ngn E ee Notes

advertisement

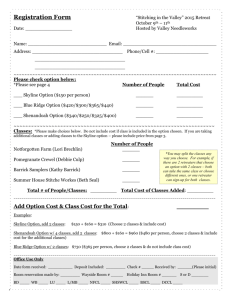

United E ngn ee ring Field Notes States partmenriculture Forest Service EZ/October Engineering Staff Washington w.. D.C. Engineering Technical Information System Another Patent Awarded to Forest Service Vertical Engineers Spar Guying Examination of Forces A Brief 1981 United States Department of Agriculture September/ Field Notes Forest Sg Service Washington Volume 13 Number 7 Engineering Engineering Technical D.C. System Information uýs ate. PROFESSIONAL DEVELOPMENT DATA MANAGEMENT RETRIEVAL Information developed contained Department States in for guidance and contractors FIELD NOTES employees of the United of Agriculture-Forest Service cooperating its The Department and Federal REPORTS been has publication this of TECHNICAL its State infor-mation agencies. responsibility for the The no of this own employees. its names trade firm or corporation of use assumes inferpretation or use than by other of Agriculture in this en-dorsement Depart-ment publication is for the the reader. Such or use exclusion The of others by the of any that in the publication the respective construed as United product may of text opinions does not constitute approval of Agriculture and convenience information be of official States or service to the suitable. represents and author recommended an the personal must not or approved be procedures FSM pub-lication mandatory instructions all not policy except Because of the type of material references. should or read intended engineers each issue exclusively and engineering however this for engineers. in by the technicians publication is October 1981 ANOTHER PATENT FOREST SERVICE AWARDED to ENGINEERS Cali-patent Three engineers Teddy L. Pickett Isidro Ignacio and Marco Rojas were credited as inventors in a issued July 14 1981 for a machine that plants tree and shrub seedlings. was Department of Agriculture as Assignee for Patent. designated the Department the Navy in is employed by also in of fully-The plant-Work employ-ees container-ized California Rojas private fornia. a firm The patent describes a for planting machine automated The machine is nursery stock. especially well-suited for ing tree and shrub seedlings on slopes and irregular terrain. fur-San on this machine started in March 1977 while all three inventors were Forest Service stationed at the San Dimas Center. Development Equipment Ignacio is still on the staff at Dimas Pickett now works for Service The Soil Conservation invention to to take the plans New Mexico where they will ther test and possibly improve it. Al wHOMI AII ýexýtt II a ESI. PRTSL\TS. THERE HAS Commissioner 4278035 BEEN 4Mj SIJ tIsLF i. TO THE PRESENTED and Trademarks of Patents CON-TAINED A PETITION NEW AND FOR THE PRAYING USEFUL THE IN THE TITLE AND INVENTION OF WHICH SPECIFICATION MADE A PART HEREOF AND THE MADE AND HAVE PROVIDED PATENT OF LETTERS GRANT A COPY IS HEREUNTO REQUIREMENTS VARIOUS THE RECORDS CLAIMANTS AND ANNEXED LAW SUCH CASES IN AND THERETO IS THJITLE AND TRADEMARK OFFICE IN THE COPY AND WHEREAS UPON DUE COMPLIED WITH BEEN III A PATENT UNDER Now OF INDICATED MADE THE SAID THE IN THE SAID IS THE LAW. THEREFORE FOR THE TERM OF SEVENTEEN SUCCESSORS STATES. Imsalmead LAW th PTO 10-77 1A GRANT Ae to 24iae de Ave s SUBJECT THE eaatooel atent anb axealatfh larAe2Cl rl a/7 1eýezr soar .Iooa/m Iaaa ýaýeýaeia a SAID TO EXCLUDE hiaoeIie dead //ýae Office ail meca THIS TO CLAIMANT THE RIGHT tubereof t1aa medeo/de OF DATE BY caaseaI Trabemark a UNTO THE THE SAID INVENTION THROUGHOUT tegtimonp ti/aoaia TO BE ENTITLED ARE TO GRANT YEARS FROM THE OF ISSUE FEES AS PROVIDED N ADJUDGED HEIRS OR ASSIGNS OF THE SAID OTHERS FROM MAKING USING OR SELLING UNITED ARE Patent Letters THESE AND THE THE PAYMENT PATENT CLAIMANTS CLAIMANTS TO REV. OF ALLEGED ARE EXAMI-NATION FROM FORM FOR AN OF WHICH DESCRIPTION ea lace a d /tae e0/ --oIAe GG2aýeaýJlaes United States Patent 19 11 Pickett 45 54 al. et MACHINE FOR PLANTING TREE AND SHRUB CONTAINERIZED Redmond Teddy L. Pickett Inventors Isidro D. Ignacio Rojas La Verne 73 Assignee 22 51 52 No. Appl. if 211915 2/1968 U.S.S.R represented by the Secretary of as 57 A seedling D.C. which AOIC ............................................. 11/00 111/2 ................................ 111/89 111/89 .................................... R. Feyrer Silverstein ABSTRACT of a consisting planter frame portable mounted a horizontally rotatable is 1981 ................................... Agent or Firm-M. Howard David G. McConnell Mar. 14 1980 C1.3 U.S.S.R Attorney States of America Washington 12/1967 Primary Examiner-James 130634 Filed Int. of The United Agriculture 21 both 6/1980 207548 Wash. Marco Altadena Netherlands 7811699 14 Jul. DOCUMENTS FOREIGN PATENT SEEDLINGS 75 4278035 movable index normally lowered a carrying plate scraper blade on vertically movable vertically a telescopic seedling motor and a pro-U.S. con-516745 scrap-1475061 58 U.S. Cl ........................................... 111/34 Field of Search 111/2 111/6 111/89 221/96 drop gear 111/1 2 3 4 6 7 73 80 89 92 221/% 222/636 tube auger an tray containing ..................... an hydraulic auger motor to the auger. A carousel seedlings is rotatably mounted on the box coupling the retraction-exten-56 111/34 406/63 gramming DOCUMENTS PATENT Pitt ground lowering the index plate and 2520809 8/1950 Miller ...................................... 111/7 2749855 6/1956 Guigas ................................... 111/3 3306239 2/1967 Martin ..................................... 3394667 7/1968 White ................................ 3712252 1/1973 3719158 3/1973 Huang Roths ...................................... 3943863 3/1976 Leonard 3998171 12/1976 111/3 al ........................... ..................................... 4091751 5/1978 Lofgren et Dri et al 4111135 9/1978 Braun 4116137 9/1978 Westerhoven 4186671 2/1980 Huang al al X 111/89 the hole and water .......................... 111/2 a cycle causing raising operating the auger and extending over the index the hole and packing resetting 111/2 open a water valve .......................... blade to pack the parts to 17 111/2 soil starting the seedling positions. Claims 11 Drawing Figures elz di 25 zl az 34 So 31 ý 29 30 yo /3 / L8 11 9r 7 S3 37 7/ I 9 yl the to deliver a quantity of around 70 28 plate the seedling to drive pressure over the drop tube into the hole then extending 111/2 ..................................... then so as cause to under through 111/2 .................................. A activating then elevating the scraper blade tube by carousel tray to rotate one step to bring a seedling over 111/2 111/2 then the drop 111/2 ......................... ...................................... first dig a hole to bring 111/1 to perform cylinders ing of the Stocker valves retracting the index plate 111/2 Frawley 1/1928 .................................. of solenoid operates sisting 11/1923 rotatable stepwise being 111/3 1657944 et circuit respective hydraulic .......................................... et the index plate over pawl on the end of the piston rod of a sion hydraulic cylinder mounted on the frame. a Cited References 3/1894 frame 64 65 66 a o e o J 0 o e 35 f7 l 6/ Z SO 14 and it a then oL ti Iz as 00 9r 81 Ll II z I Ot f7.9 oz .9 z o Z 00 ý I ff iý iI ý ZZ ýI ýfi zý tL1 OW l 9 1 06 o \ fi Ll 8l f ý / l9 O o to o o L o Of z -ý OL LIZ 2 -Mtn o 171 00 fiz 0 0 0 0 0 o O 0 e /9 00 O i Z/ý 04 I I II i IZ ý ý i 5z 1 i i 1I iý zý 8 7 li I oc i- I ý a e O. . ID D1 O n n O 00 ýý o G O/ i fiz zz Gz M I ýý 1 v l l I / ýýý o 00 N ES 00 k FIGB L jllý ýirlo sq ý I i II 33 57 6 ýz by Iýo Iýi 7/ i j 80 - Po i .1 78 8 _ý 6S r/onl ýARattsFý Booy 81 76 FiXEp I 34 A FIG 70 50 23 33 38 ýý s J1 _ o I 40 71 39 i 37 310 35 34 70 I i .5 /Z 4278035 8 of 4 Sheet 1981 14 U.S. Patent Jul. U.S. Patent Jul. 14 4278035 Sheet 5 of 8 1981 3.5 37 CAM FIXED 4-8 7b 36 I FRAME ý/8ý 3q /ý 83 So \ 33 76 z7 70 4- -4 8 06 40 7 71 l05 / \ 79 8 FIGS ý 8ý .S 0 X08 j 57 i 37 7e 3$3 1 33 /0 70 7y z7 64 69 6 2. I ý FIG. 7z 73 FIG7 ýWw toy 00 SUPPLY POWER c RYD4ACALI 90 OurPur PS/ 2000 9 FIG 95 9ý 93 ýý 9 crLvoL-R PAeýrývcý 00 1 ýýD 90 HOLE Co6RW4 fat as 97 /OZ ion 108 9 Il7 52 150 RerR. //Z 114 103 lob 99 00 98 ID5 sopq /0 oý BLADE t/ l RýN R yý RACY 113 YE rROL Al Co I06 118 48 o.e/ At RASIAIy Low.T/MCP AuyER /11 35 R iNDE of Aosirlow-vo CAROUSEL / /NDEX/Ny 31 AuyER M IlCr4 /07 30 4 Jý /0 V yL/NoER C AforoýQ HYDRAUUc t/j AvyER C DECAY ON OFFDELAy OFFDELAy SEC jr SEC - /23 R.