Document 11416100

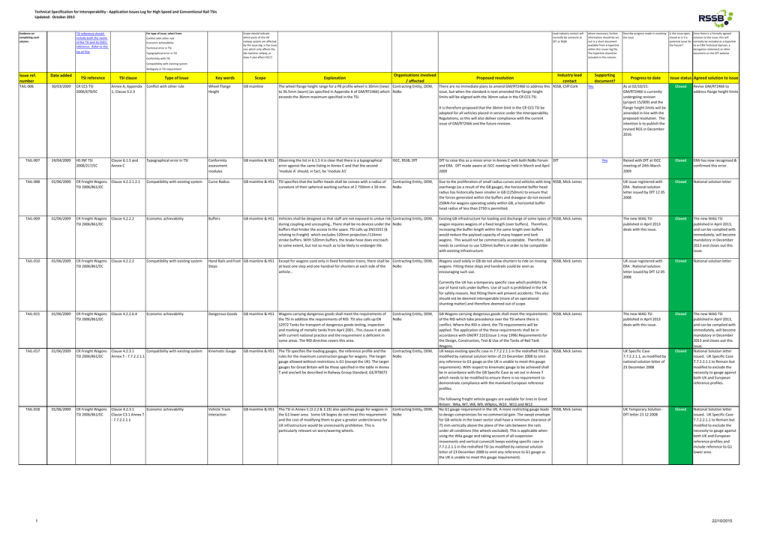

advertisement

Technical Specification for Interoperability - Application Issues Log for High Speed and Conventional Rail TSIs Updated: October 2015 Guidance on completing each column: For type of issue, select from: TSI reference should include both the name of the TSI and its OJEU reference. Refer to the Scope should indicate which parts of the UK railway system are affected by the issue (eg, is the issue one which only affects the GB mainline railway, or does it also affect HS1?) Conflict with other rule Economic achievability Technical error in TSI list of TSIs Typographical error in TSI Conformity with TSI Lead industry contact will normally be someone at DfT or RSSB where necessary, further information should be set out in a short document available from a hyperlink within this issues log file. The hyperlink should be included in this column. Describe progress made in resolving the issue Is the issue open, closed or is it a potential issue for the future? Once there is a formally agreed solution to the issue, this will normally be included as a hyperlink to an ERA Technical Opinion, a derogation statement or other document on the DfT website Compatibility with existing system Ambiguity in TSI requirement Issue ref. number Date added TAIL-006 30/03/2009 TSI reference CR CCS TSI 2006/679/EC TSI clause Annex A, Appendix 1, Clause 5.2.3 Type of issue Conflict with other rule Key words Wheel Flange Height Scope GB mainline Explanation Organisations involved / affected The wheel flange height range for a P8 profile wheel is 30mm (new) Contracting Entity, OEM, to 36.5mm (worn) (as specified in Appendix A of GM/RT2466) which NoBo exceeds the 36mm maximum specified in the TSI. Proposed resolution Industry lead contact There are no immediate plans to amend GM/RT2466 to address this RSSB, Cliff Cork issue, but when the standard is next amended the flange height limits will be aligned with the 36mm value in the CR CCS TSI. Supporting document? Yes It is therefore proposed that the 36mm limit in the CR CCS TSI be adopted for all vehicles placed in service under the Interoperability Regulations, as this will also deliver compliance with the current issue of GM/RT2466 and the future revision. Yes Progress to date Issue status Agreed solution to issue As at 02/10/15: GM/RT2466 is currently undergoing revision (project 15/009) and the flange height limits will be amended in line with the proposed resolution. The intention is to publish the revised RGS in December 2016. Closed Revise GM/RT2466 to address flange height limits Raised with DfT at ISCC meeting of 24th March 2009 Closed ERA has now recognised & confirmed this error. TAIL-007 24/04/2009 HS INF TSI 2008/217/EC Clause 6.1.5 and Annex C Typographical error in TSI Conformity assessment modules GB mainline & HS1 Observing the list in 6.1.5 it is clear that there is a typographical error against the same listing in Annex C and that the second ‘module A’ should, in fact, be ‘module A1’ ISCC, RSSB, DfT DfT to raise this as a minor error in Annex C with both NoBo Forum DfT and ERA. DfT made aware at ISCC meetings held in March and April 2009 TAIL-008 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.2.1.2.1 Compatibility with existing system Curve Radius GB mainline & HS1 TSI specifies that the buffer heads shall be convex with a radius of curvature of their spherical working surface of 2 750mm ± 50 mm. Contracting Entity, OEM, NoBo Due to the proliferation of small radius curves and vehicles with long RSSB, Mick James overhangs (as a result of the GB gauge), the horizontal buffer head radius has historically been smaller in GB (1250mm) to ensure that the forces generated within the buffers and drawgear do not exceed 250kN.For wagons operating solely within GB, a horizontal buffer head radius of less than 2750 is permitted. UK issue registered with ERA . National solution letter issued by DfT 12 05 2008 Closed National solution letter TAIL-009 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.2.2 Economic achievability Buffers GB mainline & HS1 Vehicles shall be designed so that staff are not exposed to undue risk Contracting Entity, OEM, during coupling and uncoupling…There shall be no devices under the NoBo buffers that hinder the access to the space. TSI calls up EN15551 (§ relating to Freight) which excludes 520mm projection /114mm stroke buffers. With 520mm buffers, the brake hose does encroach to some extent, but not so much as to be likely to endanger life. Existing GB infrastructure for loading and discharge of some types of RSSB, Mick James wagon requires wagons of a fixed length (over buffers). Therefore, increasing the buffer length within the same length over buffers would reduce the payload capacity of many hopper and tank wagons. This would not be commercially acceptable. Therefore, GB needs to continue to use 520mm buffers in order to be compatible with existing infrastructure. The new WAG TSI published in April 2013 deals with this issue. Closed The new WAG TSI published in April 2013, and can be complied with immediately, will become mandatory in December 2013 and closes out this issue. TAIL-010 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.2.2 Compatibility with existing system Hand Rails and Foot GB mainline & HS1 Steps Except for wagons used only in fixed formation trains, there shall be Contracting Entity, OEM, at least one step and one handrail for shunters at each side of the NoBo vehicle… Wagons used solely in GB do not allow shunters to ride on moving wagons. Fitting these steps and