TOWN OF FLOWER MOUND ORDINANCE NO. ___________

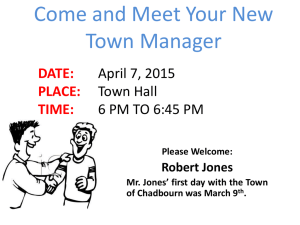

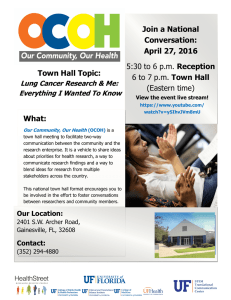

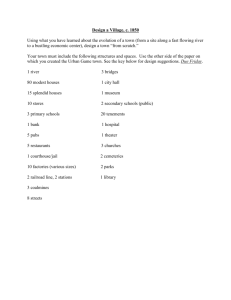

advertisement