Signature redacted

Compost Marketing Guidelines for Solid Municipal Waste

Management in India

ARCHIVES by

M ASSACHUSETTS INSTITUTE

OF TECHNOLOLGY

Ellen Huang

JUL 02 2015

B.S.E. Civil and Environmental Engineering

Duke University, 2012

LIBR ARIES

SUBMITTED TO THE DEPARTMENT OF CIVIL AND ENVIRONMENTAL ENGINEERING IN

PARTIAL FULFILLMENT OF THE REQUIREMENTS OF THE DEGREE OF

MASTER OF ENGINEERING IN ENVIRONMENTAL ENGINEERING

AT THE

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

JUNE 2015

2015 Massachusetts Institute of Technology. All rights reserved.

Signature of Author:

Signature redacted

rtment of Civil and Environmental Engineering

May 21, 2015

Certified by:

Accepted by:

Signature redacted

Dr. DaviA/9 angseth of Civil Environmental Engineering

Senior Lecturer

Thesis Supervisor

1/

/1-)Ae

Signature redacted

I$ofes or Heidi Nepf

Donald and Martha Harleman Professor of Civil and Environmen al Engineering

Chair, Departmental Committee for Graduate Students

Compost Marketing Guidelines for Solid Municipal Waste

Management in India

by

Ellen Huang

Submitted to the Department of Civil and Environmental Engineering on May 21, 2015 in

Partial Fulfillment of the Requirements for the Degree of

Master of Engineering in Civil and Environmental Engineering at the

Massachusetts Institute of Technology

Abstract

India has a waste problem. With the world's second largest population at 1.252 billion individuals, a population density of 382 persons per square kilometer and consumer behavior demanding a higher standard of life and preferences for more goods, the Indian municipal waste management systems are struggling to keep up with the increasing amounts of waste coming from households.

Composting is a way to divert waste away from landfills and reclaim value by transforming waste into a new product. The Indian Government has accepted the value of compost and has promulgated in 2000 that it is a recognized form of agricultural fertilizer. Due to this legislation, waste recycling start-ups have sprung up but they struggled to make ends meet due to poor market demand. Compost's main competition, chemical fertilizers, are embedded into

Indian agricultural practices since the Green Revolution. Additionally, the Indian government subsidizes the chemical fertilizers to promote agriculture at both the small- and industrial-scale.

Compost currently does not receive subsidies from the federal level. Thus, companies need to independently develop sustainable business models for compost production and sales if they are to meet government mandates regarding waste management. A key element of such sustainable business models will be the marketing practices, on which this thesis focuses.

Keywords: Marketing, Solid Waste Management, Compost, India

Thesis Supervisor: Dr. David Langseth

Title: Senior Lecturer of Civil and Environmental Engineering

3

4

Acknowledgements

First, I would like to thank the MIT Tata Center for this research opportunity; my advisor, Dr.

David Langseth for his guidance and patience; my project teammates, Ching-ching Liu and

Julie Karceski for their contributions to this project and their company while in India. I would also like to thank A2Z Infrastructure Ltd., Sanpurn(e)arth, and Ecofil for providing me access and information to their composting facilities; Pankaj Aggarwal, for being a wonderful host in

Muzaffarnagar; and the students and faculty at Shri Ram Group of Colleges for the translation help and collaboration. Finally, I thank my classmates, friends, and family for their love and support.

5

6

Table of Contents

In tro d u ctio n ............................................................................................................................................... 10

1.1 Background on Municipal Solid W aste M anagement in India...................................... 11

1.2 Advancements in Municipal Solid W aste M anagement in India................................. 12

1.3 W aste M anagement Options in India................................................................................

1.4 Report Structure .......................................................................................................................

Sco p e o f P roject.........................................................................................................................................15

2 .1 O b je ctiv e s...................................................................................................................................15

13

14

2.2 The Composting Process ....................................................................................................

2.2 M arketing Process ....................................................................................................................

L iteratu re R ev iew .....................................................................................................................................

3.1 Compost Awareness, Pricing, and Demand.....................................................................

3.2 The Potential of Compost....................................................................................................

3.3 Compost Application and Interaction with Soil .............................................................. 18

3.3.1 M SW Compost Application in Muzaffarnagar ............................................................ 20

3.3.2 Effects of M SW Compost on Vegetables.......................................................................21

17

18

15

16

17

3.4 Sustainable Composting Business Case Studies .............................................................. 21

Case Study 1 Decentralized Composting Initiatives in India............................................. 21

Case Study 2 Composting as a Social Business Enterprise in India ................................... 24

Case Study 3 - Composting in Dhaka Bangladesh ................................................................

