Chabot College Academic Services Program Review Report

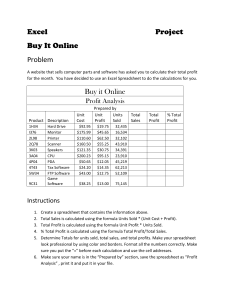

advertisement

Chabot College Academic Services Program Review Report 2016 -2017 Year in the Cycle: Year Three Program: Machine Tool Technology Submitted on Contact: Ashley Long Mike Absher FINAL 9/24/15 Table of Contents __X_ Year 3 Section 1: What Have We Accomplished? Section 2: What’s Next? Required Appendices: A: Budget History B1: Course Learning Outcomes Assessment Schedule B2: “Closing the Loop” Assessment Reflections C: Program Learning Outcomes D: A Few Questions E: New and Ongoing Initiatives and Projects F1A: New Faculty Requests F1B: Reassign Time Requests F2A: Classified Staffing Requests F2B: Student Assistant Requests F3: FTEF Requests F4: Academic Learning Support Requests F5: Supplies Requests F6: Services/Contracts and Conference/Travel Requests F7: Technology and Other Equipment Requests F8: Facilities YEAR THREE Resource Request Spreadsheet Directions: In addition to completing the narrative portion of program review, add all your requests to a single Resource Request Spreadsheet: • Follow the link to the spreadsheet provided in Appendix F1A, save the spreadsheet where you can continue to access it and add requested resources from each appendix to it as appropriate. Once completed, submit to your Dean/Area Manager with this finalized Program Review Narrative. • Requests should be made for augmented/ additional resources (more than what you are already receiving). If you have questions about what constitutes an “additional/augmented” request, please talk with your administrator who can tell you what maintenance resources you are already receiving. • Prioritize your requests using the criteria on the spreadsheet. Your Administrator will compile a master spreadsheet and prioritize for his or her entire area. d. Submit resource requests on time so administrators can include requests in their prioritization and discuss with their area at November division meetings. 1. What Have We Accomplished? Complete Appendices A (Budget History), B1, C (PLO's), and D (A few questions) prior to writing your narrative. You should also review your most recent success, equity, course sequence, and enrollment data at http://www.chabotcollege.edu/ProgramReview/Data2015.asp. Limit your narrative to two pages. In year one, you established goals and action plans for program improvement. This section asks you to reflect on the progress you have made toward those goals. This analysis will be used to assess progress toward achievement of our Strategic Plan and to inform future budget decisions. In your narrative of two or less pages, address the following questions: • What program improvement goals did you establish? The Machine program has established a number of priorities for areas of improvement. The primary goal of the machining program was to increase the number of students gaining employment or advancing in their current employment. The machining program focus is also to continually improve productivity, safety, and efficiency of the student’s tangible learning environment in the laboratory this is partly achieve through replacing old equipment, adding state of the art equipment, and purchasing new technologies. Finally the machining program focused efforts to increase its adjunct faculty and advisory committee with additional members that have a vested interest in the machining program to start the process of revising its curriculum to keep the program relevant to the latest industrial information, processes and innovations while adhering to college policy. • Did you achieve the goals you established for the three years? Specifically describe your progress on goals you set for student learning, program learning, equity, and Strategic Plan achievement. The Machine Tool Technology program, through the use of Measure B bond funds, has an updated manual machining facility in building 1400 an a new Numerical Control facility in building 1600 has been built. All malfunctioning equipment has been repaired or replaced and updated technologies have been added to the manual shop. The creation of a numerical control machining laboratory in building 1600 along with the general renovation of the manual machine shop in building 1400 has freed up space and allowed for the positioning of equipment to provide a safe and efficiently functioning manual lab for the Machine Tech students. The construction of a numerical control machining lab in building 1600 has brought our machining program up to date with the latest technologies used in the local area businesses. All the new equipment has been integrated into the curriculum and students are learning the operation, programming, and setups required to create parts and projects on each piece of the new equipment. The Machine program offers instruction in commonly used CAD/CAM (Computer Aided Design / Computer Aided Machining) and Solids Modeling software. The equipment and the software are the same equipment and software a student will see in the work place making them more employable. The Machine Tool Program would not be able to provide its services and course offerings without vital program funding. During this past program cycle, the Machine Tool Program has received 100% of its funding from the Perkins fund. This fund was established for the technological advancement of the program, instead; out of necessity due to zero funding support from the general fund, the Perkins fund has supplied the funding needed to purchase the consumables required by the machine students. As consumables such as