ý /22 R3 /2/ R2 /2o R/ 27 /37 REr crED i r3Z z9 3 SEC S cJEC. DELAY 0/i /44 145 Isla a.J 7 V. /zrý 13 PRESSURE IAI ATER G POs 129 /2 f 131 SOLID AA7USrASLE 33 7 1 RELAYS AMER SrArF \ 70/p 00 SGlrAPER ý8 vyER /30 rxrrWDEO /3v Posi77oel C s /34 133 /33 28 UNDER- rc tu VALE 8 89- 53 O 00 /oz 04 9ý /z8 138 z5 EXrEMD /08 /17 /l3 119 i 8 pWI /z4 /z7 SWircH / 00 E AZ VALVE V. VALVE _/Z ALE RA/SE cyl. /07 VALVE /03 CyuNDER N BUTIO.I RETRACT //1aEX/N4 MorbR AUyER /Z 4 LoýJER /P. Cyl PAf1CJNy CrUAIOER SCRAPER v. t/2 FIG.10 12 // 10 6 7 ro 5 4 3 I2 / I0 CD Orr OFF - OFf R2 ON R3 ON R2 Rq 7Pf oN R3 00 OFF Ri ON fjI RA/SEP P. /. LOWERED /.P RETRACTED I.P. EXTENDED BLADE PACK/Ny S OPERA qugER I BLADE PACK/NCI 00 RETRAcrS /.P. EXTENOED SECONDS OFF P8 oM PB 0 ON WATER I VP SCPER DO1Iý SCRROtR D/SCNRRCE N JEEDL/Nq FIG11 U 4278035 2 1 MACHINE FOR PLANTING CONTAINERIZED TREE AND SHRUB SEEDLINGS This relates invention improved for planting nursery stock which lings and human quiring as 5 which and without automatically steps seed10 perform to and the auger so carousel rotated by the pawl is the drop by scraping to time the one through then plate the same at then the index dig a hole to a first occur the index the hole of the extension of the index intervention. as tube over to is lowering bring the drop bring a seedling over re- then horizontally extending tray causing where the planting area operated is cycle consisting of the index plate retracting activating and circuit a the scraper blade elevating raising planting such for button switch plate machine shrub terrain irregular and planters and tree push of the ground automated suited especially is the required performs such slopes and seedlings on mechanical to an to particularly circuit. horizontally FIELD OF THE INVENTION more The programming ming step to At the end portion tube. solenoid valve a plate for ex-seedlings ma-place disadvan-and BACKGROUND OF THE INVENTION Ordinarily the planting of In them the planting to the seedling then insure proper nourishment Various mechanical proposed but these devices tory mainly because they cannot perform and proper sequence in human considerable each moisten have of plant the a novel and A have satisfac- 25 is and steps Also to A considerable 30 the invention seedling to is planting planting machines. the invention automatically to is provide be can an which containerized plant which or tree used efficiently on terrain. irregular automated improved this and deficiencies further object of the invention still is after seedling planting machine seedlings and slopes or on in the of automated arranged shrub in of object available further object improved blade and tube positions. improved which overcomes the the drop packing a as to pressure onto the seedling starting a main Accordingly seedling. labor. a to reset tages of previously short time without involve are provide under thereafter around soil chine not been and supervision 20 Shortly hole. to pack parts water so energized is drive the seedling through the plant self-contained a reasonably the tended to quantity seedling and system to the necessary all cases the prior devices most for planting devices are not they deliver a clear the immediate growth of the been supply conduit into ter- necessary the plant root and 15 shrub irregular first suitably and aids because is site around soil it or tree proper depth to the hole in the pack as for required is slopes or other on dig a hole planting area labor such the seedlings planting transport stock nursery particularly rain. human considerable a pressurized water is provide an to seedling planting machine which automati-Furthermore amount of individual handling of the seedlings or more of the required planting forming one use of the prior proposed in can be readily positioned per- steep slopes or on steps. ma- planting cally for terrain and irregular performs sequentially planting seedlings even on which the various required steps step-Martin se-Roths chines A not is on practical search preliminary prior U.S. following Miller U.S. the prior revealed art the 35 patents of interest human A 2520809 2749855 No. 3306239 of planting intervention and efficiently No. Pat. correct for slopes. No. Pat. Guigas U.S. of or on terrain irregular without seedlings which and performs these steps rapidly. further object of the invention still improved requiring seedling which planter is provide an to includes a ar-ery U.S. Huang U.S. U.S. Dri et Pat. al U.S. 3712252 3719158 No. 4091751 No. Pat. 40 No. Pat. Pat. actuated carousel tray containing number which can be planted in substantial number of seedlings to of containerized seedlings quence enabling said a substantial container-The includ-machine deliver-on be Braun U.S. Pat. No. 4111135 Westerhoven U.S. Pat. No. 4116137 45 and ized of the present invention automatically then adapted is and vehicle similar packs be to is around the machine from which can be the boom operated the transported in rough by a crane of a crane to place 50 or terrain. or successively selected locations which similar the frame automated is vehicle a desired in irregular ranged to perform required machine seedlings on for terrain in for a seedling over ing water pressure onto under the hole pack and around soil then all readily being the necessary then digging the hole a hole then the seedling to drive extending the seedling growth conditions being planting a seedling scraping the planting area first to provide an on slopes and proper sequence properly is without labor. planting machine said or then positioning into 55 or shrub tree steps human further object of the invention still usable ing operation for a frame comprises The seedlings. adapted especially steep slopes and relatively In general suspended soil A improved digs holes and then plants containerized seedlings nursof trees stock sometimes called tubelings and shrubs in requiring handling of the seedlings or SUMMARY OF THE INVENTION machine planted a packing root blade to system it to insure seed-vertically planting rally A location. movable index horizontally plate is and rotatable proper A verti- frame said with a normally lowered provided on the still for the seedling. further object of the invention is to provide an seed-lic index being plate retractile provided scraper blade drop tube and a digging auger. ing a substantial tubes plate is is solenoid auger rotatable stepwise valve-controlled cylinder mounted on valve-controlled motor are provided a telescopic seedling 60 A carousel circularly rotatably mounted on and solenoid number of tray contain- arranged the frame over by a pawl seedling the index driven retraction-extension the frame. hydraulic Respective cylinders controlled by by a hydrau- other and an a program- of the carousel type successively planting containerized tree or shrub improved lings said automated machine sequence all seedling and machine being the necessary arranged steps to perform for properly in for proper planting a having for arrangements automatically the containerized seedlings into discharge over the holes prepared for positions receiving the lings so that the successive seedlings will be planted in advancing 65 successively selected locations without handling of the seedlings by the operator. requiring the cen-become 4278035 3 OF THE DRAWINGS BRIEF DESCRIPTION Further objects and the frame of the invention advantages 4 Thus other mechanism. each with a provided is for will 19 the two crossbars being and tral mechanism planting mounted crossbar rigidly connected rigidly by a con-inner adja-FIG. from apparent claims wherein from the is 1 description accompanying drawings a perspective view partly broken and FIG. the following a seedling planting machine members having post said shown with one of the containerized seedling carousel trays lifted off the machine to show associated below invention the includes also of intersections lower portions 22 depending the longitudinal bar with Said 20. opposite transverse end nected by divergent 19 frame short frame provided is 23 23 bars 24 24 bars rigidly the verti-FIG. structure. 