handrails could be seen as encouraging such use. RSSB, Mick James UK issue registered with ERA . National solution letter issued by DfT 12 05 2008 Closed National solution letter RSSB, Mick James The new WAG TSI published in April 2013 deals with this issue. Closed RSSB, Mick James UK Specific Case 7.7.2.2.1.1, as modified by national solution letter of 23 December 2008 Closed The new WAG TSI published in April 2013, and can be complied with immediately, will become mandatory in December 2013 and closes out this issue. National Solution letter issued. UK Specific Case 7.7.2.2.1.1 to Remain but modifed to exclude the necessity to gauge against both UK and European reference profiles. UK Temporary Solution DfT letter 23 12 2008 Closed Currently the UK has a temporary specific case which prohibits the use of hand rails under buffers. Use of such is prohibited in the UK for safety reasons. Not fitting them will prevent accidents. This also should not be deemed interoperable (more of an operational shunting matter) and therefore deemed out of scope. TAIL-015 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.2.6.4 TAIL-017 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.3.1 Compatibility with existing system Annex T - 7.7.2.2.1.1 TAIL-018 1 01/06/2009 CR Freight Wagons TSI 2006/861/EC Economic achievability Clause 4.2.3.1 Economic achievability Clause C3.1 Annex T - 7.7.2.2.1.1 Dangerous Goods GB mainline & HS1 Wagons carrying dangerous goods shall meet the requirements of Contracting Entity, OEM, the TSI in addition the requirements of RID. TSI also calls up EN NoBo 12972 Tanks for transport of dangerous goods testing, inspection and marking of metallic tanks from April 2001…This clause it at odds with current national practice and the requirement is deficient in some areas. The RID directive covers this area. Kinematic Gauge GB mainline & HS1 The TSI specifies the loading gauges, the reference profile and the Contracting Entity, OEM, rules for the maximum construction gauge for wagons. The target NoBo gauge allowed without restrictions is G1 (except the UK). The target gauges for Great Britain will be those specified in the table in Annex T and are/will be described in Railway Group Standard, GE/RT8073 Vehicle Track Interaction GB mainline & HS1 The TSI in Annex C (3.2.2 & 3.23) also specifies gauge for wagons in the G1 lower area. Some UK bogies do not meet this requirement and the cost of modifying them to give a greater underclerance for UK infrastructure would be unnecesarily prohibitive. This is particularly relevant on worn/waering wheels. Contracting Entity, OEM, NoBo GB Wagons carrying dangerous goods shall meet the requirements of the RID which take precedence over the TSI where there is conflict. Where the RID is silent, the TSI requirements will be applied. The application of the these requirements shall be in accordance with GM/RT 2101(issue 1 may 1996) Requirements for the Design, Construction, Test & Use of the Tanks of Rail Tank Wagons. UK keeps existing specific case in 7.7.2.2.1.1 in the redrafted TSI (as modified by national solution letter of 23 December 2008 to omit any reference to G1 gauge as the UK is unable to meet this gauge requirement). With respect to kinematic gauge to be achieved shall be in accordance with the GB Specific Case as set out in Annex T which needs to be modified to ensure there is no requirement to demonstrate compliance with the mainland European reference profiles. The following freight vehicle gauges are available for lines in Great Britain: W6a, W7, W8, W9, W9plus, W10 , W11 and W12 No G1 gauge requirement in the UK. A more restricting gauge leads RSSB, Mick James to design compromises for no commercial gain. The swept envelope for GB vehicle in the lower sector shall have a minimum clearance of 75 mm vertically above the plane of the rails between the rails under all conditions (the wheels excluded). This is applicable when using the W6a gauge and taking account of all suspension movements and vertical curvesUK keeps existing specific case in 7.7.2.2.1.1 in the redrafted TSI (as modified by national solution letter of 23 December 2008 to omit any reference to G1 gauge as the UK is unable to meet this gauge requirement). National Solution letter issued. UK Specific Case 7.7.2.2.1.1 to Remain but modifed to exclude the necessity to gauge against both UK and European reference profiles and include reference to G1 lower area. 22/10/2015 Technical Specification for Interoperability - Application Issues Log for High Speed and Conventional Rail TSIs Updated: October 2015 Issue ref. number Date added TSI reference TSI clause TAIL-019 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.3.2 TAIL-020 01/06/2009 CR Freight Wagons TSI 2006/861/EC TAIL-021 01/06/2009 CR Freight Wagons TSI 2006/861/EC Type of issue Compatibility with existing system Key words Scope Explanation Organisations involved / affected Proposed resolution Industry lead contact Supporting document? Progress to date Issue status Agreed solution to issue Static Axle Load GB mainline & HS1 The classification of lines and line sections in Great Britain is carried Contracting Entity, OEM, out according to the Notified National Standard (Railway Group NoBo Standard GE/RT8006 “Interface between Rail Vehicle Weights and Underline Bridges”). Vehicles intended to operate in Great Britain shall obtain classification according to this standard. The classification for the wagon is determined according to the geometrical position and the loads on each axle. But the TSI states that lines shall be classified in accordance