Surface segregation in palladium based alloys from density-functional calculations O.M. Løvvik

advertisement

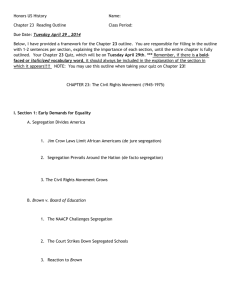

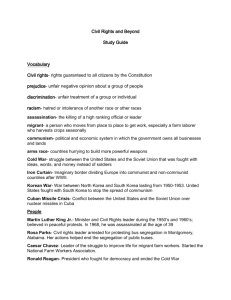

Surface Science 583 (2005) 100–106 www.elsevier.com/locate/susc Surface segregation in palladium based alloys from density-functional calculations O.M. Løvvik * University of Oslo, Center for Materials Science and Nanotechnology, P.O. Box 1126 Blindern, N-0318 Oslo, Norway Received 17 December 2004; accepted for publication 16 March 2005 Available online 7 April 2005 Abstract The surface segregation in Pd based alloys has been investigated by density-functional band-structure calculations. Twelve different metals were substituted in Pd(1 1 1) slabs at a level of 5%: Ag, Au, Cd, Cu, Fe, Mn, Ni, Pb, Pt, Rh, Ru, and Sn. The segregation energy (the difference in calculated total free energy between surface sites and bulk-like sites) was calculated for each alloy, and the results were in very good agreement with experimental data where available. Particularly, we predict an oscillatory depth profile for Cu and Ni, similar to what has been found experimentally for the PdNi(1 0 0) surface. There are more or less pronounced correlations between the segregation energy and the relaxed position at the surface of the substituted atom, the metal radius of the substituted atom, and the experimental surface energy of the metal. It is proposed that the segregation energy is an indirect measure of the stability of Pd based hydrogen permeable membranes. 2005 Elsevier B.V. All rights reserved. Keywords: Density functional calculations; Surface segregation; Palladium; Alloys 1. Introduction Palladium is a metal with important existing and potential applications both as a catalyst in heterogeneous catalysis and in membranes for hydrogen separation. Alloying may be used to substantially alter the catalytic properties of palla- * Tel.: +47 22 840 689; fax: +47 22 840 651. E-mail address: o.m.lovvik@fys.uio.no dium surfaces, and a detailed knowledge of the atomic arrangement and electronic structure of alloy surfaces could aid in the search for better catalysts [1–4]. Surface segregation is a central concept when such properties are to be described and understood. Thin palladium based membranes have excellent hydrogen permeability and exhibit very high hydrogen selectivity [5,6]. The most common alloys for hydrogen selective membranes are Pd77Ag23 and Pd60Cu40, which both have enhanced mechanical 0039-6028/$ - see front matter 2005 Elsevier B.V. All rights reserved. doi:10.1016/j.susc.2005.03.028 O.M. Løvvik / Surface Science 583 (2005) 100–106 and permeation properties compared to pure Pd membranes [5,7]. There is, however, still a need to improve the membranes; their long-term mechanical stability is for instance not yet acceptable for the thinnest membranes. The atomistic understanding of the mechanisms that are involved in the rupturing and cracking of membranes is very limited, and a deeper understanding could facilitate improved materials, treatments, and designs of future hydrogen permeable membranes. One phenomenon that may be of importance for the mechanical stability of thin metal membranes is surface segregation, including segregation to the surface of grain boundaries. If the thermodynamic driving force towards surface segregation is large, this may lead to excessive solid-state diffusion and hence possibly an increased density of faults and defects in the crystal structure. Furthermore, bulk order may be broken at grain boundaries and interfaces if segregation is strongly promoted, leading to local disorder and weakened bonds between grains. Thus, the tendency of strong surface segregation may be a measure of the mechanical instability of the membrane. Experimental studies of surface segregation have been performed for most of the alloys in this paper. It is for instance well-known that silver surface segregates in PdAg alloys (95% of the (1 1 1) surface of Pd67Ag33 is silver at 720 K) [8], and that gold [9,10] and copper [11] surface segregate in Pd alloys. It has further been shown that Pd surface segregates when alloyed with Fe [12,13], Ni [14– 18], Pt [19,20], Rh [21], and Ru [22]. These results are valid for pure surfaces, and may be changed in the presence of adsorbents. Since oxygen adsorbs more strongly on palladium than on gold, for instance, palladium surface segregates in PdAu alloys with adsorbed oxygen [10]. The orientation of the surface has also been shown to play a role. The (1 1 0) surface of PdNi shows, for instance, a larger tendency of Pd surface segregation than the (1 1 1) surface [17]. PdNi and PdAu alloys have shown oscillations