3.5 Challenges and Limitations of Compost..........................................................................

Observations and Data Collection ....................................................................................................

24

25

27

4.1 Interviews of Farmers at Agricultural Fair .......................................................................

4.2 Interview of A2Z Compost Users ..........................................................................................

27

29

4.3 Interviews of Composting Firms: A2Z Group ................................................................

4.3.1 W aste Collection Process in M uzaffarnagar............................................................

31

31

4.3.2

4.3.3

W aste Operations Process in Muzaffarnagar .........................................................

M arketing Operations in Muzaffarnagar.................................................................

31

31

4.4 Interviews of Composting Firms: Sanpurn(e)arth.......................................................... 34

4.5 Interviews of Composting Firms: EcoFil..........................................................................

Discussion and Analysis..........................................................................................................................37

34

5.1 Compost Opportunities based on Interviews ................................................................

5.2 M arketing Guidelines derived from Case Studies...............................................................38

Phone Application and Game Development..................................................................................

37

41

6.1 Phone Application....................................................................................................................41

6.2 Game Development .................................................................................................................

Conclusions and Future W ork................................................................................................................44

W o rk s C ited ...............................................................................................................................................

42

45

A p p en d ices................................................................................................................................................50

Appendix A: Notes from Interviews Conducted in Muzaffarnagar .................... 50

Appendix B: Summary Tables of Interview with Farmers and Composting Firms........82

Appendix C: Notes from Interviews Conducted in Indore ........................................................... 87

7

Appendix D: Notes from Interviews Conducted in Mumbai.................................................. 95

A ppendix E: CO U H ES Q uestionnaire ............................................................................................ 105

Appendix F: Phone A pplication Screenshots.................................................................................108

List of Figures

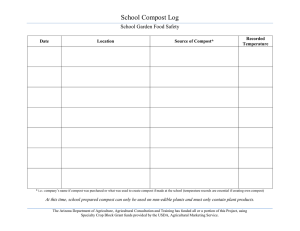

Figure 1: Suggested Application Rates of Compost (Pfeiffer 1954)..............................................20

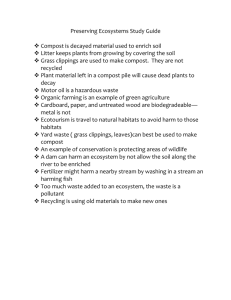

Figure 2: A2Z Mass Balance Sheet from Operations Manager (Saifi 2015).................20

Figure 3: First Screen to Select Cash Crop of Interest........................................................................108

Figure 4: Second Screen with Various Chemical Deficiencies Listed ............................................. 108

Figure 5: Phosphorus Deficient Sugar Cane Plants Display Purple-Edged Leaves......................109

Figure 6: Calcium Deficient Sugar Cane Tend to have Necrotic Tips.............................................110

Figure 7: Sulfur Deficient Sugar Cane Leaves Display Streaking and Purple Leaf Margin........111

List of Tables

Table 1: Overall Waste Composition in India (Annepu 2012) ......................................................

Table 2: Understanding the Market (Ali 2004)................................................................................40

Table 3: Farm er Interview Sum m ary Table ....................................................................................

Table 4: Farmer Interview Summary Table (continued)................................................................82

12

82

Table 5: Chemical Fertilizer Usage Among Interviewed Farmers ................................................ 83

Table 6: Chemical Fertilizer Usage Among Interviewed Farmers (continued)..........................83

Table 7: Purchase Receipts from Muzaffarnagar ...........................................................................

Table 8: Purchase Receipts from Indore...........................................................................................

84

86

8

9

Chapter 1

Introduction

Waste management is a significant concern worldwide, particularly in population-dense countries like India (Sharholy et al. 2008). Municipal solid waste management focuses only on waste generated by households, and not industrial, hazardous, and agricultural wastes.

Increasingly, municipal solid waste management practices are receiving enhanced scrutiny by local governments and scientific researchers alike. As of 2000, around half of all municipal solid waste in the world is landfilled, and 30 percent of that waste is the organic fraction (Mata-

Alvarez, Mace, and Llabres 2000).

