Notes Field Mee ENGINEERING

advertisement

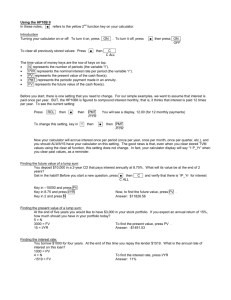

7y ENGINEERING TECHNICAL INFORMATION SYSTEM NOTESTECHNICAL REPORTS DATA RETRIEVALMANAGEMENT PROFESSIONAL DEVELOPMENT FIELD VOLUME -PP llrtjraiiisfor in Abandoned Washinqton Civil Hand Calculators Strip Aline Reclamation Mee News JANUARY sw4 U.S. 1 Enqineerinq FOREST SERVICE F.s NUMBER Notes Field Selected 11 DEPARTMENT OF AGRICULTURE 1979 US ENGINEERING Volume Information contained in this FIELD NOTES Number 11 has publication 1 been developed for of guidance employees respon-sibility of the United Federal cooperating the for The and State or service text in may be the be construed or policy except engineers not by its contractors Department of Agriculture of this information names use does not in this by other than publication constitute is an official for and its assumes no its own employees. the information and endorsement or approval by the United States Department of Agriculture to the exclusion suitable. as FSM and engineering intended The corporation publication must not Service Agriculture-Forest agencies. Such of the reader. that of interpretation or use product of others The Department of trade firm or use convenience of any States exclusively the represents recommended personal Because references. technicians opinions or approved should of the read of the respective procedures mandatory type each issue however FOREST SERVICE DEPARTMENT OF AGRICULTURE Washington D.C. 20013 instructions of material in the publication for engineers. U.S. author and this publication all is EDITORS NOTE This issue introduces some format changes to Field Notes. First we are now using the Courier type style this larger more open type will make this and following issues easier to read. We also are using larger paper Government agencies now have the option of using the commercial x 11-inch size their for publications. paper 8 Gordon Editor L. Rome SELECTED PROGRAMS IN CIVIL FOR HAND CALCULATORS ENGINEERING BernhoZd Rankenberg 5 Region Com-puter solu-tion. are times when it is not practical to use the Regional Center or mini-computers in Civil Engineering although the recurring nature of some problems those consisting of a series of arithmetic calculations makes them amenable to a programmed Use of hand-held programmable calculators such as those found in most National Forest Engineering Offices provides the alternative method. necessary There Pro-grams nec-essity mag-netic calcu-late here are written for calculators The programs presented that use such as Texas Instruments Model SR-52. algebraic notation usually can be stored on magnetic cards to eliminate the of keying-in the program each time it is used. Without This not cards the keying-in process would be necessary. only is tedious for the longer programs but the keying-in process is -- in itself -- a prime source for introducing errors. PROGRAM EXAMPLES A Three-Axle Truck on Simple Beam. This program will Program maximum moments and shear at any point in a simple beam loaded with a 3-axle truck having axles 14 feet 4.27m apart. The truck loads are AASHTO HS loads. The usual procedure is to select a maximum moment from AASHTOs Standard Specifications for Highway Bridges for a given span then the moment curve is calculated using the assumption that it is That assumption is erroneous however. The moment for parabolic. 