in the atomic layer composition near the surface [17,9], similar to what has previously been found in Pt alloys [23,24]. Most previous theoretical studies of surface segregation are based on atomic potential methods like the (modified) embedded atom method [25], semi-empirical N-body potentials [10], quantum 101 approximate methods [26], and tight-binding methods [27,28]. So far, very few studies have used ab initio methods to calculate segregation in binary Pd alloys; one such study showed surface segregation of Co in PdCo alloys [29], and another showed surface segregation of Ag in PdAg alloys [30]. A density-functional study concluded that Mn overlayers on Pd are metastable [31], implying that Pd probably surface segregates in PdMn alloys. For PdCd and PdSn there are no data on surface segregation in the literature. This paper aims to calculate the tendency of the 12 metals mentioned above to segregate either to the surface or away from the surface when substituted in a palladium slab. This has been done by comparing the total energy of different substitution configurations after relaxation of internal forces in the slab, using density functional theory (DFT) at the generalized gradient approximation (GGA) level. The induced local distortions of the lattice due to such substitutions in the form of atomic displacements from the relaxed positions of the pure Pd slab have also been investigated. Finally the correspondence between the segregation energy and the metal radii (half the interatomic distance within the metals) and the surface energies of the substituted atoms is investigated. 2. Computational method The calculations were carried out using the Vienna Ab-initio Simulation Package (VASP) [32,33], in which the electronic band structure is calculated from density functional theory using a plane-wave basis sets. The projector augmented wave (PAW) scheme [34,35] was used to represent the wavefunctions, and the plane-wave energy cutoff was 500 eV. The k-spacing was less than 0.02 Å 1 in reciprocal space, and the convergence criterion for the self-consistent electronic calculations was that the energy difference between two successive iterations be less than 10 5 eV. The tetrahedron method with Blöchl corrections was used to smear out partial occupancies. The overall convergence of the total free energy due to the mentioned numerical parameters was around 1 meV. In addition comes the unknown uncertainty from 102 O.M. Løvvik / Surface Science 583 (2005) 100–106 the exchange-correlation potential, in our case the PW91 gradient-corrected functional [36]. Slabs were constructed by inserting vacuum regions of 1 nm in the z-direction. Fig. 1 shows the geometry of one such slab, with an outline of the 2 · 2 surface unit cell being used. Shown are also the three substitution sites investigated for the metals. We used five-layer slabs, since this was found to yield acceptable convergence with respect to surface energy and segregation energy. This means that the impurity level is 5% in these models, and that the minimum distance between each impurity is 559 pm. The optimized bulk cell parameters were kept fixed in the slab plane, and the start geometry for the relaxation was the relaxed geometry of a pure Pd slab of the same size. The residual minimization method with direct inversion in iterative subspace implementation of the quasi-Newton method was used for the force minimization, keeping the bottom layer fixed to mimic bulk continuation. The tolerance for remaining ionic forces was 0.03 eV/Å. A single high-accuracy calculation was performed after reaching this criterion, in order to get reliable total energies. 3. Results and discussion The tendency of an impurity to segregate to or from a surface may be expressed by the segregation energy Esegr. This is defined as the difference in calculated uncorrected total free energy between a surface (or near surface) site and a bulk-like site (in our case in the middle of the slab; site ‘‘3’’) for each substitution metal. This means that positive segregation energy implies a tendency to move into the bulk, while a negative segregation energy suggests surface segregation. Fig. 2 summarizes the calculated Esegr for the upper two layers of the 12 metals in this study. The distribution of segregation energies at the surface is quite broad; seven of the atoms have positive segregation energy at the surface, while five have negative segregation energy. The largest positive energy is found for Ru and Mn, while Pb has a particularly high negative energy. It is interesting to note that Cu and Ag, which improve the mechanical properties of Pd when added, both have relatively low segregation