with categories A, B1, B2, C2, C3, C4, D2, D3, D4 as defined in a table in the TSI. Retain UK Specific Case as classification of lines and line sections within the UK remain unchanged. RSSB, Mick James UK issue registered with ERA Closed UK Specific Case in Annex T TSI Open Point Compatibility with existing system Clause 4.2.3.3.2 & Annex LL of Commission Decision 2009/107) Hot Box Axle Detection GB mainline & HS1 The dimensions of the prohibitive zone's cuboid, taking into account Contracting Entity, OEM, mechanical tolerances, shall be: lateral width, WPZ, greater than or NoBo equal to 100 mm; — longitudinal length, LPZ, greater than or equal to 500 mm. GB Wagons with wheel sets of diameter 730mm or less will not achieve the axle box clearance. Wagons with wheel sets of diameter 730mm or less shall not be required to achieve the axle box clearance. RSSB, Mick James The new WAG TSI published in April 2013 deals with this issue. Closed Clause 4.2.3.4.2.1 Clause 4.2.3.4.2.2 Clause 6.2.3.2.1.1 Dynamic Behaviour GB mainline & HS1 For bogies not listed in annex Y, EN 14363 or leaflet UIC 432 apply. In Contracting Entity, OEM, addition to the specifications of section 4.2.3.4.2.2 of this TSI on NoBo safety against derailment when running on twisted tracks: — One of the three methods given in EN 14363 applies; — Freight wagons are exempted from these tests if they comply with the requirements of UIC leaflet 530-2. Wagons operating solely on the GB network should comply with the RSSB, Mick James requirements of GM/RT2141. Resistance of railway vehicles to derailment and roll over. UK issue registered with ERA Closed The new WAG TSI published in April 2013, and can be complied with immediately, will become mandatory in December 2013 and closes out this issue. UK keeps existing specific case in 7.7.2.2.1.1 in the redrafted TSI (as modified by national solution letter of 23 December 2008 to omit any reference to G1 gauge as the UK is unable to meet this gauge requirement). Due to the constraints of the GB infrastructure, GB freight vehicles have historically used an overhang to wheelbase relationship which is outside the limits prescribed in annex R to avoid the Longitudinal Compressive Forces test. The GB gauge means that long wagons require long overhangs to retain a reasonable gauge width in the centre of the wagon. RSSB, Mick James The new WAG TSI published in April 2013 deals with this issue. Closed The new WAG TSI published in April 2013, and can be complied with immediately, will become mandatory in December 2013 and closes out this issue. Compatibility with existing system The dynamic behaviour of a vehicle has strong effects on safety against derailment and running stability. TAIL-022 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.3.5 Clause 6.2.3.2.2 Annex R Compatibility with existing system Overhang GB mainline & HS1 The TSI requires all vehicles to be able to pass over convex or concave transition curves of radius Rv ≥ 500 m, without any part other than the wheel flange descending below the running surface. This may concern mainline vehicles whose:— wheelbase is greater than 17,8 m,— overhang is greater than 3,4 m Contracting Entity, OEM, NoBo To ensure safety against derailment, wagon(s) shall be assessed by tests, calculations or through comparison with the characteristics of already approved (certified) wagons. When it is necessary to require the certification of the admissible longitudinal compressive force by tests, then the tests have to be carried out according to the method described in Annex R, at least with the measurement areas given in this Annex. TAIL-023 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.4.1.2.2 Technical error in TSI Brake Performance GB mainline & HS1 In the UK under these conditions the braking S max would be Contracting Entity, OEM, equivalent to 890m (for 75mph). The use of mixed braking modes NoBo on tare wagons would provide a significant risk of longitudinal compressive forces (LCF) which could pose safety risk factors of poor vehicle dynamics leading to flange climb, Coupling fatigue and failure, Bogie and Vehicle Frame fatigue, Excess wheel wear and profile and Excess thermal dissipation in wheels. Foot Notes 5, 6 and 7 for wheels less than 940mm, on axles no less than 22,5T at a maximum speed of 120KPH using brakes blocks are permitted to use national rules for calculating Smax. Extend Foot Note requirements to adopt NNTR for Tare: RSSB, Mick James UK Specific Case 7.7.2.3.1.1 UK issue registered with ERA Closed National Solution letter issued 5/6/09 TAIL-024 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.4.1.2.3 Compatibility with existing system Pneumatic Half couplings GB mainline & HS1 TSI specifies that the opening of the automatic air brake coupling Contracting Entity, OEM, head shall face the left when looking at the end of the vehicle. The NoBo opening of the main reservoir coupling head shall face the right when looking at the end of the vehicle. The requirement in the UK is for both the BP and MRP coupling heads to be left handed. The majority of vehicles are singled piped brake only and this forms the interoperable interface. The requirement for the UK to convert the MRP to the opposite hand will require existing vehicles to change. prEN 15807 doesn't reference the orientation of the individual coupling heads. It describes the conformance of the product not how it is used. Either delete the requirement or Confine the ‘interoperable’ requirement to the Brake Pipe only.If we need to define the MRP then add 'where fitted the orientation of the MRP coupling