In the developed world, many waste management plans aim for 'zero-waste;' instead of disposal, waste management planners try to find a myriad of ways to reuse and repurpose both synthetic materials and organics and avoid landfilling (Ngoc and Schnitzer 2009). In 2011, the

United States generated 250 million tons of waste, which included materials that could be recycled and composted (EPA 2013). Less than 12 percent was used for energy recovery.

Landfilling waste is highly undesirable due to space considerations, especially in nations with a high population density. Additionally, incineration can be toxic to the environment. The content of municipal solid waste (MSW) oftentimes contains chlorinated compounds, which can form hydrogen chloride and byproducts during incineration (Hartmann and Ahring 2006).

Moving towards more sustainable waste management practices, experts envision a hierarchy of waste treatment methods: first minimization, then recovery, than incineration, and landfilling as a last resort (Hartmann and Ahring 2006). But these plans oftentimes require advanced planning as well as investment and experience in technology that can make waste management less attractive in developing nations.

In less economically developed countries, the challenge is to implement a model that focuses on resource recovery, oftentimes in the absence of existing waste management. Municipal solid waste can be rich in resources, and also highly varied in composition, generally consisting of food waste, paper, plastic, metal and glass; hazardous household items, such as electric light bulbs, batteries, and discarded medicines are also common (Ngoc and Schnitzer 2009).

10

Wilson (2007) identified six broad drivers for waste management practices: public health, environmental protection, resource recovery, institutional responsibility and public awareness.

Additionally, he noted that the resource value of waste ('waste picking') could provide a livelihood for the urban poor. Given the high removal rate of valuable recyclables, via waste pickers, and the high fraction of municipal solid waste that is food waste, the bulk of the remaining waste is organic.

Resource recovery, particularly of organics, presents an opportunity to close the energy and nutrient loop. As Hansen et al. (2006) noted, "Waste treatment options allowing recycling of the content of organic matter and nutrients to agricultural land might be a method for closing the cycle between city and agriculture and simultaneously reduce the production and use of commercial fertilizers."

Additionally, improved waste management practices can lead to lower global warming emissions. Eriksson et al. (2005) observed "landfilling of all waste contributes most to the global warming potential of the studied scenarios," and also noted that recycling of nutrients and materials led to lower global warming emissions than incineration.

The focus of this report is to address waste management 'recovery' within a viable financial model. The goal is to address existing waste management technology, specifically anaerobic digestion, and address a method through which it can be improved upon.

1.1 Background on Municipal Solid Waste Management in India

India is home to more than 1.2 billion people, and, with a rapidly growing economy, is finding a foothold in the developed world. Economic growth averaged seven percent per year between

1997 and 2011 (Central Intelligence Agency 2014). As a result of rapid economic growth and urbanization, lifestyle changes have been correlated to an increase in per capita waste generation of about 1.3% per year (Ambade et al. 2013). Currently, 1 out of every 3 people in

India lives in an urban area and this statistic is expect to increase up to 1 in every 2 in the next

10 years (Dimpal 2012). Like many developing countries, India faces swelling waste management problems and currently lacks appropriate infrastructure and policies for dealing with these challenges (Annepu 2012). With an economy still nimble enough to adapt to emerging markets, India also has enormous opportunities in waste management.

In particular, cities in India face serious problems in the management municipal solid waste

(Kumar et al. 2009). Waste generation rises as population and urbanization increases. If India continues utilizing current methods of waste disposal, such population changes will require more land for the ultimate disposal of municipal solid waste (Idris, Inanc, and Hassan 2004).

The annual load of solid waste in Indian cities rose from 6 million tons in 1947 to 48 million tons in 1997. At the current growth rate of 4.25% per year, annual waste will reach 300 million tons

by 2047 (Sharholy et al. 2008). Additionally, Kumar et al. observed that in most urban centers in

11

the nation, waste is merely disposed of into low-lying areas and unregulated landfilling is common in most cities. Other issues include lack of proper vehicle transportation of waste, lack of coordination between civic bodies leading to poor waste management, and lack of public concern and accountability for waste disposal and littering (Dimpal 2012).

As a heavily agricultural nation, India creates high volumes of organic waste. Rural and urban areas of India face distinct and pervasive waste management problems, and both are ripe for improved management strategies. An overview of MSW composition in India by regions is provided in Table 1.

