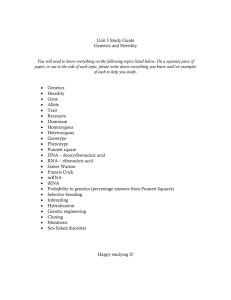

SEATTLE GENETICS TOUR + MIXER

advertisement

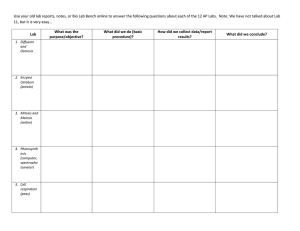

SEATTLE GENETICS TOUR + MIXER WELCOME 4:00 – 4:15 p.m. Registration + Networking 4:15 – 4:30 p.m. Opening Remarks 4:30 – 5:30 p.m. Seattle Genetics Building Tours 5:30 – 6:30 p.m. Networking Mixer + ISPE Announcements APPETIZERS + DRINKS WILL BE PROVIDED AFTER THE TOUR. SEATTLE GENETICS PROJECT TEAM OWNER Seattle Genetics, Inc. SYSTEMS PCS ARCHITECT PSF Mechanical Stock & Associates Auburn Mechanical STRUCTURAL DESIGN DESIGN-BUILD MECHANICAL + PLBG RODI CONTRACTOR Sparling GLY Construction Nelson Electric ELECTRICAL DESIGN LIGHTING DESIGN + ELECTRICAL INSTALLATION The Greenbusch Group COMMISSIONING AGENT S E AT T L E G E N E T I C S H I S TO RY is a biotechnology company focused on developing Company founded in 1998 and commercializing empowered antibody-based First building mixed use lab and office 2001 Second building dedicated to office 2008 Third building mixed use lab and office 2011 Total square foot 196,000 therapies for the treatment of cancer. We are leading the field in developing antibody-drug conjugates (ADCs), a technology designed to harness the targeting ability of antibodies to deliver cell-killing agents directly to cancer cells. ADCETRIS® was approved by the FDA in 2011 and Health Canada in 2013 for two indications. PROJECT APPROACH PHASED DELIVERY PHASE 1 CORPORATE OFFICE TI PHASE 2 LABORATORY CONSTRUCTION PHASE 3 LABORATORY + LARGE MEETING SPACE CONSTRUCTION 45,000 SF Duration: May 23, 2011 – September 26, 2011 [~5 Months] 23,000 SF Duration: July 23, 2012 – March 5, 2013 [~8 Months] 15,000 SF Duration: March 15, 2013 – October 10, 2013 [~7 Months] PHASED DELIVERY TOUR AREAS LEVEL 1 LEVEL 2 SUCCESS STORY PRE-PLANNING APPROACH Master Plan Pre-planning Early Preconstruction with City of Bothell Leverage Multiple Permit Packages Clarify Validation Requirements/Needs Equipment Procurement Strategies Pull Planning 3D Model Collaboration + Prefabrication Lean Principals ZONED WORK PLAN | PHASE 2 SUCCESS STORY LESSONS LEARNED Lab Equipment Procurement [Sterilizers] Mechanical Equipment Coordination + Procurement HazMat Prefab Building [Early Procurement] Phased Permit Strategies with Coordinated Procurement Schedule Ensure VMP is Developed During Preconstruction QUESTIONS? Se at tle genetics | ph ase 2 logistic s Construction Access from East Lot (job trailer staging) NO Construction Access ***Phase 2 Work Area*** 21'-1" GWB GWB (through taping, then finish sub# 5) Safety Perimeter Finish Sub #3 8'-11" ***PPE Beyond this Point*** ***Lay Down Area*** 8'-7" ***NORTH Loading Dock*** 10'-0" 21'-1" (through framing, then "just-in-time" deliveries) Finish Sub #4 WEST Corridor Access 12'-0" GLY GLY PSF PSF (through rough-in, then finish Sub #1) Nelson Nelson (through rough-in, then finish Sub #2) Limited Work/Access to this area NO WORK - NO ACCESS in this area General Notes: 1. NO TABACCO USE on-site 2. Parking is in designated construction parking zones only. 3. Site access is through the man doors at the Northend of the buildings. 4. Visitors must check-in at the GLY Office 5. Coordinate deliveries 48 hours in advance with GLY. Deliveries should go directly to the building Loading Dock - DO NOT check-in at the building reception desk. SOUTH Staging Area and LOAD/UNLOAD EAST Corridor Access ***SOUTH Loading Dock*** Seattle Genetics Storage ~4400 sf Seattle Genetics - Phase 2 Logistics Plan_REV. 0 GLY Sketch dated 06-14-12 21717 30th Dr. SE, Bothell WA Se at tle genetics | e x terior logistic s Con ) rking (19 ction Pa Constru stru ctio nP arkin g (1 Construction Fence AD NLO 0) *** Area AD/U H LO ORT ***N GLY Park ing ape (9) a Are dsc Lan OW ***N General Notes: 1. NO TABBACO USE on-site 2. Parking is in designated construction parking zones only. 3. Site access is through the man doors at the Northend of the buildings. 