RackCooler E P I

advertisement

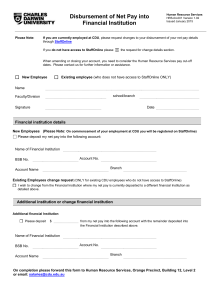

ENVIRONMENTAL PROTECTION RackCooler INSTALLATION MANUAL 8 kW Nominal Capacity TABLE OF CONTENTS Warnings and Cautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1.0 PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 General RackCooler System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2.0 PRE-INSTALLATION CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Parts Included With RackCooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 3.0 CABINET DOOR MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 4.0 INSTALLING THE RACKCOOLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 5.0 ADDING A RACKCOOLER MODULE TO AN EXISTING SYSTEM . . . . . . . . . . . . 7 FIGURES Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6 Figure 7 Figure 8 RackCooler overall view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RackCooler model number nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Door cutout detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Line cord bushing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hose connection to RackCooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RackCooler mounting detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hose connections to CDU supply and return ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vent locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2 4 5 5 6 7 7 WARNINGS AND CAUTIONS ! CAUTION System contains hazardous electrical voltage. Disconnect all power before working within. Sharp edges and heavy parts may cause personal injury. Wear protective gloves. Two people may be required for some installation operations. Before proceeding with installation of RackCooler, read all instructions, verify that all the parts are included, and check the nameplate to be sure the RackCooler voltage matches available utility power. Follow all local codes. ! ! ! CAUTION Drilling and cutting doors for required modifications may leave sharp edges. To protect personnel and equipment, remove burrs or cover metal edges after finishing door modifications. CAUTION Unit is heavy—over 60 lbs (27 kg)—and may cause injury if dropped. Obtain assistance before lifting or installing this unit CAUTION Tip Hazard—Cabinet may become top-heavy after installation. Use caution when opening doors of lightly loaded cabinets. 1 1.0 PRODUCT DESCRIPTION 1.1 General RackCooler System Description The RackCooler is a cooling system for high-density heat loads. The RackCooler system includes cooling modules that are mounted on a door of each cabinet containing heat-producing equipment. Chilled water circulates through the module. Four fans in the RackCooler draw heat out of the cabinet, through a heat exchanger and return it to the critical space at nearly room temperature. Figure 1 A Coolant Distribution Unit (CDU) (sold separately) provides an isolated source of chilled water for the RackCooler modules. It controls temperature to ensure maximum heat removal with no reduction in room humidity. RackCooler ER MOUNTED mounted on cabinet Coolant is distributed through piping run under T the flooring between the CDU and the area where the RackCooler modules are to be installed. Flexible hoses and double-shutoff, quick-connect couplers provide easy, reliable connection of the RackCooler modules to the under-floor coolant distribution ports (see Figure 1. The Coolant Distribution Unit (CDU) controls the fluid temperature for up to 12 RackCooler modules, preventing the water temperature from causing coil condensation. Each CDU is rated for 100kw (341,300 BTUHs) of cooling, and each RackCooler is rated for 8kw (27,300 BTUHs). RackCooler overall view R Raised floor Cooling portsCOO CDU supply and return lines The control on the CDU monitors room conditions and controls the temperature water leaving the CDU and entering the RackCooler, keeping it above above the room dew point to prevent coil condensation. An internal purge system pumps fluid to a drain if a leak is detected. Refer to the CDU installation and operation manual for more information. Figure 2 RackCooler model number nomenclature R C 08 C – K RC = RackCooler 0 = Revision level = 8 kw nominal capacity C = Chilled water 2 Product Description 0 K = 120V-1ph-50/60hz S = 200V/220V-1ph-50/60hz Place holder 2.0 PRE-INSTALLATION CHECKS Before beginning installation of the RackCooler, read all the instructions and verify that all parts are included. 2.1 Parts Included With RackCooler • • • • 1. 2. 3. 