Plastic yielding as a frequency and amplitude independent mechanism arushina Podladchikov

advertisement

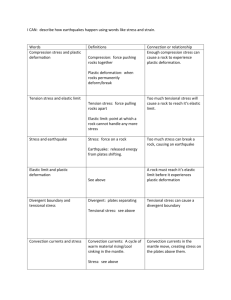

GEOPHYSICS, VOL. 75, NO. 3 共MAY-JUNE 2010兲; P. N51–N63, 10 FIGS. 10.1190/1.3420734 Plastic yielding as a frequency and amplitude independent mechanism of seismic wave attenuation Victoria M. Yarushina1 and Yuri Y. Podladchikov1 Gurevich and Lopatnikov, 1995; Pride et al., 2004; Carcione and Picotti, 2006; Quintal et al., 2009兲, scattering 共Kuster and Toksöz, 1974; Frankel and Clayton, 1986兲, or matrix anelasticity 共Mindlin and Deresiewicz, 1953; Knopoff and MacDonald, 1958; Walsh, 1966; Hagin and Zoback, 2004兲 have been proposed 共see e.g., Johnston et al., 1979; Bourbié et al., 1987兲. Although dissipation mechanisms associated with a characteristic time scale are important for interpreting the frequency dependence of attenuation 共Aki, 1980; Sams et al., 1997; Sothcott et al., 2000兲, there is a considerable amount of data indicating weaker-than-expected dependence of attenuation on frequency 共Knopoff, 1964; Gordon and Davis, 1968; McKavanagh and Stacey, 1974; Tittman, 1977; Clark et al., 1980; Murphy, 1982; Winkler and Nur, 1982; O’Hara, 1985兲. Several alternative explanations for frequency-independent attenuation were proposed, e.g., hysteresis with discrete memory in nonlinear elastic materials 共McCall and Guyer, 1994兲, frictional dissipation 共Mindlin and Deresiewicz, 1953; Knopoff and MacDonald, 1960; Walsh, 1966兲, grain contact adhesion hysteresis 共Sharma and Tutuncu, 1994; Aleshin and Van Den Abeele, 2007兲, scattering in the fractal earth 共Van der Baan, 2002兲, and a superposition of intrinsic attenuation mechanisms, each with an individual resonance 共Debye兲 peak 共Liu et al., 1976兲. The idea of frictional sliding on crack surfaces and grain boundaries was particularly popular due to the works of Walsh 共1966兲 and Mindlin and Deresiewicz 共1953兲. Walsh 共1966兲 considers a very thin 2D elliptic crack with contacting surfaces sliding relative to each other during the passage of the wave and Mindlin and Deresiewicz 共1953兲 assume two identical elastic homogeneous spherical particles in contact when subjected to external loads. Although these and similar frictional models provide attenuation that is independent of frequency, they also predict some features that contradict early experiments 共Mavko, 1979; Winkler et al., 1979; Winkler and Nur, 1982兲. First, the specific attenuation factor 1 / Q that is predicted by these models is proportional to strain amplitude although experimental attenuations are independent of the signal amplitude. Second, for typical strain amplitudes of seismic waves and for reasonable microcrack dimensions, the computed slip across crack faces is less than the interatomic spacing; therefore, frictional losses at small strains are negligible ABSTRACT We have developed a mathematical formulation of two mechanisms of compressional wave attenuation, which can occur within the solid rock frame prestressed up to its yield stress in part of its volume. Energy losses are attributed to two distinct processes: irreversible plastic yielding and formation of radial microfractures around microscopic cavities. Smallamplitude waves propagating through the rocks prestressed at their yield point would cause nonelastic strain to avoid building local stresses above the yield limit and attenuate some fraction of their energy per every loading cycle. New mechanisms of microscale yielding and microfracturing give rise to frequency-independent attenuation due to rate-independence of plasticity formulation. Quality factor Q predicted by the model is independent of strain amplitude for small strains and decreases with increasing amplitude for large strains. We found that attenuation can be high even for small seismic strains 共10ⳮ9 – 10ⳮ5兲. Thus, Q ⳱ 12. . . 20 is achieved at effective pressures greater than twice the yield strength of the solid matrix for the plastic yielding mechanism and at overpressures exceeding half tensile strength for microfracturing. INTRODUCTION The attenuation of elastic waves has received a good deal of attention from the experimental 共e.g., Toksöz et al., 1979; Castagna et al., 1985; Klimentos and McCann, 1990; Best et al., 1994兲 and the modeling points of view 共Johnston et al., 1979; Carcione et al., 1988; Chapman et al., 2006兲. Several seismological observations on the attenuation of seismic waves have been recorded 共Aki, 1980; Fehler et al., 1992; Beresnev et al., 1995; Dasios et al., 2001兲. Based on experimental and in situ data, several alternative explanations relating attenuation to the global or local flow of saturating fluids 共Biot, 1956; Palmer and Traviolia, 1980; Stoll, 1989; Dvorkin et al., 1994; Manuscript received by the Editor 1 April 2008; revised manuscript received 29 December 2009; published online 20 May 2010. 1 University of Oslo, Physics of Geological Processes, Oslo, Norway. E-mail: v.m.yarushina@matnat.uio.no; iouri.podladtchikov@matnat.uio.no. © 2010 Society of Exploration Geophysicists. All rights reserved. N51 Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ N52 Yarushina and Podladchikov in rock samples 共Savage, 1969兲. In addition, it was shown that frictional attenuation results in nonlinear wave propagation. This was in contradiction with early data indicating that at seismic strains 共⬍10ⳮ6兲 attenuation is dominated by linear processes because there was no transfer of energy between frequency components of the signal. Although frictional losses are still accepted to be considerable even at strains on the order of 10ⳮ6 – 10ⳮ7, for unconsolidated marine sediments 共Prasad and Meissner, 1992; Buckingham, 1997兲 friction is considered only as a secondary loss mechanism in rocks. Recent observations reported important nonlinear effects. In a great variety of laboratory experiments over large intervals of stress, strain, and frequency, rocks exhibit a resonance frequency shift, dependence of wave velocity and attenuation on strain amplitude, nonlinear stress-strain relation, and stress-strain hysteresis 共Beresnev and Nikolaev, 1988; Johnson et al., 1996; Johnson and Rasolofosaon, 1996; Mashinskii, 2006; Nazarov et al., 2007兲. These and other nonlinear phenomena can be seen even at very low strains 共10ⳮ9兲. Seismological data from the recordings of large earthquakes agree with laboratory measurements and support the idea of nonlinear hysteretic ground behavior 共see Beresnev and Wen 关1996兴 for a review兲. Usually, a common belief is that the intrinsic anelasticity of minerals is small and therefore totally neglected. The observed stressstrain hysteresis indicates that no unique dependence exists between stress and strain, which casts doubt on the elastic nature of the process. Cusped hysteresis loops reported by Beresnev and Wen 共1996兲 and Kadish et al. 共1996兲 allow us to suspect the presence of permanent time independent 共i.e., plastic兲 deformation to which such cusped loops are peculiar 共Kachanov, 2004; Figure 1兲. In the experiments on bending prismatic bars of dry sedimentary rocks from Western Siberia with a stepwise increasing load, Mashinsky 共1994兲 shows that at strains as small as 10ⳮ6 – 10ⳮ3 a permanent deformation is achieved. This deformation was proven to be plastic because it appeared immediately after unloading and did not change over a) b) c) d) Figure 1. Hysteresis loops for different types of rheology: 共a兲 Maxwell viscoelastic solid, 共b兲 Kelvin-Voight solid, 共c兲 elastic–perfectly plastic solid, and 共d兲 elastic solid with microdamage. Maxwell and Kelvin-Voight viscoelastic solids exhibit smooth hysteresis loops. Cusped loops are specific to elastoplastic materials and microdamaged elastic solids. The hysteresis in elastoplastic solids shows permanent deformation upon unloading whereas elastic hysteresis upon unloading returns strains to zero. time. Moreover, elastic and plastic strains in the specimens were almost equal when the total strain was within the range of 10ⳮ6 – 10ⳮ5. The presence of permanent deformation in rocks is not surprising. The high temperatures and presence of fluids reduce its strength 共Nur and Byerlee, 1971; Byerlee, 1978兲. Furthermore, the heterogeneities, e.g., pores and cracks, are well-known stress concentrators. So, the real stresses around the cavities, grain boundaries, etc., can be much higher than in the rock in general and can lead to plastic yielding or fracturing around structural imperfections. If local stresses are already at the critical state, the passing