energies. This could mean that a low segregation energy is beneficial for the mechanical properties of thin alloy membranes. The correspondence with the calculated segregation energy and what has been observed experimentally is very good. It is predicted that Ag, Au, 60 MnRu Fe 40 Esegr (kJ/mol) Rh 20 0 -20 -40 Ni Cu Pt Ag Cd Au Sn -60 -80 Pb 1 2 3 Layer Fig. 1. The five-layer slab used for the calculations. The substitution sites ‘‘1’’ to ‘‘3’’ are marked—only one of them is substituted at a time. The 2 · 2 surface unit cell has been outlined. Vacuum regions of 1 nm separate the slabs in the zdirection. Fig. 2. The segregation energy Esegr in kJ/mol per unit cell at the three sites shown in Fig. 1 for the various substituted atoms. Esegr is defined as the total free energy of a slab with a substituted atom in the specified layer relative to that of a slab with the same atom substituted in layer 3. O.M. Løvvik / Surface Science 583 (2005) 100–106 The thermodynamic driving force for segregation, as discussed in the previous paragraphs, is one possible important factor governing mechanical stability of a thin alloy membrane, since it induces solid-state diffusion and disorder at the surfaces, thereby possibly creating more lattice defects and weaker bonds between grains in the structure. Another possible factor is local distortions around the substituted atoms; large displacements could lead to defects that additionally weaken the lattice. So how does the local geometry around the substituted atoms change upon relaxation? Because of symmetry, the lateral position of all atoms was unchanged, and any changes happened in the z-direction. Fig. 3 shows how the displacement in the z-direction dz of the substituted atom relative to the equilibrium position of the replaced Pd atom varies with substitution site for the different impurity atoms. We first note a clear negative correlation between Esegr and dz; the atoms with largest negative Esegr (like Pb) have the largest displacement out of the surface, and vice versa. The displacements are not very large, but they may be sufficient to decrease the mechanical stability of alloy membranes, since this inevitably increases disorder at grain boundaries. Experimental results on this are scarce in the literature, but a SEM study measured the Pd atoms to be 25 pm higher than Ag in a Pd67Ag33(1 0 0) surface containing 95% silver [8]. The calculated displacement 50 Pb 40 Cd dz (pm) Cd, Pb, and Sn surface segregate in Pd, in agreement with what has been seen for Ag [8] and Au [9,10]. Similarly, most of the atoms that are predicted not to surface segregate (having positive segregation energies), are supported by experimental findings; Pd surface segregation has been observed in Fe [13], Ni [17,18], Pt [19,20], Rh [21], and Ru [22]. There is one exception, however; Cu has been observed to surface segregate in Pd–Cu nanoparticles on a SiO2 support [11], while atomistic simulations predict Pd to surface segregate in Cu [26]. A corrected effective medium study found depletion of Cu at the surface at low Cu concentrations [37]. We shall see that these conflicts may to a certain extent be explained by an oscillatory depth profile. The segregation energy varies monotonically when going from layers 3 to 1 for all the atoms except two: Cu and Ni. Additional calculations were performed with the number of layers increased to seven, and the result remained the same for both Cu and Ni—the most stable substitution site is that of the second layer. This is consistent with the oscillatory depth profile observed in PdNi(1 0 0) surfaces; while a bulk concentration of 50% Ni decreased to 22% in the surface layer, the concentration was 72% in the second layer [17]. A similar trend is expected to appear in PdCu as well, based on the present results. This could explain why different studies gave different results, particularly if it turns out that the depth profile depends on the surface orientation. It is furthermore known that there is an oscillation of the Au content near the surface of Au3Pd(1 0 0) [9], but this is not seen in our data. In order to check this more thoroughly, new calculations should be performed with systematic variation of the Au content in several layers, but this is beyond the current scope. There is not enough experimental data available to see whether the strength of Esegr generally correlates with the concentration of the impurity at the surface. This is not necessarily the case, since there may be effective repulsions between the impurities at the surface due to electronic and/or geometric effects. But we do expect a stronger and more rapid segregation taking place at lower temperatures when the absolute value of Esegr is larger. 