4. Installation manual (this document) RackCooler module Supply and return hoses—two total Parts bag including: • four bolts 5/16"-18 x 1-1/4" • two nuts 5/16"-18 • one snap bushing 2" Verify that the RackCooler unit voltage matches the available utility power. The nameplate with this information is located on the bottom of the cooling module, adjacent to the hose connections. Installation of the RackCooler requires physical modification to the door of the equipment cabinet. Your cabinet supplier may be able to provide doors with pre-cut holes and openings. Check with your supplier. Pre-cut doors are available for Liebert Foundation and Framework products. Contact your Liebert representative or Liebert Technical Support at 1-800-222-5877. Please have the serial number of your Foundation or Framework product available when you call. The RackCooler is intended for use on doors at least 22 inches wide. Installation on doors less than 22 inches wide may prevent the doors from being fully opened. The top of the door on which the RackCooler will be mounted should be at least 66 inches above the floor. Using a shorter door may cause difficulty in routing hoses. NOTE :The RackCooler is designed to mount on cabinet doors hinged on the left side. The RackCooler can also be mounted on a door hinged on the right using the right-hand mounting kit. Pre-Installation Checks 3 3.0 CABINET DOOR MODIFICATIONS ! Caution Drilling and cutting doors for required modifications may leave sharp edges. To protect personnel and equipment, remove burrs or cover metal edges after finishing door modifications. 1. Decide which door—front or rear—the RackCooler will be mounted on. This will be where the cabinet discharges heat. Typically the rear door is chosen. NOTE When modifying more than one door, mark or number the doors and cabinets to ensure the doors are placed back on their original cabinets. Figure 3 Door cutout detail 11 " 11" 11 2. Remove the door from the cabinet. Place the door on a flat surface where it 7/16" 7/16 " 7/16""" 7/16 7/16 can be marked for cutting or drilling. 3/42-3/4" " -3/4" 3. Refer to Figure 3 for specific cutout and hole dimensions. Carefully and accurately mark where the door cutout, Door Door DOOR CU CU DOOR six mounting holes and power cord hole cutout cutout are to be located. The six mounting holes are most critical and must line up correctly with RackCooler mounting 24"" 24 24 holes. Use the guidelines below for placing cutouts and holes on the door. RackCooler RackCooler All measurements are made facing the RACKCO RACKCO outline outline outside of the door. 48" 48" 48 48 "" 4. The door cutout should be placed 2 inches below the top of the door. 5. The RackCooler should be centered left to right on the door if possible. Follow Steps a through d below to accomplish 24""" this. 24 24 2-3/4" 2 3/4 3/4 "" a. Measure the door width. 22-3/4" 2-1/2" 2 1/2 " b. Subtract 15 inches. c. Divide this number by 2. d. Add 2-1/2 inches. This is the Mounting Mounting distance needed from the left edge R CORD holes 3/8" MOUNTI CORD HOLE HOLE MOUNTI holes 3/8" of the door to the left edge of the Typically O O Power 2 " cord 1-3/4" 1 3/4 1 3/4 " hole 2" door cutout for the RackCooler to be 6Typically places TY TY 6 places centered left-to-right on the door. 6. Check for interference with the door handle. If the handle on the door swings to the center rather than to the outside of the door, it may interfere with mounting the RackCooler. Measure the distance from the left edge of the door cutout to the most inward part of the handle. This distance must be at least 12-1/2 inches. If this is less than 12-1/2 inches, then the door cutout must be moved to the left to eliminate interference with the door handle. 7. After the door cutout is placed and marked, the remaining holes can be placed and marked. Refer to Figure 3 for detail placement of the power cord hole and the mounting holes relative to the door cutout. Carefully mark the placement of these holes on the door. 8. Recheck all measurements and hole and cutout placements before modifying the door. 9. Cut or drill the holes in the door. Remove any burrs from around the openings. 10. Place the modified door back on the cabinet. 4 Cabinet Door Modifications 4.0 INSTALLING THE RACKCOOLER 1. Complete the required door modifications detailed in 3.0 - Cabinet Door Modifications. 2. Place the 2" snap bushing in the 2" power cord hole from the outside as shown in Figure 4. 3. Push the door closed but do not latch it. ! ! CAUTION Heavy (over 60 lbs/27 kg.) May cause injury if dropped. Obtain assistance before lifting or installing this unit WARNING TIP HAZARD—CABINET MAY BECOME TOP-HEAVY AFTER INSTALLATION. USE CAUTION WHEN OPENING DOORS OF LIGHTLY LOADED CABINETS. Figure 4 Line cord bushing installation 4. Ensure that the two studs protruding from the RackCooler are fully extended. 5. Route the power cord through the snap bushing from outside to inside. Ensure the power cord is not pinched between the RackCooler and the door. Refer to Figure 6. 6. Lift the RackCooler using the handles provided. Place the two studs through the lower two mounting holes in the door. Ensure that the studs are completely through the holes. 7. While holding the door and RackCooler module securely, carefully open the door slightly. Thread one 5/16" bolt into each of the upper two mounting holes until they are finger tight 8. Install one 5/16" bolt into the RackCooler through each of the two remaining mounting holes. Tighten all four of the bolts. 