head shall be compatible with existing arrangements in the member state.' RSSB, Mick James UK issue registered with ERA. National solution letter issued 6 March 2009 to substitute the relevant text in the TSI with “The opening of the main reservoir coupling head shall face to the left when looking at the end of the vehicle” Closed National Solution letter issued TAIL-025 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.4.1.2.5 Economic achievability Energy Limits GB mainline & HS1 The TSI requires the brake system to be designed to allow the Contracting Entity, OEM, vehicle to run on all existing lines of the trans-European NoBo conventional rail system. The brake system shall stop the vehicle loaded and maintain the speed of the vehicle without any thermal or mechanical damage for: 1. two successive emergency braking applications from the maximum speed to a stop on straight and level track with minimum wind and dry rail. 2. Maintain an average speed of 70 km/h in a slope with a mean declivity of 21 ‰ and a length of 40 km. Wagons intended to operate solely in the UK will not be exposed to RSSB, Mick James the braking environment stipulated in the TSI (L.1.4.2.1 in Annex L). The design of UK wheels is expected to include assessment of the most severe thermal loadings through braking, including drag braking and the most severe repeated braking cycle to be experienced by the vehicle, including an additional stop to represent peak thermal loading during the cycle.This is governed by the UK Railway Group Standard GM/RT2466. UK issue registered with ERA. National solution letter issued by DfT 12 05 2008 Closed National Solution letter issued 2 22/10/2015 Technical Specification for Interoperability - Application Issues Log for High Speed and Conventional Rail TSIs Updated: October 2015 Issue ref. number TAIL-028 Date added 01/06/2009 TSI reference CR Freight Wagons TSI 2006/861/EC TSI clause Clause 4.2.6 Type of issue Economic achievability Key words Environmental Conditions Scope GB mainline & HS1 Explanation Organisations involved / affected All freight wagons intended for international traffic shall comply as a Contracting Entity, OEM, minimum with temperature class TRIV. NoBo While clause 4.2.6, as reproduced here, only applies to wagons intended for international traffic, the net effect is that passe-partout wagons would need to straddle a wide temperature range which seems excessive for most continental traffic. In addition, feedback from manufacturers is that no products are actually certified in the way the TSI requires, consequently most wagon component costs are going to increase to meet testing, certification and design change to cope with the extreme temperature ranges included in the TSI. Proposed resolution Industry lead contact Supporting document? Progress to date Issue status Agreed solution to issue UK does not encounter the temperature ranges listed in any of these RSSB, Mick James 3 classes. Therefore for wagons operating solely within GB, the UK proposes a temperature range of -20C to +35C To manufacture wagons to meet all temperature ranges would be more expensive (for steel and all components).The contracting entity shall specify the temperature range for the wagon according to its intended use. The new WAG TSI published in April 2013 deals with this issue. Closed The new WAG TSI published in April 2013, and can be complied with immediately, will become mandatory in December 2013 and closes out this issue. TAIL-029 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 4.2.7.2.2.3 Technical error in TSI Design Rules: Spark GB mainline & HS1 Guards Spark protection of the load shall be provided separately where the Contracting Entity, OEM, floor does not provide that protection. Yet due to the restraints of NoBo the UK loading gauge, spark guards on some types of vehicles are impracticable. When those vehicles are fitted with composite brakes blocks or disc brakes spark guards should not be mandated. For Wagons operating solely within GB spark guards should only be fitted on vehicles utilising cast iron brake blocks where the floor does not provide protection in its own right. RSSB, Mick James UK issue registered with ERA Closed National Solution Letter issued 14/7/09 TAIL-031 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 5.4.3.11 Annex PI10 Technical error in TSI Brake Blocks GB mainline & HS1 The ERA (from UIC) maintains the list of approved composite brake blocks (including geographical restrictions of use and conditions of use, according to P.1.10 and P.2.10). The brake blocks specified on the ERA website only provides 1 K block (Becorit 929-1) suitable for UK use (i.e. I Bg).It is limiting for the UK because it only provides suitable braking up to 18 t / axle and the approval is due to end on the 30th June 2009.There are no candidate blocks and Bogie configurations for 2 Bg use in the UK.There are also no candidate Bgu systems available for UK use. UK suggest that the provision of National rules for vehicles with (1 Bg) push braking system for wheels less than 940mm, on axles no less than 22,5T at a maximum speed of 120KPH (for passe-partout wagons, the TSI applies).For wagons operating solely in the GB, brake blocks which have been accepted in accordance with GB National Rules shall be acceptable RSSB, Mick James UK issue registered with ERA Closed National Solution Letter issued 14/7/09 TAIL-032 01/06/2009 CR Freight Wagons TSI 2006/861/EC Clause 6.2.3.3.2 Technical error in TSI Brake Release Timings GB mainline & HS1 TSI specifies the G-setting as 45-60 seconds. Most UK brake timings