end mills, taps, drills, cutters, metal, and equipment accessories have increased, the Machine Tool program budget has also increased. Lack of funding would directly affect all machine students in all courses. Every machine class offered requires students to learn vital skillsets that directly require the use of consumables in order to teach the course. If funding was to be reduced, the success of the student learning outcomes would decline, and students would not receive the opportunity to learn and practice these skillsets. The Machine Tool faculty are all very proud that our students are being sought after and hired by shops and manufacturing facilities all over the western United States. We not only have many students hired locally but students have found good jobs as far south as San Diego, as far north as Seattle Washington, and eastward to Phoenix Arizona. Employers tell us they are very pleased with our students and their skill sets which causes them to return and hire more students. • What best practices have you developed? Those could include pedagogical methods, strategies to address Basic Skills needs of our students, methods of working within your discipline, and more. The program is a stellar example of one of the college’s missions to prepare students for employment and to provide education for updating skills that provide improved employment potential in today’s world market. Students in today’s program are exposed to current industry tools, equipment, and manufacturing processes providing the necessary critical thinking skills to be successful as a worker in the industry today. Due to Measure B Bond funding our facilities mirror local manufacturing facilities and prepares students for real world experiences and working on the same equipment and software they will see in the local industry. That investment has improved our enrollments and increased our job placements. The increased use of Blackboard, creating video instruction for projects and machine operation, detailed procedure sheets for all machine functions and operations, and making these all available to students in pdf form. • Are these best practices replicable in other disciplines or areas? Yes. • What were your greatest challenges? We need to continue to keep up with industry practices and technologies. We have a five axis machine tool and need to upgrade our CAD/CAM systems to five axis capability. Continue to update our program to more closely match what is being done in the local industry, like adding a "hole popper" to our wire EDM curriculum to more closely match industry practices. Both the manual and numerical control labs still need work to organize and better utilize the space and equipment. We need to continue to update our curriculum and software to more closely match the changing needs of the machining industry. • Were there institutional barriers to success? Lack of a lab technician to maintain and repair equipment which would free the faculty to work on pedagogy. Inconsistent supply funding which hinders planning and student work. The loss of the pcard system also means that purchases take a long time to complete which inhibits students from designing and creating their own projects. This affects student motivation and accomplishment. The procedure for software and hardware purchases are a major problem. It is very difficult to get some critically needed purchases done. • Cite relevant data in your narrative (e.g., efficiency, persistence, success, FT/PT faculty ratios, CLO/PLO assessment results, external accreditation demands, etc.). B. What’s Next? This section may serve as the foundation for your next Program Review cycle, and will inform the development of future strategic initiatives for the college. In your narrative of one page or less, address the following questions. Please complete Appendices E (New and Ongoing Initiatives and Projects) and F1-8 (Resources Requested) to support your narrative. • What goals do you have for future program improvement? Continue to update our equipment and SOFTWARE. It is critical to maintain our software to what is used in the industry today. Students MUST be efficient with the software used by the local industries. We must obtain more secured sustainable source of funding for the Machining Program. Forge stronger ties with local industry leaders. Update our curriculum. Foster articulation between the welding program and local High schools/ROP programs. Build up our adjunct faculty and prepare for the retirement of our current full time faculty. • What ideas do you have to achieve those goals? Make justifications through the budget committee for the need of sustainable secured sources of funding for the program. Create stronger ties with local industries through direct relationships/partnerships with local industry leaders. Encouraging student employment through these relationships. Foster articulation between the machining program and local High schools/ROP programs by promoting the Machining Program, and evaluation whether a dual student enrollment is possible for credits. • What must change about the institution to enable you to make greater progress in improving student learning and overall student success? Hiring a Lab Technician for the Machine Tool program would allow the faculty to focus more on student learning goals without having to be heavily involved in the day-to-day operations needed to run the program. Making computer hardware and software purchases easier and fewer obstacles to the required purchases. Appendix A: Budget History and Impact Audience: Budget Committee, PRBC, and