GAO NUCLEAR WASTE CLEANUP DOE’s Paducah Plan

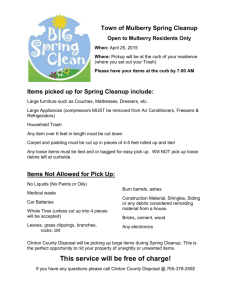

advertisement