Contracting Entity, OEM, operate at 30-45 seconds (albeit Technical Note 031 from Railway NoBo Group standard GM/RT 2045 issue 2 - October 2004 specifies a range of 30-60 seconds applies) so do not meet the TSI timings of 45-60 seconds (which is viewed by some Member States not as a range, but as an absolute parameter to be met at both ends). Change the text of the new TSI to a range of 30-60 seconds, rather RSSB, Mick James than a strict timing of 45-60 seconds. This would allow wagons to operate at 30-45 seconds or 45-60 seconds. UK proposes to keep the 45 – 60 seconds settings only for passe-partout Wagons. UK issue registered with ERA Derogation being Sought Closed National Solution Letter issued 14/7/09 TAIL-033 27/07/2009 HS CCS TSI 2006/860/EC and CR CCS TSI 2006/679/EC Various, as Technical error in TSI described in the detailed supporting document GSM-R GB mainline & HS1 ISCC, RSSB, DfT The proposed resolution for each issue has been captured within the RSSB, Tom Lee Railway Group Standard GKRT0094 (which has superseded GE/RT8082) and the relevant clauses have been notified as national technical rules. Yes National technical rules notified, DfT to follow up with ERA Closed TAIL - 034 04/08/2009 HS INF TSI (revised) Clauses relating to Placing product (rails) onto the 2008/217/EC interoperability market and assessment of constituents - parts conformity. 5, 6 and Annex C Between July and October 2007, ISCC reviewed critical errors associated with GSM-R with a view to raising these errors with the Rail Interoperability and Safety Committee. The additional information available in 2007 is summarised in the detailed document for TAIL-033. The issue relates to the placing on the market of interoperability coinstituents and their assessment of conformity and NoBo involvement with respect to the requirements of the HS INS TSI (revised). NoBo, Suppliers Interpretation of requirements of HS INS TSI (revised) as set out in supporting document. Yes Issue resolved. Closed Interoperability GB mainline & HS1 constituent, conformity assessment, Notified Body, CE marking Contracting Entity, OEM, NoBo RSSB, Paul Gray The new Interoperability Directive 2008/57/EC, published in June 2008, replaces the High Speed Interoperability Directive (96/48/EC) and the Conventional Rail Interoperability Directive (2001/16/EC). It is required to be transposed into UK law ‘not later than 19 July 2010’. The current UK regulations, the Railways (Interoperability) Regulations 2006 (Statutory Instrument 2006 No. 397) have transposed directives 96/48/EC [for high speed] and 2001/16/EC [for conventional rail]. The Conventional Rail Infrastructure TSI is not yet published, so the requirements for Vignole rails would need to be met 3 22/10/2015 Technical Specification for Interoperability - Application Issues Log for High Speed and Conventional Rail TSIs Updated: October 2015 Issue ref. number TAIL - 035 Date added 16/02/2010 TSI reference TSI clause Persons of Reduced 4.1.2.19 Mobility TSI, OJEU Reference 2008/164/EC Type of issue Ambiguity in TSI requirement Key words Platform widths Scope GB mainline & HS1 Explanation Clause 4.1.2.19 states: It is permitted for the width of the platform to be variable on the whole length of the platform. The minimum width of the platform without obstacles shall be the greater of either: Organisations involved / affected Contracting Entity, OEM, NoBo Proposed resolution The "acceptable length of the platform end taper" needs to be defined. Industry lead contact RSSB, Bridget Eickhoff Supporting document? Progress to date No formal progress. Issue status Agreed solution to issue Open Define the length of the taper at platform ends Closed This issue has been partially addressed by GB specific case 7.4.2.9.5 'Conformity assessment of OCL as component' in the combined ENE TSI for the UK (Commission Regulation (EU) No 1301/2014 of 18 November 2014 The length of the 'taper at the platform ends' remains undefined. - the width of the danger area plus the width of two opposing freeways of 800mm (1600mm) or; 09/2015: Waiting for ERA to address the issue - so issue remains open. For a single side platform 2500mm, or for an island platform 3300mm (this dimension may taper to 2500mm at the platform ends). The issue is that the length of the taper at the platform ends is not defined. Taking this requirement to the extreme, a platform could be 3300mm at one point only and then taper throughout its length down to 2500mm and be fully compliant with the TSI. I would have thought that this is not in the spirit of the intention of the TSI. TAIL-036 08/08/2013 CR Energy TSI (Overhead line assessment) Decision 2011/291/EU with TSI (as Annex) Clause 6.1.4.1 in Economic achievability both the CR ENE TSI and draft combined ENE TSI. Electrification, Conformity assessment, NoBo, Interoperability constituient, GB mainline UK project entities using the Conventional Rail Energy TSI 2011/274/EU cannot comply with the requirements to dynamically test new 25kV AC overhead line. Identical testing requirements are replicated in the revised and merged TSI. The paper sets out why the UK Member State should raise a critical error in the revised TSI at RISC before the TSI is offered for vote . Contracting Entity, OEM, NoBo, ORR The TSI should permit an alternative method of dynamic testing to be used where an IC certified pantograph or test track with TSI compliant overhead contact line is not available. National rules for dynamic testing of new overhead contact line should be permitted to be used where the design uses specific cases. Paul Hooper, ORR David