Administrators Purpose: This analysis describes your history of budget requests from the previous two years and the impacts of funds received and needs that were not met. This history of documented need can both support your narrative in Section A and provide additional information for Budget Committee recommendations. Instructions: Please provide the requested information, and fully explain the impact of the budget decisions. • How has your investment of the budget monies you did receive improved student learning? When you requested the funding, you provided a rationale. In this section, assess if the anticipated positive impacts you projected have, in fact, been realized. The financial needs of this program are satisfied exclusively on the availability of Perkins fund and State initiated funding through Lottery 3, with no financial help originating from the college general fund. The allocation partially satisfied the purchasing of essential machining consumables, accessories and maintenance needed to ensure proper lab activities for the entire machine student body. The yearly expenditure allocation for consumables, worn out equipment, and equipment services is insufficient to properly maintain our program. The price of a single carbide endmill is $78.50 each, the amount we spent to ensure the laboratory accommodation for one of our students was insufficient and has a negative educational effect. In the same time 2013-2014 machine shop operation cost for machine tool related items such as: precision tools, cutters, 3D printing materials, machining raw materials, machining accessories and equipment maintenance have substantially increased thus limiting effects of our purchasing power and adding additional strain to student’s ability to fully accomplice the lab curriculum requirements. More than in any other vocational discipline, student’s skill level can be achieved or improved only through intense lab tasks repeatability supported by appropriate supplies at the time of demand. A “onetime mid-year state supply funding” is a very welcome event but hasn't happened often enough for current and future students to benefit. Budget sufficiency and dependability is one of the essential factors for this program to be able to sustain the proper student skill development. The funding that was received directly impacted/aided in the students learning. In order for students to develop their machining skills, functional machinery needs to be provided. Another necessity for student learning is for the student to advance their skillset through repeating the lab machining and programming tasks, this requires a substantial amount of consumables and supplies. The funding provided for Supplies and Services is linked directly to the progress of student learning outcomes. Technology and Equipment was used to purchase equipment specifically for lab safety. The remaining funding received for staffing (Student Assistant) went into the safety of the students. The Student Aid assisted with the lab safety and security of the students. • What has been the impact of not receiving some of your requested funding? How has student learning been impacted, or safety compromised, or enrollment or retention negatively impacted? The program already runs with funds under the requested amount. This has a direct impact on student’s performance. The successes of these machining courses are strictly tied to lab performance. The lack of supplies and materials limits the students ability for lab work and refine their skills in the machining trade. The attainment of expected skills is directly dependent on consistent and adequate funding. Inadequate program support will severely handicap student’s learning objectives an skills which will make them less prepared for the job market. The lack of proper funding will directly negatively impact each students learning experience and limit their academic growth and job readiness. Appendix B1: Student Learning Outcomes Assessment Reporting Schedule • Course-Level Student Learning Outcomes & Assessment Reporting (CLO-Closing the Loop). • Check One of the Following: • X No CLO-CTL forms were completed during this PR year. No Appendix B2 needs to be submitted with this Year’s Program Review. Note: All courses must be assessed once at least once every three years. • Yes, CLO-CTL were completed for one or more courses during the current Year’s Program Review. Complete Appendix B2 (CLO-CTL Form) for each course assessed this year and include in this Program Review. • Calendar Instructions: List all courses considered in this program review and indicate which year each course Closing The Loop form was submitted in Program Review by marking submitted in the correct column. Appendix B2: “Closing the Loop” Course-Level Assessment Reflections. Form Instructions: • Complete a separate Appendix B2 form for each Course-Level assessment reported in this Program Review. These courses should be listed in Appendix B1: Student Learning Outcomes Assessment Reporting Schedule. • Part I: CLO Data Reporting. For each CLO, obtain Class Achievement data in aggregate for all sections assessed in eLumen. • Part II: CLO Reflections. Based on student success reported in Part I, reflect on the individual CLO. • Part III: Course Reflection. In reviewing all the CLOs and your findings, reflect on the course as a whole. Part I: Course-Level Outcomes – Data Results If more CLOs are listed for the course, add another row to the table. * Defined Target Scores: What scores in eLumen from your students would indicate success for this CLO? (Example: 75% of the class scored either 3 or 4) **Actual scores: What is the actual percent of students that meet defined target based on the eLumen data collected in this assessment cycle? Part II: Course- level Outcome Reflections • Course-Level Outcome (CLO) 1: • How do your current scores match with your above target for student success in this course level outcome? 