40-ft. 12.19m span for example is approximately 6 percent low at the 1/4 The error point using the parabolic assumption. for longer an 80-ft. 24.38m span has a 20 percent spans error. This program will not work for off-highway loads or for spans of less than 14 ft. 4.27m. in-creases The moments are based on the shear diagram for the area under the The center moment however rear axle of the truck. is calculated the center of the span equidistant by placing from the resultant of all axle loads and the nearest axle. It is likely that the area calculation used in this program could be used as well on procedure a moment beam diagram to calculate deflection by the conjugate method. 1 a The shears shears for given produce a moving load 4.27m from Ra. a shear envelope of maximum and minimum they are given until x in Program A is mo-ments fac-tor pin-con-nected 14 ft. B Moment Distribution. This program will calculate structure shown. The user must provide fixed-end and distribution factors for each joint. The carry-over is assumed to be 0.5 therefore the sections must be uniform. end joints can be assumed to be completely fixed or ends. or nonexistent i.e. a structure with cantilever Program in The the This to problems in sidesway and program probably could be adapted It can be applied to haunched members by temperature expansion. going into the program and substituting. an appropriate carry-over factor other than 0.5. the operations involved are simple and repetitious they Although must be made in a specific sequence and the results must go to a With eight moments to manipulate the program specific location. is a long one that requires 218 steps. mo-ment C I Moment of Inertia. This program will inertia of an section one or more of eliminated and the program will still work. Program calculate the the flanges can iner-tia compos-ite of be the moment of program is especially useful in calculating To do so use the given thickness of composite sections. width for the flange and slab but calculate an equivalent slab and flange using an appropriate N value. The program also is helpful in the beam method for calculating conjugate As shown in the exhibits the program produces other data including the distance of the center of gravity from the bottom This of deflec-tions. flange. so-lution D Mannings Program 7-36 shown is in by Equation. This program solves the Equation The 5th. Edition pages 7-13. Kings Handbook trial and error but converges rapidly generally two de-rive or three trials are adequate depending on the accuracy desired. After the proper depth is calculated to produce a given pressing the RUN button will calculate velocity in fee per second. Q This program might be improved the equation to by manipulating function of D directly rather thereby calculating than using a trial-and-error method. However since X and Y are defined in terms of the small increase in convenience does not seem to justify the effort. D as Q a D 2 EXHIBIT 3 Truck TITLE Axle -OAK on A Span Simple PAGE I --T I-x PROCEDURE STEP P1 OF 3 fBK ENTER PRESS P1 STO 02 P STO 03 L STO 06 X. A P2 P2 1 2 L DISPLAY RB RA Mx vMAX RCL ASSUMPTIONS RCL 05 1. /141 RCL 04 2. Y 4.27m 18.67 B 5.69m 3 RA MMAX RBVX 4 - 07187 2 6 a 3 5 0 2 1 222 0 X RCL 035 0 X 182 RCL 070 4 RA 147 3 11 RCL C 0 FLAGS 19 3 0 0 03042 217 18 105 B 17 2 177 065 16 HLT 0 15 4 1 0 RCL 025 RCL 1 100 RCL 172 2 X RCL D 05567 Pos f i INV 4 03 P2 X 060 3 92 020 207 RCL 0 095 6 C 1 06 2 0 RA 04 02 P1 127 015 STO 090 8 6 2 0 6 162 - 050 RCL 0 1 122 010 2 D X E 97 RCL 085 _ 57 6 045 RCL 0 4 117 005 RCL 1 92 1 E 080 4 D 0 1 0 3 Main ST 152 040 RCL B MMAX Pro 137 i 212 13 0 12 11 10 5 09 08 07 L 05RBVMAX RA 01 X 00 R REGISTERS 0 C B A if P10 RB2P2P1-R ram LABELS 9 A COMMENTS11 KEY A LBL X CODE LOC COMMENTS KEY CODE LOC COMMENTS PAGE 2 00112 CODE LOC KEY PROGRAMMER DATE