seismic wave of even the smallest amplitude will only add to the existing load and will lead to further plastic flow or to the development of microfractures that radiate from the inclusions. In this paper, we propose two new frequency-independent mechanisms of intrinsic energy losses in prestressed porous media. Attenuation is due to dissipative processes, i.e., permanent plastic deformation 共failure兲, at the heterogeneities scale. Unlike viscous deformation, which is also permanent but rate dependent, plastic deformation is rate independent and occurs only when stresses reach a certain yield criterion. An increment of plastic strain is related to a stress increment only; there is no characteristic time scale in the model. This deformation is illustrated by a mass-spring system sliding on a rough surface 共Kachanov, 2004, p. 454–455兲 and in this sense our model can be considered as a modification of a frictional sliding mechanism. We consider two distinct failure processes 共microscale yielding and microfracturing兲 around cavities in the prestressed rock matrix as a potential source of energy losses. We estimate attenuation in terms of the quality factor Q. In our model, energy loss per cycle of harmonic oscillation is independent of the time scale of oscillations and therefore Q is exactly independent of frequency 共Knopoff, 1964兲. Porous rock can be fully saturated, partially saturated, or dry. The proposed mechanism is nonlinear; however, its nonlinearity is weak and the attenuation is amplitude independent at low seismic strains. The organization of the body of this paper is as follows: first we describe the mathematical model for P-wave attenuation around cavities and state the boundary-value problem for a representative volume element 共RVE兲 for porous rock. Then we give a rigorous mathematical analysis of deformation of the RVE during one cycle of harmonic oscillation 共plastic loading, elastic unloading, and subsequent reloading兲 caused by a passing seismic wave for two distinct failure modes: microscale yielding and microfracturing. In the “effective behavior of porous media” section, the response of a single pore is generalized and macroscopic properties of a porous rock are established. Details of the numerical computations are presented in the “numerical verification” section. The section on “results and discussion” presents the main new results of the paper, including the behavior of the quality factor with changing parameters and discussion on the relevance of the new mechanisms. This is followed by a section in which our conclusions are summarized. MODEL FOR P-WAVE ATTENUATION AROUND CAVITIES We base our analysis on the effective media theory approach 共Christensen, 1979; Nemat-Nasser and Hori, 1999兲 and model porous rock as a distribution of cylindrical or spherical pores embedded in a solid matrix 共Figure 2兲. The study of a typical response of a single cavity gives an estimation of the bulk response of a porous rock. It was shown previously that a similar spherical model gives a Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ Plastic yielding as attenuation mechanism good fit to experimental data on compaction of porous carbonate rocks and tuff 共Carroll and Holt, 1972; Baud et al., 2000; Vajdova et al., 2004兲. Microstructural observations have shown that inelastic compaction in limestone is associated with pore collapse that seems to initiate from stress concentrations at the surface of an equant pore, which induces a ring of localized damage in its periphery 共Zhu et al., in press兲. We consider a single cylindrical or spherical cavity of radius R in a solid deformable matrix that is subjected to a confining far-field pressure P⬁ at the remote boundary 共Figure 2兲. The cavity wall is subjected to pore pressure p. We do not consider the origin of this pressure. At fully saturated conditions, p is the fluid pressure. When gas is present in the fluid phase, p gives the pressure within the fluid and the gas. Because we consider the low-frequency regime here, these two pressures are equilibrated. Dry conditions are reproduced when p ⳱ 0. The behavior of the solid in general is controlled by the effective pressure ⌬P ⳱ P⬁ ⳮ p, which is prescribed to vary in time as a periodic function to imitate a seismic P-wave. The cavity can contract or dilate depending on whether the confining pressure is higher than the fluid pressure or the fluid pressure is higher than the confining pressure. We measure the stresses as positive in tension and pressures as positive in compression. Here ⌬P ⬎ 0 for contracting pore space and ⌬P ⬍ 0 for the expanding cavity. In the case of the cylindrical cavity, plane strain conditions are fulfilled. If no voids or imperfections are present at smaller scales, which can weaken the solid matrix, then it can be considered incompressible with a Poisson ratio of 0.5. By considering the elastoplastic pore collapse, Carroll and Holt 共1972兲 show that the effect of elastic compressibility on the overall compaction of the porous rock is quite small. Therefore, the assumption of matrix incompressibility seems to be justified. ⳱ ⳮp0 ⳮ ⌬P0 r r Ⳮk rⳮ ⳱ 0, r 共1兲 the incompressibility condition u u Ⳮ k ⳱ 0, r r 冉冉 冊 1 R0 k r kⳭ1 冊 Ⳮ1 , 共4b兲 where R0 is the initial cavity radius. PLASTIC YIELDING AROUND THE CAVITY Initial elastoplastic state Note that the elastic stress state given by equation 4a and 4b is not hydrostatic. It has a nonzero deviatoric component r ⳮ ⳱ ⌬P0共R0 / r兲kⳭ1共1 Ⳮ 1 / k兲. At an elevated initial effective pressure ⌬P0 ⳱ P⬁0 ⳮ p0, it can exceed the yield stress. In the case of cylindrical and spherical pore geometry, the Tresca and von Mises yield criteria reduce to the form r ⳮ ⳱ 2Y , 共5兲 with Y being the yield limit of solid matrix for pure shear for the cylindrical pore and half of the yield limit for simple tension for the spherical one, ⳱ sgn共⌬P兲. The cavity is contracted when the pressure of the host rock exceeds the pore pressure 共⌬P ⬎ 0兲, which can be the case for the connected porosity when fluid can be expelled from the pore without raising the pore pressure when a wave passes. The pore dilates if ⌬P ⬍ 0, i.e., pore pressure pushes the cavity wall more than the host rock tends to squeeze it. The latter can happen in the case of occluded porosity when a passing wave raises pore pressure. Our modeling accounts for pore compaction and pore dilation modes. The parameter ⳱ 1 if the pore space is compacting and ⳱ ⳮ1 if the pore space is dilating. In either case, the yield criterion from equation 5 will first be reached when the initial effective pressure ⌬P0 ⳱ P⬁0 ⳮ p0 reaches the critical value INITIAL ELASTIC STATE AROUND THE CAVITY If before the initial arrival of the first wave the undisturbed effective pressure ⌬P0 ⳱ P⬁0 ⳮ p0 is small, then the deformation of the solid matrix around the pore will be purely elastic and governed by the equilibrium equation N53 ⌬Pcr ⳱ 2k Y , kⳭ1 共6a兲 2k Y. kⳭ1 共6b兲 or equivalently, 兩⌬Pcr兩 ⳱ We assume that the absolute value of the initial undisturbed effective pressure ⌬P0 exceeds 兩⌬Pcr兩 and the initial state of the rock is elastoplastic. In this case, a plastic region spreads into the shell surround- 共2兲 and Hooke’s law 共Muskhelishvili, 1953兲 u 2Ⳮk 共 ⳮ r兲, ⳱ r 12k 共3兲 where r and are the radial and hoop stresses, u is the radial displacement, and is the shear modulus of the solid matrix. Parameter k indicates the geometry of the pore, with k ⳱ 1 for the cylindrical pore and k ⳱ 2 for the spherical pore. The solution to equations 1–3 gives an initial elastic distribution of stresses around the cavity, r ⳱ ⳮp0 Ⳮ ⌬P0 冉冉 冊 R0 r kⳭ1 冊 ⳮ1 , 共4a兲 Figure 2. The cylindrical 共spherical兲 model of the representative volume element in the porous material. The cavity wall of radius R is subjected to a uniform fluid pressure p and a pressure P⬁ at a great distance from the cavity. At a sufficiently high pressure difference, plastic regions can increase in volume. Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ N54 Yarushina and Podladchikov ing the pore 共Figure 2兲. For symmetry reasons, the plastic boundary is a cylindrical 共spherical兲 surface. Its initial radius is denoted by c0. Due to incompressibility of the solid matrix expressed in equation 2, the radial displacement in the shell is u ⳱ A0 /rk, r ⳱ ⳮp0 ⳮ 2kY ln共r/R0兲 ⳱ ⳮp0 ⳮ 2Y 共1 Ⳮ k ln共r/R0兲兲 冎 共R0 ⱕ r ⱕ c0兲. 共8兲 Stresses in the elastic region can be found by solving equations 1–3 together with the remote boundary condition 再 r ⳱ ⳮP⬁0 Ⳮ B0 /rkⳭ1 ⳱ ⳮP⬁0 ⳮ B0 /共krkⳭ1兲 冎 共r ⱖ c0兲. 