100% of the class was able to complete this task which matches our expectations. • Reflection: Based on the data gathered, and considering your teaching experiences and your discussions with other faculty, what reflections and insights do you have? Course provided adequate preparation and experience on this area of measure. Students show entry level knowledge and experience that will benefit them in industry. This confirms that the cognitive and practical learning experiences are providing adequate opportunity for students to develop necessary capabilities. Continue with current delivery methods and try to increase applied learning experiences • Course-Level Outcome (CLO) 2: • How do your current scores match with your above target for student success in this course level outcome? 92.3% of the class was able to complete this task which is below our expectations. • Reflection: Based on the data gathered, and considering your teaching experiences and your discussions with other faculty, what reflections and insights do you have? Insufficient preparation and experience were provided for those students with no prior ence with edge finders and the edge finding process. experi- C. Course-Level Outcome (CLO) 3: • How do your current scores match with your above target for student success in this course level outcome? 100% of the class was able to complete this task which matches our expectations. • Reflection: Based on the data gathered, and considering your teaching experiences and your discussions with other faculty, what reflections and insights do you have? Course provided adequate preparation and experience on this area of measure. Students show entry level knowledge and experience that will benefit them in industry. This confirms that the cognitive and practical learning experiences are providing adequate opportunity for students to develop necessary capabilities. Continue with current delivery methods and try to increase applied learning experiences Part III: Course Reflections and Future Plans • What changes were made to your course based on the previous assessment cycle, the prior Closing the Loop reflections and other faculty discussions? More use of video instruction and comprehensive instruction and procedure sheets. • Based on the current assessment and reflections, what course-level and programmatic strengths have the assessment reflections revealed? What actions has your discipline determined might be taken as a result of your reflections, discussions, and insights? Overall the program and the courses that comprise it have adequately prepared graduates to meet industry expectations for entry level employment. Our equipment is a good sampling of the equipment found in the local industry. However we are always updating and improving the curriculum to meet the changing machining technologies and our own methods of instruction. • What is the nature of the planned actions (please check all that apply)? • Curricular - x • Pedagogical - x • Resource based • Change to CLO or rubric • Change to assessment methods • Other:_________________________________________________________________ Appendix C: Program Learning Outcomes Considering your feedback, findings, and/or information that has arisen from the course level discussions, please reflect on each of your Program Level Outcomes. Program: Machine Tool Technology Certificates and Associate in Science Degrees • PLO #1: Students completing the Chabot Machine Tool Technology AS Degree or Certificate Training will be able to entry level machining tasks using standard hand tools, manual lathes, and manual milling machines. They will be able to inspect their parts and use standard precision measuring instruments. • PLO #2: Students completing the Chabot Machine Tool Technology AS Degree or Certificate Training will have an entry level understanding of G-code programming, CAD/CAM software programming, and numerical controlled vertical milling machine operation. They will be able to perform entry level setup, G-code programming, and machining operations on numerical controlled vertical milling machines. What questions or investigations arose as a result of these reflections or discussions? Feedback from our advisory committee, current employers of our students, and the NTMA has endorsed our student's capabilities and our program. Students that have found jobs report that they were well prepared but would like more hands on time to better refine their skills. What program-level strengths have the assessment reflections revealed? Ongoing equipment acquisitions to maintain industry relevance. Keep up on the maintenance of our machines to keep them in working order to allow as much hands on time as possible. Our courses provide adequate preparation and experience for the local machining industry. Students show entry level knowledge and experience that will benefit them in industry. This confirms that the cognitive and practical learning experiences are providing adequate opportunity for students to develop necessary capabilities. What actions has your discipline determined might be taken to enhance the learning of students completing your program? Program: Machine Tool Technology NC Programmer Certificates and Associate in Science