2 away 10 an is enlarged 3 an is away broken view top plan of the seedling planting FIG. 1. The frame 20. members 21 forming post vertical bar the longitudinal bar 20 with the respective crossbars of the present to according away 5 longitudinal frame enlarged of FIG. machine cent ends partly 4 an is end enlarged elevational of FIG. view of the connected portion 22 the top end to end free 27 shaft of portion member 21 arm 25 and of post horizontal the bottom to to 16. end of depending arm longitudinally extending a is stationary cal 16 bars side longitudinally extending rigidly 15 seedling planting machine a is of FIG. of the seedling planting machine of the Rigidly connected 1. view elevational side broken partly mounted arm 26 and is the in supportingly is the bottom post A 26. en-invention FIG. 5 an is enlarged one of the carousel index-plate and a modified arrangement machine the index planting top plan view fragmentary trays pawl rotating planting seedling 1. shown being plate of clamped of an A 25. at top portion its member collar portion of to the vertical sleeve in an gaged employed as according form in a 20 present extended on 28 27 shaft fixed shaft 29 arm A 27. on and arm the upper An 25. slidably is elongated rotatably 30 hydraulic cylinder vertical member sleeve to portion of top secured rigidly subjacent member secured the end to is rigidly 29 in spaced limit-FIG. FIG. 6 of FIG. mal position. is a fragmentary is 5 showing top plan view the index of the structure a retracted in plate nor- 7 view tional 8 taken view tional fragmentary on substantially an enlarged is and sealingly rod being an enlarged is therewith relation 25 position. FIG. rigidly taken vertical on substantially 7-7 line fragmentary of FIG. vertical 8-8 line to 5. cross-sec- of FIG. 30 5. has piston rod 31 its through connected rigidly arm top its to collar extending end said piston member 28 by a The hydraulic cylinder 30 is employed and lower the sleeve member 29 between bracket cross-sec- and slidably parallel raise ing positions and bottom 32. established by abutment abutment upper arm 26. and extending 28 collar piv-FIG. trans-ming FIG. 9 a schematic is the present invention. FIG. 10 is a schematic typical Rigidly secured of the hydraulic oper- diagram of a seedling planting machine circuit ating according the lower end to wiring electrical of diagram programming system which may be employed a in 35 which 33 plate to in above spaced slightly shown in FIG. portion of plate the of level an index is position on is 13 the frame secured Rigidly 3. 29 elevated normally its horizontally from member of sleeve portion as the outer end Z-FIGS. bear-prises accordance with draulic circuit 11 the present invention of FIG. of FIG. the hy- indexing 9. a timing diagram is system with the for program- typical OF PREFERRED EMBODIMENTS to I 12 generally more and to the drawings 4 hydraulic a designates in 2 FIG. portion particularly tree typical to 38 or bracket shrub seedling planting machine constructed dance with the present invention. The machine 12 rectangular portable in accor- 45 to 37 vertical shaft 13 23 arm of a the top bracket supporting bottom of flange frame shown as an intermediate at the 24 bar portion The piston rod 39 4. An substantially a bottom the 34. horizontally and 36 between at and the adjacent FIG. in is the frame connecting 37 35 cylinder shown bracket rigidly shown upstanding pivotally connected being thereof Z-shaped an near the end bar element versely thereof 40 is mounted on otally 10. DESCRIPTION Referring 33 as with an provided is hy-tures asseni-includes depend-formed an frame elongated 13 having outwardly a generally pair extending the corners of one downwardly 15 structure and outwardly leg thereof said sleeve 40 ing in at a depending supporting extending end and 14 14 structures and having thereof the opposite end at downwardly of depending supporting end com- shaft as leg index viewed A 33 plate the at sleeve Extension position. horizontal vertical leg.struc- FIGS. 2 and 4 the piston rod 39 retracted its rotates 50 rotatably receiving the upstanding In 34. of FIG. supporting 29 and a shown direction 2. 41 plate carries is piston rod said counterclockwise in a side left of is secured rigidly to mounted vertically de-site depend-the there-at being a of longitudinal square be suspended to cables suitable site. holes 17 to receive eye crane vehicle tional the frame selected planting opposite with the frame to support adapted over position from the or other not in The 16 a coupling 55 enabling The of shaft to the underside ground-digging vertical motor 42 a conventional connected is reducing of plate auger 45. via gear 33 to a In the retracted of piston rod 39 shown in FIG. 2 the auger is located to dig a hole at the desired location for planting position by means may the machine 42. 43 and bly 44 secured ing of a conven- vehicle shown whereby 16 18 draulic motor stable 13 tubing bolts boom suitable a frame as will be presently described. exten-of be transported to and for example on lowered onto a slope adjacent embodiments herein a selected planting to a highway. described and 60 In Designated pending illus- 46 at 3 see FIG. seedling delivery tube ing from a delivery provided in aperture or 47 in a telescoping drop tube see FIGS. 8 and 10 clock-scription typical trated two in the identical drawings the frame is designed to carry located planting mechanisms each being a respective end of the frame. In the following the detailed elements the planting understood that mechanisms the associated will de- with only one be described same elements are employed it being for the 65 index from shaft from by an angle wise 27 rotation as of 33 plate auger 45 to said move the same but angularly corresponding index sion stroke of piston rod required at plate spaced to the angle produced tube 46 into of by the 39 namely through the drop distance radial the angle registry with a dis-44 de-hydraulic respec-described. con-Vertically 4278035 6 5 dug by the auger hole planting be will as presently secured the same 46 and to from depending distance radial clear tainers successively aperture 60 of stationary flange 59 digging during the for 35 cylinder blade can as permit the descent to of the index of cycles machine the the seedling successive for presently is 10 secured resiliently located so 71 with 4 embodiment of FIGS. Ito the In is The scraper be presently described. will be elevated planting with registry be to scribed. stroke of retraction initial 5 into the move the seedling to charge substantially it required steps with correspond box them is a scraper midway between rod carries a scraper cylinder 48 whose piston blade 49 which is located so as to scrape the ground and but to spaced tube gear 45 and drop auger as are indexing tive at 72 recesses 75 member 40 and with drivingly engage as to each member a pawl piston rod sleeve to a tooth ratchet 39 namely 35 to cyclinder extension stroke of piston rod move-plane bot-wardly 33 plate and At each 45 the auger planting hole for 13 there end of the frame directed packing located in of frame with the depending the a blade packing for 51 indexing subsequent one carrier delivery stroke retraction the step. resiliently a around a detent recess 50 15 dug by the auger 45 as shown in FIG. 3. The cylinder 50 may be connected at its out- 20 to a longitudinal arm 54 projecting top end from the end frame bar 23 and may be supported a hole 53 in seedling deposited the of the seedling carrying soil packing activation mounted pawl 75 slides past the adjacent ratchet tooth 71 the seedling carrier being then held against ment by the detent ball 73 seated in the last-engaged blade cylinder piston rod 52 On down- a each thereby advance 48. longitudinal vertical central with required cylinder provided is wardly and inwardly substantially the digging the hydraulic by activating 72. shown In the modification FIGS. 5 6 and 8 a pawl in mem-FIG. con-will a in inclined suitably the intermediate portion of the 55 connecting arm 54 nal position by a supporting the intermediate portion to the auger 45 located is in substantially in 34 said and 40 member of connected ber 79 having on the end bearing supported rod 39. The elongated plate inclined by a a shaft top and piston have rigidly the upstanding identical parallel members 77 78 rotatably engaged plate above members 77 78 25 pivoted on is of spaced consists shaft 76 at elongated torn sleeve cylinder. 39 shown 34 and on longitudi- of the In the retracted position of the piston rod 2 rod link member shown front vertical vertical which edges rectangular front are plate 80. The rear end edge members 77 78 are suit-7 cam-bottom longitudinal vertical be blade In the normal elevated as shown cylinder 50 the planting hole 53 that located with properly 52. so plane portions of the elongated respect to the packing of packing position blade 52 nected by a An it is plate pin vertical 81. arm 82 rigidly secured to member 40 extends upwardly past lower 78 as shown in FIG. 8. A flat elongated upstanding vertical mem-seedlings FIG. 3 dotted view its The carousel assemblies are designated ousel assembly body having 8 and a 56 a view but when line full 52 extended is sub- a 56 at Each 56. 