;ensure compliance Engineering may wonder: Quality = police & spell checkers; “right” the first tyme Application: Regular/frequent communication with VRB & project team Lessons Learned Sustainable Paradigm Shift Sites: Implementation, accountability & ownership a must for sustainability Resources: People, time & money, site retaining technical knowledge Application: Training & support implementation as applicable Thank you! • Questions will be addressed during the Panel Q&A session (after break) Eli Lilly & Company Commissioning and Qualification Approach Eli Lilly & Company Approach to Commissioning & Qualification • C&Q Delivery Strategy • C&Q Metrics • C&Q Lessons Learned • Improved C&Q Delivery Strategy Recent GFD C&Q Delivery Strategy ~ Baseline Guide approach (’02 – ‘07) • • • • Developed procedures governing C&Q activities Fully commissioned all assets ~ GEP Reserved qualification for critical aspects of DI systems only Leveraged commissioning documentation to support qualification – commissioning subject to GDPs • Involved Quality at C&Q strategy level • In addition, • Simulation has been used to commission automation aspects • CSV testing has been integrated within C&Q test documents Fundamental C&Q Delivery Strategy ~ for Global Facilities Delivery (GFD) Capital Projects Profile Approve CQMP System Classification DQ/DR Component Classification Planning Design Construction QA Requirements Initial Cals Procurement Loops Construction/ Installation Simulation/ Offline Testing Commissioning Package Project Commissioning IQ OQ PQ Qualification Owner IV FT SAT FAT Startup Approve Systemlevel Plans RV Validation Operations/ Maintenance C&Q Delivery Strategy ~ Results This strategy has resulted in: • Earlier resolution of issues • Opportunity to understand systems • Reduced Qualification time • Reduced Qualification costs • Fewer Qualification comments/discrepancies C&Q Metrics • Schedule Metrics • Cost Metrics • Discrepancy Metrics Typical C&Q Schedule Metrics ~ Durations • 10 months from facility mechanical completion to OQ completion • Total Commissioning duration: 24 mos. (172 days/system) • Total IQ/OQ duration: 6 months • FT duration/system: 42 days • IQ duration/system: 11 days • OQ duration/system: 17 days • Average # of days from MC to OQ completion: 227 days Note: Metrics for new powder filling facility consisting of approx. 40 systems C&Q Cost Metrics ~ Historical view C&Q Cost as % TIC 40% 25% 20% 10% 10% 5% 5% No C&Q prog 1998- 2001 Part. C&Q prog 2001-2003 Full C&Q prog 2002- pres. 3% GOAL C&Q Budget Metrics ~ capital projects completed in ‘07 Total Installed Cost $319MM $186MM $180MM $145MM $14.5MM $11.6MM $7.2MM C&Q Cost (% TIC) 6.0% 1.5% (comm. only) 5.5% 5.7% (incl. non-CQ activities) 4.3% 4.3% 2.2% Average: 4.7% (C&Q projects only) C&Q delivery strategy has resulted in a step change in C&Q savings!! Lilly C&Q Work Breakdown Structure Lilly budgets/tracks C&Q expenses via 4 primary WBS categories: • • • • Planning & Design Commissioning Qualification Administration New C&Q Cost Data spec recently approved to provide guidance Planning & Design - Subcategory • • • • • • • • • • • • C&Q plans and strategy Initial schedule development Estimating System classification Component classification System C&Q plans Vendor assessments User requirements Design review, spec review, drawing review reviews/tag list Engineering requirements Design Qualification Traceability Matrices Commissioning - Subcategory • • • • • • • • • FAT development FAT execution Receipt Verification development Receipt Verification execution Installation Verification development Installation Verification execution SAT development SAT execution Construction turnover packages • • • • • • • • Start-up protocol development Start-up protocol execution Functional testing development Functional testing execution Commissioning packages C&Q plan summary reports FAT travel Supporting documents Qualification - Subcategory • • • • • • IQ development IQ execution OQ development OQ execution PQ development PQ execution Administration - Subcategory • • • • • • Training Project management C&Q resource travel Administrative assistance Audits CSV support Typical C&Q Budget Metrics ~ Cost Breakdown (%) Procedures 2% OQ 2% IQ 2% CCs 2% Training 1% Impact Assessment SAT RI 1% FAT 1% 1% 1% Doc Revs 1% Scheduling 0% Doc mgmt 12% DQ/EDR 3% Project mgmt 11% URs 3% CSV Support 3% FT 11% Construction QA 4% IV 7% Planning 5% SU 9% Note: Only includes cost data for C&Q contractor Travel 10% RV 10% C&Q Discrepancy Metrics ~ Philosophy C&Q delivery strategy based on risk mitigation approach • DR/DQ reduced risk during Construction/Build, Commissioning, Qualification • Construction quality assurance activities reduced Commissioning risks • Simulation reduced risk during Commissioning (Startup, SAT, FT) • Commissioning (RV, IV, FAT, SAT, FT) reduced risk during subsequent Commissioning activities and Qualification • As risk decreased, the number of discrepancies also decreased resulted in cleaner qualification documentation and better schedule adherence during qualification Typical C&Q Discrepancy Metrics # of Discrepancies 700 600 500 400 300 200 100 0 RV SIM FAT IV SU SAT IL