Degrees • PLO #1: Students completing the Chabot Machine Tool Technology NC Programmer AS Degree or NC Programmer Certificate Training will have an entry level understanding of G-code programming, CAD/CAM software programming, numerical controlled vertical milling machine operation, numerical controlled lathe operation, wire electrical discharge machining, and coordinate measuring machine operation. They will be able to perform entry level setup, G-code programming, CAD/CAM programming, and machining operations on numerical controlled vertical milling machines, lathes, five-axis milling machines, wire EDM machines, and manual Coordinate Measuring Machines. • PLO #2: Students completing the Chabot Machine Tool Technology NC Programmer AS Degree or NC Programmer Certificate Training will have a sufficient level of understanding and skills to obtain and flourish in an entry level position in any normal machine shop environment. What questions or investigations arose as a result of these reflections or discussions? Feedback from our advisory committee, current employers of our students, and the NTMA has endorsed our student's capabilities and our program. Students that have found jobs report that they were well prepared but would like more hands on time to better refine their skills. What program-level strengths have the assessment reflections revealed? Overall the program and the courses that comprise it have adequately prepared graduates to meet industry expectations for entry level employment. Our equipment is a good sampling of the equipment found in the local industry. What actions has your discipline determined might be taken to enhance the learning of students completing your program? Ongoing equipment acquisitions to maintain industry relevance. Increased use of video instruction to help student visualization. Keep up on the maintenance of our machines to keep them in working order to allow as much hands on time as possible. Appendix D: A Few Questions Please answer the following questions with "yes" or "no". For any questions answered "no", please provide an explanation. No explanation is required for "yes" answers. Write n/a if the question does not apply to your area. • Have all of your course outlines been updated within the past five years? Yes • Have you deactivated all inactive courses? (courses that haven’t been taught in five years or won’t be taught in three years should be deactivated) Yes • Have all of your courses been offered within the past five years? If no, why should those courses remain in our college catalog? Yes • Do all of your courses have the required number of CLOs completed, with corresponding rubrics? If no, identify the CLO work you still need to complete, and your timeline for completing that work this semester Yes • Have you assessed all of your courses and completed "closing the loop" forms for all of your courses within the past three years? If no, identify which courses still require this work, and your timeline for completing that work this semester. Yes • Have you developed and assessed PLOs for all of your programs? If no, identify programs which still require this work, and your timeline to complete that work this semester. Yes • If you have course sequences, is success in the first course a good predictor of success in the subsequent course(s)? Yes • Does successful completion of College-level Math and/or English correlate positively with success in your courses? If not, explain why you think this may be. NO. The Math and English requirements do not reflect the practical math and technical english use in a shop environment. Appendix E: Proposal for New and Ongoing Initiatives and Projects (Complete for each initiative/project) Appendix F1A: Full-Time Faculty Request(s) [Acct. Category 1000] Audience: Faculty Prioritization Committee and Administrators Purpose: Providing explanation and justification for new and replacement positions for full-time faculty Instructions: Please justify the need for your request. Discuss anticipated improvements in student learning and contribution to the Strategic Plan goal. Cite evidence and data to support your request, including enrollment management data (EM Summary by Term) for the most recent three years, student success and retention data, and any other pertinent information. Data is available at: http://www.chabotcollege.edu/programreview/Data2015.asp Spreadsheet: To be considered, requests must be added to the Resource Request Spreadsheet. You can find the template for the spreadsheet here: http://www.chabotcollege.edu/prbc/academicprogramreview.asp. Add your requests to your spreadsheet under the 1000a tab and check the box below once they’ve been added. Appendix F2A: Classified Staffing Request(s) [Acct. Category 2000] Audience: Administrators, PRBC, Classified Prioritization Committee Purpose: Providing explanation and justification for new and replacement positions for full-time and part-time regular (permanent) classified professional positions (new, augmented and replacement positions). Remember, student assistants are not to replace Classified Professional staff. Instructions: Please complete a separate Classified Professionals Staffing Request form for each position requested and attach form(s) as an appendix to your Program Review. Spreadsheet: To be considered, requests must be added to the Resource Request Spreadsheet AND a separate Classified Professionals Staffing Request form must be completed for each position requested. Add your requests to your spreadsheet under the 2000a tab and check the box below once they’ve been added. Please