Origami-Inspired Nanofabrication Utilizing Physical

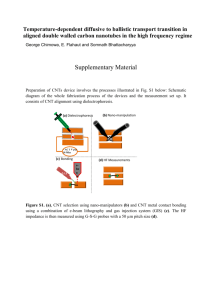

advertisement