Policy Brief Aquifer Storage and Recovery 2010

advertisement

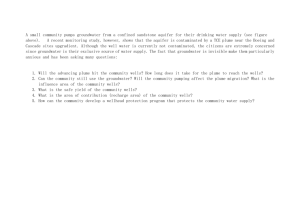

Policy Brief 2010 w ater Aquifer Storage and Recovery What is aquifer storage and recovery? Aquifer storage and recovery (ASR) is the injection of treated or untreated ground or surface water (source water) into an aquifer (an underground layer of soil, sand, gravel or rock that can yield water to a well or spring), and recovery of that water through the same well when it is needed. Injection typically occurs when excess source water is available, such as in winter or spring, while recovery usually occurs during summer peak demand or emergency periods. ASR may be used for a variety of purposes, including supplementing municipal, industrial, agricultural or recreational water supply, long-term water storage, or restoration of groundwater levels. What happens to the water that is injected? It flows outward from the injection well into the aquifer, and displaces the groundwater that is already there. This creates a “bubble” of injected water around the well, and a “mixing zone” around the bubble, where the injected water mixes with the existing groundwater. When the injected water is needed, it is pumped back out, and the bubble shrinks. Repeated “cycles” of injection and recovery cause the mixing zone to expand, usually improving water quality of the existing groundwater with successive cycles. Can ASR systems be installed anywhere? No. ASR systems require suitable source water, and an aquifer with the right characteristics to store the injected water. Sand or limestone aquifers with an impermeable layer above and below to prevent the injected water from leaking out and existing groundwater leaking in provide the best possibilities for ASR. Aquifers with lots of large openings or caverns where groundwater is moving too quickly are undesirable, because much of the injected water http://www.cviog.uga.edu/services/policy/environmental/ would move too far away from the injection well, and reduce recovery efficiency. Also, ASR wells are not good in areas where the receiving aquifer has other nearby injection wells or wells for water withdrawal, because that causes confusion over whose water is being withdrawn. And perhaps most importantly, a cost-effective ASR system needs a nearby customer base of sufficient size. The feasibility of ASR wells is very location specific. Are there places in Georgia where ASR systems could work? Yes. In Georgia, the best places for ASR are in the south-central and coastal areas where the aquifers are deep, confined above and below, and not too cavernous. In northwest and southwest Georgia, the main limestone aquifers are too cavernous and leaky to hold the injected water in a bubble, but deeper aquifers in the southwest should be able to do so. In the Piedmont areas of north Georgia, the deep bedrock is not porous enough and would not let the bubble form properly, making ASR almost impossible. Can the injected water affect the aquifer or existing groundwater? Yes. The injected water may have a significantly different chemical composition, even after treatment. During injection, the injected water may react with chemical components of the existing groundwater and the naturally-occurring minerals in the aquifer. This may change the pH of the existing groundwater, release iron or salts from the aquifer minerals, or release other naturally-occurring chemicals from the aquifer such as arsenic or mercury. Are ASR systems currently operating in the United States? Yes. ASR technology has been used for more than 40 years. ASR systems currently store drinking water in Aquifer Storage and Recovery | CVIOG Policy Brief | 2 27 sites in Florida and South Carolina. Many systems also operate in 13 other states across the nation. At least nine additional states have studies and pilot projects underway. ASR systems are also used to supply water in other counties, such as in Australia, Kuwait, the Netherlands, and Israel. In Florida and South Carolina, operating ASR systems are storing water in the same aquifer that we use for groundwater withdrawals in south Georgia, the Upper Floridan aquifer. states generally regulate ASR systems through the underground injection control provisions of the Safe Drinking Water Act. The Act strictly prohibits the injection of substances that would endanger underground sources of drinking water. The federal underground injection control rules, which mostly focus on the injection of waste materials, specify the minimum requirements and allow states to have stricter policies. Under the federal rules, ASR wells are regulated as “Class V (5)” or shallow injection How much water can be stored and recovered using ASR? Storage capacity depends in large part on the characteristics of the receiving aquifer, and the cost of treating the injected water. Typical systems inject between 8 and 10 million gallons per day (mgd), and recover most of that when needed. For example, in Cocoa, Florida, the ASR system there withdraws 8 mgd during the peak demand season from its storage 300 feet below ground. Why isn’t all the injected water recovered? Sometimes it is. However, the “recovery efficiency,” that is, the ratio of the amount of injected water to the amount of recovered water that meets the required water quality standards, is strongly affected by the quality of the existing groundwater. As soon as the recovered water drops below the required standards, it means that native groundwater is being drawn into the pump, and the withdrawal stops. The recovery efficiency may be as high as 80 percent, or as low as 20 percent or less. What challenges do ASR systems face? ASR systems are subject to the same challenges as other groundwater injection or withdrawal systems (e.g. residential wells). Sometimes, the well or the area directly around it in the aquifer may become clogged with sand and grit, or bacteria and algae, that require removal or treatment. On occasion, unexpected chemical contaminants show up in the recovered