Document 11495641

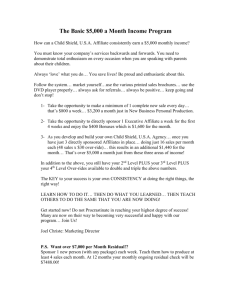

advertisement