click here to find the link to the Classified Professional Staffing Request form: http://www.chabotcollege.edu/prbc/APR/201617%20Classified%20Professionals%20Staffing%20Request%20Form.pdf This is a fillable PDF. Please save the form, fill it out, then save again and check the box below once you’ve done so. Submit your Classified Professionals Staffing Request form(s) along with your Program Review Narrative and Resource Request spreadsheet. Total number of positions requested (please fill in number of positions requested): One x☐ Separate Classified Professionals Staffing Request form completed and attached to Program Review for each position requested (please check box to left) x☐ Summary of positions requested completed in Program Review Resource Request Spreadsheet (please check box to left) Appendix F2B: Student Assistant Requests [Acct. Category 2000] Audience: Administrators, PRBC Purpose: Providing explanation and justification for student assistant positions. Remember, student assistants are not to replace Classified Professional staff. Instructions: Please justify the need for your request. Discuss anticipated improvements in student learning and contribution to the Strategic Plan goal, safety, mandates, and accreditation issues. Please cite any evidence or data to support your request. If these positions are categorically funded, include and designate the funding source of new categorically-funded positions where continuation is contingent upon available funding. Rationale for proposed student assistant positions: Two student assistants are requested, one for the manual classes and one for the advanced machining classes. The primary tasks/responsibilities of this student assistant will be to increase safety in the lab environment and to help students complete their lab projects. Machining skill sets require highly individualized and manual processes. Due to the nature of these skill sets, group learning is not usually optimal. The student assistants help students complete their lab assignments in a timely and safe manner. The risk of accident occurrence increases due to the fact that there is only one instructor overseeing an average of 24 students per session. The ability to essentially have a second set of eyes monitoring student activities would greatly reduce the risk of future student safety incidents. How do the assessments that you preformed to measure student learning outcomes (SLO’s) or service area outcomes (SAO’s) support this request? The request for two student assistants is in line with the Machine Course Learning Outcomes and the Colleges Goals to provide a safe learning environment for the entire student body. Spreadsheet: To be considered, requests must be added to the Resource Request Spreadsheet. Add your requests to your spreadsheet under the 2000b tab and check the box below once they’ve been added. Total number of positions requested (please fill in number of positions requested): Two ☐x Summary of positions requested completed in Resource Request Spreadsheet (please check box to left) Appendix F3: FTEF Requests Appendix F5: Supplies Requests [Acct. Category 4000] Audience: Administrators, Budget Committee, PRBC Purpose: To request funding for supplies and service, and to guide the Budget Committee in allocation of funds. Instructions: In the area below, please list both your anticipated budgets and additional funding requests for categories 4000. Do NOT include conferences and travel, which are submitted on Appendix F6. Justify your request and explain in detail the need for any requested funds beyond those you received this year. Please also look for opportunities to reduce spending, as funds are limited. Spreadsheet: To be considered, requests must be added to the Resource Request Spreadsheet. Follow the link below and check the box below once they’ve been added. ☐ SUPPLIES tab (4000) completed in Program Review Resource Request Spreadsheet (please check box to left) How do the assessments that you preformed to measure student learning outcomes (SLO’s) or service area outcomes (SAO’s) support this request The financial needs of this program are satisfied exclusively on the availability of Perkins fund and State initiated funding through Lottery 3, with no financial help originating from the college general fund. The allocation partially satisfied the purchasing of essential machining consumables, accessories and maintenance needed to ensure proper lab activities for the entire machine student body. The yearly expenditure allocation for consumables, worn out equipment, and equipment services is insufficient to properly maintain our program. The price of a single carbide endmill is $78.50 each, the amount we spent to ensure the laboratory accommodation for one of our students was insufficient and has a negative educational effect. In the same time 2013-2014 machine shop operation cost for machine tool related items such as: precision tools, cutters, 3D printing materials, machining raw materials, machining accessories and equipment maintenance have substantially increased thus limiting effects of our purchasing power and adding additional strain to student’s ability to fully accomplice the lab curriculum requirements. More than in any other vocational discipline, student’s skill level can be achieved or improved only through intense lab tasks repeatability supported by appropriate supplies at the time of demand. A “onetime mid-year state supply funding” is a very welcome event but hasn't happened often enough for current and future students to benefit. Budget sufficiency and dependability