35 see FIGS. 2 main portion 57 58 car- hat-shaped and frame 13 coaxially with the associated fixed vertical connected rigidly at end front its a direction urging the pawl in of the vertical to vertical spaced top and being 80 edge has an 6 toward cam 84 stationary 13 and the path of in 81 pin A 68. the frame to 85 located ming edge 40 wall retaining ably fastened which has a seedling discharge aperThe hat-shaped body is fixedly secured on the 60. namely the outer annular an is arm 82 and bears against pin 81 biasing the pawl ber 76 counterclockwise as viewed in FIGS. 5 and flange 59 ture member plate the containerized generally top wall bearing sleeve spring 83 carrying generally circular 30 position. comprises cylindrical with in the blade activated is to stantially in is inclined movement retractile receivable between the members 77 78. When rod the stationary cam is engaged by pin 81 bottom plate dis-a sole-the 27 Zexample by diametrically opposed 61 61 connecting the flange 59 to the in opposite longitudinal square tubes 16 16 as shown with a layer 62 FIGS. 2 3 and 4. Flange 59 is provided shaft of 39 for brackets shaped such bearing material suitable or the as Teflon like. is retracted the pawl causing 71 ratchet teeth 39 45 causes pin 81 pawl 80 edge 5 FIG. the top end stroke of index wall of fixed to bear on a vertical 3 annular channel-shaped containerized as on top said 27 shaft above short relatively in 65 said discharge 8. having A 69 86 flange 66 70 at in 55 plate noid valve said in cam 84 from this a allowing of 60 and vertical the drop registry tube 10 secured to the frame shown in rigidly is means not 86 8 namely of the discharge when As will be with source suitable a normally pressure through to carousel flange a to 13 by a position in registry fixed connected is 46. conduit directed 87. the of rod a seedling to be point position opening aperture 60 under of clear Extension 6. the top of a seedling container 70 into conduit water rotated FIG. downwardly bracket discharge At 33. placed the position of FIG. The with registering shown 68 see FIG. charge formed is vertical suitable an upstand- outer retaining wall seedling containers cylindrical for carrier Bottom flange 66 apertures the carrier an annular bottom cylindrical FIGS. 7 and circular rotatable provided is showing with the discharge 50 in to disengage planted has been of the stationary rigidity wall of the carrier and the bottom shown with seedlings inner wall cylindrical forming ing insuring allows body of the assembly. hat-shaped An 64 provided collar arm 25 see FIG. 27 and shaft to be shown a ratchet tooth as in drivingly engage the pawl 76 at the end of the extension to The top wall 58 has a central aperture 63 which receives 80 edge as is it the 59. of closed presently explained valve 87 ener-outwardly containers 70 being FIGS. 7 and indexing from As shown in The outer wall 68 8. regularly spaced between vertically 68 the outer retaining wall inner wall 65 and in received its upper 7 FIG. ratchet is teeth as the shown spaced detent assembly and extending 74 flange 66 through mounted bearing 33 to is formed with in lining 62. The detent for 65 responsive discharge its 8 FIG. a short time near of mounted on the valve 87 a stationary frame at namely to the position 60. tube 46 the end of in registry is The valve 87 is the extension 33 by the passing engagement cam 88 on the edge of index plunger the extension of index the drop aperture plate to position wherein discharge stroke of index uni- stationary flange 59 in said gized bottom ball plate with portion. to open energized shown projecting indexing recesses 72 to yieldingly receive a springbiased detent ball 73 forming part of a formly 60 with provided 71 is 13. plate microswitch This passing the appropriate of a 33 with the operating 89 engagement point in suitably opens the planting 4278035 8 7 cycle be presently described will as The respective normally open switch contacts of the shown respectively at 120 121. delay relays R1 to R4are provide a short to termi-moisten termi-the sustained pulse of pressurized water top of the subjacent force the seedling downwardly formed previously 9 FIG. to above-described seedling be mounted on the associated 90 unit a 2000 12 vehicle PSI The return conduit 94 conventional connected is % valve relief a return to connected is The A 15 wire a 124 the lower 126 a to and pole 125 12 contacts of a two-pole terminal wire volt of the winding terminal other its the lower and of The pole 128 volt R3 relay of 131 the remaining terminal push 127. said line of 129 wires via being relay grounded. The the across one 130 line 92. line 95. with button switch and con- is via associated with the upper upper contacts between 12 switch 126 are connected a said output. high pressure output conduit 93 of the unit 90 nected via a check valve 91 to a high pressure 10 terminal grounded 97 has one connected associated conven- a such as a suitable power source which has a grounded negative retract solenoid 102 of indexing cylinder employs battery The nal is 123. circuit 12-volt valve for 90 which may unit a 5 nal. circuit comprises supporting example having for The soil. machine planting circuit 122 and to adequately to hydraulic typical power supply pump hydraulic tional and the surrounding a The hydraulic illustrated. sufficient the seedling hole 53 into therebelow the seedling and Referring 70 the into injected seedling container switch R3 are connected 122 of relay contacts con-including termi-102 92 95. The hydraulic carousel indexing cylinder nected to the lines 92 95 via a conventional lines reversing solenoid valve closed 97 and 35 R4 con- is normally- 98 99 conduits the between 12 132 via wires R4 volt 129 and one line relay grounded. is One terminal of the winding 20 terminal of The remaining terminal of relay 133. of the R2 relay is Mi-The de-justable The valve 97 has an index 101. and be to index an energized alternately be will as de- The hydraulic motor 42 a conventional 105 and connected is closed normally Valve 106. 104 to 92 lines solenoid valve 25 93 auger nected and lowering across 92 lines solenoid valve 95 108 and flow via a conventional con- is of line 129. said relay of The remaining R2 is grounded. of R1 relay connected is 121 of the switch contacts line volt 123 the switch contacts R2 relay to The remaining terminal of the 129. grounded. is The extend solenoid 103 of indexing cylinder valve and wire 135 via a 97 is connected between ground 30 wire 136 and croswitch reversing member 109 110 including an ad111. As will be presently lines valve control 30 cylinder raising 12 relay winding has a valve-opening 1conduits 12 volt via a wire 135 and the 104 solenoid and One terminal of the winding scribed. via 134 nal of the winding 103 adapted presently a wire via relay R4 to the solenoid retraction plate extension solenoid plate netted 100 respective adjustable flow control valves 29 144 opens closed a normally 144 in held closed is elevated its shortly 145 a lug normal sleeve after and closes when microswitch by sleeve Microswitch position. member 144. on 29 starts its member completes sleeve micro-trated described elevated 30 cylinder and reversing valve ning of a planting cycle and deenergized FIG. in 112 to piston rod 31 relative positions 9. member sleeve being biased Valve 108 at 29 are the begin-The in 35 then 108 being the condition to has an scent ascent on illus- which reverses the valve when energized. Reversal 40 causes cylinder 30 and sleeve member 29 to switch said descend. to The packing 50 cylinder connected is 92 lines to 95 reverses valve energized 52 the packing blade a retracted in The scraper cylinder 48 via a conventional 118 having 49 blade sive is elevated to performing seedling for 5 The relays typically R1 relay to R4 to R2 at circuit The herein. 