OF 3 Span Simple on Axle 3 Truck TITLE TITLE 3 Truck Axle on Simple PAGE Span PROGRAMMER LOC CODE KEY . OF 3 DATE COMMENTS CODE LOC KEY COMMENTS LOC CODE KEY 000 112 B STO RCL 04052 0 0 HLT 5 117 2 045 57 2 08092 A 0 B C RCL D 0 3 3 197 E REGISTERS X 3 E LBL 085 01122 C 0 RTN 6 005 LABELS A - X COMMENTS 00 2 050 62 01 X 02 09 202 RCL RCL 015 127 0 3 0 6 05 _ 06 055 X 67 4 207 10 - 06072 11 7 12 C 100 RCL 025 137 08 09 1 HLT LBL 095 0 MMAX 02132 07 RCL 1 03 04 212 13 0 RCL 14 4 0 15 6 16 os 177 17 2 ST0 X 0 RCL 5 030 142 070 0 182 3 10 217 18 19 FLAGS 0 RCL 0 1 110 222 5 03147 2 RCL X 3 0 RCL 4 075 2 87 0 5 EXHIBIT Moment TITLE f B Distribution PAGE K 1 4 K PROCEDURE STEP A ENTER B PRESS DISPLAY F C D JE ASSUMPTIONS 1. Constant 2. JTs A any degree of All distr. factors 3. OF Section. F can be fixity. ar entered with minus signs. 1. F.E.M CF STO 02 2. F.E.M. CE STO 03 3. F.E.M. BD STO 04 4. F.E.M. FC STO 05 5. F.E.M. CB STO 08 6. F.E.M. BC STO 09 7. F.E.M. BA STO 10 8. F.E.M. AB STO 11 9. Distr. factor CE - STO 12 10. .Distr factor CB - STO 13 11. Distr. factor BD - STO 14 12. Distr. factor BC - STO 15 13. Distr. factor BA - STO 16 14. Distr. factor AB - STO 17 15. Distr. factor FC - STO 18 6 TITLE Moment Distribution PAGE ENTER PROCEDURE STEP Distr. 16. factor PRESS CF - STO A MOB 4 OF fBK K MDB% 2 MBD 0 if if D D is fixed. is pin-connected. DISPLAY 19 M @ JT RCL 02 MOM. CF RCL 03 MOM. CE RCL 04 MOM. BD RCL 05 MOM. FC RCL 08 MOM. CB RCL 09 MOM. BC RCL 10 MOM. BA RCL 11 MOM. AB B TITLE Moment Distribution PAGE PROGRAMMER LOC 00112 CODE 3 OF 4 DATE KEY COMMENTS LOC LBL CODE KEY COMMENTS LOC 0 KEY A SUM A CODE FEM COMMENTS D.F.CB BD B 152 D 4 ST0 c RCL 0 o 0 00517 192 6 oa157 SUM 1 SUM 1 FEM AB BA 0 13 X B RCL 18 C RCL 14 RCL 12 RCL 17 1 OF. CF STO 0 7 7 BC SUM 015 127 SBR 1 00 2 0 FEM DF CE 9 SUM 0 05167 FEM CB SUM C FEM X A 8 DF CB 09207 020 132 X D CE 3 RCL B 2 DF BA 06072 6 137 0 0 9 0 6 C 8 06177 8 FEM 10212 STO BC FEM CF FEM CE 04 FEM BD 05 FEM FC 06 Storage 07 SUM FEM CB Storage 08 FEM CB 09 FEM BC 10 FEM BA 11 FEM AB 13 DF CE DF CB 14 15 RCL x dsz 03 t2 SUM 025 C F B 16 DF BA 17 DF AB CC X E DF 1 BC DF CF 10217 7 030 _ 18 DF FC 19 O F C F 142 STO 0 070 82 B 0 x 5 035 147 0 SUM 7 C FLAGS SUM 2 2 FEM FC 110 222 FEM CF 0 1 2 RCL 0 3 4 DF C BD 075 87 X 8 19 02 X D BC RCL 01 C 09202 D E 08197 0 DF JTC C RCL E @ 15 B 050 162 EM A RCL 1 X JTB 16 010 122 @ RCL E 6 SBR FEM Prog. EM RCL 080 D.F.BA LABELS Main B 040 X A TITLE Moment Distribution PAGE PROGRAMMER LOC CODE 4 OF 4 DATE KEY COMMENTS LOC CODE KEY COMMENTS LOC CODE KEY COMMENTS LABELS 000 5 112 3 X B D.F. BC 04052 RTN B 0 LBL C 4 2 080 192 005 117 SUM 0 FEM CF 04157 B D RCL E RTN 1 LBL 8 C 2 122 B C LBL D RCL 1 0 RCL 2 1 08197 A RTN RCL 1 A RCL C E REGISTERS 00 050 X E 4 162 D.F.AB RCL 090 0 01127 2 _ SUM 02132 02 LBL 03 RCL 05167 RCL 1 0 0 8 1 2 09207 B STO RTN D 3 06072 01 04 05 06 07 RTN 08 LBL 09 RTN E LBL RCL 11 1 12 0 D 0 RCL 10212 7 10 13 025 137 dsZ RTN A HLT LBL 6 06177 LBL RTN 1 LBL RCL 14 15 16 17 105 B E 217 1 18 030 19 RCL 142 RCL 0 182 5 0 RTN 9 FLAGS RTN 1 070 1 LBL 11222 2 036 147 RCL 1 0 A 3 RCL 4 075 187 1 9 EXHIBIT Moment TITLE of Inertia of I Section PAGE -AN PROCEDURE Enter 1 3 OF fBK STEP 1 C height bottom ENTER Enter width 3 Enter height 4 Enter width 5 Enter height 6 Enter width DISPLAY of flange 2 PRESS of of of of of bottom flange web web top top flange flange STO 01 STO 02 STO 04 S.TO 05 STO 07 STO 08 A 7 10 Ad2 10 RCL 03 Area Bot. RCL 06 Area Web RCL 09 Area Top RCL 11 4 RCL 12 Ad2 from Flg. Flg. Bot. TITLE Moment of Inertia I of Section PAGE PROGRAMMER LOC CODE 2 3 OF DATE KEY