Table 1: Overall Waste Composition in India (Annepu 2012)

Region MSW (TPD) Compostables (%) Recyclables (%) Inerts (%) Moisture (%)

Metros 51,402

Other ities

Cities

2723

Indi

India

380

North

India

6835

South 2343

India

West

Indi

India IIII11

380

50.89

51.91

50.41

52.38

53.41

50.41

16.28

19.23

21.44

16.78

17.02

21.44

32.82

28.86

28.15

30.85

29.57

28.15

46

49

46

49

51

46

1.2 Advancements in Municipal Solid Waste Management in India

As a response to a public interest litigation that was filed against the government of India in

1996 for failing to manage MSW properly, the Supreme Court of India appointed an expert committee called the Burman Committee to make recommendations and improve the situation

(Joseph 2013). The Supreme Court made composting of biodegradable municipal solid waste mandatory based on recommendations from this Committee report in 1999. The Supreme Court then directed the government of India, state governments and municipal authorities to take action. As a response, the Ministry of Environment and Forests issued the Municipal Solid

Waste (Management and Handling) Rules of 2000 under the Environmental Protection Act of

1986, mandating specific policies and regulations regarding MSW management (Ministry of

Environment and Forests 1991). Furthermore, the MSW Rules required biodegradable waste be processed by composting, vermicomposting, anaerobic digestion or any other biological processing that would effectively stabilize the waste (Ministry of Environment and Forests

1991). In 2007, the Supreme Court indicated compost and biomethanation technologies were

12

appropriate for the typical quality of MSW found in India. Such typical traits included high organic waste (40-60% by weight), high moisture content, and low calorific values (Rawat,

Ramanathan, and Kuriakose 2013). In tandem, the Government stipulated that around 25% of all fertilizer come from composted-derived soil amendments. However, government subsidies of urea based fertilizer and common practices of bundling compost with traditional fertilizer create difficulties for MSW composting facilities to sell only compost (Kanhal 2014).

1.3 Waste Management Options in India

Though the wealthy are usually able to contribute their waste to recycling programs and other waste management practices, the fact remains that more than 90 percent of municipal solid waste in India is disposed of into open dumps (Silva and Naik 2007). Additionally, Kumar et al.

noted that such open dumping is improper because "open dumps pose environmental hazards which cause ecological imbalances with respect to land, water, and air pollution." This is staggering not only in its scale, but also is a detriment to human and environmental health. It is a significant lost opportunity in reuse and repurposing of waste.

Gupta et al. (1998) noted that in India:

"Uncontrolled dumping of waste on outskirts of towns and cities has created overflowing landfills, which are not only impossible to reclaim because of haphazard manner of dumping, but also have serious environmental implications in terms of groundwater and pollution and contribution to global warming."

Additionally, nearly half of municipal solid waste is comprised of organic matter. In fact, in cities with a population between two and five million, 56 percent of municipal solid waste is organic material (Sharholy et al. 2008). Organic waste, rich in energy and nutrients, can be digested aerobically (also known as composting) or anaerobically. Composting, a fast-growing option in India, produces soil amendments that can be sold as fertilizer.

Comprehensive collection of municipal solid waste is generally viewed as a first-world priority, due to lack of resources, expertise, and political will in the developing world (Silva and Naik

2007). Improvements in waste management practices take a considerable amount of time to trickle down to the poorest. Additionally, due to lack of lack of adequate storage capacity, waste is often dumped directly on the road (Kumar and Goel 2009). In Muzaffarnagar, A2Z has considerably improved cleanliness of wealthier neighborhoods, but the low-income districts are not as active in the disposal process (observation, August 12, 2014).

The mindset towards waste in poor neighborhoods is generally explained by expectations and priorities. Low-income neighborhoods do not generally have municipal solid waste collection and disposal (Sharholy et al. 2008). Paying for waste disposal is not a high priority for the poor, and they also have not grown up with the expectation of clean streets.

13

The impact of reduced waste on quality of life could be significant. The portion of organic waste in municipal solid waste generally increases as socio-economic status decreases, so the poorest have the most to contribute, in terms of volume, and the most to gain, in terms of public health

(Sharholy et al. 2008). Improper disposal has an enormous effect on human health and the environment, as disposal sites tend to be located in poorer districts. Organic waste can contain pathogenic bacteria, such as Salmonella, Escherichia coli, and heavy metals such as copper, cadmium, lead, mercury and arsenic (Shyamala and Belagali, n.d.).