89 55 for 60 of programming of other the the than is open held open by a lug 140 elevated normal position its when the sleeve member the auger starts motor of ground ground cylinder the and of scraper 12 120 of 113 is line 129 relay Rt. valve 118 is via a wire 146 and the microswitch as when a short time period for above to thereof to upper 10 and the 11 in operation a of index retraction for a short bridge the lower closed typical 33 time contacts for bridging example button causes of the switch to of the upper switch contacts energizes the off-delay relay R3 for by the retract solenoid 102 of valve 97 130 131 which hold them plate button switch 126 and holding pressed pole 128 moves lug 88 mentioned. FIGS. with The simultaneous wires and wire valve volt cylinder two seconds. The actuation of the push by and lowering plate between the switch contacts 119 thereby energize the 65 the index between begins pole 125 seconds are preferably a normally 105 terminal via a wire 143. ground and wire 135 between solenoid of water valve 87 is connected therepast button typical a conven- 5 volt is connected actuation of the push seconds off-delay and set solenoid closed cycle a conventional desired time values employed The for off-delayrelay on-delay R4 is wire 135 and ground the above-described seconds to enable type cycle events shown The norposi- 118 respon- 12 thus energizing 112 108 between Referring illustrated. set for 5 on-delay adjustable-delay these set for 3 off-delayrelay R3 on-delay. is solenoid valve connected The scraper timing with 118 in a 134 via a wire 141. The solenoid 117 of the packing 119. typical a conventional seconds off-delay a conventional various a machine comprises on-delay relay Rt tional 10 The raising 50 valve lowered of a planting cycle. planting cycle planting circuit timing set a Valve by the reversal of valve FIG. 92 95 lines reversing in a the energization of solenoid to Referring 29 closing via a wire 142 and to 119. member move downwardly connected position. operating solenoid an 113 maintains connected solenoid-operated at the beginning tion is lines causes the packing maintains the scraper blade 49 mally and Normally valve be extended. to and - blade 113 113 and 139 Microswitch microswitch motor valve of the auger ground its be presently described. 42. 114 115 including an adjustable flow control valve 116. The 45 when valve 113 has an operating solenoid 117 which valve reversing 107 between 139. on sleeve of the valve via a conventional solenoid will as 137 via a wire 138 and wire operating solenoid upstroke its connected said 5 will close seconds its after contacts the push 122 via and button is namely until the 7-second point of the cycle is reached. The index plate 33 is thus moved to the dotted released actua-a 4278035 9 view line 10 thereof of FIG. position extended 10 from previous its At full- The scraper blade 49 being in its thus scrapes the ground area where a with the index position. lowered position seedling is to be planted and the auger 45 brought point this in the all 33 plate in R4 are deenergized to elevated its 10 and the remaining FIG. the above-described to RI relays extended position in position parts cycle responsive to repeat another to seed-gizes modifi-the Since the planting over position energize the on-delay relay R4 the cycle contacts contacts 123 121 to close and move downwardly same time ener- machine and member microswitch rais- 29 144 10 to and moves downwardly 33 and the auger wire 12 volt 135 to the which energizes solenoid 119 disclosed of the invention within and of an and tree improved shrub the foregoing description in may occur intended to and those skilled it the the in adaptations and that are intended the meaning is being various modifications within that it is machine after location. planting containerized been The 126. the cycle embodiments specific cations should 15 comprehended be to of range of equivalents the disclosed embodiments. 129 wire line for Therefore art. switch repeat to the next planting be understood scope The closure of contacts ing a planting hole 53 to be dug. 121 connects rotates caus- reset certain have lings will 139 energizing the solenoid 107 of valve 104 via wire 138. Thus the index motor auger now to While sleeve button the push moved closes microswitch plate of tion therefore to point of relay lowering plate opens this the as R2 turns on at 108 causing valve so the 5-second at This close. solenoid 112 of the index ing cylinder 5 site. 122 of relay R3 are closed the contacts causing is What of the scraper cylinder the scraper blade to be claimed is A 1. is seedling planter comprising frame portable car-becomes 118 wire via raised so 143 that and causes does it auger. As the 7-second not hinder the descent of the 20 means means frame R3 times out opening slidably relay contacts opening 108 restoringsaid ergizes the solenoid 112 of the valve said This deep- 123. rigid to shaft by index said index vertical two vertically plate a at means and shaft spaced depending said rotatably and plate said means vertical means mounted on shaft horizontal movable between being 122 whereby relay R4 contacts deenergized reached is a connected - point of the cycle bearing vertical distance from radial on levels means auger said posi-upper valve 30 to nal the index Also elevation. and configuration original its to raise the opening of member reaches causing 25 cylinder by lug 140 139 from said means auger index said at opening said between sleeve as means shaft discharge 33 and auger 45 to their origithe auger motor 42 is turned off by plate microswitch vertical a retracted distance radial index said and position a seedling having plate but spaced being plate rotatable an extended position carou-the 29 limit 145. This energizes the valve ing cylinder 97 full-line extend position thereof FIG. in FIGS. 1 75 element pawl 136 causing wire via closed is this 30 to As 10. 4 or 76 index occurs FIGS. 56 opening 35 the containerized seed- moves a seedling container 70 hole sel and a ratchet tooth 71 on that to index said said raise extended said to being in vertical extended in said seedling tray forms index said retracted in said plate means auger thereafter horizontally plate the so means position to the this means to lower tion by lug solenoid 103 of index- from the dotted view 33 to be extended 8 upper limit of microswitch 144 its reached is As travel. a planting and plate said position with registry hole rotate it discharge planting said of the index plate position means mounted to rotate around said said tray means being peripherally means vertical shaft formed to carry communica-As move-thereby con-water engages ling rotatable into vertical charge and carrier with registry 60 and opening wardly adjacent the subjacent water vertical 46 tube drop stationary and with the up- 40 conduit discharge tubular dis- 86. means to such tively register index plate to rotates extended its 1 89 near the end of the extension stroke and microswitch energizes the solenoid of water 87 valve means to 45 a of with is to such in steps index pressure to plate as cause to said when opening extended position into the and the top end seedling container responsive said distance radial respectively said under vertical spaced said discharge to water at means said brought inject registering ment pro- tray containers full-line 33 plate of FIG. of evenly plurality containers said rotate vertical 10 which takes place in about secposition ond the cam 88 engages and moves past the plunger of the index a seedling of to the extended position ex-Three ele-When conduit through seedling container 86 newly the into the seedling seedling and the adjacent seconds for after contacts wire via 135 and 121 cylinder to extend blade the packing relay opening its and of relay cylinder 5 R4 its valve 50 starting to the site of the planting hole. soil planting The said 60 hole. seedling scraping blade so as the pack said 4. planter distance radial of claim means depending and from 1 and located being retractile the index plate between at said means and said discharge opening. The seedling planter of claim 4 and means to vate said means substantially out of scraping blade when said index plate and auger means ground contact auger 5. opens cylinder original to The seedling planter of claim 1 and extensible soil blade means carried by said frame means and The seedling planter of claim 2 and means to tend said packing blade means against the soil adjacent to the planting hole after the seedling has been moved into 113 via wire seconds at after to contacts solenoid retract position. the the 12-second becomes deenergized 121 and packing causes the packing blade 52 to 52 55 been seedling. relay R1 of contacts deenergizes 123 R2 close the contacts 50 to be operated R2 times out namely of contacts point of the cycle opening planted the means. located adjacent This energizes valve cylinder 142 and causes packing the newly 121. its dug by previously packing initial relay RI having said 2. hole from 3. of relay contacts the solenoid 117 of packing around provides adequate point of the cycle 120 of on-delay relayR1 close energized an 50 the growth. subsequent the 8-second at and with soil force to sufficient the hole 53 the planting into auger into amount of moisture namely tainer presented 70. The burst of pressurized water has drive whereby to move a seedling downwardly of pressurized viding a short-length period of discharge by the 120. 