COMMENTS LOC CODE KEY COMMENTS LOC CODE KEY COMMENTS LABELS 000 112 LBL A X A RCL RCL B 0 C 04052 RCL 3 0 D 0 080 1 005 921 X E 4 2 A 117 RCL 045 0 1 57 SUM 2 1 A.Y. X B RCL C 0 D 9 E 085 0 197 010 1 22 REGISTERS SUM 0 Al RCL 3 RCL 015 0 05062 1 4 0 - 4 2 00 SUM EAY 02 0 09202 01 RCL 03 Bot.of WWidthFof at. la. Area f F1 Bot. 04 Ht. 05 Width RCL 06 ofeWeb 0 0 07 Top 5 1 1 127 X 0 RCL 05167 095 207 020 09 0 132 SUM F1 Top 0 Fla. rea 10 X of t 1 08 RCL Web of 0 EAY 060 0 A2 172 6 RCL 02137 11 RCL 0 RCL 12 6 0 13 10212 0 14 6 15 SUM 7 6177 X A2A1Y RCL 16 0 17 9 18 RCL - 19 0 STO 1 0 RCL 5 10217 0 03042 8 FLAGS 070 182 SUM 0 A 0 7 1 - 1 110 222 2 9 03147 RCL 187 1 3 4 075 1 y 2 RCL RCL 0 EAd2 0 L1 Web TITLE of Moment Inertia of PROGRAMMER LOC CODE I PAGE_-OF Section 3 DATE KEY COMMENTS LOC CODE KEY COMMENTS LOC CODE KEY COMMENTS LABELS 000 112 0 A x SUM 1 oaa 1 152 2 A A d 2 RCL B 0 C D 2 080 E 192 00517 RCL RCL 1 A RCL 0 0 B 7 4 C yx D oa 1 157 X 01122 085 2 E. 3 97 11 x REGISTERS x RCL RCL 00 RCL 050 0 162 3 01 0 1 02 5 090 03 202 015 1271 SUM 1 2 A1d2 05167 RCL RCL 04 0 0 05 4 7 06 x 07 y 020 RCL RCL 3 08 0 1 X 09 1 RCL 10 8 12 132 4 09207 1 060 11 nz - X2 2 100 13 212 025 137 RCL 1 14 RCL 0 065 77 0 1 15 9 2 16 17 _ 03142 RCL SUM 1 1 1 2 10217 EAd2 RCL 1 19 EAd2 FLAGS 2 EAd 182 X2 18 RCL HLT ID 0 1 110 X 0 R C L 1 2 222 035 147 3 4 yx 0 075 6 187 3 12 EXHIBIT TITLE s Manning for Equation Trapezoidal D Channel PAGE fAK 1 OF 4 -OBW PROCEDURE STEP ENTER PRESS DISPLAY e LD This is trial a 486 1 1/x2 n here 1. Z z and Z21 e D X D b S Slope N Mannings D Depth Q CFS Enter average ratio of 5/3 1/x Z of 8/3 D of the f llowin 1/2 2/3 l T/FT stream N Known side 21 2. Enter width 3. Enter Slope 4. Enter Mannings 5. Enter Assumed of slope to as vertical Z 2 bottom N 01 b Ft STO 02 S Ft STO 03 STO 04 STO 06 N Depth STO D Ft A 6. 7. uaton a S /2 horizontal Example solution error If Q is incorrect enter another D 13 STO 06 Q CFS TITLE Mannings Equation for Trapezoidal Channel -OAK ENTER 8. 9. 2 OF 4 or PROCEDURE STEP PAGE DISPLAY PRESS A If is correct RUN 14 Q V FPS TITLE Moment Distribution PAGE PROGRAMMER LOC CODE 3 OF 4 DATE KEY COMMENTS LOC CODE KEY COMMENTS LOC CODE KEY COMMENTS LABELS 11 00112 LBL A SUM A FEM 0 D. F. CB BD A Main B Prog. EM @ JTB EM @ JTC 040 B X D 4 STO c RCL 0 0 R 1 6 E RCL 15 C A RCL 13 RCL 18 RCL 14 RCL 12 RCL 17 152 D.F.BA oeo92 0 005 6 - 117 B x 045 157 SUM SUM 1 FEM 1 FEM AB C SBR BA 0 1 DF. CF D E 08597 010 RCL STO B 0 0 7 7 01 C 02 122 1 SBR 1 00 r 19 RCL dsz 050 X E 162 DF BC 09202 SUM - X - FEM CF 03 FEM CE 04 FEM BD 05 FEM FC 06 Storage 015 127 2 FEM 0 BC D DF CE 9 SUM 0 05167 FEM CB SUM C X FEM CE 07 _ A 8 02132 DF CB 09207 B 08 FEM CB RCL 09 FEM BC FEM BA FEM AB 10 X D DF BA 06072 SUM 02537 6 11 - 12 SUM 13 STO 0 0 9 0 6 C 8 081 B 77 E DF BC BC 10212 FEM CB R 1 DF CE DF CB 14 15 RCL X B X FEM Storage 3 CF BC 16 DF BA 17 DF AB 18 DF FC 19 D C F 0 DF CF 10217 7 030 142 STO 2 FLAGS SUM 070 0 182 0 SUM 7 B 0 x 5 2 FEM FC 11222 RCL FEM C F 0 1 2 035 147 C DF BD 0 C 07187 X 15 F 3 TITLE Mannings Equation for Trapezoidal Channel PROGRAMMER LOC CODE PAGE 4 OF 4 DATE KEY COMMENTS LOC CODE KEY COMMENTS LOC CODE KEY COMMENTS LABELS 000 112 A 5 B 040 RC L c 152 D 1 080 1 192 005 A 117 B STO 045 1 C 157 D 2 085 197 122 E E REGISTERS HLT 00 050 01 162 02 090 202 015 03 04 127 05 055 06 167 07 095 207 020 08 09 132 10 060 11 172 12 100 13 212 025 14 137 15 065 16 177 17 105 18 217 030 19 142 FLAGS 070 0 182 110 2 222 035 3 147 4 075 187 16 ABANDONED STRIP MINE RECLAMATION AZ VanderpoeZ Engineer National Wayne-Hosier Forest For-res Almost 10000 acres 4047 