4. Visitors must check-in at the GLY Office 5. Coordinate deliveries 48 hours in advance with GLY. Deliveries should go directly to the building Loading Dock - DO NOT check-in at the building reception desk. Construction Trailers MAIN CONSTRUCTION ENTRANCE ape ng dsc Lan agi r St Ko OR NO Construction Access through East Doors low this verf nO ctio on stru Con a Are Pedestrian "Safety Path" to Building 1 ) (15 sid a Are tag 1" ing 1 27'- *** ing uild ape dsc Lan Construction Overflow (8) I-405 eB f th eo Bothell-Everett Highway ***Location of Boiler Enclosure/HazMat Enclosure Work*** XS NNE CO AD NLO a*** Are D/U A g LO ) tagin low " 32'-0 HS OUT ***S C verf nO ctio tru ons (10 Se at tle genetics | ph ase 2 zones Se at tle genetics | ph ase 1 PH ASE Facts 5 Months 45,000 SF $115/SF 27 RFIs | 16 Confirming Designed to LEED Certification Standards Corporate Offices High Density File Storage Campus IT Hub New Elevator, Feature Stair, Main Lobby, Entry Canopy Building 3 – Level 2 Demo/Structural Upgrade Included Look-Ahead Phase 2 Work Building 3 – Level 1 New BMS System Se at tle geneti cs | ph ase 2 PH ASE Facts 8 Months | 23,000 SF $76/SF Rooftop Platform + MEP $274/SF Lab Construction 30 RFIs | 22 Confirming 3 Miles Pipe | 312 Plbg Fixtures 16 Tons Ductwork 80 Miles Electrical + Communication Wiring 5.5 Miles Conduit 21 Fume Hoods 19 Bio-Safety Cabinets 500 Gall Validated RODI System 1,700 LF 50mm DI Piping 84 Pre-Fab Spool Pieces + 1,312 Shop Welds Building 3 – Level 1 13 Qualified Labs 4,600 LF Lab Piping 900 LF Underground Waste + Vent Plumbing New 450KW Genset Se at tle geneti cs | phase 3 PH ASE Facts 7 Months 9,000 SF | $200/SF Laboratory 5,000 SF | $176/SF Meeting Space/Laboratory 30 RFIs | 18 Confirming New Rooftop Mechanical Platform 1,000 LF Lab Piping 3.5 Tons Ductwork 37 Miles Electrical + Communication Wiring Building 3 – Level 1 Working Adjacent/Below Phase 2 Labs + Corporate Offices S E AT T L E G E N E T I C S Think. Plan. Build. 200 112th Avenue NE, Suite 300 Bellevue, WA 98004-5878 PO Box 6728 Bellevue, WA 98008-0728 p: 425.451.8877 f: 425.453.5680 w: www.gly.com S E AT T L E G E N E T I C S T O U R OCTOBER 24, 2013 PROJECT OVERVIEW — ­ PHASING IN A MASTER PLAN + LEAN PROCESS Owner/Developer Seattle Genetics Architect Stock + Associates, Inc. PROJECT OBJECTIVE Provide appropriate lab and office resources while simultaneously creating a better working environment for staff and lowering overall costs. General Contractor GLY Construction, Inc. Partners – Design-Build Structural Design: PCS Electrical Design: Sparling MP Design-Build: PSF Mechanical RODI: Auburn Mechanical Electrical Installation: Nelson Electric Commissioning Agent: The Greenbusch Group PROJECT GOALS Use phased plan + Lean process to develop design that aligns with business operations LEAN EXPEDITES EFFICIENCY. The corridor MEP rack systems were fabricated Early in the design process, the team man hours in the corridor, installing piping and used 3D modeling to identify areas of conduit to the racks. in sections and trucked to the site on casters, rolled into place, lifted to their final elevation and bolted to the wall. This process eliminated hundreds of congestion in the lab work spaces and Underground drainage pipe was fabricated in minimize them. Modeling coordinated sections, trucked to site and installed the same the systems in these areas at a Collaborate with design team to implement modeling to support prefabrication through a shared 3D Model [BIM] that is reviewed + refined as design evolves level of detail that allowed for offsite Focus on modularity, flexibility, sustainability, lower energy consumption and install with maximum efficiency. day. This strategy minimized the need for lay down areas and open trench time that would conflict prefabrication. Then Lean processes with installation of overhead utilities systems via helped us plan, build, expedite delivery overhead lifts. Our multi-faceted approach allowed PROJECT APPROACH Nine phases of sequenced construction of the Master Plan helped Seattle Genetics grow. Now on the fourth consecutive project, GLY just completed 23,000 square Surface Mounted Raceway at the lab benches was unrestricted flow of labor and materials pre-wired and trimmed-out prior to arriving onsite. through the corridor and into the labs, As soon as it was delivered, it was attached to the while overhead MEP systems were wall, thus eliminating congestion at the lab benches feet of validated development and research laboratory space, and nearly 81,000 square feet being installed in the corridor. where other trades were trimming-out the plumbing and electrical systems. of renovated office