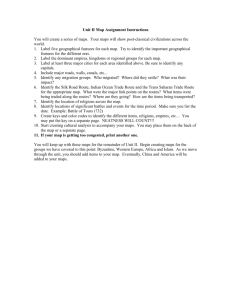

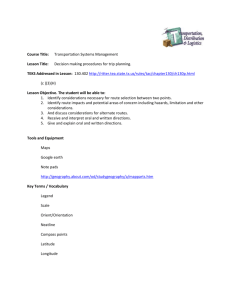

Incorporating Traffic Patterns to Improve Delivery...

advertisement