Welcome Sustainability at Roche Palo Alto 2007

Welcome

Sustainability at Roche Palo Alto

2007

What is Sustainability

• “Development must meet the needs of the present without compromising the needs of future generations” (Roche Corp. Policy, UN).

• The industrial business model must transition from a focus on profits only to the “Triple Bottom

Line”; financial effectiveness, environmental responsibility, and social activism.

• “leave the world better than you found it, take no more than you need, try not to harm life or the environment, make amends if you do."

Palo Alto Green Operations

Focus Areas

• Energy Conservation

• Natural Resource Conservation

• Recycling and Resource Reuse

• Daily Operations Impact Minimization

• Green Engineering and Construction

• Employee Growth and Health

• Community Support and Outreach

Energy Conservation

• Gas and electricity reductions of +40% over the past 5 years with an annual reduction target of 3% minimum.

• A Formal Site Energy Management Team headed by Jerry

Meek, Manager of Utilities has been assembled. The Team sets goals, prioritizes projects, provides technical support, and monitors progress. The Team is responsible for ensuring that energy conservation is pursued aggressively.

• Recent highlights include replacing 10,000 light fixtures and ballasts with energy conserving types, new high energy efficient chillers resulting in a 60% reduction in electricity, VAV fume hood controllers across site, site wide variable flow controls for Heating and Chilled Water, and 90+% efficient condensing boilers for HVAC loads.

• The site has received over $4M in rebates and grants for energy management and conservation projects since 2001.

Natural Resource Conservation

• 60% reduction in irrigation water use through the use of drought tolerant landscaping

• All accent paints are recycled.

• 30 electric vehicles for site Maintenance fleet.

• Use of recirculation cooling systems versus oncethru cooling to drain.

• Minimal use of new laboratory and office furniture, with a very high re-use rate of over 30% average for all projects on site.

• Leading Purchaser of “Green Power” (Wind) in the

City of Palo Alto.

Recycling and Resource Reuse

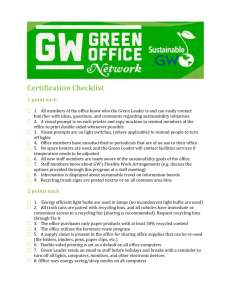

• Site Goal : 85% of all recyclables will be recycled.

We need to drive towards 100%. Goal for 2007 to improve rate to 90%.

• Current Recycle Success = 540 Metric Tons

• Roche managed on-site construction waste recycling center includes: concrete, sheetrock, metals, ceiling tiles, plastics, and wood. Site requirement is 90% of all construction waste to recycling.

• “Re-Usables”: furniture, laboratory casework, carpeting, construction materials.

• Each year at least one new item is added to the recycle program (v-belts- 2005, composting of kitchen waste, research plastics, and restroom paper towels - 2006).

Recycling Categories

• Office paper, paper towels, magazines, and cardboard

• Glass, research and domestic

• Plastic: pipette boxes, plastic bags, shipping waste, and research disposables

• Styrofoam

• Metals

• Drywall and ceiling tiles

• Concrete and asphalt

• Wood

• Landscape waste

• Toner cartridges, computers, and monitors

• Fluorescent tubes

• Specialties: V-belts, vermiculite, cafeteria green waste composting, laboratory research equipment

Re-Usables

• Roche Palo Alto focuses on the re-use of building and office materials.

• Internal inventory maintained for stand-alone office furniture and modular components.

• External sources used for all appropriate office, laboratory, and facility equipment use

• Our philosophy is that existing is better than new. ( Sources: CraigsList, E-Bay, etc)

Green Engineering and

Construction

• Facility design to focus on Green technologies and design concepts, including LEED recognized methods. Site recently received LEED certification for the new Chemical Storage

Facility, a first for Roche.

• All Roche Palo Alto facility projects are completed as fully

Green projects regardless of certification goals.

• Standardization of Green Building materials to be used on all projects.

• Construction to focus on waste management and minimization with a target goal of 90% to recycling versus landfill for all construction projects. Site preservation also key.

• All projects focused on the principles of sustainability. Our goal is to ensure that the projects we build represent the most environmentally compatible, natural resource efficient, and cost effective.

Daily Operations Impact Minimization

• Sustainable material selection and purchasing

- Review all chemicals and materials used on the site for environmental impact minimization. (Engineering and

Chemistry)

- Work with Purchasing to identify vendors and products that support our Green goals.

Current target areas: copy paper (30% recycled), restroom paper, cafeteria products, and cleaning chemicals .

• Sustainable work processes.

- Review methods, techniques, SOP’s, and other general operational practices to identify opportunities for changes that reduce environmental impact and improve community conditions .

Sustainable Purchasing

Sustainable Purchasing in action:

• Implemented a “just in time” stocking program for key solvents eliminating over purchasing and eventual disposal of out dated chemicals.

• Currently working with several vendors to implement changes to packaging methods to reduce environmental impact.

• Partnering with research and engineering to standardize on products to ensure consistent sustainable purchasing.

• Sustainable Purchasing policy.

Employee Growth and

Development

• Safety

• Training and development focus.

• Formal Development

Plans for all employees

Community Support and

Outreach

Community starts with our employees.

• Sustainability awareness programs for all employees.

- Site wide presentations, award programs (

WRAP, ECOmpetitiion), safety coordinator program, displays.

• Sustainability Home Start-Up kit.

• Home waste management support program.

• Sustainability Fairs

• Green Goals.

Community Support and

Outreach

Reaching out to our neighbors:

• Supporters of numerous local organizations committed to improving our community: RAFT, Canopy, BABEC, The Tech

Museum, Breath California, SVLG, iiSME,local schools.

• Target populations: Alzheimer, Hepatitis C, Transplant, AIDS

• Environmental Clean-up days.

• Rebuilding together events.

• Annual winter coat drive.

• Implementing a monthly volunteer program for 2007.

• Palo Alto Community Star award.

Our Corporate Goals

• Reduce our energy consumption by 10% from 2005 to 2010.

• Improve the Ecobalance in points per employee by 10 % in 2015.

- Our site is evaluated for use of resources, generation of waste and output of emissions. RPA’s different types of emissions, waste and resources are weighted by defined factors according to their negative impact on nature and an ecobalance rating is calculated .

What’s Next

• Cogeneration plant to improve electrical energy production efficiency.

• PV installation.

• Native landscaping education garden.

• Continued push to integrate sustainability throughout the site.

• Celebration of success.

This is

t h e i r