1.4 Report Structure

Chapter 2 covered the objectives of this thesis and then described what was composting and marketing. The process of composting was documented more thoroughly by Liu (2015). Liu

(2015) studied various composting facilities around the world with respect to relevant government regulations, perceptions, and social values.

Chapter 3 provides a literature review on the demand for compost in India and the scientific basis behind integrating compost as an agricultural practice. This information helped to develop the questionnaires for Chapter 4's interviews with farmers and compost businesses.

Chapter 5 analyzes the data collected and presents conclusions on how to best market to the

Indian consumer. From there, Chapter 6 presents an alternative method of marketing compost through a pilot phone application and gamification. Finally, Chapter 7 concludes and points to future research options to create further acceptance of compost as a viable fertilizer product.

14

Chapter 2

Scope of Project

2.1 Objectives

The question is, "How to market effectively MSW compost in India?" The objective is to provide recommendations to those operating compost plants who wish to expand their markets and for anybody who plans on starting a composting enterprise. The motivation for addressing this question is the Indian government mandate regarding producing and using compost from municipal waste that was discussed in Chapter 1. As a companion activity, I believe that there should be increased emphasis on educating farmers regarding agricultural sustainability. This type of outreach program would ideally be sponsored by the government to enhance its credibility.

According to the World Health Organization, approximately Rs 6,500 per person have been lost due to poor sanitation and lack of hygiene due to public health impacts (PTI 2014). In 2014, the

Indian Prime Minister (PM) Narendra Modi implemented the Swachh Bharat Abhiyan, translated to Clean India Mission. This initiative has only been partially successful. PM Modi did generated awareness regarding lack of cleanliness in India's streets and general surroundings, but he has not been able to convince the citizens to perform actual cleaning.

Therefore, it is clear that additional methods need to be employed. I see a parallel between the

Clean India mission and the mandate regarding compost production and use. General education and awareness, if useful, but not ultimately successful, if the end users do not follow through. To partially address this issue, the use of gamification will be explored in this document as a means of more readily engaging existing and potential compost users.

2.2

The Composting Process

The purpose of composting is to convert organic material into effective soil amendment material, called compost. In this particular case, the feedstock is MSW. Compost produced from MSW can be used in various industries, primarily agriculture, horticulture, and forestry.

15

To accomplish decomposition, Indian compost producers commonly use mechanical separation to sort the MSW into compostable and non-compostable materials and then use a windrowbased process and subsequent additional mechanical sorting. Liu (2015) describes this and alternative processes in detail.

In general, windrow composting is controlled by the removal of carbon dioxide and excess water vapor, involving substantial loss of mass. To achieve 1 ton of waste with 25% of dry matter by weight, the waste mass has to lose 100 m

3 of carbon dioxide and 600 m

3 of water vapor (Jakobsen 1994).

2.2 Marketing Process

Marketing is the process of promoting and selling products or services. Among the issues one needs to consider in marketing are sales, public relations, pricing, packaging, and distribution

(Welborn-Nichols 1993). Marketing is about allocating resources (i.e. time and money) to enhance sales of a product. There are two main areas of concern for marketing. First are the various elements of the market environment, and second is the specific link between product promotion. Regarding the first, factors such as legislation, technology, and competition can shape the market environment in ways that necessitate business adaption.

One of the primary challenges for a compost business is creating and/or finding a market for compost. Since compost is a much bulkier product than chemicals, transportation is a major concern. Diesel prices are high but at-home delivery increase service quality in the eyes of the customer. Further compounding this problem is compost's relatively short shelf life. During the rainy season in India, windrows must be stored under monsoon sheds, but this limits the production capacity as the sheds only have so much area.

Marketing is meant to increase information availability. Farmers need to be educated on the importance of using compost versus chemical fertilizer. Compost perpetuates the soil fertility and productivity of the soil while chemical fertilizers disrupt the microbial activity and eventually lead to leached fields (Mani 2014).

Overall, the key to running a successful business operation is customer satisfaction. Market research is meant to answer the key following questions: Who are the customers? What do they need and want from compost? And finally what is the right price?

16

Chapter 3

Literature Review

3.1 Compost Awareness, Pricing, and Demand

Sahmia Khan, project manager of Chemists Without Borders, conducted a study in Hyderabad,

Andhra Pradesh, India regarding the business potential of composting for small-scale entrepreneurs (Khan 2013). Hyderabad has a population of 7.5 million and thus has started facing the challenge of managing their people's 3800 million tons of solid waste. The survey encompassed 27 peri-urban villages, 2 fertilizer markets, 3 vegetables, and fertilizer shops around Hyderabad City.

