Quality Infrastructure for Renewable Energy Technologies Small Wind Turbines

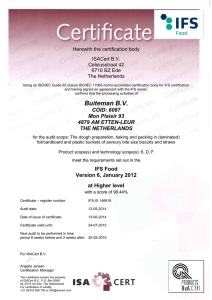

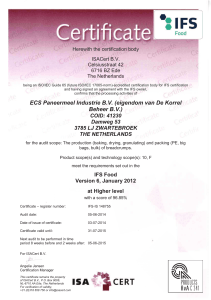

advertisement