冉 冊 RkⳭ1 k Ⳮ 1 ⌬P0 Y 0 exp ⳮ1 , 共k Ⳮ 1兲 2k Y 冉 冊 RkⳭ1 k Ⳮ 1 ⌬P0 B0 ⳱ 0 2kY exp ⳮ1 , kⳭ1 2k Y where an upper dot stands for the material time derivative 共ȧ ⳱ a / t Ⳮ v · a / r兲. The initial distribution of stresses in the elastic region is given by equation 9 at the remote boundary r ⳱ ⳮP⬁. Solving equilibrium equation 1 and Hooke’s law 共equation 15兲 for r and with a velocity taken in the form of equation 13 yields 冦 r ⳱ ⳮP⬁ Ⳮ ⳱ ⳮP⬁ ⳮ RkⳭ1 2k 0 rkⳭ1 k Ⳮ 1 RkⳭ1 0 2 rkⳭ1 k Ⳮ 1 冉 冉 Y exp Y exp k Ⳮ 1 ⌬P0 2k Y k Ⳮ 1 ⌬P0 2k Y 冊 冊 ⳮ1 ⳮ ⳮ1 Ⳮ B rkⳭ1 B krkⳭ1 冧 共10a兲 共10b兲 冊 1 ⌬P0 c0 ⳱ R0 exp ⳮ . 2kY kⳭ1 冦 r ⳱ ⳮP⬁ Ⳮ 2 ckⳭ1 ⳱ ⳮP ⳮ Y k Ⳮ 1 rkⳭ1 ⬁ 冉 共11兲 v⳱ⳮ The P-wave disturbs the medium and causes the redistribution of stresses. Its first phase can add to the load or cause unloading from the current stress state. Consider the wave that first increases the absolute value of the effective pressure by changing the pore and outside pressures 共Figure 3兲. It provokes the further plastic flow regardless of the wave amplitude. The plastic region grows to the radius c ⬎ c0, dissipating the energy of the wave. We follow the incremental solution procedure 共Hill, 1950兲 to evaluate changes in the rock caused by the wave. The radial velocity v in the volume satisfies the incompressibility equation v 2k ckⳭ1 Y k Ⳮ 1 rkⳭ1 c ⳱ R exp Loading v Ⳮk ⳱0 r r 共12兲 v ⳱ A/rk . 共13兲 共r ⱖ c兲. 共16a兲 Unknown parameters A and B and the current elastoplastic radius c are found from the continuity of stresses at the elastoplastic boundary, leading to and the initial radius of the elastoplastic boundary 冉 共15兲 共9兲 From the continuity of stresses at the elastoplastic interface, we find parameters A0 ⳱ ⳮ v 2Ⳮk ⳱ 共˙ ⳮ ˙ r兲, r 12k 共7兲 where A0 is a parameter to be determined. Stresses in the plastic region are defined by the equilibrium equation 1, the yield criterion 5, and the boundary condition at the radius of the hole 再 where we accounted for the fact that the pore pressure at the current cavity radius R equals p. The increments of stresses in the elastic region satisfy Hooke’s law 冧 共r ⱖ c兲, 冊 1 ⌬P ⳮ , 2kY kⳭ1 冉 共16b兲 共17兲 冊 1 d⌬P ckⳭ1 Y dR Ⳮ . k r R dt 2k dt 共18兲 Although stresses given by equation 16b are already in the final form, the velocity can still be resolved further. Because v ⳱ dR / dt at the cavity wall, the equation for the evolution of the hole radius can be written as and is of the form Parameter A is to be determined. From the equilibrium equation 1 and the yield criterion 5, we find stresses in the plastic region 再 r ⳱ ⳮp ⳮ 2kY ln共r/R兲 ⳱ ⳮp ⳮ 2Y 共1 Ⳮ k ln共r/R兲兲 冎 共R ⱕ r ⱕ c兲, 共14兲 Figure 3. A passing pressure wave causes an increase in the absolute value of the initial pressure up to ⌬Pu and starts to decline up to the value ⌬Pr, which can be above the reverse plastic flow point. Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ Plastic yielding as attenuation mechanism 冉 1 dR ⌬P R d⌬P exp ⳮ ⳱ⳮ dt 2kY dt 2kY kⳭ1 冉 冉 exp 冊 冊 冊冒 is greatest on the internal surface as it follows from equation 21a and 21b, reverse plastic flow will initiate from the hole rim when the effective pressure reaches the critical value 1 ⌬P ⳮ Ⳮ . 2kY kⳭ1 Y 共19兲 Substitution of equation 19 into equation 18 yields the final result for velocity v⳱ⳮ 1 ckⳭ1 d⌬P 2kY rk dt 冒冉 冊 ckⳭ1 . kⳭ1 Ⳮ R Y 共20兲 Unloading As the wave approaches its crest, the effective pressure reaches its extreme value ⌬Pu 共Figure 3兲 and starts to decrease, giving rise to elastic unloading. From this moment, stresses and velocity in the entire shell are governed by equilibrium equation 1, incompressibility condition equation 12, and elastic constitutive equation 15. Confining and fluid pressures are prescribed at the external and internal boundary as before 共Figure 2兲. The solution to these equations gives the following increments of stresses d r ⳱ ⳮdP⬁ Ⳮ d⌬P · d ⳱ ⳮdP⬁ ⳮ d⌬P · and velocity v⳱ 冉 冊冉 kⳭ1 R 2k r k 共⌬P ⳮ ⌬Pu兲 冉冊 冉冊 R r kⳭ1 1 R k r 共21a兲 , kⳭ1 共21b兲 , 冊 R d⌬P dR ⳮ , dt k Ⳮ 1 dt 共21c兲 where ⌬Pu is the effective pressure at the onset of unloading. The residual stresses in the shell can be obtained by subtracting equation 21a and 21b from equations 14 and 16b. Because v ⳱ dR / dt at the cavity wall, the equation for the evolution of the hole radius during unloading can be written as d⌬P dR R . ⳱ⳮ dt 共k Ⳮ 1兲共⌬P ⳮ ⌬Pu兲 Ⳮ 2k dt 共22兲 Combining equations 21c and 22, one can write v⳱ⳮ N55 1 RkⳭ1 d⌬P . 共23兲 k 共k Ⳮ 1兲r ⌬P ⳮ ⌬Pu Ⳮ 2k /共k Ⳮ 1兲 dt Reloading Elastic unloading will continue until the stresses reach the yield criterion again and the reverse plastic flow starts or until the wave reaches its trough and turns to its final phase, leading to an increase in the absolute value of the effective pressure 共Figure 3兲. In the latter case, stresses might not reach the yield criterion again and unloading will be purely elastic. The yield criterion for the reverse plastic flow is r ⳮ ⳱ ⳮ2Y . Because the numerical magnitude of r ⳮ ⌬Prf ⳱ ⌬Pu ⳮ 2Y 2k . kⳭ1 共24兲 Whether stresses reach the critical value during unloading or not depends on the material parameters and the wave amplitude defined through ⌬Pu. For waves with very small amplitude, the critical pressure for reverse flow might not be reached. The scenario when the plastic flow will develop at both wave peaks provides more energy losses than that of the plastic flow occurring only during the first phase of the wave. We consider the worst possible situation and assume that the stresses during unloading did not reach the critical value given by equation 24 and, after passing a trough, began reloading elastically again. Stresses, velocity, and cavity radius during elastic reloading are determined by equations 21a–21c, 22, and 23 until the effective pressure reaches its initial value ⌬P0 and the wave is gone. MICROFRACTURING AROUND THE CAVITY Rocks forming the earth have composite or heterogeneous microstructures with a variety of pre-existing or stress-induced defects in the form of voids, microcracks, and weak interfaces. These imperfections cause localized stress amplification, which can be high enough to lead to microfracturing around larger defects if slightly disturbed. It has been observed that the microfracturing process can be correlated to the progressive failure of a circular opening in brittle rock 共e.g., Suknev et al., 2003; Guéguen and Boutéca, 2004兲. Microfractures due to overpressures extending from intraskeletal pores are observed in reservoirs 共Márquez and Mountjoy, 1996兲. Seismic waves, when traveling through the critically stressed formations, could cause brittle fracturing around spherical or cylindrical pores in rocks. The earth is a dynamic system. After a seismic event, a number of mechanisms can anneal the induced microscopic fractures around defects and cavities and reduce their number, particularly in high-temperature environments. In addition, the stress state in the earth’s interior is always slightly changing due to a number of processes, e.g., fluid migration, metamorphic reactions, seismicity, tectonic processes, etc. There are infinitely many virtual stress states in rock and seismic waves that never have repeating paths. One seismic wave cannot open all cracks; therefore, every new seismic event could possibly generate a new set of fractures. Even in well-controlled experiments, cracks are still forming after a number of loading cycles. It is known from damage mechanics 共Chaboche, 1988兲 that crack propagation is either stable or unstable. Results from damage-control tests involving cyclic loads exceeding the crack-damage threshold show that subsequent to the first damage increment, very little new cracking occurred when under stable conditions; crack growth can be stopped by controlling the applied load. It appears that with each subsequent damage increment, new cracks and existing cracks initiate and propagate 共Eberhardt et al., 1999兲. This would seem to imply that with each damage increment, a crack population of new and existing cracks develops and grows. In addition, the population of cracks is being changed by high stress with each opening or extension so that new microfractures can be generated by passing elastic waves, producing acoustic emission events reported in experiments on cyclic loading 共Holcomb, 1981兲. Some researchers report that the width of the hysteresis loops changes very little for several cycles during cyclic loading experiments 共Son- Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ N56 Yarushina and Podladchikov dergeld and Estey, 1981兲. Soils and rocks show that all subsequent unload-reload cycles result in a gradual accumulation of permanent strain and excess pore pressure 共for undrained cases; Wood, 1990; Yu et al., 2007兲. The memory of a rock of all the previous deformation results in a softening behavior and a loss of cohesion 共Cox and Meredith, 1993; Gatelier et al., 2002兲, which would make it easier to deform rocks irreversibly even by small-amplitude seismic waves. Microdamage on a grain scale leads to a permanent rate-independent deformation in rocks; it is a major mechanism of brittle plastic failure. 