water due to unanticipated minerals in the aquifer. ASR systems may affect nearby wells and groundwater levels by increasing or decreasing hydraulic pressure in the aquifer. Disinfection byproducts, which are tightly regulated by federal and state agencies, may be present in the injection water. And if the injection treatment system fails, there is a danger of contaminating the aquifer. How are ASR systems regulated? Depending on the location, source of injected water, and use of recovered water, ASR wells may be regulated differently. The (USEPA) and http://www.cviog.uga.edu/services/policy/environmental/ Illustration of an ASR well. From “What is ASR?” http://www.asrforum.com/ wells. As of July 2006, USEPA reports more than 6800 Class V injection wells in Georgia – none are ASR wells. Because ASR wells do not typically inject waste materials, some states have chosen to adopt regulatory provisions specifically for these wells. ASR wells may also be subject to requirements under state groundwater protection programs. The Georgia Environmental Protection Division requires owners and operators of Class V injection wells to obtain a permit before construction. GAEPD rules and the permit include specific requirements for construction, operation (monitoring, testing, reporting, and maintenance of mechanical integrity), and closure. Class V wells must be installed by a licensed water well contractor, subject to the requirements of the Water Well Standards Act. In Georgia, withdrawals from ASR wells would likely be subject to groundwater withdrawal permitting requirements. If the ASR system is part of a public water supply/drinking water system, it would require approval as part of the system permit. How are ASR systems developed? Development of an ASR system requires a series of carefully planned steps, typically over two to three years. Aquifer Storage and Recovery | CVIOG Policy Brief | 3 • First, the feasibility of an ASR system must be determined, taking into account site selection, water demand and supply, projected costs of construction and operation, community and political concerns, and other relevant matters. • Investigations to determine the hydrology, mineralogy and geochemistry of the receiving aquifer usually begin by drilling test wells, recovering samples of the aquifer, and performing pumping tests on the aquifer. Groundwater flow models tell hydrologists the maximum amount of water the aquifer can receive, the anticipated size of the bubble, and the expected recovery efficiency. • A pilot injection well is then drilled, and treated water is injected into the aquifer. Several cycles of injection and recovery are performed, and scientists evaluate the amount and quality of the recovered water and resulting changes in the aquifer. Any significant water quality or aquifer performance problems should appear during this initial testing phase. If the pilot well meets all technical and regulatory requirements, approval may be sought for a fully operational system. It should be noted that project development may be stopped at any phase if unresolvable issues arise. What are some non-technical challenges related to ASR systems? Because ASR systems store water, owners and operators must ensure they have the right to use the source water for ASR, to manage stored water (most importantly to exclude others from withdrawing it) and to withdraw and use recovered water. These owners/operators must also consider impacts on existing nearby wells, such as changes in water levels and pressure during injection and withdrawal. Many ASR systems are part of public water supply systems. Therefore, the use of such systems is among the alternatives available for water storage, and like other options (such as elevated storage tanks and reservoirs) they must be cost-effective or the lowest-cost alternative considering all capital, operational, and maintenance costs. Social concerns also play an important role in discussions about ASR systems. Citizens may express concerns due to the perceived high costs associated with ASR technology and/or fears of potential aquifer or drinking water contamination or water quality reduction. http://www.cviog.uga.edu/services/policy/environmental/ What are some benefits of ASR systems? The benefits of ASR systems vary by project, since the projects are so location specific. ASR systems providing monitored underground storage of potable (drinking) water are not subject to the evaporative losses, sedimentation, high costs, extensive land use and environmental impacts associated with surface water reservoirs. ASR systems can provide secure long-term storage or emergency supplies. ASR systems may also be used to maximize the opportunities for water reuse, allowing injection of highly treated re-use water during the times when demand for such water is low. (Lack of storage capacity is a major deterrent to construction of direct re-use systems). In areas where coastal salt-water intrusion is a threat, ASR could be used to restore groundwater levels or improve water quality, without increasing the risk of greater salt-water intrusion. In its 1999 report, The Class V Underground Injection Control Study, the USEPA stated, “no contamination incidents associated with the operation of aquifer recharge or ASR wells have been reported.” Additionally, the Water Science and Technology Board of the National Research Council/National Academies of Science acknowledged, “Collective experience with MUS [managed underground storage] systems is substantial. A significant number of these systems are decades old, and experience indicates that many of them perform consistently and well over the longer term.” See Prospects for Managed Underground Storage of Recoverable Water (The National Academies, 2008). Sources: Ronald Reese, 2002, Inventory and Review of Aquifer Storage and Recovery in Southern Florida, USGS Water Resources Investigation Report 2002-4036 David G. Pyne, 1995, Groundwater Recharge Through Wells: A Gude to Aquifer Storage Recovery