103 30 Ag 20 Sn Au 10 Pt 0 Cu -10 Ru -20 MnFe Rh Ni 1 2 3 Layer Fig. 3. The displacement in the z-direction dz of the substituted atom relative to the relaxed position of the replaced Pd atom in pm. 104 O.M. Løvvik / Surface Science 583 (2005) 100–106 Esegr (kJ/mol) of Ag is in this work out of the surface, that is the opposite direction of what could be expected from the experimental results. This is probably because of the different surface compositions and/or geometries. It is interesting to know whether the surface segregation is primarily a geometric or electronic effect. To check this, we have in Fig. 4 plotted the connection between Esegr and the metal radius of the impurity atoms (as a measure of the geometric effect—do large atoms move towards the surface?) and the experimental surface energy Esurf [38] (as a measure of the electronic effect—how easily are various surfaces formed compared to Pd?). There is a visible correlation in both cases. One general trend is that larger atoms tend to segregate more strongly to the surface (Fig. 4(a)). This correlation is not strong enough, however, to be used to predict segregation direction. For example, Cu, Mn, and Rh have larger metal radii than Pd, but they are not predicted to surface segregate. Similarly there is evidently a positive correlation between Esegr and Esurf (Fig. 4(b)): the lower the surface energy, the more likely we find surface segregation. But also here the predictive power is limited. Cu and Mn have, for instance, lower Esurf than Pd, but are still predicted to surface segregate. Thus, surface segregation is governed by a combination of geometric and electronic effects. 60 60 40 40 20 20 0 0 -20 -20 -40 -40 -60 (a) (b) -80 120 140 Covalent radius (pm) -60 -80 1 2 3 Esurf (J/m2) Fig. 4. The correlation between Esegr and the metal radius (half the interatomic distance in the metals) of the substituted atoms (a) and the experimental surface energy (b). The symbols correspond to the same atoms as in Figs. 2 and 3, while the Pd values are marked by open circles. The catalytic activity of these materials may depend strongly on the alloying. It is, e.g., known that catalytic hydrogenation may be improved by adding Ni to Pd despite the surfaces are dominated by Pd [14,39,16,17]; this may be explained by electronic modification of Pd by surrounding Ni atoms. We should expect a similar effect in PdCu alloys based on the predicted oscillatory composition of the near surface layers. We have seen that the segregation energy is correlated with both the difference in radius and the difference in surface energy between the two metals of the palladium based alloys of this study. But how is it related to the mechanical stability of membranes based on such alloys? There does not exist any systematic investigation of the mechanical stability of Pd based alloy membranes that could give a quantitative answer to this question. It is known, however, that PdAg and PdCu alloys exhibit the best mechanical stability among these alloys. Interestingly, Ag has the lowest negative segregation energy in this study, while Cu has the next lowest positive segregation energy, closely following Pt. This gives strength to our starting hypothesis that the segregation energy may be a measure of the mechanical instability of the membrane. This may seem surprising, since real membranes have all different surfaces, not only the low-index ones. Since surface segregation depends on the orientation of the surface, it is possible that both segregation and desegregation is found in real membranes. We should expect, however, that this is true only for the alloys with lowest segregation energy; if the size mismatch and/or surface energy difference is too large, there will probably be surface segregation for most or all surface orientations. Moreover, orientational dependence of surface segregation has only been reported for the alloys with lowest segregation energy. This means that an important factor for achieving mechanical stability could be that both species of an alloy is found at its surfaces. The ‘‘surfaces’’ of importance for mechanical stability may be both the surfaces facing the vacuum (or the gas phase) and the grain surfaces facing the grain boundaries. It is likely that cracking and rupturing of thin metal membranes take place O.M. Løvvik / Surface Science 583 (2005) 100–106 along grain boundaries or in their near vicinity. The segregation of metal atoms at the grain surfaces is not necessarily the same as the segregation at surfaces towards vacuum, since impurities only located in the grain boundaries may bond more strongly to one of the metals of the alloy. This means that a more realistic study of the importance of segregation for the mechanical stability of membranes must include the effect of adsorbents. Such investigations are in preparation. 