In the villages, 65 farmers and 20 fertilizer retailers were interviewed. According to the compiled results, apparently only 20% of farmers were even aware of organic compost from municipal waste. Of the 20% of farmers, the 50% of the farmers did not perceive compost positively. This was probably due to the origin of compost, being organic waste. Meanwhile, the fertilizer sellers did not have such a negative attitude towards the compost. Around 10 of the 20 shops sold compost, of which 3 expressed positivity towards the product.

In addition to being asked what their awareness level of compost, farmers were also questioned on what they thought was a reasonable price to pay for it. The best price was supposedly Rs

2.30-2.50 (translated to US dollars $0.046-0.05) per kilogram. In comparison, the 2012 market price for compost was Rs. 5 ($0.10) per kilogram.

While, this does not demonstrate much demand for compost, both did express interest and curiosity, though they did not have much of a knowledge base. They wanted to learn more and were willing to consider compost as an alternative to the chemical fertilizer. Thus demand for compost can still be anticipated. Just in the city of Hyderabad alone, Khan estimated that there will be demand for municipal waste compost between 1000-1200 MT per day. Revenue would be expected to be $3,791 per day for all the participants involved.

17

Before composting production, Khan (2013) recommends there should first be a focus on environmental awareness with campaigns conducted by both public and private agencies

(Khan 2013).

3.2 The Potential of Compost

According to estimates from the National Solid Waste Association from a report in 2003, the organic fraction of solid waste is 40-85% of the waste (Zurbrugg et al. 2004). With such high organic waste fraction, there should be plenty of feedstock for compost production.

Dr. Radha Kale argues that only 16% of applied chemical fertilizers can be absorbed by the plant because the rest needs to be broken down by bacteria before being assimilated into the plant (Shah 1997). Microorganisms in organic manure or fertilizer accelerate chemical reactions in the soil and liberate carbon dioxide from the ground. The organic acids that are produced during the decomposition process release phosphates which can then be utilized by the next cycle of crops. Also compost can act as a binding agent and increase the soil's overall water absorptive quality, percolation, and holding capacity. Thus, according to Dr. Kale, compost is a better product to help plants grow.

Furthermore, manufactured chemical fertilizers might not be able to keep up with the demand for higher crop yields due to population gains. According to the National Center for

Agricultural Economics and Policy Research, the crop yields and consumption rate of fertilizer have been declining (Prasad 2012). With imbalanced emphasis and use of NPK, India's soils are suffering from multi-nutrient deficiencies, lacking secondary and micronutrients.

Chemical Deficiency Percentage of Indian Soils

Sulfur

Zinc

Boron

42%

48.50%

33%

It is estimated that by 2025, food grain requirements for India will be 300 million MT/year. To meet that demand, it is estimated that 45 million MT of N

+

P205

+

K20 will be necessary. Of that amount 10 million MT of N

+ P205+ Ko could come from organic options such as compost

(Prasad 2012). Thus, compost can play a sizable role in future to maintain optimal crop output levels.

3.3 Compost Application and Interaction with Soil

As stated in Section 3.2, while chemical fertilizers and compost have similar nitrogen, phosphorus, and potash values, they do not interact with the soil in the same fashion.

18

When chemicals are applied to the soil, they are not immediately available for plant uptake. For example, when phosphate applied to acidic soil, only 2-10% by weight of the phosphate is available for plant use (Pfeiffer 1954). The bulk of the phosphate ends up "tied down" to the soil, in other words, unavailable. If the soil conditions are optimal with active microorganisms, the phosphate maybe be freed up to be used in the future.

Meanwhile, compost's individual NPK constituents behave differently. Nitrogen in compost is in its organic form. The dominant forms of nitrogen used by plants are ammonium (early in the season for synthesis of amino acids and proteins) and nitrate (in the late season). There is also nitrite and nitrous oxide but in lower quantities, since nitrite is toxic to plants. (University of

Nebraska 2015). Therefore, compost with organic nitrogen will contain some ammonium and nitrate and very little ammonia and nitrite.