hectares of the Wayne National Forest in southern Ohio are scarred by abandoned strip mines. In 1978 as a result of a grant from the Appalachian Regional Commission the Service undertook its first large-scale reclamation of such lands on 40 acres 16.19 hectares that had been mined soon after World War II. Known the Yost Tract this area was characterized by 50-ft. 15.24m vertical walls strip pits filled with acid water and mounds of overburden material Fig. 1. Because of the exposed coal residues there was almost no vegetation and surface water runoff was very acidic the pH level in the soils ranged from less than 3.5 to as 5.5. ti 1 . yp R Figure 5 i a v 1.--Conditions work before reclamation and strip pit spoil bank 17 . showing i highwaZZ A Forest Service team of specialists developed guidelines that were to reclaim the site and in used in preparing a contract package consisted of Use Plan for the area. The a Land plan developing the acid water ponds 1. Draining 2. Burying as much acid material as covering the site with a minimum 60.96cm of nontoxic material and inches possible 24 of 3. Restoring the land to its original top of the vertical walls contour 4. Covering 5. Cleaning and opening 6. fertilizing and revegetating grasses immediately and 7. Planting to the top-soil the area with 12 inches 30.48cm of drainage-ways Liming the site with appro-priate to a variety the of tree species that seemed site. in April 1978 A public works contract was awarded for this project the earthwork subcontracted to coal firm mining was a experienced with this type of reclamation work. Using D-9 dozers for clearing grubbing and earthwork the area was leveled initially and the acid ponds drained after which the site was shaped to final grade Fig. 2. Scrapers were used to haul borrow material for covering 10 4.047 hectares of the 40 acres 16.19 hectares with 12 inches of the 10 cover soil acres chosen were the worst soils 30.48cm the site.. on to replace the existing drainages on were constructed waterways stone site using Also diversion ditches were riprap Fig. 3. down the finished The halfway slope to intercept runoff. work was completed when the entire area was lined heavily with hay as mulch an and then fertilized seeded and covered the disk was used to crimp the hay into the soil. Figure is in 1. the same location as shown completed project Figure New the cut con-tractors anti-erosion 4 Three D-9 dozers two scrapers and a front-end loader were used in the project which was completed in 122 days at a cost of $4950 per The time and cost compare favorably with the acre .404 hectare. Downtime State and Soil Conservation Service projects in the area. was essentially zero but the work was delayed 4 weeks because of wet weather. 18- _r r n x 3i h7r s _ a a Alt tis a kN-Spy i ate swsyi t t t 5. t. iti . O N Q l . eK c.a r L 4 r fR O N. Figure 4.--Completed project at same Based on this work some recommendations similar projects in the future are 1. 3. 4. that could as be Figure 1 applied to Reduce construction and overhead costs by using a service contract. Calculate earthwork quantities from rather than field by work or by use photogrammetry of 2. location design Cut the land to quantities. amount of earthwork required by restoring the other than its original contour. mater-ial in sorting excavation Accomodate the difficulty in the to obtain topsoil planning stage thus borrow material is needed. Note in planning particular type of in this that the material excavated about 30 site may expand percent. 