and large meeting space, and complex mechanical, electrical, plumbing and fireproofing installations. Seattle Genetics’ new research lab spaces were on a fast track to support work on their growing cancer drug development pipeline. The complex work took careful planning with a project team of trusted partners. It’s all about flow + timing was crucial. Stock & Associates Validated = Qualified. The aggressive permitting and multi-zone plus GLY partnered with subcontractors in a series of Lean Pull Planning schedule aligned with our Quality Control approach. Throughout Seattle Genetics, architect Stock & Associates and Design-Build subcontractors PSF Mechanical, sessions to coordinate sequencing and scope durations into a Phasing the lab build-out, GLY supported documentation for 11 qualified lab Nelson Electric and Auburn Mechanical. The team developed a strong collaborative approach to Plan that maximized schedule efficiency. Laboratories were designed spaces and worked directly with Seattle Genetics’ Facility Compliance challenging requirements, that began with Stock completing their design in Revit, which became around a corridor with all gases and utilities installed in overhead team and their third party validation agent to ensure a timely, efficient the foundation for the 3D MEP coordination. rack systems that fed directly into the lab spaces and down to the lab transition into newly qualified and validated lab spaces – so research benches. The most efficient approach was to figure out how to install the teams could get underway as soon as possible. Strong collaboration makes it work. Throughout all phases, GLY worked closely with With the designers working hand-in-hand with the contractor and subcontractors through actual construction, decisions were made and issues resolved quickly in Phase 2 and Phase 3. MEP systems in the corridors while concurrently building out lab spaces. Together, the team accomplished a lab build-out that included 20 adjustable-height Bio-Safety The highly accurate 3D software model and lean prefabrication strategy cabinets and 24 fume hoods, supported by all new mechanical and electrical systems, new emergency provided the solution. This approach jump-started the MEP process, generator, and a validated RODI pure water generation system and loop that fed the lab areas. eliminated redundancies, assured accuracy, accelerated schedule and BOTTOM LINE | DESIGN, SYSTEMS AND INSTALLATIONS CAME TOGETHER SMOOTHLY, MET END-USER PHASED START-UP AND OCCUPANCY OF THE NEW LAB SPACES. 05.23 Start Demo/ Structural Upgrades MAY 2011 06.13 GMP Executed 07.01 Start Finishes 09.26 Certificate of Occupancy JUN 2011 JUL 2011 SEATTLE GENETICS TOUR | OCTOBER 24, 2013 AUG 2011 SEP 2011 07.23 Demo/ Structural Upgrades 07.24 CLEAN BUILD: Initiate Level 1 JUL 2012 08.01 Coordination + Procurement Long-lead Casework + Equipment Coordinate Logistics with Validation 10.04 Needs CLEAN 08.22 BUILD: 07.30 90% CD Initiate Start Model Level 2 Demo/ Complete Structural 08.27 Upgrades Install Plumbing in Labs AUG 2012 SEP 2012 11.29 CLEAN BUILD: Initiate Level 3 10.05-10 Start Lab + Corridor MEPF Rough-in 10.15 100% CD Set Issued 10.31 GMP Established 11.13 RODI Rough-in Begin MEP Install Verifications Checks OCT 2012 11.17 Set Rooftop Equipment NOV 2012 12.17 Rooftop Equipment Start-up 12.18 Lab Equipment + Casework Install 12.27 Begin Lab MEP Trim-out DEC 2012 JAN 2013 01.28 Start Commissioning MEP + Lab Equipment 02.04 SeaGen Begins Early Equipment Validation Work in Labs FEB 2013 03.01 Lab Commissioning 100% Complete 03.05 Certificate of Occupancy MAR 2013 APR 2013 2013 PHASE 3 KEY PROJECT DATES 2012 PHASE 2 2011 PHASE 1 created efficiencies in timing, installation and cost control. 03.15 Begin Demo/ Structural Upgrades 03.29 Begin Under Slab Plumbing MAR 2013 APR 2013 04.17 Prep + Fireproof Structure 05.14 Start MEPF Rough-in 06.01 Begin MEP Install Verification Checks Prior to Wall + Ceiling Cover 07.13 Set Rooftop Equipment 06.17 Start Finishes MAY 2013 JUN 2013 08.12 Install Lab Equipment + Casework Start-up Rooftop Equipment 09.13 RODI Validated Loop Tie-in 08.19 Begin Lab MEP Trim-out 10.07 Commissioning 100% Complete 10.10 Lab Certificate of Occupancy 08.26 Begin Lab Commissioning JUL 2013 AUG 2013 SEP 2013 OCT 2013 NOV 2013