is one of the essential factors for this program to be able to sustain the proper student skill development. The funding that was received directly impacted/aided in the students learning. In order for students to develop their machining skills, functional machinery needs to be provided. Another necessity for student learning is for the student to advance their skillset through repeating the lab machining and programming tasks, this requires a substantial amount of consumables and supplies. The funding provided for Supplies and Services is linked directly to the progress of student learning outcomes. Technology and Equipment was used to purchase equipment specifically for lab safety. The remaining funding received for staffing (Student Assistant) went into the safety of the students. The Student Aid assisted with the lab safety and security of the students. Appendix F6: Contracts & Services, Conference & Travel Requests [Acct. Category 5000] Audience: Staff Development Committee, Administrators, Budget Committee, PRBC Purpose: To request funding for contracts & services and conference attendance, and to guide the Budget and Staff Development Committees in allocation of funds. Instructions: Please list specific conferences/training programs, including specific information on the name of the conference and location. Your rationale should discuss student learning goals and/or connection to the Strategic Plan goal. Spreadsheet: To be considered, requests must be added to the Resource Request Spreadsheet. Follow the link below and check the box below once they’ve been added. 1. 2. There should be a separate line item for each contract or service. Travel costs should be broken out and then totaled (e.g., airfare, mileage, hotel, etc.) Rationale: Maintenance contracts for our software enable us to continue to use our CAD/CAM software necessary for our classes. Printer maintenance contract greatly reduces the cost of using and repairing our 3D printer. ☐ TRAVEL/SERVICES tab (5000) completed in Program Review Resource Request Spreadsheet (please check box to left) Rationale: Maintain instructor education, experience, and competency on current and new equipment in our laboratories as well as the latest versions of our CAD/CAM softwares. Appendix F7: Technology and Other Equipment Requests [Acct. Category 6000] Audience: Budget Committee, Technology Committee, Administrators Purpose: To be read and responded to by Budget Committee and to inform priorities of the Technology Committee. Instructions: Please fill in the following as needed to justify your requests .If you're requesting classroom technology, see http://www.chabotcollege.edu/audiovisual/Chabot%20College%20Standard.pdf for the brands/model numbers that are our current standards. If requesting multiple pieces of equipment, please rank order those requests. Include shipping cost and taxes in your request. Spreadsheet: To be considered, requests must be added to the Resource Request Spreadsheet. Follow the link below and check the box below once they’ve been added. ☐x EQUIPMENT tab (6000) completed in Program Review Resource Request Spreadsheet (please check box to left) Please follow the link here to make your request and summarize below http://intranet.clpccd.cc.ca.us/technologyrequest/default.htm Appendix F8: Facilities Requests Audience: Facilities Committee, Administrators Purpose: To be read and responded to by Facilities Committee. Background: Although some of the college's greatest needs involving new facilities cannot be met with the limited amount of funding left from Measure B, smaller pressing needs can be addressed. Projects that can be legally funded with bond dollars include the "repairing, constructing, acquiring, and equipping of classrooms, labs, sites and facilities." In addition to approving the funding of projects, the FC participates in addressing space needs on campus, catalogs repair concerns, and documents larger facilities needs that might be included in future bond measures. Do NOT use this form for equipment or supply requests. Instructions: Please fill in the following as needed to justify your requests .If requesting more than one facilities project, please rank order your requests. Brief Title of Request (Project Name): Machine Tech Storage and Air Compressor Area behind bldg. 1600 Building/Location: Building 1600 Type of Request __x_ Space Need ___ Small Repair ___ Large Repair ___ Building Concern ___ Larger Facility Need ___ Other (grounds, signage…) Description of the facility or grounds project. Please be as specific as possible. The current structure has walls, no ceiling, two gates, an air conditioning unit cement pad, and a partial floor. Remove the gates and add a double door keyed access, enclose with a ceiling, add electricity and lighting, finish the cement floor and remove the old air conditioning pad. Install and auxiliary air compressor for MTT and ET classes. What educational programs or institutional purposes does this request support and with whom are you collaborating? Machine Tool Technology Briefly describe how your request supports the Strategic Plan Goal? Currently storage for both Machine Tool Labs is in the shops themselves. This causes loss of valuable shop floor space and tripping hazards. Storage of raw materials, coolant drums, and spare equipment would make for more efficient use of our shop floor space for students and faculty. The building 1600 air compressor has sporadic breakdowns and when this happens the machine tool and electronics equipment won't function leaving students with no equipment to operate.