117 This and the packing are lowered 65 6. index to to form a planting hole. The seedling planter of claim 1 and plate rotate extended is it provided with hydraulic horizontally between positions. said wherein cylinder said means retracted and 4278035 12 11 7. The seedling planter of claim 6 and hydraulic der pivoted means pivot on said and means tion when cylin- said discharge having a rod piston and slidably upstanding rotat- 5 The seedling planter of claim 6 and wherein said to rotate the tray means in steps comprises spaced ratchet carousel seedling coupled said to tray and retraction to 9. pawl by on and with the periphery hydraulic cylinder index said contact 13. to with in registry is depending from and located said being said opening and means to means substantially out of when index said form planting a and plate means auger hole. The seedling planter of claim 12 and wherein plate rotate it is at plate between discharge scraping blade to retractable index the with provided hydraulic horizontally between retracted said means cylinder and extended positions. 14. plate means. 15 means. The 10. ground index The seedling planter of claim 8 and wherein said means is resiliently connected to said hydraulic cylinder said 10 responsive teeth extension cycles of said said means movably means and being ratchet said of means and elevate are lowered pawl cylinder hydraulic drivingly engageable performed teeth means distance radial auger vertical means evenly said seedling opening. scraping blade means means. shaft a containerized The seedling planter of claim 11 and 12. piston means on the index plate shaft with said last-named ably engaged 8. vertical a hydraulic comprises frame said to rod upstanding and means cylinder said wherein The seedling planter of claim 13 and wherein index plate is means to spaced levels with provided move between vertically it on further hydraulic first-named said said vertically means. shaft vertical said cylinder soil The seedling planter of claim 14 and extensible blade means carried by said frame means packing and located adjacent 15. of seedling planter 1 claim wherein said subse-hydraulic index to is plate rotate with provided hydraulic horizontally between it cylinder 20 means retracted and extended means to extend - the to said of the planting hole and site blade packing means the against hy-standing positions said hydraulic cylinder cylinder pivoted to means comprising soil means and frame said a adjacent quent to the planting to the delivery hole immediately of the seedling into planting said pro-means rod upstanding vertical the index plate and pivot means on having a piston and slidably vertical to the rotate with tile pawl said said ratchet means pawl the periphery on rotatably vertical means teeth of said means toward and of mounted shaft from the ratchet movement means teeth upstanding biasing rod piston last-named hole. 25 on last- 30 means teeth to disengage responsive teeth during to lowering raising 35 extension with cooperating yieldable detent yieldably hold the carousel tray means in means stepped to water plate plate injection reaches soil 40 posi- 45 50 55 60 65 for extending around first then packing to for a position to into blade said means and as then rotating activating period position the seedling and then blade means. plate then means brief container the packing means. timed dig the planting hole auger extended extended its blade 15 and rotating the index and means said said energizing the auger plate plate to said the seedling from then to planter of claim the index the index the index retrac- movement of the index plate. 11. The seedling planter of claim 1 and wherein said rotatable carousel tray means and said frame means are provided gramming means retracted position said the pawl connected The-seedling 17. driving engagement means the operatively tray the spring piston rod by allowing to drivingly engage said The seedling planter of claim 15 and wherein said blade extension means comprises a further draulic cylinder carried by said frame means and being 16. packing up- means and wherein said means means in steps comprises evenly means pawl named said said on shaft tray ratchet spaced on rotatably engaged means shaft said the index whereby to expel the planting means retracting to hole compress the packing VERTICAL SPAR GUYING EXAMINATION OF FORCES A BRIEF main-Logging John Warner J. to the skyline or high-lead line only. Line weight and sheave friction have no bearing on the problem. Specialist Alaska Region Dennis J. Caird Logging Specialist Southwestern Region analy-Pacific Virgil RIGGING BinkZey Specialist Northwest Region ARRANGEMENTS W. Logging When working with guyline sis or design with vertical spars three basic situations are encountered drum-The com-resultant Devon B. Visual Nickerson Simulations Arizona Inc. free-of Glendale. 1. Portable yarder/spar combinations distance from set to spar is fixed by machine guyline system for vertical metal or wooden spars and tail trees is designed to resist the horizontal component force generated by the tensioned operating lines as they change direction at the spar or tail tree. This is a complex because the magnitude and problem direction of this horizontal component changes with the geometry of the setup. a feel Developing for the magnitude and direction of the horizontal component is essential to predicting location and distribution of guylines both for the and the woods worker. DESCRIPTION assump-tion The satis-factory design. 2. Wood spar/yarder binations rigged tree or standing metal spar with separate sled- or trailer-mounted drumset that can be located at varying distances from the spar. Tail 3. or lift trees standing trees at the back of skyline setting away from the yarder used to provide to the a elevation skyline. sky-an as-resultant design-er By making a simplifying and examining three common rigging arrangements sufficient to give examples can be developed idea of what is happening to the horizontal component of the force during various of types spar loading. OF GEOMETRY skyline is broken into two segments for analysis figure 1. One segment describes the line from the support or spar to the anchor or drumset. The sociated vertical angle measured from the horizontal is called the back vertical angle of the The other segment skyline. scribes the skyline from the support or spar to the setting and generates the front vertical angle of the skyline. Vertical angles are visualized from the top of the spar or support. de-BASIC ASSUMPTION To keep the-problem simple and easy to visualize we have limited the possible operating lines 17 Angle - Angle Back Vert Angle of Skyline Rngle I Front Sýy Vert Angle of Skyline v CY v L 0 0 Drum or Anchor N COMBINA-the Figure plan view the direction of skyline segment from the spar or support to the anchor or drum is called theback azimuth of the The direcskyline figure 2. tion of the skyline segment from the spar or support to the turn or setting is called the front azimuth of the skyline. These azimuths are also visualized from the top of the spar or support. In the discussion that follows are used to graphs display the and direction of the magnitude horizontal component of the force generated by the tensioned skyline or mainline in the case of high-lead spars for the three basic rigging arRemember that the rangements. vertical component of force the compression load is accepted by the spar itself. In re-sultant 18 1. CASE 1 PORTABLE YARDER/SPAR TIONS A unique feature of portable combinations is the yarder/spar fixed distance from the drumset to the spar. In most cases this vertical a back provides angle of the skyline of more than 80. In this discussion the back angle is assumed to be 80. verti-cal STRAIGHT LEAD For the first example examine a combination set up in yarder/spar lead. In the view straight plan drum set is at azimuth and the skyline headed toward the turn is at 180 azimuth. 0 SL 0 A o Hack Az-. of Support Skyline L 0 0 L 0 N . E 0 7 C approxi-of LM Figure 2. direc-the Figure 5 expresses the magnitude the resultant horizontal component as a percent of skyline load. The back vertical angle of the skyline is fixed at and front vertical angle is allowed to vary through a 100 As might be expected the range. maximum horizontal force on the top of the spar is generated with the tensioned skyline horizontal and amounts to about 82 percent of skyline tension. At steep yarding angles the horizontal 80 component mately 48 tension. reduces percent to of skyline Figure 6 illustrates the tion azimuth of the resultant force. In a straight lead the direction of the resultant does not change as the front vertical angle of the skyline changes. The load is always directly away from the drumset at an azimuth of 180. Back of 50 Az Skyline 0 Az Drum Back Vert Support Angle of Skyline -50 -80 Support Drum 180 Az Front Az of Figure 3. Skyline Figure 4. 