20 WASHINGTON OFFICE CONSULTATION COST-EFFECTIVENESS NEWS STANDARDS Walter Assistant E. ANALYSIS IN ENGINEERING Furen Director MANAGEMENT in 1936 benefit-cost by civilian economists Originally developed analysis evolved naturally into cost-effectiveness analysis -- a national defense familiar tool for economic evaluation of complex That tool can be applied efficiently and space exploration systems. to routine problems particularly for engineering management in which personnel equipment or dollar resources are situa-tions re-stricted. analysis of a functional Simple cost-effectiveness as geotechnical engineering can be used 1. to obtain program benefits to 3. to available from a limited effort determine investigation for the program 2. 4. maximum such specialty intensity levels required commensur-ate to as provide assurance that work levels are with project opportunities risks and values costs as develop an awareness of operating unit costs for meaningful work segments. SITUATION and well EXAMPLES Alternative Methods to Accomplish Work Element. a Specific Evaluating Suppose that laboratory work is being accomplished by force account and that commercial facilities to are available methods laboratory do that work under contract. The cost elements in this situation then can be compared directly on a unit cost basis. of To provide a comparison base determine the relative importance other pertinent elements such as responsiveness turnaround time and other factors. Then availability of equipment accuracy 21 alter-native for each independently evaluate each element including cost factors. The and compute a weighted rating for those alternatives. weighted ratings are a means for comparing the Determine 1. 2. 3. Priorities for Projects and Programs.. For each unit of work compute the fixed cost to for the estimated time to be dedicated be expended to the work including the cost of personnel and supplies. equip-ment objectives and make a Identify the project/program Evaluate the predicted comparative rating for each. in terms of each objective. accomplishments project/pro-gram weighted ratings computed for each can be used to determine the greatest potential of in return for expenditures benefit to be derived limited resources personnel equipment supplies and dollar equivalents. The devel-oped --coupled meaning-ful day-to-day for cost-effectiveness analysis were the techniques Although the methods in to solve highly-complex economics problems with rational decision analysis -- become extremely on a tools for an engineering manager in making decisions basis. REFERENCES 1. Fabrycky W.J. Prentice-Hall 2. Grant Eugene Decision Jersey. Analysis Engineer-ing Economy 3. Economic and Thuesen G.J. Inc. Englewood Cliffs New L. and Ireson W. Grant. Ronald Press Company New Kepner Charles Book McGraw-Hill H. and Tregoe Benjamin Company New York. 22 Principles of York. York New B. The Rational Manager IMPROVEMENTS TECHNOLOGICAL Heyward Assistant SOLAR POWERED VAULT T. Taylor Director TOILET VENTING SYSTEM disagree-able conse-quently There are some 27000 vault toilets located in the National Forests. The natural odors associated with those installations are to the people using and maintaining those structures there is a tendency to avoid using them as well as to the units. postpone or avoid servicing van-dalism Other problems are related to the disagreeable conditions the is greater and people use the area around incidence of vandalism the Increased building instead of the facilities provided. results in increased maintenance costs and the human wastes on the ground can become health hazards that are transmitted by insects rodents and water. Center SDEDC has