Knights, RSSB Issue raised with ERA with regard to revised TSI. An attempt made to resolve the point, but not agreed with other stakeholders. TSI with commission without any changes. Draft combined ENE TSI Refer to the TSI Application Issues Log, applicable from January 2015, for updates on this issue. NTR has been published GL/RT1210 (clause 3.9) to describe the process to be adopted under the specific case referred to above. TAIL-037 01/10/2013 CR INF TSI (2011/275/EU) 4.2.7.2.2 - Magnetic Conformity with TSI track brake load Comformance, GB mainline Placing into service Three specific issues have been identified by a project applying the Contracting Entity, OEM, CR INF TSI. NoBo, ORR, NR The issues represent elements of the infrastructure subsystem where evidence of conformance will need to be supplied to support authorisation for placing into service in accordance with the Railway Interoperability Regulations 2011. The issues are not limited to one project and may affect other project entities seeking authorisation for other parts of the UK rail network in the future. Magnetic track brake load Section 4.2.7.2.2 of the Infrastructure TSI states: “1) Track shall be designed to be compatible with the use of magnetic track brakes for emergency braking.” Following cross-industry discussions it is noted that:1) the CR RSSB, Bridget LOC&PAS TSI Clause 4.2.4.5.1 gives a maximum deceleration rate of Eickhoff 2.5m/s2 including the use of 'the brake independent of wheel-rail adhesion' and states that 'this requirement is linked to the longitudinal resistance of the track';2) this is believed to be consistent with existing vehicles which use Magnetic track brakes (including Tyne & Wear Metro). It is therefore suggested that the 2.5m/s2 can be used to derive a suitable design longitudinal load for the track structure which is the key issue. Proposed resolution will be followed and conclusions reported. Open A proposed solution has been given but there is no evidence that projects are using the work around. 09/2015: For ISCC - is there any information from projects that work around has been used and if so, is helpful. Until evidence is shown - issue remains open. Any other potential risks identified may need to be mitigated, perhaps by reference to an existing system. No further guidance is provided in the TSI or the supporting application guide as to how to satisfy this requirement e.g. reference standards or limiting factors. Furthermore currently no UK mainline rolling stock utilises magnetic track brakes. Therefore infrastructure managers have not had to consider the implications of their application on existing or novel track forms (this is with the exception of the Tyne and Wear Metro operation on Network Railcontrolled Infrastructure between Pelaw Junction to South Hylton which were authorised under the superseded ROTS process). A review of draft 5.0 of the Infrastructure TSI of 16th May 2013 confirms that the requirement for compatibility with magnetic track brakes will be retained in future versions of the Infrastructure TSI and therefore remain a requirement for authorisation (see Section 4.2.6.2.2 of the draft TSI). It should be noted that (i) informal 4 22/10/2015 Technical Specification for Interoperability - Application Issues Log for High Speed and Conventional Rail TSIs Updated: October 2015 Issue ref. number TAIL-038 Date added 01/10/2013 TSI reference CR INF TSI (2011/275/EU) TSI clause 4.2.5.5.2 - 2.2 Requirements for the controlling equivalent conicity in service Type of issue Conformity with TSI Key words Scope Comformance, GB mainline Placing into service Explanation This relates to TAIL-037. Requirements for controlling equivalent conicity in service Section 4.2.5.5.2 of the Infrastructure TSI states: “(1) Requirements for controlling equivalent conicity in service are an open point.” Organisations involved / affected Contracting Entity, OEM, NoBo, ORR, NR The UK has notified standard GC/RT5021 Issue 5 and equivalent conicity is dealt with in Appendix D. Appendix D states the following: Proposed resolution Industry lead contact Supporting document? A review of Draft 5.0 of the revised Infrastructure TSI confirms that RSSB, Bridget the Open Point has been removed and further information is Eickhoff provided in relation to limit values for maintaining equivalent conicity in service. Clause 4.2.11.2 gives actions to be taken 'if ride instability is reported' whilst Annex B, Table 32 shows this item as 'n.a.' and therefore not needing assessment by a NoBo or DeBo. The issue should therefore be resolved with the update of the TSI. GC/RT5021 Iss 5 GI/GN7608 Clauses G 8.1.1 and G,.8.1.2 states RSSB, Bridget 'G 8.1.1 The CR INF TSI and HS INF TSI refer to the RST TSI limits on Eickhoff the maximum dynamic wheel forces for defined test conditions and state that the resistance of the track to applied loads shall be consistent with these values. The load limits in the RST TSI refer to specific test conditions which are not the most extreme that can exist for either the vehicle or the track and therefore the actual loads experienced by some track sections may be higher. The rolling stock values should therefore not be taken as design values for the track. A suitable margin is required. G 8.1.2 The general practice for the design of track resistance to loads is to make reference to existing designs which have been demonstrated to provide satisfactory performance in similar service conditions. It is not normal practice to assess the track structure from first principles.' GI/GN7608 Iss 1 Progress to date Proposed resolution