Low nitrogen amounts in compost (1 to 2% by weight) actually produce comparable plant growth results as the application of fertilizers with high concentrations of nitrogen (about 6-16%

by weight) (Pfeiffer 1954). While fertilizer will be able to shock the plant system into rapid with growth after 6 weeks of application, the effects were not long-lasting. Meanwhile, compost will slowly but steadily release nutrients 3 to 6 months after application. If the soil is rich in organic material, the compost can be expected to continue to release nutrients 2 to 3 years after application.

Thus, one usually cannot use too much compost on a garden plot or farm land (Pfeiffer 1954). It is important to note that the kind of compost Pfeiffer studies compost derived from garden wastes. Maximum applications have been observed at 150 tons per acre but the average amount is 5 to 20 tons per acre. If the compost is dehydrated, well-manufactured, and/or concentrated, as little as 1 ton per acre may be sufficient (Pfeiffer 1954). NPK (nitrogen, phosphate, potash) values of compost do not determine the maximum amount of applicable compost; instead, there are a multitude of factors to consider.

Plant growth results vary depending on the type of compost, especially the organic matter content. Average farm-grade compost regularly contains a lot of earth and thus organic matter content is low. Most compost have a range of 12-20% by weight of organic matter; a rarity is 20-

30%. On the lower end 6-9% by weight have been observed (Pfeiffer 1954).

There is also differentiation among raw compost versus well-digested, humified compost

(Pfeiffer 1954). The effect upon the soil is different despite having the same organic matter content due to mineral content and water content. Humified compost is preferred since raw compost requires additional time to degrade before proper nutrient release.

The upper limit of compost that is still effective can be calculated using the maximum acceptable nitrogen per acre for crops. For most crops, the maximum is 200 pounds of nitrogen per acre and in many cases, 50-120 pounds is a more acceptable range (Pfeiffer 1954). Compost or manure that contains 1% by weight of nitrogen means there are 20 pounds of nitrogen per

19

ton. With 10 tons of 1% compost spread on an acre of land, then the maximum of 200 pounds of nitrogen is reached. This is basis for the rule of thumb that 10-20 tons of compost per acre should be used.

3.3.1 MSW Compost Application in Muzaffarnagar

Despite the rule of thumb stated by Pfieffer of 10 tons of compost application per acre, a closer examination of a cited table indicates a suggested application rate of 1 ton per acre for compost derived from garbage and industrial waste (Pfeiffer 1954).

Type of Comp

Manufactured (Dry) From

Garbage and industnal Wastes

% Analysis of Compost

Type CompTon

2 2 1 20-4 beo

20

Lbs. Plant

Food per

Coin

40 40 20

Suggested Lbs Plant Foods

Application Rate in per Acre at

Tons per Lbs. per Given Rates

1 5 40 40 20

Suggested for fertile. medium moderate to to heavy light

Figure 1: Suggested Application Rates of Compost (Pfeiffer 1954)

Figure 2: A2Z Mass Balance Sheet from Operations Manager (Saifi 2015)

According to A2Z mass balance sheet, out of 100 kg of waste, there is 17.95 kg of usable material transformed into compost. Therefore about 18% of the incoming waste is processed into compost (Liu 2015). Based on the approximate values given in Indore by Chaunhan (2015), that would mean 17.95% of 120 MT/day = 13.98 MT/day = 5102 MT/yr of compost produced.

Based on the receipts given, the average quantity of compost purchased per trip is 3.21 MT.

Assuming that farmers apply the compost twice a year, each farmer would need to purchase

6.42 MT of compost on their fields. So for the Muzaffarnagar A2Z plant to sell out its compost, they would need 794 farmers to consistently purchase compost on 397 acres. The A2Z marketing director estimated that currently there are 700 farmers who purchase from the

Muzaffarnagar plant, but there is still plenty of compost stored on site. This indicates that farmers might not purchase compost consistently. With these calculations, it shows that if A2Z

20

in Muzaffarnagar can convince their farmer customer base to regularly purchase compost from them twice a year, they would be able to use up all the compost that is being produced. This would justify further compost production and transform it into a more desirable product to manufacture.

3.3.2 Effects of MSW Compost on Vegetables

Unlike standard compost formed from garden or farm waste, MSW compost faces a few challenges such as increased levels of trace elements and heavy metals. This is primarily due to the lack of presorting and thus inorganic materials mixing into the composting materials (Liu

2015).