been testing Dimas-Equipment Development and to reduce the objectionable odors systems to provide ventilation in the buildings. Several general patterns and constraints were identified during the preliminary work The San 1. day-time The buildings than at are used more frequently are used more frequently during during inclement conditions 2. They than 3. Because sources 4. Servicing and the units are isolated is severely limited of during night ventilating clear access equipment to must be weather power simple 20-watt 5. Costs for installation must be The low. for the ventilation SDEDC prototype system consisted of a solar array supplying electrical energy to a small fan motor in a 6-inch 15.2cm diameter stack for the roof of the building See The installation requires only small modification to Figure. structures. existing 23 j JIV VVVV Solar-powered ventilating unit designed by SDEDC for The use in vault toilets. shows a completely photo in-staZZed unit. AW r S c 24 satis-factory. 4 and were tested in Regions 5 and they proved The solar array provides sufficient energy on clear sunny days to aspirate the structures at a maximum of750 cf/minute .229cm/minut this results in an exchange of all the air in the vault every few minutes. Since the most frequent use occurs the daytime no backup electrical system was required and the usual regulator batteries and diodes were unneccessary. dur-ing The units The Department of Energy has funds available for other Federal of agencies to purchase solar arrays for use in the development solar energy systems. The Forest Service plans to install about 500 SDEDC ventilation systems at selected sites throughout the United States about 2 percent of the existing vault toilet The cost will run about $235 per unit. instal-lations. results of this project State and local agencies. The will be 25 shared with other Federal INVITATION TO READERS OF FIELD NOTES Every reader is short article author potential you would like of an article for Field Notes. share to with you have a news item or If we Service engineers invite send to you for it Field Notes. in publication a ac-curate Material submitted to the Office for Washington Office to Regional respective that see the should publication information is current be timely FSM reviewed by the technically 7113. The length of Washing-ton and of informative material submitted however short articles Office should drawings is be Field to list short sentences news items are preferred. and double-spaced several to typewritten All material submitted to the all ideally illustrations pages be original should or negatives. Forests Office directly and Forest Service from the Washington available personnel their Forest Service Engineers several to all Regional Station and you are not currently on the Technical ask your Office Manager or the Regional Engineering Data Systems to increase the number of copies sent to your office. Copies of back issues are Coordinator also to from distributed from the Washington Area Headquarters mailing or interest vary typed prints glossy Field Notes may should retirees. If Office. submit material for publication or questions concerning Field Notes Coordinators Regional R-1 Melvin Dittmer R-4 Ted Wood R-9 Fred Hintsala R-2 Royal M. Ryser R-5 Walt Weaver R-10 F. R-3 Juan R-6 Kjell WO Al Colley R-8 Bob Coordinators Gomez should direct questions Bakke concerning Engineering Attn P.O. - format editing USDA RP-E Bldg Staff Gordon L. Rome Editor Box 2417 Washington Telephone Baxandall Bowers problems to Forest Service W. D.C. 20013 Area Code 703 235-8198 publishing dates and other