再 r ⳱ Y ⳮ p0 ⳮ Y共R0 /r兲k ⳱ Y ⳮ p0 冎 共R0 ⱕ r ⱕ c0兲. 共27兲 As before, the subscript 0 denotes initial undisturbed values of parameters. In the elastic region, one has to satisfy the stress balance equation 1, the incompressibility condition equation 2, and Hooke’s law 共equation 3兲. The solution to these equations is in the form of equation 9 as before with B0 ⳱ ⳮYRk0c0 k . kⳭ1 共28兲 The initial radius of the elastoplastic interface is Initial state When ⌬P ⬍ 0, i.e., fluid pressure locally exceeds the confining pressure, the pore space undergoes isotropic expansion and tensile microcracks might develop around major pores 共Figure 4兲. According to Griffith’s failure criterion, mode I cracks will generate in the vicinity of the cylindrical or spherical pore when tensile hoop stress reaches the critical value. For fluid-saturated rocks, the effective stress concept suggests that the criterion for failure takes the form 共Paterson and Wong, 2005, p. 163; Jaeger et al., 2007, p. 99–100兲 Ⳮp⳱Y. 共25兲 Through substitution of the elastic stresses defined by equation 4a and 4b into failure criterion equation 25, we find that tensile cracks will be generated if the effective pressure reaches the threshold value ⌬Pc ⳱ ⳮ k Y. kⳭ1 共26兲 In the failure region adjacent to the cavity, equilibrium stresses are fully defined by stress balance, i.e., equation 1, failure criterion equation 25, and the boundary condition at the pore radius, resulting in ck0 ⳱ Rk0 Y . k Ⳮ 1 ⌬P0 Ⳮ Y 共29兲 Loading When a wave comes and disturbs the initial equilibrium, further failure occurs. Radial cracks propagate further into the rock, causing the growth of an initial failure region. From stress-balance equation 1 and failure criterion equation 25, together with the boundary condition at the cavity wall 共兩 r兩r⳱R ⳱ ⳮp兲, one finds that 再 r ⳱ Y ⳮ p ⳮ Y共R/r兲k ⳱Y ⳮp 冎 共R ⱕ r ⱕ c兲. 共30兲 The plastic flow rule can be used to find a pressure-expansion relation for the shell. We assume that the total strain increment in the failure region is the sum of the elastic and irreversible plastic strain increments, i.e., de ⳱ dee Ⳮ de p. For the total strain increments, one has 共Hill, 1950兲 der ⳱ v r dt, v de ⳱ dt. r 共31兲 The associated flow rule gives derp ⳱ d F r , dep ⳱ d F , 共32兲 where d is a positive increment of the plastic multiplier and F ⳱ Ⳮ p ⳮ Y is a plastic potential. Elastic strain increments are given by Hooke’s law dere ⳱ 2Ⳮk 共d r ⳮ d 兲, 12 共33a兲 dee ⳱ 2Ⳮk 共d ⳮ d r兲. 12k 共33b兲 Rearranging equations 31–33, we obtain a differential equation for velocity v Figure 4. The cylindrical 共spherical兲 model of tensile brittle failure around the pore. At sufficiently high isotropic tensile pressure P⬁, at a great distance from the cavity, or at a pore pressure that is significantly higher than the confining pressure P⬁, mode I cracks form in the vicinity of the pore. r ⳱ 2Ⳮk 共˙ r ⳮ ˙ 兲, 12 共34兲 where the stresses are known from the solution given by equation 30. Integrating and neglecting the convective part of the time derivatives of stresses, we find after some rearrangements that Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ Plastic yielding as attenuation mechanism v⳱ⳮ Y dR ln r Ⳮ A 共R ⱕ r ⱕ c兲 4 dt 共35a兲 v⳱ⳮ N57 c2 2Y共R ⳮ r兲 Ⳮ 3r d⌬P 2r YR Ⳮ c共6 ⳮ 4Y兲 dt 共R ⱕ r ⱕ c兲, 共41a兲 for the cylindrical cavity and v⳱ 2Y R dR Ⳮ A 共R ⱕ r ⱕ c兲 3 r dt for the spherical cavity. Parameter A is to be determined. In the elastic region, we solve the force balance and incompressibility equations 1 and 12 and Hooke’s law, i.e., equation 15, together with the remote boundary condition. Demanding the continuity of the stresses and velocities at the interface r ⳱ c between the failure and elastic domains, we obtain 冦 r ⳱ ⳮP⬁ ⳮ Rkc kY rkⳭ1 k Ⳮ 1 R kc Y ⳱ ⳮP Ⳮ kⳭ1 r kⳭ1 ⬁ 冧 共r ⱖ c兲, 1 ckⳭ1 d⌬P Y Rkⳮ1c dR ⳮ 2 rk dt 2k rk dt ck ⳱ Y Rk . k Ⳮ 1 ⌬P Ⳮ Y 共r ⱖ c兲, 共36b兲 共36c兲 共R ⱕ r ⱕ c兲 共37a兲 around the cylindrical cavity and v⳱ c d⌬P Y R 4c ⳮ r dR ⳮ 6 c r dt 4 dt 共R ⱕ r ⱕ c兲 共37b兲 2c d⌬P dR ⳱ⳮ dt 共ln共R/c兲 ⳮ 2兲Y Ⳮ 4 dt Achieving its crest point at an effective pressure ⌬Pu, the wave causes the unloading of the media. As for the ductile plastic yielding, we assume that unloading is purely elastic and is totally described by equations 21a–21c, 22, and 23. EFFECTIVE BEHAVIOR OF POROUS MEDIA The next step is to determine the effective response of porous aggregate with random distribution of voids. The macroscopic stresses in the porous material are given in terms of the surface data by Nemat-Nasser and Hori 共1999, p. 27–38兲, ¯ ij ⬅ 3 d⌬P dR c2 ⳱ⳮ 2 共6 ⳮ 4Y兲c Ⳮ YR dt dt for the cylindrical case and 1 V V 冕 tix jdS, 共42兲 V where ti are surface tractions, xi are coordinates on the boundary, and V is the overall volume of the representative sample bounded by a surface V. For the case at hand, the average stresses in the porous ¯ r ⳱ ⳮP⬁, ¯ ⳱ ⳮP⬁. The average mean stress is ¯m material are ⬁ ⳱ ⳮP ; the average effective pressure is ⌬P ⳱ P⬁ ⳮ p. The porosity of a porous aggregate equals the ratio of the volume of pores V p to the total volume of the porous material V, namely ⳱ V p /V. 共43兲 From equation 43, we also have that d dV p dV ⳱ ⳮ . Vp V 共44兲 d dV p ⳱ 共1 ⳮ 兲 Vp 共45兲 d dV ⳱ . 共1 ⳮ 兲 V p 共46兲 共R ⱕ r ⱕ c兲, 共r ⱖ c兲 ijdV ⳱ 共39兲 共40a兲 4 ⳮ Y ln共c/R兲 d⌬P c2 2r Y共ln共c/R兲 Ⳮ 2兲 ⳮ 4 dt 冕 The total volume V is occupied by the pore space V p and solid volume Vs so that V ⳱ Vs Ⳮ V p. If rock mineral grains composing the matrix are assumed to be incompressible then dVs ⳱ 0 and dV ⳱ dV p. Thus, equation 44 takes one of the two forms: for spherical geometry. Substitution of equations 38 and 39 simplifies the equations for velocities and gives v⳱ 1 V 共38兲 for cylindrical geometry and 4 ⳮ Y ln共r/R兲 d⌬P c 2 Y共ln共c/R兲 Ⳮ 2兲 ⳮ 4 dt 共41b兲 Unloading and reloading around the spherical cavity. From equation 37a and 37b, we find that the velocity of the cavity wall is v⳱ 共r ⱖ c兲 for the spherical case. 共36a兲 Because v must be continuous across the plastic boundary, we find from equations 35b and 36b that in the plastic region velocity has the following form: c d⌬P Y dR 共ln共c/r兲 Ⳮ 2兲 ⳮ 4 dt 2 dt c3 2YR Ⳮ c共3 ⳮ 2Y兲 d⌬P 2r2 YR Ⳮ c共6 ⳮ 4Y兲 dt General considerations v⳱ v⳱ v⳱ⳮ 共35b兲 共40b兲 or Equations 45 and 46 are equivalent. The particular choice of one or the other equation depends only on computational convenience. These equations give a description of porosity evolution in a porous material in terms of pore-space compressibility. In poroelastic or poroelastoplastic materials, the relative change of pore volume would depend on the material properties of solid rock grains, porosity, and Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ N58 Yarushina and Podladchikov d applied effective pressure. For the axisymmetric model considered here, porosity can be expressed in terms of internal and external radii because the pore and total volumes are defined as 2Ⳮk Vp ⳱ RkⳭ1, 3 2Ⳮk kⳭ1 V⳱ Rout , 3 exp t Ⳮ ⵜ 共共1 ⳮ 兲vs兲 ⳱ 0, ˙ . 1ⳮ 共49兲 共50兲 共51兲 The logarithmic volumetric strain of the matrix can be obtained by the integration of the last equation 冉 冊 1 ⳮ 0 ēv ⳱ ln , 1ⳮ 冉 ⳱ 0 共1 ⳮ 0兲exp k Ⳮ 1 ⌬P0 k Ⳮ 1 ⌬P 2k Y 2k 冊 Y 冊 冉 共53兲 d⌬P. ⳮ 1 Ⳮ /Y ⳮ 1 Ⳮ 0 exp k Ⳮ 1 ⌬P0 2k Y 冊 . ⳮ 1 Ⳮ /Y 共54兲 Combining equations 51 and 53 gives the desired equation for volumetric strain rate where vs is the solid matrix velocity and is the porosity. Defining the volumetric strain rate of the matrix ¯v as the divergence of the matrix velocity and introducing the material time derivative of porosity in equation 50, we obtain ¯v ⳱ ⵜ vs ⳱ 2k Ⳮ Y ckⳭ1 /RkⳭ1 共48兲 As before, equations 48 and 49 are two alternative forms of the porosity equation. Equation 48 explicitly accounts only for the changes in porosity due to contraction-expansion of a cylindrical 共spherical兲 void whereas equation 49 accounts for all possible porosity changes due to void growth and developing microfractures. To obtain the final form of the pressure-expansion relation, one needs to specify radii as functions of external load. The effective strain rate of a porous rock can be related to porosity changes in a porous rock with an incompressible solid. The conservation of solid mass requires 共1 ⳮ 兲 冉 共47兲 and Rk dRout d ⳱ 共k Ⳮ 1兲 outkⳭ1 . 