19 Front RzT -r T T Rz- 0 Vert Rngle X-Hack 198r T Back 180 T T T of Skyline T T T T T -r -r T i i i i i i -r -r 1801- C 1701- C 1601- E 0 O v 150 i 1- C pH 1- 1301- N - C i I. 1401- o 1201- O i 1- C i 1- 1101- i i 1- Y 2 1 O I y- 100 3c 701- C 601- a E C ý i 1- 50L i It 1- LO a i 1- 801- O O i i i 901- c a 1- i i i i i 1X- 1401- i 1- 101- i i 1- 0 1 UI . i I CO L9 1 ru I -. Figure LEAD ý- f9 Front Vertical SQUARE -80 i 1- 301201- O 1 i I- Rngle ru m of a t9 U m Skyline 5. tension as the front vertical For a yarder/spar angle varies. combination with an 80 back vertical skyline angle the magnitude varies from a little over 65 percent of skyline sion at steep yarding angles to around 102 percent of skyline tension when the yarding angle The direction of is horizontal. this force varies about as vertical various front skyline figure angles are examined and it is always inside the right angle described by the front and back skyline azimuths. ten-example 0 If you talk to a yarder engineer he will tell you that a square lead pulls harder. For our assume the drumset is at an azimuth of as before but the azimuth of the front segment of the skyline is at 90. Figure 8 shows the variation in magnitude of the horizontal component of the resultant force.in of skyline terms of percentage 20 5 9 . o N/ d r Xi W m1 iý i i i i i i T M mT A w . iý ia iý i J ip i i A. fi 0 4 T f f T N / 4 N 61 T M A. T 4 4 4 T A mT 4 T t ff W mT 4 4 .-.--. N mT .-- T ý Rzimuth 61 mT m f T J4.4. 1 T W mT 1 f T Mm T V Resultant M 1 ff 1 s T T l T f T l i T t11 A T 1 T T 4. 1 T W T N mT A. .----- 1 4 T T . m 1 1 iii T 09- 0- 2b- -1 O 01 0j- d 0 02 ma 0s a a 0- 09 vN -h N o .O C N 0 ý CA JN fD N N Front Rz- T T - Back Vert Rngle X-Back Igor - 90 T T - T T Rz- 0 of Skyline T T T T T T i i i i i i T T 1801I- 1701- c I h C E O V i 1601- C oo 150 h i e140h C 1301h i c o N L o o C ýc 1201h 4 0 c 701- o -- C CD o o L i i i 4Xi i h p 401- i i i i h i h 301201- 0 h i 101h i cn .0 W ru rd Front Vertical Rngle Figure SUMMARY YARDER/SPAR COMBINATIONS can be inferred then about combinations guying yarder/spar What 1. A straight lead produces the smallest horizontal load for a given range of vertical angles. When rigged in square lead horizontal loads at the or top of the spar will approach exceed the skyline tension as the front vertical skyline angle approaches horizontal. 2. the 22 -80 i h 50 CC i 601- Eao r i h 901h 801- i i 1101- 100 i i I- 3. The load at the top of spar is in the same direction 8. of ca . Skyline cn the skyline in straight lead and is at least 100 inside the spar when rigged in square lead. that a guyline set it follows behind the skyline in directly lead is still at least 10 square from the load opposing away truly the tower. on imposed as 4. The maximum horizontal component of the resultant force occurs when the front segment of the skyline is horizontal. the location 5. Changing the back guys occasionally while yarding through a quarter will help to oppose the resultant load more efficiently. of Front Rz190f 1- Vert. X-Back T T T T T 90 T r T T Back Rngle T T Rz- 0 of Skyline T T T T T T T a a 4 a a i a a i a i 18011701- a 1- 1601- a 1- 150 i 1- 1401- 4 1- 1301- N E 1 Q 4 C M 0 Ix 1201- a 1- 1101- a 1001- a 1- 901- 4 8011- 701- i 501- -1 1- 50 i 1- a i a 1- 401- 4 1- i 301201- 4 1- 101- 0 4 i 1- I . i A m W 0 I N m I I m Front Vertical l9 2 WOOD SPAR/YARDER - N 0 19 Rngle Figure CASE 1 of W 0 . 0 ui 0 Skyline 9. COMBINATIONS above Using the process developed for portable spar/yarder combinations we can investigate the magnitude and direction of the horizontal component of the force in rigged trees with separated drumsets. resul-tant For a worst-case situation such as might occur on a restricted landing a back vertical skyline .mainlin angle of 501 is As before we figure 10. will let the front vertical angle vary between plus and minus 50. as-sumed 50 Front Vert Angle of Skyline -50 Back Vert Angl a of -50 Skyline Drum Support Figure 10. 23 Back STRAIGHT Az LEAD Skyline of 0 0 With the drums at azimuth and the skyline mainline at 180 azimuth figure 11. the following graph is obtained Az straight-away Drum compo-Support sky-line resultant horizontal with the back vertical varies angle fixed at from zero when the front angle is either plus or minus to about 35 percent of tension when the front vertical angle of the skyline is zero horizontal figure 12. The nent 180 Az Front Az verti-cal 50 sky-line of Skyline Figure 11. Front Rz190 r T T 50 XBack T T T T Back 180 Rz- 0 Vert Rngle F T T of Skyline T T T T T T T T T T a a 180F 170F 1601 C O C 0 F i i 4 E o 150 F 0 v e 1401 a 4 a i 4 a a 4 aI 1301 1 C O N 4 01201 C F i - 1101 oY 1001 F U 901 4 I O . O F 4 801 a 0 c 701 C 80F i F i C z C ti O O O L O CL o F 50 4 1 a i 401 F a F i 301- 201 F 4 101 0 i F i I CA I m W 1 to M m 1 1 ý- Front Vertical m . m Angle Figure 24 7 i 12. N of W m . m Skyline CA m -50 il-assume What direction does the force would not visible. For shown a sloping line between the 90 and 1800 azimuth. When the front vertical skyline angle becomes less than the back vertical angle regardless of algebraic sign the direction of the sultant immediately switches from to or toward the test angle. No shock load is apparent during this seemingly violent transition because the magnitude of the resultant is zero figure 12. be lustration we have This situation is impossible to clearly in figure 13 flat-are display re-resultant. because when the front and back skyline angles are equal in straight lead there is no The forces are either all compressive when both angles negative or neutral when the front angle is positive. On the graph this would be dislines up and played as vertical down the -50 and 50 axes and vertical 0 180 150a Front Az- X-Back I90r T T T T T Hack 180 Vert.. T T T T Rz- 0 Angle of Skyline T 1 T T T r 1801 1701 1 1601 T T T 4 1 a a i i r i 1 a 1 1401 1 1301 1201 4 4 1 Q 0 C 4-1 e 4 r 1101 1001 901 801 1 1 01 4 a 4X4 4 ra i 1 601 50 i 1 i - 1 401 4 1 A 4 101 a 4 301 201 1 0 -50 -1 1 A 1 i I Ln I .A W I N I - - I Front Vertical Rngle Figure M of W . UI Skyline 13. 25 re-case straight-lead yarding with a separated drumset an extreme may be encountered when downhill logging or when landing logs close to the base of the tree. The magnitude of the front vertical skyline angle can exceed the back vertical angle. This causes the azimuth of the to switch toward the drumset since the back vertical skyline angle is now the flattest Again no shock load is angle. introduced because the magnitude of the resultant is very small during the transition. In must resist. the resultant vealing The direction is also very of spar feels a force pushing toward an azimuth of for equal front and back vertical angles through about 57 when the skyline is horizontal In other words if ure 16. suddenly cut loose the spar would tend to fall between the log slip and the yarder. The 45 it fig-resultant SQUARE LEAD the previous 50 back angle and placing the system in square lead with the azimuth and the front drums at segment of the skyline at 90 azimuth figure what occurs Assuming vertical 0 14 The magnitude of the resultant horizontal component varies from 90 percent of skyline tension when the magnitude of front and to back vertical angles are nearly 120 percent of skyline tension when the skyline is horiBecause of zontal figure 15. the separated drumset this system definitely pulls harder in square lead at least when considering the force the guylines 50 Back of Drum 26 COMBINATIONS Guying a wooden tree is significantly different from guying a portable spar/yarder combination because the load the feels can come from the spar front side or back of the spar direction changes from as yarding straight to square lead and as the front vertical angles change during each yarding and landing cycle. 1. load-bearing 90 Figure WOOD SPAR/YARDER Because of this a more uniform guyline arrangement is necessary than for the portable combination since spar/yarder side front or front-quarter guys may become primary guys as a square lead is approached or when landing logs. Az Support SUMMARY 2. Az Skyline 0 Flatter back vertical angles For this problem. accentuate instance a square-lead setup with a 10back vertical angle a resultant force generates toward an azimuth of only 33 if the front vertical angle is 50. The correct placement of the guylines is primary load-bearing case intuitive in this hardly 14. Az Front of Az Skyline 3. It follows that guy anchor selection can be more there may be Indeed critical. in which to no safe quadrant hide a questionable anchor or Front AzX-Hack 190 r T T T T T T 90 Back Rz- 0 Vert Angle of Skyline T T T T T T T T T T t T 4 T 4 1801c 1701 C 1601- 0 4 1- E o O v e C aH I I O . N . O 0 c O C O 19 L CL 4 4 1- 1301- o 1201- O 4 4 4 1- 1401- - C 4 1501 N O 4 1- c 4 1- 1101- 4 1- 4 100 4X- 9011- 4 801- 4 701- 4 1- 601- 50 C 4C e $ 4 4 1- 4 4 4 4 401- 4 1- 301- 2011- 101- 0 -50 4 1- 1- a 1 1- 1 m ill I m 4h. 1 1 a1 ru 9 l9 -ý 4 4 4 W 1 m Front Vertical Figure m t9 Angle ru m of m . cn t9 Skyline 15. fol-the get by with an excessively guyline angle. steep An operator should weigh the possibility of moving the yarder as leads change in order to lessen the magnitude of horizontal component of the resultant force. 