IC FT CP IQ OQ C&Q Activities 1230 discrepancies resulting from Construction QA activities 2800 discrepancies during commissioning 130 discrepancies during qualification PQ CQP US Pr ot Aut oc om ol De atio ve n/S lo pm oftw M ar en iss e t Er in g/ r M In ec ors co I rre nco han ic ct r Do rec al cu t D a m en ta Tr ac tatio kin n g To Ta ol M g od Pr el ging ot oc De Num ol c b M Exe ision er iss cu in tio Too g M nE l od rr Un el N ors u av a i mb la bl er e Pr da oc Sy ed Vo ta st em ur id Ch ed M al/P at er lan ang ial D e of evi s a Co t ns ions t M isc ruct io el n la ne ou De s sig n # of Discrepancies Typical C&Q Discrepancy Metrics ~ Categories 900 800 700 600 500 400 300 200 100 0 Accepted Corrective Action C&Q Lessons Learned 1. Properly define User Requirements Testable, verifiable, applicable Not too prescriptive, no design details, no guesses Include C&Q engineers in review/approval process 2. Clearly define data and documentation requirements 3. Change management Don’t implement formal change control too soon Don’t confuse change control with version control Ensure commissioning change process is well understood Ensure construction changes are communicated to team Ensure automation changes are reflected in design docs Current GFD C&Q Delivery Strategy ~ Enhanced Baseline Guide approach • Conducted several six sigma initiatives to improve C&Q processes • Developed additional procedures and best practices pertaining to C&Q • • • • GDP SOP Change Management SOP Transfer of Care, Custody and Control SOP Discrepancy Management Best Practice • Developed new specifications governing the following • • • Vendor data and documentation FAT/SAT C&Q cost data • Defined new project information management role • Implementing new requirements definition process based on systems engineering principles • Implementing formal Construction QA program (last 2 years) Current GFD C&Q Delivery Strategy ~ Enhanced Baseline Guide approach (cont.) • Developed Automation Lifecycle Management engineering standard to accommodate integration of CSV and C&Q resulting in: • • • Elimination of duplicate requirements, design reviews, testing Elimination of “all or nothing” approach to software testing Allowance for risk-based delivery strategies Leverage offline or simulation testing to meet requirements • Assessing risk in areas beyond product quality to streamline C&Q delivery • • • Vendor risk Technology risk Automation strategy • Leveraging vendor testing to support commissioning vs. just using as contractual gate/risk mitigation The resulting C&Q delivery strategy will hopefully be realized as another step change in C&Q savings! Potential C&Q costs as low as 3% of TIC Questions? Q&A Risk Based Commissioning & Qualification Benchmarking Presented by: Nick Andreopoulos Senior Manager/Team leader Pfizer Global Engineering Peapack, NJ Chris Beltz Senior Manager/Team Leader Pfizer Quality Operations Kalamazoo, MI Agenda • • • • Basis of C&Q Practices C&Q Program Management Approach C&Q Cost Management Key Lessons Current C&Q Practices • Primarily based on C&Q Baseline® Guide 5 • Certain sites have streamlined C&Q process • C&Q “Lite” version for small projects and minor equipment changes • Leveraging of Commissioning tests into IOQ • Applying some ASTM concepts – Focusing IOQ on risk to product quality/patient safety • Functional Level Impact Assessment - Replacing Component Level Impact Assessment • Currently developing and piloting full ASTM E2500 based Verification approach at targeted sites C&Q Program Management • C&Q supported jointly by Quality, Engineering and Automation/IT • Quality requirements defined in Corporate Quality Standards • C&Q Approach defined in Global Practices • Sites develop their own procedures and validation master plans based on the global documents C&Q Cost Management • C&Q costs that are associated with equipment qualification are included in Project Capital budgets. Process Validation and Cleaning Validation are not included in project budgets • C&Q cost managed by Project team Key C&Q Lessons Learned • Upfront involvement by key stakeholders in the Assessment steps to define the appropriate scope for qualification • IOQ scope should be focused on critical aspects/functions. All other testing is GEP • Testing documents should be based on SME execution and leveraged, where possible, from vendors. Level of documentation should be commensurate with risk to product quality/patient safety. • Roles/Responsibilities need to be clearly defined at the outset of projects Risk-Based Commissioning & Qualification Benchmarking Educational Track #1 Part 2 Agenda Part 1 (8:30 – 10:00) • ISPE Baseline® Guide Volume 5: Commissioning & Qualification vs. ASTM E2500 – Mr. Robert Chew • Overview of C&Q approaches – Abbott, Lilly, Pfizer Break – Vendor areas open Part 2 (10:30 – Noon) • Panel Q&A Wrap-up (10:00 – 10:30) Thank You!! • • • • • • • • • • Robert Chew, Commissioning Agents Matt Warhover, Commissioning Agents Steve Connelly, Abbott Laboratories Dave Dolgin, Abbott Laboratories Scott Hamm, Eli Lilly Rick Gunyon, Eli Lilly Nick Andreopoulos, Pfizer Chris Beltz, Pfizer Great Lakes Chapter Board and Directors Ron Dunn, GLC Manager