共1 ⳮ 兲 R ckⳭ1 /RkⳭ1 kⳭ1 We integrate equation 53 and obtain where Rout is the external radius of the representative volume. Substitution of equation 47 into 45 and 46 leads accordingly to d dR ⳱ 共k Ⳮ 1兲 共1 ⳮ 兲 R 共1 ⳮ 兲 ⳱ⳮ ¯v ⳱ ⳮ ckⳭ1 /RkⳭ1 kⳭ1 d⌬P . kⳭ1 kⳭ1 2k Ⳮ Y c /R dt 共55兲 Loading: microfracturing When microfracturing occurs during the active plastic loading, i.e., the first cycle of deformation, changes of the pore volume are influenced by the growth of the cylindrical 共spherical兲 void and by the initiation of new microfractures. Therefore, we use equation 49 to obtain the pore dilation relation. Noting that RkoutdRout / dt ⳱ 兩r · v兩r⳱Rout and using equations 40b and 41b, we obtain 4 ⳮ Y ln c/R d c2 ⳱ⳮ 2 d⌬P 共1 ⳮ 兲 R 4 ⳮ Y共ln c/R Ⳮ 2兲 共56兲 for cylindrical voids and 3 c3 2Y Ⳮ 共3 ⳮ 2Y兲c/R d ⳱ⳮ d⌬P 共57兲 共1 ⳮ 兲 2 R3 Y Ⳮ 2共3 ⳮ 2Y兲c/R for spherical voids. The elastoplastic radius c is defined by equation 36c. Substitution of equations 56 and 57 into equation 51 gives the effective strain rate of a porous rock with cylindrical voids ¯v ⳱ ⳮ 4 ⳮ Y ln c/R d⌬P c2 2 R 4 ⳮ Y共ln c/R Ⳮ 2兲 dt 共58兲 and the effective strain rate of a rock with spherical holes 共52兲 where 0 is the initial porosity corresponding to an undisturbed state. In the next sections, we are interested in quantitatively predicting the amount by which the porosity and total volumetric strain in rock are altered because of a passing seismic P-wave. One cycle of loading consists of plastic loading and subsequent elastic unloading-reloading modes. Calculations are based on the averaging procedure outlined above. Loading: plastic yielding The behavior of a small volume of material containing a single void with localized plastic yielding is described by the analytical solution given by equations 12–15, 16a, 16b, and 17–20. Substitution of equation 19 for dR / dt into equation 48 gives the following porosity equation: ¯v ⳱ ⳮ 3 c3 2Y Ⳮ 共3 ⳮ 2Y兲c/R d⌬P . 2 R3 Y Ⳮ 2共3 ⳮ 2Y兲c/R dt 共59兲 Unloading and reloading Substitution of equation 22 into equation 48 gives the porosity equation for unloading and subsequent elastic reloading in porous media with microscale yielding and microfracturing d d⌬P ⳱ⳮ . 共1 ⳮ 兲 ⌬P ⳮ ⌬Pu Ⳮ 2k /共k Ⳮ 1兲 共60兲 Integration gives the finite form of porosity-pressure relation ⳱ 2k u . 2k Ⳮ 共k Ⳮ 1兲共⌬P ⳮ ⌬Pu兲共1 ⳮ u兲 Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ 共61兲 Plastic yielding as attenuation mechanism 2 冕 From equation 51, the volumetric strain rate during unloading will be d⌬P ¯v ⳱ ⳮ . ⌬P ⳮ⌬Pu Ⳮ 2k /共k Ⳮ 1兲 dt N59 ⌬E ⳱ ⳮ ⌬Pdev ⳱ ⳮ 共62兲 冕 ⌬Pvdt. 共64兲 0 Strain induced by a seismic wave in all considered cases of loading and unloading can be obtained by time integration of obtained volumetric strain rates. One cycle of harmonic loading is imitated by a sinusoidal perturbation of effective pressure of frequency , ⌬P ⳱ ⌬P0 Ⳮ 共⌬Pu ⳮ ⌬P0兲sin共2 t / 兲, taking for a period of t ⳱ 0..2 共Figure 3兲. The maximum stored strain energy is given by NUMERICAL VERIFICATION E ⳱ max共ⳮ ⌬P · ev兲. Analytical solutions for a single void considered above are obtained under several assumptions. First, we assumed that the rockmineral grains composing the matrix are incompressible. Second, plastic flow occurs only during the first phase of harmonic loading and the possibility of the reverse plastic flow during unloading is ignored. Finally, we assumed that the effect of the void is not felt on the outside boundary. To investigate the behavior of the system beyond these limits, a finite-element numerical code for the von Mises type of plasticity was developed. Our numerical approach is based on the incremental first-order forward Euler solution strategy with correction of the drift from the yield surface and use of continuum-tangent moduli. The algorithm is combined with Galerkin’s finite-element method in its weak form and implemented using the 2D MATLAB-based finite-element method. We used an adaptive moving grid with a 2D four-node isoparametric element for plane strain. Due to radial symmetry, an analysis needs only to account for a quarter-cell. The mesh thickens as r2 at the vicinity of the hole. The applied load is partitioned in several small incremental loads that are repeatedly applied to the internal and external boundaries. After stresses reached the prescribed value imitating the initial prestress in a porous rock, the cycle of loadingunloading-reloading is performed during which applied effective pressure 共defined as the difference between outside and inside pressures兲 repeats the path shown on Figure 3. The analytical solution for a cylindrical cavity described previously was used as a benchmark for the code. During each cycle of harmonic loading, porosity evolution is computed as a squared ratio of internal and external radii, i.e., ⳱ 共R / Rout兲2. Average strain and strain rate are calculated using equations 51 and 52. Loading cycles were repeated for different values of initial porosity, initial prestress, and wave amplitude. The comparison of numerical results for different Poisson ratios with analytical incompressible solution shows that compressibility of the solid matrix has little impact on porosity evolution during quasi-static loading as was already noted by Carroll and Holt 共1972兲. The effect of reverse plastic flow during unloading and finite radius of external boundary on results for attenuation will be discussed in the next section. RESULTS AND DISCUSSION As a measure of attenuation in porous media, we choose the specific attenuation factor 1 / Q defined as 2 /Q ⳱ ⌬E/E, 共63兲 where ⌬E is the amount of energy dissipated per stress cycle and E is strain energy stored in the unit volume when the strain is a maximum 共Knopoff, 1964兲. The dissipated energy can be found by integrating the deformation work over the whole cycle of harmonic loading: 共65兲 As discussed earlier, one stress cycle consists of active loading, unloading, reloading, and final unloading; therefore, equation 64 is decomposed into four separate integrals over quarter periods: /2 ⌬E ⳱ ⳮ 冕 兩⌬Pv兩loadingdt ⳮ 0 冕 /2 3 /2 ⳮ 冕 兩⌬Pv兩unloadingdt 2 兩⌬Pv兩reloadingdt ⳮ 冕 兩⌬Pv兩unloadingdt. 3 /2 In each of the four integrals, one of equations 55 and 59 or 62 for volumetric strain rate during different deformation modes was substituted. Volumetric strain ev from equation 65 is found by time integration of equations 55 and 59 or 62. Here Q is further computed as a function of the following four dimensionless parameters: ratio of initial effective pressure to the yield stress 共⌬P0 / Y兲, strain amplitude e0, porosity, and ratio of the shear modulus to the yield stress of the solid frame 共 / Y兲. In computations, ⌬P0 / Y was varied from one to six, e0 from 10ⳮ9 to 10ⳮ3, and was changing in the 10%–50% range. The dependence of Q on / Y and porosity is relatively unimportant within the porosity range investigated. The contouring of Q versus the remaining two parameters for the case of microscopic plastic yielding around cylindrical and spherical pores is shown in Figures 5a and 6a for / Y ⳱ 33 and 10% of initial porosity. Figures 5b and 6b show Q as a function of normalized prestress ⌬P0 / Y, initial porosity , and wave amplitude e0. The abscissa parameter on both plots is chosen in such a way that 3D data for Q at various ⌬P0 / Y, , and e0 would fit a single curve. At strains below 10ⳮ5, the dependence of quality factor on amplitude and porosity disappears and effective pressure is a dominant factor influencing attenuation. However, at higher strains 1 / Q almost linearly depends on e0 so that prestress and strain amplitude additively contribute to Q. The porosity effect is very low at small seismic strains but increases at larger strains. Attenuation increases 共and Q decreases兲 with an increase of initial prestress given in terms of normalized effective pressure ⌬P0 / Y. Figures 5b and 6b show that the quality factor asymptotically approaches a minimum value of approximately 12. However, this limiting value can be a consequence of the limited range of initial prestress 共⌬P0 / Y ranges from one to six兲 and strain amplitude used in computations presented in Figures 5 and 6 and of the assumption on dilute void distribution. Lower values of Q can be obtained if the model of a cylinder 共sphere兲 of finite radius would be considered. Such a model would allow for the full plastic pore collapse at some values of initial prestress and wave amplitude and therefore would provide Q ⳱ 2 corresponding to the total energy absorption. Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ N60 Yarushina and Podladchikov Figures 7 and 8 demonstrate energy losses in porous media due to the opening of mode I microfractures around the major cylindrical or spherical pores for / Y ⳱ 33 and 10% of initial porosity. They correspond to a case of “expanding” porosity, when fluid pressure locally exceeds pressure in a solid frame, which can happen in fluid-bearing rocks. The quality factor Q increases with increasing isotropic pressure P⬁0 and decreases with an increase in pore pressure p0. The lowest Q that can be achieved with this mechanism is 2 . This value corresponds to situations when rock is in a fully plastic state and all the energy that was imparted to the rock frame was dissipated. It is the lowest possible theoretical value for Q defined as a ratio of peak elastic energy to the energy dissipated per stress cycle 共Barton, 2007兲. Figure 9 shows the comparison of analytical and numerical results for the specific attenuation factor obtained for microscopic von Mises yielding. The slight discrepancy of results is caused by the a) b) – – – a) b) – –1.2 – –1.3 – –1.4 – – –1.5 – –1.6 – –1.7 – –1.8 – –1.9 – – – – – –2.0 – – – –2.1 –2.2 – – – – Figure 5. Quality factor as a function of the initial prestress, strain amplitude, and porosity in the model of attenuation due to microscale yielding around cylindrical pores. 共a兲 Contour plot for Q as a function of strain amplitude e0 and normalized prestress ⌬P0 at ⳱ 10%. 共b兲 The data collapse of Q as a function of a single expression ⌬P0 / Y Ⳮ 200共1 ⳮ 2 兲e0. a) b) Figure 7. Quality factor as a function of the initial prestress, strain amplitude, and porosity in the model of attenuation due to microfracturing around cylindrical pores. 共a兲 Contour plot for Q as a function of strain amplitude e0 and normalized prestress ⌬P0 at ⳱ 10%. 共b兲 The data collapse of Q as a function of a single expression ⌬P0 / Y ⳮ 110共1 ⳮ 兲2.5e0. The quality factor Q increases with increasing isotropic confining pressure P⬁0 and decreases with an increase in pore pressure p. a) b) – – – –1.2 – –1.3 – –1.4 – –1.5 – –1.6 – – – –1.7 –1.8 –1.9 –2.0 – – – – – –2.1 – – – – – –2.2 – – – – – – – – Figure 6. Quality factor as a function of the initial prestress, strain amplitude, and porosity in the model of attenuation due to microscale yielding around spherical pores. 共a兲 Contour plot for Q as a function of strain amplitude e0 and normalized prestress ⌬P0 at ⳱ 10%. 共b兲 The data collapse of Q as a function of a single expression ⌬P0 / Y Ⳮ 250共1 ⳮ 2 兲e0. Figure 8. Quality factor as a function of the initial prestress, strain amplitude, and porosity in the model of attenuation due to microfracturing around spherical pores. 共a兲 Contour plot for Q as a function of strain amplitude e0 and normalized prestress ⌬P0 at ⳱ 10%. 共b兲 The data collapse of Q as a function of a single expression ⌬P0 / Y ⳮ 170共1 ⳮ 兲2.5e0. The quality factor Q increases with increasing isotropic confining pressure P⬁0 and decreases with an increase in pore pressure p. Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ Plastic yielding as attenuation mechanism presence of reverse plastic flow during unloading and the effect of a pore on the finite external radius of the shell at higher porosities. It can be noted that these factors tend to increase attenuation. The dependence of the attenuation factor on / Y calculated according to the model of plastic yielding around cylindrical cavity is presented in Figure 10. In the case of spherical pore geometry and microfracturing, the same trend is observed. Figures 5–8 demonstrate that the attenuation factor 1 / Q is strongly strain-amplitude dependent at large strains 共⬎10ⳮ5 for / Y ⳱ 33兲 and independent of the wave amplitude at smaller strains, as is observed experimentally 共Winkler et al., 1979; Murphy, 1982兲. The strain at which attenuation loses its amplitude dependence is controlled by the ratio of the yield stress to the shear modulus. For both mechanisms considered in the paper, attenuation is negligible if the initial prestress 共measured as initial normalized effective pressure ⌬P0 / Y兲 is small. However, at larger initial effective pressures, larger values of attenuation are predicted while preserving strain amplitude independence for the small strain amplitudes. In other words, increasing initial prestress leads to progressing failure within the rock, thus causing an increase in attenuation. This is consistent with laboratory measurements of attenuation in increasingly damaged rocks where attenuation caused by increasing fracturing of the samples was shown to increase 共Q decreases兲 with increasing uniaxial pressure 共Wulff et al., 1999兲. However, most of the experiments on dry or saturated rocks show that attenuation decreases 共Q increases兲 with increasing confining pressure 共i.e., Johnston et al., 1979; Bourbié et al., 1987兲, which is most probably caused by the closing of thin cracks and minor pores. This is not captured by our simple model having effective pressure as a single parameter quantifying the entire stress state, which cannot reproduce the opposite effects of confining pressure and differential stress on the yielding of a rock sample. In this paper, we therefore do not aim to predict the precise experimental dependence of attenuation on pressure, porosity, effect of partial saturation, or other physical parameters. Our main Figure 9. Analytical 共solid line兲 and numerical 共dotted line兲 calculations for the quality factor Q. Analytical calculations are performed for the incompressible solid matrix while numerical calculations on this graph are for v ⳱ 0.3. In numerical computations, initial normalized prestress varies in 0.4 increments over the range of one to five, initial porosity varies from 10% to 50% in increments of 10%, and wave amplitude changes from 10ⳮ9 to 10ⳮ3 in ten logarithmic increments. N61 goal is to demonstrate that a nonlinear mechanism can cause attenuation of small-amplitude seismic waves independent of the wave amplitude. To summarize, the essence of our result is that for local effective pressures, lower than or slightly higher than the yield stress, the attenuation due to plastic yielding around cavities is negligible indeed. Attenuation curves presented in Figures 5b and 6b show that for ⌬P0 ⬎ 2Y the quality factor Q lies within the range of 12–18, typical for reservoir rocks 共Klimentos, 1995; Dasgupta and Clark, 1998; Korneev et al., 2004兲. Observed at hydrocarbon-saturated zones, Q ⳱ 50– 100 共Dasgupta and Clark, 1998; Dasios et al., 2001兲 can be achieved at ⌬P0 ⳱ 1.5Y. Microfracturing would cause Q ⳱ 12. . . 20 at effective pressures exceeding half tensile strength 共Figures 7 and 8兲. If we assume that confining pressure is lithostatic 共which would mean that there are no other heterogeneities in a rock other than spherical or cylindrical pores that would cause local stress amplification兲 and the fluid pressure is hydrostatic, then the estimation of the critical depth at which plastic yielding becomes important can be obtained from the inequality ⌬P0 ⳱ gz共 s ⳮ f 兲 ⬎ 2Y. Substitution of typical values of the yield stress Y ⳱ 20 MPa, density of the fluid f ⳱ 103 kg/ m3, and density of the rock s ⳱ 2 · 103 kg/ m3 give the critical depth of 4 km for Q ⳱ 12. . . 15 and 3 km for Q ⳱ 50. These depth restrictions seem high and exclude typical reservoir depth. However, they provide only the upper bound on the depth estimates. Indeed, if similar assumptions on depth dependence of effective pressure and the tens of MPa strength level would be used for the prediction of the porosity with depth, the sediments would preserve their near-surface porosity up to the same 1 – 4-km depth range because the conditions for the plastic pore collapse would not be reached and elastic deformation cannot significantly reduce porosity. The effects of pore interaction 共Tvergaard, 1990兲, pores of different shapes 共such as elliptical cracks of different aspect ratios兲, and a nonhydrostatic stress state 共Baud et al., 2000; Vajdova et al., 2004; Yarushina and Podladchikov, 2007兲 would reduce the critical depth necessary for the initiation of inelastic compaction and increase the volume fraction of the rock frame at plastic yield and therefore further decrease Q. Figure 10. Dependence of the minimum value of the quality factor Q on shear modulus and yield stress Y. Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ N62 Yarushina and Podladchikov In the paper, we considered two processes that might happen in porous rocks: compaction and dilation of pore space. The first one is associated with confining pressure exceeding fluid pressure, whereas the second one takes place when fluid pressure exceeds local confining pressure. Pore-scale yielding might happen in compaction and dilation modes and indeed there is experimental evidence for pore collapse happening in compacting sedimentary rocks 共Baud et al., 2000兲. Pore-scale plastic yielding is much more easily triggered in fluid-saturated rocks with elevated fluid pressures and therefore might be more pertinent to fluid-filled formations such as reservoirs in which inelastic deformation and failure are manifested by surface subsidence, well failure, and induced seismicity 共i.e., Boutéca et al., 1996; Segall, 1989兲. Microfracturing around pores in some sense is a process similar to hydrofracturing and this mechanism would be significant in rocks with high fluid overpressures close to the lithostatic pressure. There is field and experimental evidence that this type of fracturing happens in reservoir rocks 共Márquez and Mountjoy, 1996; Zhu et al., in press; Applod and Nunn, 2002; Zoback, 2007兲. CONCLUSION In this paper, the model of seismic wave attenuation due to porescale plastic yielding and microfracturing in prestressed porous materials is introduced and studied. Modeling is concerned with the components of P-wave loss that occur within the rock framework; there will be additional losses arising from the interaction between the solid and the pore fluid, which are not considered here. The relative importance of solid frame inelasticity over viscous flow mechanisms is yet to be determined. The effects of strain amplitude, effective pressure, and porosity have been investigated. We showed that the amplitude dependence of attenuation disappears at strains below 10ⳮ5 共at / Y ⳱ 33兲, whereas at larger strains there is a clear increase in attenuation in agreement with experimental data. The effect of the initial porosity and the ratio of the shear modulus to the yield stress on attenuation is rather weak. The effective pressure in the prestressed media is the main factor controlling the level of attenuation 共Figures 5–9兲. At low effective pressures, attenuation due to pore-scale inelasticity is indeed negligible. However, if the local effective pressure is amplified, the effect of plastic yielding on attenuation becomes more pronounced and asymptotically approaches a minimum value of approximately 12 in the model of microscale yielding and 2 in the model of microfracturing. The theory does not aim to predict the attenuation in dry or saturated rocks under “normal” pressure conditions 共negligible differential stress兲 for small-strain seismic waves 共although it might predict a component of that attenuation兲, but the mechanisms are very relevant for waves propagating in rocks under stress near or above their yield point. ACKNOWLEDGMENTS We are grateful to Clive McCann, Harro Schmeling, and anonymous reviewers whose constructive comments improved this paper. This work was supported by the Research Council of Norway; additional financial support was from Spectraseis AG and ETHZ. REFERENCES Aki, K., 1980, Attenuation of shear-waves in the lithosphere for frequencies from 0.05 to 25 Hz: Physics of the Earth and Planetary Interiors, 21, 50–60. Aleshin, V., and K. Van Den Abeele, 2007, Microcontact-based theory for acoustics in microdamaged materials: Journal of the Mechanics and Physics of Solids, 55, 366–390. Applod, M. S., and J. A. Nunn, 2002, Numerical models of petroleum migration via buoyancy-driven porosity waves in viscously deformable sediments: Geofluids, 2, 233–247. Barton, N., 2007, Rock quality, seismic velocity, attenuation and anisotropy: Taylor & Francis. Baud, P., A. Schubnel, and T.-F. Wong, 2000, Dilatancy, compaction and failure mode in Solnhofen limestone: Journal of Geophysical Research, 105, 19289–19303. Beresnev, I. A., and A. V. Nikolaev, 1988, Experimental investigations of nonlinear seismic effects: Physics of the Earth and Planetary Interiors, 50, 83–87. Beresnev, A. I., and K.-L. Wen, 1996, Nonlinear soil response — A reality?: Bulletin of the Seismological Society of America, 86, 1964–1978. Beresnev, A. I., K.-L. Wen, and Y. T. Yeh, 1995, Seismological evidence for non-linear elastic ground behavior during large earthquakes: Soil Dynamics and Earthquake Engineering, 14, 103–114. Best, A. I., C. McCann, and J. Sothcott, 1994, The relationships between the velocities, attenuations and petrophysical properties of reservoir sedimentary-rocks: Geophysical Prospecting, 42, 151–178. Biot, M. A., 1956, Theory of propagation of elastic waves in a fluid-saturated porous solid. I. Low-frequency range: Journal of the Acoustical Society of America, 28, 168–178. Bourbié, T., O. Coussy, and B. Zinszner, 1987, Acoustics of porous media: Gulf Publishing Company. Boutéca, M., J.-P. Sarda, and F. Schneider, 1996, Subsidence induced by the production of fluids: Revue de l’Institut Français du Pétrole, 51, 349–379. Buckingham, M., 1997, Theory of acoustic attenuation, dispersion, and pulse propagation in unconsolidated granular materials including marine sediments: Journal of the Acoustical Society of America, 102, 2579–2596. Byerlee, J., 1978, Friction of rocks: Pure and Applied Geophysics, 116, 615– 626. Carcione, J. M., D. Kosloff, and R. Kosloff, 1988, Wave-propagation simulation in a linear viscoelastic medium: Geophysical Journal, 95, 597–611. Carcione, J. M., and S. Picotti, 2006, P-wave seismic attenuation by slowwave diffusion: Effects of inhomogeneous rock properties: Geophysics, 71, no. 3, O1–O8. Carroll, M. M., and A. C. Holt, 1972, Static and dynamic pore-collapse relations for ductile porous materials: Journal of Applied Physics, 43, 1626–1636. Castagna, J. P., M. L. Batzle, and R. L. Easwood, 1985, Relationships between compressional-wave and shear-wave velocities in elastic silicate rocks: Geophysics, 50, 571–581. Chaboche, J. L., 1988, Continuum damage mechanics. 1. General concepts: Journal of Applied Mechanics — Transactions of the American Society of Mechanical Engineers, 55, 59–64. Chapman, M., E. Liu, and X.-Y. Li, 2006, The influence of fluid-sensitive dispersion and attenuation on AVO analysis: Geophysical Journal International, 167, 89–105. Christensen, R. M., 1979, Mechanics of composite materials: Wiley-Interscience. Clark, V. A., B. R. Tittman, and T. W. Spencer, 1980, Effect of volatiles on attenuation and velocity in sedimentary rocks: Journal of Geophysical Research, 85, 5190–5198. Cox, S. J. D., and P. G. Meredith, 1993, Microcrack formation and material softening in rock measured by monitoring acoustic emissions: International Journal of Rock Mechanics and Mining Science & Geomechanics Abstracts, 30, 11–24. Dasgupta, R., and R. A. Clark, 1998, Estimation of Q from surface seismic reflection data: Geophysics, 63, 2120–2128. Dasios, A., T. Astin, and C. McCann, 2001, Compressional-wave Q estimation from full-waveform sonic data: Geophysical Prospecting, 49, 353–373. Dvorkin, J., R. Nolenhoeksema, and A. Nur, 1994, The squirt flow mechanism — Macroscopic description: Geophysics, 59, 428–438. Eberhardt, E., D. Stead, and B. Stimpson, 1999, Quantifying progressive prepeak brittle fracture damage in rock during uniaxial compression: International Journal of Rock Mechanics and Mining Sciences, 36, 361–380. Fehler, M., M. Hoshiba, H. Sato, and K. Obara, 1992, Separation of scattering and intrinsic attenuation for the Kanto-Tokai region, Japan, using measurements of S-wave energy versus hypocentral distance: Geophysical Journal International, 108, 787–800. Frankel, A., and R. W. Clayton, 1986, Finite difference simulations of seismic scattering: Implications for the propagation of short-period seismic Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/ Plastic yielding as attenuation mechanism waves in the crust and models of crustal heterogeneity: Journal of Geophysical Research, 91, 6465–6489. Gatelier, N., F. Pellet, and B. Loret, 2002, Mechanical damage of an anisotropic porous rock in cyclic triaxial tests: International Journal of Rock Mechanics and Mining Science, 39, 335–354. Gordon, R. B., and L. A. Davis, 1968, Velocity and attenuation of seismic waves in imperfectly elastic rock: Journal of Geophysical Research, 73, 3917–3935. Guéguen, Y., and M. Boutéca, 2004, Mechanics of fluid-saturated rocks: Elsevier Academic