4. increase ground clearance lateral yarding easier. to make Established state logging safety codes limit some of the cable For the geometry at tail trees. of this example the purpose lowing assumptions which are within the tolerances of current state logging safety codes are made. fig-in CASE Tail 3 TAIL OR LIFT TREES or lift trees are employed skyline yarding to elevate the skyline at the back end of the setting to provide additional deflection to improve skyline load-carrying capability and to The vertical angle of skyline from the tail tree to skyline anchor is 301 1. the the ure 17. 2. The front of the the setting skyline azimuth in tail tree towards is 0 figure 18. 27 -. 150i 100i Front Az- X-Hack 1 9 Or T T h 90 Vert. T T T T T T Hack Rz- 0 Angle of T T Skyline T T T T T T T T i 18OE -I i i 1701- i 1- 1601- 1- i 1- 1401- - h - 1301- a 1201- i 1- 1101- i 1- 4 1- 4 -1 i 4X4 i i 901- a e 0 1 i i 1- 801701- i 6011- i 1- 501401- i 1- 301201- a 1- 4 101- i 1- 0 W . I I UI I . m N m 1 I Front Vertical m Il9 N Angle of Figure GJ . Ui Skyline 16. Az Front 30 Front Vert Angle of Skyline of Skyline 0 Az -----300 --------Back Vert Angle of Skyline 50 Support Anchor Support 172 Anchor Back Az Az of Skyline Figure 28 17. Figure 18. -50 The 3. back azimuth of the angle could approach 500. The resultant force is pushing on the tail tree toward an azimuth of 150 or only 30 away from being pushed straight over ward. As the load proceeds toward the landing the front vertical When angle changes. the front vertical angle of the the skyline reaches horizontal tail tree feels a force toward an azimuth of 40 figure 19. back-figure skyline from the tail tree to the skyline anchor is 172. In other words the anchor is 8 out of line with the skyline 18. 4. The front vertical angle of the skyline will not exceed 50 figure 17. Using these assumptions and tracking the situation from log pick-up to landing what force does the tail tree and from what direction This azimuth is only 40 from pulling the tail tree straight over frontward. In other words during any yarding cycle the tail tree can feel both ward and backward pulls. If the front-tail feel When a turn is up near picked tree the front vertical the Front AzX-Back 19Or T T T T T 1 Vert. T T Back 0 T T Rz- Angle of T T T 172 Skyline T T T T T T 4 1 i I a 1 1 I a 4 4X4 a i 4 i 4 18Oý 17Of 1601 4 I- 1 a 1501 1401 1 1301 1201 1 1 4 1 N Q 11 C 4 e 1101 4 1001 901 801 701 601 4 1 50 -30 4 1 f 401 301 201 1 4 1 i -4 1 -1 101 i i 1 A I . I W I N 1 - Front Vertical -. m lD Angle Figure N of CA . at Skyline 19. 29 vertical angle to a high of 25 percent of skyline tension when the front vertical angle is maximum 501 at a of yarding from directly in front of the tail tree. Another high point of about 18 percent of skyline tension occurs when the skyline is horizontal figure 20. out-of-line with the skyline as in our example there is also a force component trying to push the tail tree over sideways. anchor is verti-angle deter-we Using the same geometry we can examine the magnitude of the resultant force on the tail tree. For the 30 back and the skyline vertical misalignment have assumed the magnitude of the horizontal resultant varies from a low of about 12 percent of skyline tension when the front vertical angle is balanced in magnitude with the back vertical angle regardless of the algebraic sign of the front The magnitude of the back angle of the skyline mines when the maximum resultant load occurs. When the back vertical angle is steep the maximum force occurs when the front vertical angle approaches horizontal and the tree is being pulled forward into the setting. Conversely when the back 8 cal verti-Front Rz- X-Back 190 r T T T T T 0 Back Vert Angle T T T T T Rz- 172 of Skyline T T T T T T T T 4 a 4 i 4 C 1701- C 1601- 4 a 1- E 0 150 o v 14011- -4 f 1- C i i 1- 1301- c o 1201- N - o c Y _ n O O o a i f 8011- f 4. f i a i 1 1- 401- f 301- i f 1- 101- f f 4Xi 1- UI A to W m R m . m Front Vertical Figure 30 i 4 1- 201- I f f 1- 50 f 1- CC i 4 4 F 601- O 0 a i 901- C e f 1001- 701- O o 4 1- 1101- 0 C 1 i 18011- . m R m Angle of 20. W m -N m Skyline UI m -30 cal angle is flat the maximum force occurs when picking up a turn from directly in front of the tree at which time the front vertical angle is maximum. The tree is being pushed over backward toward the anchor. SUMMARY TAIL OR LIFT TREES lateral forces on the tree and simplifies the guying problem. 5. The maximum horizontal load on a tail tree occurs either when the back skyline vertical angle is steep and the front segment of the skyline is or when the back vertical is flat and the front angle vertical angle is steep as when in picking up a load immediately front of the tail tree. hori-zontal in-this en-2. 1. Four guylines spaced uniformly around the tail tree should be employed whenever yarding activities will generate a wide range of front skyline vertical In some states angles. is a requirement. The back vertical angle of the skyline and the range of possible front vertical angles should be taken into account when guying a lift tree with The possionly two guylines. bility of putting the guys on the wrong side of the tree is very real. 3. It might be helpful to consider selecting tail or lift trees beyond the area to be This has the effect of yarded. minimizing the range of front vertical skyline angles experienced while yarding the entire setting thereby simplifying the guying problem. CONCLUSIONS The foregoing discussion is tended to give the logging gineer or woods foreman a sense for the direction and magnitude of the horizontal loads imposed on various types of spars or These horizontal supports. loads must be resisted by the Ideal guying guyline system. situations are seldom found in a cable logging operation but careful attention to the general observations made should help avoid problems and make the best of the situations we face. with limited or questionable guyline anchors When faced unusually tall spars high tensions limited operating yarder positions or artificial anchor designs a more detailed See analysis may be helpful. Vertical Spar Guyline Force Analysis Using a Desktop D. Nickerson U.S. Forest Service Region for 12/80 such one analysis technique. Compu-anchor worth some extra effort to select a skyline as in-line with the skyline as possible. This minimizes the magnitude of the 4. It is ter 6 31 REST SEt U S ENTOFA6RK TO READERS OF INVITATION NOTES FIELD reader Every is author of an article for Field Notes. a potential we If you have a news item or short respec-tive informa-tive article Field in would you like to share with Service engineers the Washington to Regional Office to see that and of interest vary from news you to send for publication it Notes. Material submitted may invite items are to ideally 7113. The typewritten of length be submitted material short articles Office should drawings original by the accurate pages however the Washington to should illustrations all FSM several submitted All material preferred. and double-spaced sentences short be reviewed current timely technically is Service Engineers Forest to several Office for publication should the information be glossy or typed prints or negatives. Field Area list to Notes distributed is ask your Office Manager increase from from the number the Washington Field personnel their Regional the Washington Forests and Forest Headquarters of or Office Service the Regional copies sent to you all Regional not currently are Copies of Data back Station Systems issues are and on the mailing Coordinator also available Office. should submit material for publication or questions concerning Field Notes to Coordinators Wood Larry Bruesch R-4 Ted R-2 Mike Clinton R-5 Paul Stutes R-3 Juan Gomez R-6 Kjell Bakke R-8 Tom problems If Engineering Technical your office. R-1 Coordinators to directly retirees. should direct questions concerning R-9 Mujeebul R-10 Fred Baxandall WO Al Hasan Colley Vanderpool format editing publishing dates and other to Forest Service-USDA Engineering Staff Attn Gordon P.O. L. RP-E Rome Bldg Editor Box 2417 Washington Telephone D.C. 20013 Area Code 703 235-8198 33 OpEST SERVq U4s EMT ofAiRK INGIIýý L7ý September/ Volume 13 October 1981 Number 7 Engineering Field Notes