will be followed and conclusions reported. Issue status Agreed solution to issue Open 09/2015: Projects can use the clause from the INF TSI to close the open point or declare if they are doing something different. There is no evidence as to what projects are doing - so issue remains open. ”D.2 In-service rail head profile D.2.1 The requirement for in-service rail head profile (set out in section 3.2.5) has not yet been developed and is an open point. D.2.2 Pending the development of this measure, industry practice has been to manage the in-service shape of the rail head profile to mitigate specific problems (for example lipping). D.2.3 If ride instability is reported on a track for rolling stock having wheelsets meeting the requirements of GM/RT2466, industry practice has been to conduct a joint investigation by the railway undertaking and the infrastructure manager to determine the reason. D.2.4 This is an explicit open point in the Conventional Rail Infrastructure Technical Specification for Interoperability (CR INF TSI)." This is not a clear requirement that can be assessed by a DeBo. TAIL-039 01/10/2013 CR INF TSI (2011/275/EU) 4.2.7.3(1)(a) - 2.3 Lateral track resistance Conformity with TSI Comformance, GB mainline Placing into service This relates to TAIL-037. Contracting Entity, OEM, NoBo, ORR, NR Section 4.2.7.3(1)(a) of the Infrastructure TSI states that for all categories of line: “(1) The track, including switches and crossings, shall be designed to withstand at least: (a) the maximum total dynamic lateral force exerted by a wheelset on the track. The HS and CR rolling stock TSIs define a limit on the lateral forces excerted by a wheel set on the track. The lateral resistance of the track shall be consistent with these values,” The referenced LOC and PAS TSI subsequently refers out to standard EN14363:2005 “Railway applications. Testing for the acceptance of running characteristics of railway vehicles. Testing of running behaviour and stationary tests”. Whilst this standard contains a number of track resistance criteria, it does not appear to provide any requirements in relation to the maximum total dynamic lateral force. Therefore in a similar manner to the issues described above, there does not appear to be a recognised route to conformance available to project entities trying to design and authorise infrastructure subsystems into service. Proposed resolution will be followed and conclusions reported. Open As at 09/2015: No evidence that projects are using the proposed solution - so issue remains open. ISCC - enquire from NR, NoBo, ORR what work arounds have been used and if RSSB's proposed solution has been successful. The revised INF TSI Clause 6.2.5.1 states: 'ASSESSMENT OF TRACK RESISTANCE FOR PLAIN LINE (1) The demonstration of conformity of the track to the requirements of clause 4.2.6 may be done by reference to an existing track design which meets the operating conditions intended for the subsystem concerned. It is suggested that track designs using standard industry load cases are therefore likely to meet the requirements unless there are very specific circumstances to consider. TAIL-040 5 14/03/2014 CR INF TSI (2011/275/EU) 4.2.9.2 The Conformity with TSI immediate action limit for track twist 4.2.9.3 The immediate action limit for variation of track gauge 4.2.9.4 The immediate action limit for cant 4.5.1 Before placing a line in service (1) A maintenance file shall be prepared setting out at least: (a) a set of values for immediate action limits, (b) the measures taken (speed restriction, repair time) when prescribed values are exceeded, ... Comformance, GB mainline Placing into service The 'immediate action limits' specified in Clauses 4.2.9.2, 4.2.9.3 and Contracting Entity, OEM, 4.2.9.4 may appear to have different values from some of the NoBo, ORR, NR requirements in national rules such as GC/RT5021 Track System Requirements. For example Clause 4.2.9.2 gives a general immediate action limit for twist of 7mm/m, which is equivalent to 1 in 143, over the 3m base used in GC/RT5021. GC/RT5021 Clause 2.11.2.1 states 'When twist faults are discovered they shall be repaired within a timescale commensurate with the risk of derailment which in any case shall not be less stringent that the timescales set out in Table 2.' Table 2 specifies minimum actions depending on the level of twist fault discovered. The action required, according to this table for a 1 in 143 fault is 'Radius < 400m: Correct fault within 1 week of discovery; Radius ≥ 400m: Correct fault within two weeks of discovery'. The action 'Stop all traffic immediately and correct fault' is only required if a twist of 1 in 90 (or worse) is discovered. It is not clear to what extent the RGS requirements accord with the TSI. The definition of 'immediate action limit' in Annex G , Glossary, RSSB, Bridget states 'The value which, if exceeded, requires taking measures to Eickhoff reduce the risk of derailment to an acceptable level.' A slightly longer definition is given in EN13848:5 (2008) Section 7: 'Immediate Action Limit (IAL): refers to the value which, if exceeded, requires taking measures to reduce the risk of derailment to an acceptable level. This can be done either by closing the line, reducing speed or by correction of track geometry'. It should therefore be understood that if the 'immediate action limit' is reached the action required is to 'reduce the risk of derailment to an acceptable level' and that an appropriate time interval should be specified for this action. Where time intervals are specified, for example in GC/RT5021, these could be appropriate to meet the TSI requirements. This clarification will be added to GI/GN7608 'Guidance on the Conventional Rail and High Speed Infrastructure Technical Specifications for Interoperability' at the next revision. Issue resolved by revising Guidance for INF TSI. Closed As at 09/15: Guidance for the INF TSI is currently being drafted and is proposed for publication in 2016. 