Press. Gurevich, B., and S. L. Lopatnikov, 1995, Velocity and attenuation of elastic waves in finely layered porous rocks: Geophysical Journal International, 121, 933–947. Hagin, P. N., and M. D. Zoback, 2004, Viscous deformation of unconsolidated sands — Part 1: Time-dependent deformation, frequency dispersion, and attenuation: Geophysics, 69, 731–741. Hill, R., 1950, The mathematical theory of plasticity: Clarendon Press. Holcomb, D. J., 1981, Memory, relaxation, and microfracturing in dilatant rock: Journal of Geophysical Research, 86, 6235–6248. Jaeger, J., N. G. W. Cook, and R. Zimmerman, 2007, Fundamentals of rock mechanics: Blackwell. Johnson, P. A., and P. N. J. Rasolofosaon, 1996, Manifestation of nonlinear elasticity in rock: Convincing evidence over large frequency and strain intervals from laboratory studies: Nonlinear Processes in Geophysics, 3, 77– 88. Johnson, P. A., B. Zinszner, and P. N. J. Rasolofosaon, 1996, Resonance and elastic nonlinear phenomena in rock: Journal of Geophysical Research, 101, 11553–11564. Johnston, D. H., M. N. Toksöz, and A. Timur, 1979, Attenuation of seismic waves in dry and saturated rocks: II. Mechanisms: Geophysics, 44, 691–711. Kachanov, L. M., 1971, Foundations of the theory of plasticity: North-Holland Publishing Company. Kadish, A., P. A. Johnson, and B. Zinszner, 1996, Evaluating hysteresis in earth materials under dynamic resonance: Journal of Geophysical Research, 101, 25139–25147. Klimentos, T., 1995, Attenuation of P- and S-waves as a method of distinguishing gas and condensate from oil and water: Geophysics, 60, 447–458. Klimentos, T., and C. McCann, 1990, Relations among compressional wave attenuation, porosity, clay content, and permeability in sandstones: Geophysics, 55, 998–1014. Knopoff, L., 1964, Q: Reviews of Geophysics, 2, 625–660. Knopoff, L., and G. J. F. MacDonald, 1958, Attenuation of small amplitude stress waves in solids: Reviews of Modern Physics, 30, 1178–1192. ——–, 1960, Models for acoustic loss in solids: Journal of Geophysical Research, 65, 2191–2197. Korneev, V. A., G. M. Goloshubin, T. M. Daley, and D. B. Silin, 2004, Seismic low-frequency effects in monitoring fluid-saturated reservoirs: Geophysics, 69, 522–532. Kuster, G. T., and M. N. Toksöz, 1974, Velocity and attenuation of seismic waves in two-phase media: Part 1. Theoretical formulations: Geophysics, 39, 587–606. Liu, H.-P., H. Kanamori, and D. L., Anderson, 1976, Velocity dispersion due to anelasticity: Implications for seismology and mantle composition: Geophysical Journal of the Royal Astronomical Society, 47, 41–58. Márquez, X. M., and E. W. Mountjoy, 1996, Microfractures due to overpressures caused by thermal cracking in well-sealed Upper Devonian reservoirs, Deep Alberta basin: AAPG Bulletin, 80, 570–588. Mashinskii, E. I., 2006, Nonlinear amplitude-frequency characteristics of attenuation in rock under pressure: Journal of Geophysics and Engineering, 3, 291–306. Mashinsky, E. I., 1994, Quasy-microplastic processes and nonlinear seismic: Fizika Zemli, 2, 3–10. Mavko, G. M., 1979, Frictional attenuation: An inherent amplitude dependence: Journal of Geophysical Research, 84, 4769–4776. McCall, K., and R. Guyer, 1994, Equation of state and wave propagation in hysteretic nonlinear elastic materials: Journal of Geophysical Research, 99, 23887–23897. McKavanagh, B., and F. D. Stacey, 1974, Mechanical hysteresis in rocks at low strain amplitudes and seismic frequencies: Physics of the Earth and Planetary Interiors, 8, 246–250. Mindlin, R. D., and H. Deresiewicz, 1953, Elastic spheres in contact under varying oblique forces: Journal of Applied Mechanics, American Society of Mechanical Engineers, 20, 327–344. Murphy, W. F., 1982, Effects of partial water saturation on attenuation in Massilon sandstone and Vycor porous glass: Journal of the Acoustical Society of America, 71, 1458–1468. N63 Muskhelishvili, N. I., 1953, Some basic problems of the mathematical theory of elasticity: Noordhoff, Groningen. Nazarov, V. E., A. B. Kolpakov, and A. V. Radostin, 2007, Experimental study of nonlinear acoustical effects in limestone: Acoustical Physics, 53, 217–225. Nemat-Nasser, S., and M. Hori, 1999, Micromechanics: Overall properties of heterogeneous materials: Elsevier Science BV. Nur, A., and J. D. Byerlee, 1971, An exact effective stress law for elastic deformation of rock with fluids: Journal of Geophysical Research, 76, 6414– 6419. O’Hara, S. G., 1985, Influence of pressure, temperature, and pore fluid on the frequency-dependent attenuation of elastic waves in Berea sandstone: Physical Review A, 32, 472–488. Palmer, I. D., and M. L. Traviolia, 1980, Attenuation by squirt flow in undersaturated gas sands: Geophysics, 45, 1780–1792. Paterson, M. S., and T.-F. Wong, 2005, Experimental rock deformation — The brittle field: Springer. Prasad, M., and R. Meissner, 1992, Attenuation mechanisms in sands: Laboratory versus theoretical 共Biot兲 data: Geophysics, 57, 710–719. Pride, S. R., J. G. Berryman, and J. M. Harris, 2004, Seismic attenuation due to wave-induced flow: Journal of Geophysical Research, 109, B01201. Quintal, B., S. M. Schmalholz, and Y. Podladchikov, 2009, Low-frequency reflections from a thin layer with high attenuation caused by interlayer flow: Geophysics, 74, no. 1, N15–N23. Sams, M. S., J. P. Neep, M. H. Worthington, and M. S. King, 1997, The measurement of velocity dispersion and frequency-dependent intrinsic attenuation in sedimentary rocks: Geophysics, 62, 1456–1464. Savage, J. C., 1969, Comments on “Velocity and attenuation of seismic waves in imperfectly elastic rock”: Journal of Geophysical Research, 74, 726–728. Segall, P., 1989, Earthquakes triggered by fluid extraction: Geology, 17, 942–946. Sharma, M. M., and A. N. Tutuncu, 1994, Grain contact adhesion hysteresis: A mechanism for attenuation of seismic waves: Geophysical Research Letters, 21, 2323–2326. Sondergeld, C. H., and L. H. Estey, 1981, Acoustic emission study of microfracturing during the cyclic loading of westerly granite: Journal of Geophysical Research, 86, 2915–2924. Sothcott, J., S. G. O’Hara, J. Khazanehdari, and C. McCann, 2000, From sonic to ultrasonic — The acoustic properties of reservoir sandstones: 62nd Conference and Technical Exhibition, EAGE, Expanded Abstracts, D-39. Stoll, R. D., 1989, Sediment acoustics: Springer-Verlag. Suknev, S. V., V. K. Elshin, and M. D. Novopashin, 2003, Experimental investigation into processes of crack formation in rock samples with hole: Journal of Mining Science, 39, 460–466. Tittman, B. R., 1977, Lunar Q in 3000–5000 range achieved in laboratory: Philosophical Transactions of the Royal Society A, 285, 475–479. Toksöz, M. N., D. H. Johnston, and A. Timur, 1979, Attenuation of seismic waves in dry and saturated rocks: I. Laboratory measurements: Geophysics, 44, 681–690. Tvergaard, V., 1990, Material failure by void growth to coalescence: Advances in Applied Mechanics, 27, 83–151. Vajdova, V., P. Baud, and T.-F. Wong, 2004, Compaction, dilatancy, and failure in porous carbonate rocks: Journal of Geophysical Research, 109, B05204, 1–16. Van der Baan, M., 2002, Constant Q and a fractal, stratified Earth: Pure Applied Geophysics, 159, 1707–1718. Walsh, J. B., 1966, Seismic wave attenuation in rock due to friction: Journal of Geophysical Research, 71, 2591–2599. Winkler, K. W., and A. Nur, 1982, Seismic attenuation: Effects of pore fluids and frictional sliding: Geophysics, 47, 1–15. Winkler, K., A. Nur, and M. Gladwin, 1979, Friction and seismic attenuation in rocks: Nature, 277, 528–531. Wood, D. M., 1990, Soil behaviour and critical state soil mechanics: Cambridge University Press. Wulff, A.-M., T. Hashida, K. Watanabe, and H. Takahashi, 1999, Attenuation behavior of tuffaceous sandstone and granite during microfracturing: Geophysical Journal International, 139, 395–409. Yarushina, V. M., and Y. Y. Podladchikov, 2007, The effect of nonhydrostaticity on elastoplastic compaction and decompaction: Izvestiya, Physics of the Solid Earth, 43, 67–74. Yu, H. S., C. Khong, and J. Wang, 2007, A unified plasticity model for cyclic behavior of clay and sand: Mechanics Research Communications, 34, 97– 114. Zhu, W., P. Baud, and T.-F. Wong, in press, Micromechanics of cataclastic pore collapse in limestone: Journal of Geophysical Research, doi: 10.1029/2009JB006610. Zoback, M. D., 2007, Reservoir geomechanics: Cambridge University Press. Downloaded 23 Jun 2010 to 129.240.85.198. Redistribution subject to SEG license or copyright; see Terms of Use at http://segdl.org/