9. Thread one 5/16" nut onto each of the two studs.Tighten the nuts. Figure 5 Hose connection to RackCooler 10. Remove the protective caps from the fittings on the bottom of the RackCooler. Connect the hoses to the fittings (refer to Figure 5). Tighten to 55 ft.-lb. torque. If a torque measuring device is not available, hand tighten the connection, then tighten an additional 1/2 flat (1/12 turn). 11. Plug power cord into utility power of the appropriate voltage: 120 VAC or 230 VAC, 50 or 60 Hz. The RackCooler should be powered from the same power source as the critical equipment in the cabinet to which the RackCooler is attached. Verify that the fans are running. Installation of the RackCooler to the door is now complete. The RackCooler must now be connected to a Liebert CDU. If this is a new RackCooler/CDU installation, refer to the CDU startup procedure in the Liebert CDU operation manual. If this RackCooler is being added to an existing, operating CDU, refer to the instructions in 5.0 - Adding a RackCooler Module to an Existing System. Installing the RackCooler 5 Figure 6 RackCooler mounting detail FIGURE 3 RACKCOOLER MOUNTING DETAIL 6 Installing the RackCooler 5.0 ADDING A RACKCOOLER MODULE TO AN EXISTING SYSTEM NOTE :Shutdown of the CDU is NOT required to connect additional RackCooler modules. Figure 7 Hose connections to CDU supply and return ports 1. If the CDU is equipped with the optional Fluid Management System (FMS), this system must be temporarily disabled before connecting the RackCooler. Refer to the CDU operation manual for specific instructions on disabling the FMS. 2. Connect the hose marked CDU SUPPLY to the underfloor cooling port labeled CDU SUPPLY. Refer to Figure 7. 3. Refer to Figure 8 for the next two steps. Remove the cap Supply Supply from the CDU SUPPLY vent port on the top of the RackCooler. Depress the valve pin to release air. Continue releasing air until a small amount of water is discharged. Replace the vent cap. Figure 8 Vent locations 4. Remove the cap from the CDU PPLY AIR VENT CDU supply air vent RETURN vent port on the top of the RackCooler. Depress the valve pin to release air. Continue releasing air until a small amount of water is discharged. AIR VENT CDU return air vent Replace the vent cap. 5. Carefully depress the plunger inside the quick-connect coupler, on the end of the hose labeled CDU RETURN, to release trapped air. Continue releasing air until a small amount of water is discharged. 6. Refer to Figure 7. Connect the hose marked CDU RETURN to an underfloor cooling port labeled CDU RETURN. 7. When connection of all RackCooler modules is completed, re-enable the optional Fluid Management System (refer to the CDU operation manual). Return Return OSE CONNECTIONS Installation and startup of the RackCooler is now complete. Keep these instructions for reference. Please take a moment to complete the enclosed startup survey card. Thank you for selecting the Liebert RackCooler for your high-density cooling needs! Adding a RackCooler Module to an Existing System 7 8 Adding a RackCooler Module to an Existing System 9 ENVIRONMENTAL PROTECTION RackCooler INSTALLATION MANUAL The Company Behind the Products Technical Support With over a million installations around the globe, Liebert is the world leader in computer protection systems. Since its founding in 1965, Liebert has developed a complete range of support and protection systems for sensitive electronics: United States 1050 Dearborn Drive P.O. Box 29186 Columbus, OH 43229 1-800-222-5877 Outside the United States +614-888-0246 • • • • • Environmental systems—Close-control air conditioning from 1 to 60 tons Power conditioning and UPS with power ranges from 300 VA to more than 1000 kVA Integrated systems that provide both environmental and power protection in a single, flexible package Monitoring and control—From systems of any size or location, on-site or remote Service and support through more than 100 service centers around the world and a 24/7 Customer Response Center While every precaution has been taken to ensure the accuracy and completeness of this literature, Liebert Corporation assumes no responsibility and disclaims all liability for damages resulting from use of this information or for any errors or omissions. © 1994 Liebert Corporation All rights reserved throughout the world. Specifications subject to change without notice. ® Liebert and the Liebert logo are registered trademarks of Liebert Corporation. All names referred to are trademarks or registered trademarks of their respective owners. SL-16810 (9/01) 24 hours a day, 7 days a week 1-800-222-5877 3-Phase UPS 1-800-543-2778 Environmental Control 1-800-543-2778 Italy Via Leonardo Da Vinci 8 Zona Industriale Tognana 35028 Piove Di Sacco (PD) +39 049 9719 111 FAX: +39 049 5841 257 Asia 23F, Allied Kajima Bldg. 138 Gloucester Road Wanchai Hong Kong +852 2 572 2201 FAX: +852 2 831 0114 Web Site www.liebert.com