22/10/2015 Technical Specification for Interoperability - Application Issues Log for High Speed and Conventional Rail TSIs Updated: October 2015 Issue ref. number TAIL-041 TAIL-042 TAIL-043 TAIL-044 6 Date added 12/06/2014 03/09/2014 27/11/2014 02/12/2014 TSI reference CR INF TSI (2011/275/EU) CR INF TSI (2011/275/EU) CR INF TSI (2011/275/EU) ENE TSI, LOC&PAS TSI (and possibly others) TSI clause Type of issue 4.2.6.2 In-service Conformity with TSI geometry of switches and crossings (2) (a) Maximum value of free wheel passage in switches 1380mm. This value can be increased if the infrastructure manager demonstrates that the actuation and locking system of the switch is able to resist the lateral impact from a wheelset. 4.2.6.2 In-service Conformity with TSI geometry of switches and crossings 4.2.7.3 Resistance of Ambiguity in TSI requirement new structures over or adjacent to tracks Chapter 6, Interoperability constituents Conflict with other rule Key words Scope Free wheel passage, GB mainline S&C, Switches Track gauge, S&C, Switches Aerodynamics, Track Interoperability constituents GB mainline GB mainline GB mainline Explanation Organisations involved / affected Proposed resolution Industry lead contact Supporting document? Network Rail CEN 56 S&C designs have a freewheel passage of 1432- Contracting Entity, NoBo, 50=1382, which is in excess of the maximum permitted in the TSI ORR, NR (including the revised draft) of 1380. It is therefore necessary to understand how to demonstrate ‘that the actuation and locking system of the switch is able to resist the lateral impact forces of a wheelset’ It is suggested that the required demonstration can be achieved by RSSB, Bridget reference to experience with existing S&C design / installation which Eickhoff meets the operating conditions intended for the subsystem concerned (ie use of a reference system) Network Rail CEN 56 S&C designs have a nominal track gauge of 1432 mm and there is concern that this is inconsistent with the required nominal track gauge of 1435mm. Network Rail CEN 56 S&C designs comply with the required dimensions given in clause 4.2.6.2 and the associated GB Specific Case in 7.6.12.5. The nominal track gauge requirement is not relevant for S&C as the required dimensions in clause 4.2.6.2 are sufficient. RSSB, Bridget Eickhoff Clause 4.2.7.3 should be revised to clarify the intent as the TSI refers Contracting Entity, NoBo, to clauses 6.6.2 to 6.6.6 of EN 1991-2:2003. This is unnecessary and ORR, NR misleading as the overall clause which references clauses 6.6.2 to 6.6.6 and importantly allows the National annex to be used instead, is not referenced, that is clause 6.6.1(3). This is as follows: (3) The actions may be approximated by equivalent loads at the head and rear ends of a train, when checking ultimate and serviceability limit states and fatigue. Characteristic values of the equivalent loads are given in 6.6.2 to 6.6.6. NOTE The National Annex or the individual project may specify alternative values. The values given in 6.6.2 to 6.6.6 are recommended. Existing text of clause 4.2.7.3 'Aerodynamic actions from passing trains shall be taken into account as set out in EN 1991-2:2003/AC:2010 paragraphs 6.6.2 to 6.6.6 inclusive ' RSSB, Bridget Eickhoff It is not possible to certify an interoperability constituent that Contracting Entity, NoBo, requires the use of specific case. The problem applies to at least the ORR, NR following "overhead contact line", "Pantograph", "wheelset" and possibly other elements. The resolution will require the ERA to change the rules applicable to RSSB, David Knights See the TSI interoperability constituent that requires the use of specific case. Application issues log for the relevant documents Contracting Entity, NoBo, ORR, NR Progress to date Proposed resolution will be followed and conclusions reported. Issue status Agreed solution to issue Open As at 09/2015: Proposed solution provided but no evidence work around is being used or if so, succsssful - so issue will remain open. Proposed resolution will be followed and conclusions reported. Open As at 09/2015: Specific Case does not address the nominal gauge, however not aware if this is still an issue - so remains open. ISCC - NR may be able to give some clarity on this issue. Proposed resolution will be followed and conclusions reported. Open Clause 4.2.7.3 remains unchanged as this issue was raised in 11/2014 when the new INF TSI had already been developed and was in the process of being published. Clause 4.2.7.3 will be revised when the INF TSI is next under revision. This issue has been transferred to the log for TSIs applicable from 2015. The problem was identified by at least two NoBos, and has been raised with the ORR. RSSB hosted a meeting to bring all parties together. The ORR, DfT, affected manufacturers, NoBos discussed the issues this raised. Closed ORR confirmed that there is a genuine issue and undertook to raise it with DfT (as Member State) and ERA. Meeting held between ORR and ERA. NoBo Forum raised the issue at RISC. Revise clause 4.2.7.3 to: 'Aerodynamic actions from passing trains shall be taken into account as set out in EN 1991-2:2003/AC:2010, paragraph 6.6.1'. 22/10/2015