4. Conclusions The surface segregation in Pd0.95M0.05(1 1 1) slabs (M = Ag, Au, Cd, Cu, Fe, Mn, Ni, Pb, Pt, Rh, Ru, and Sn) has been calculated using a density-functional band-structure formalism at the GGA level. The lowest absolute value of the segregation energy (which also may be a sign of mechanical stability) was found for Pt, Cu, Ni, and Ag. This is identified as a probable measure of the stability of alloy membranes. The displacement of the impurity from the equilibrium position of the replaced Pd atom is negatively correlated with the segregation energy: The larger negative segregation energy (and thus surface segregation), the larger displacement of the substituted atom out of the surface. There is also a negative correlation between the segregation energy and the size of the substituted atoms (measured by their covalent radii) and a positive correlation between the segregation energy and the experimental surface energy of the metals. Both geometric and electronic effects are needed to explain the segregation. Acknowledgements Economic support from the Norwegian Research Council through the NANOMAT program and generous grants of computational resources via the NOTUR project are acknowledged. References [1] G.A. Somorjai, Introduction to Surface Chemistry and Catalysis, Wiley and Sons, New York, 1994. 105 [2] J.H. Sinfelt, Bimetallic Catalysts: Discoveries, Concepts and Application, Wiley and Sons, New York, 1983. [3] F.B.I. Chorkendorff, S.B. Clausen, B. Hammer, A.M. Molebroek, J. Nørskov, I. Stensgaard, Science 279 (1998) 1913. [4] P. Liu, J.K. Nørskov, Phys. Chem. Chem. Phys. 3 (2001) 3814. [5] S. Uemiya, Sep. Purif. Meth. 28 (1999) 51. [6] R. Bredesen, K. Jordal, O. Bolland, Chem. Eng. Proc. 43 (2004) 1129. [7] S.N. Paglieri, J.D. Way, Sep. Purif. Meth. 31 (2002) 1. [8] P.T. Wouda, M. Schmid, B.E. Nieuwenhuys, P. Varga, Surf. Sci. 417 (1998) 292. [9] J. Kuntze, S. Speller, W. Heiland, P. Deurinck, C. Creemers, A. Atrei, U. Bardi, Phys. Rev. B 60 (1999) 9010. [10] Z. Kaszkur, Phys. Chem. Chem. Phys. 6 (2004) 193. [11] S. Lambert, B. Heinrichs, A. Brasseur, A. Rulmont, J.P. Pirard, Appl. Catal. A—General 270 (2004) 201. [12] J.C. Bertolini, J.L. Rousset, P. Miegge, J. Massardier, B. Tardy, Y. Samson, B.C. Khanra, C. Creemers, Surf. Sci. 281 (1993) 102. [13] C. Creemers, Surf. Sci. 360 (1996) 10. [14] J.C. Bertolini, P. Miegge, P. Hermann, J.L. Rousset, B. Tardy, Surf. Sci. 331–333 (1995) 651. [15] G.N. Derry, C.B. McVey, P.J. Rous, Surf. Sci. 326 (1995) 59. [16] A.C. Michel, L. Lianos, J.L. Rousset, P. Delichere, N.S. Prakash, J. Massardier, Y. Jugnet, J. Bertolini, Surf. Sci. 416 (1998) 288. [17] S. Helfensteyn, J. Luyten, L. Feyaerts, C. Creemers, Appl. Surf. Sci. 212 (2003) 844. [18] G.N. Derry, R. Wan, Surf. Sci. 566 (2004) 862. [19] D. Radosavkic, N. Barrett, R. Belkhou, N. Marsot, C. Guillot, Surf. Sci. 516 (2002) 56. [20] A.M. Venezia, Catal. Today 77 (2003) 359. [21] M.A. Newton, L. Jyoti, A.J. Dent, S. Diaz-Moreno, S.G. Fiddy, J. Evans, ChemPhysChem 5 (2004) 1056. [22] I.G. Batirev, A.N. Karavanov, J.A. Leiro, M. Heinonen, J. Juhanoja, Surf. Interf. Anal. 23 (1995) 50. [23] Y. Gauthier, R. Baudoing, J. Jupille, Phys. Rev. B 40 (1989) 1500. [24] Y. Gauthier, R. Baudoingsavois, J.J.W.M. Rosink, M. Sotto, Surf. Sci. 297 (1993) 193. [25] C. Creemers, P. Deurinck, S. Helfensteyn, J. Luyten, Appl. Surf. Sci. 219 (2003) 11. [26] G. Bozzolo, J.E. Garces, R.D. Noebe, P. Abel, H.O. Mosca, Progr. Surf. Sci. 73 (2003) 79. [27] C. Massen, T.V. Mortimer-Jones, R.L. Johnston, J. Chem. Soc.—Dalton Trans. 23 (2002) 4375. [28] L.D. Lloyd, R.L. Johnston, S. Salhi, N.T. Wilson, J. Mater. Chem. 14 (2004) 1691. [29] A. Saul, M. Weissmann, Phys. Rev. B 60 (1999) 4982. [30] O.M. Løvvik, R.A. Olsen, J. Chem. Phys. 118 (2003) 3268. [31] W. Olovsson, E. Holmstrom, A. Sandell, I.A. Abrikosov, Phys. Rev. B 68 (2003) 045411. [32] G. Kresse, J. Hafner, Phys. Rev. B 47 (1993) 558. [33] G. Kresse, J. Furthmuller, Phys. Rev. B 54 (1996) 11169. 106 O.M. Løvvik / Surface Science 583 (2005) 100–106 [34] G. Kresse, D. Joubert, Phys. Rev. B 59 (1999) 1758. [35] P. Blöchl, Phys. Rev. B 50 (1994) 17953. [36] J.P. Perdew, J.A. Chevary, S.H. Vosko, K.A. Jackson, M.R. Pederson, D.J. Singh, C. Fiolhais, Phys. Rev. B 46 (1992) 6671. [37] L. Yang, Phil. Mag. A 80 (2000) 1879. [38] F.R. de Boer, et al., Cohesion in Metals: Transition Metal Alloys, North-Holland, Amsterdam, 1988. [39] P. Miegge, J. Rousset, B. Tardy, J. Massardier, J. Bertolini, J. Catal. 149 (1994) 404.