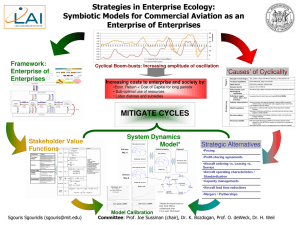

by CREATING HIGH PERFORMANCE ENTERPRISES

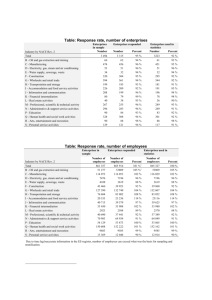

advertisement