When Giannakis et al. (2014) performed a study using traditional fertilizer and MSW compost on tomato and lettuce plants, the plants to which compost was applied showed lower growth levels than the plants than the plants with conventional fertilization. The problem was diagnosed as a sharp cut in N03-N content (Giannakis et al. 2014).

In the Giannakis et al. study, nitrogen was the only macro-nutrient that performed poorly.

Potassium, phosphate, magnesium, calcium, and iron were found to be at the appropriate levels to promote plant growth. The concerns for heavy metals were unfounded as the levels were similar to soil unamended by the MSW compost and thus public health was not impeded

(Giannakis et al. 2014). It is to be noted that MSW compost originated from Greece and thus might not display the same contaminant levels as India.

3.4 Sustainable Composting Business Case Studies

Case Study 1 Decentralized Composting Initiatives in India

There are advantages operating solid waste management in a decentralized fashion. As the community is more involved in the endeavor, environmental awareness is enhanced. The operations are more adaptable and flexible, able to change to fit the users' needs. These initiatives benefit the municipality since the organic waste is treated locally and thus diverted from the waste stream. The community actions also reduce the transportation and disposal costs. Cities that have supported decentralized efforts include Bangalore, Chennai, Pune, and

Mumbai.

There are three primary types of decentralized composting organizations:

1. Community-based enterprise

These operations are small and highly involve the local community. Typically, residents spearhead the initiative, responding to problems in waste management such as

21

unreliable secondary collection services from the municipal board.

In Mumbai, there are neighborhood schemes called Advanced Locality Management

(ALM) (Ali 2004). There is no distinct structure to ALMs and they can address various aspects of urban life and sanitation. These ALMs have formed to give residents a forum to convey issues regarding waste collection, road repair, lighting, water supply, or drainage problems to the municipal authorities. Of the 670 ALMs in Mumbai, 284 have box composting activities. The goal of the municipality is eventually to have one composting site per ward. The main challenge to overcome is odor complaints.

The compost produced is usually sold in the neighborhood since the marketing is limited to the word-of-mouth by the core members of the community composting initiative. Prices for compost range from Rs 6/kg in Pune to Rs 20/kg in Mumbai (Ali

2004). The income levels of the residents can be inferred based on the pricing; the higher the prices are the more middle to high income users of compost.

2. Medium-scale private sector composting start-ups enterprise

These groups are usually run by entrepreneurs or NGOs. Typically, they work in conjunction with the municipality and use land that is provided either free or at a discounted rate. Their compost feedstock is usually are derived from waste from vegetable or flower markets along with residues from agro-industries. This removes the need for presorting that should occur if using household wastes.

An example is Vermigold, a vermi-composting company located in Mumbai. Their main goal is to provide composting design and solutions to organizations (e.g. hotels, colleges, etc.). They design vermi-compost plants and sell their clients compost and worms as starter and feedstock. These are produced on land they receive from the municipality at reduced rent. Unfortunately, the compost and worms are their only source of income as they do not receive a collection fee for the market waste they collect as feedstock. The product sells irregularly so Vermigold faces high risk of closure.

Most of these enterprises, like Vermigold, struggle from difficult market situation, weak marketing, and poor sales strategies. They have trouble making ends meet. Three out of four companies Drescher and Zurbrugg interviewed lacked accounting records of the amount of compost produced and sold (Zurbrugg et al. 2004). These business organizations play an important role providing job opportunities to low income groups.

Both men and women can be hired to collect, sort waste, and then create compost.

Therefore, it is to the community benefit to keep them in business.

To survive, the company has to capture the consumer quickly and operate more efficiently than the municipality. Excel Industries Limited got into the marketplace early and developed innovative products such as a machine which cuts down the amount of

22

time that it takes for solid waste to decompose to compost (Shah 2014). Private industry typically has to innovate to be able to expedite the composting process in order to compete with the more subsidized groups funded by the government entities or NGOs.

3. Company and institutions composting on premises

The motivation for starting a composting endeavor is typically for environmental reasons or cost savings. Cost savings may be derived from cutting fees to municipality for transport of waste from premises to waste processing facilities.

In these situations, operations are handled by the employees of the company/institute or

by a hired private contractor. Unlike enterprises, the compost produced is used on campus landscaping and/or gardens so there is no need for marketing outside offcampus. Decisions are made by department heads in charge of waste management and thus changes can be made easily and quickly. On the flip side, there is usually little engagement with the rest of the community.

Bin composting was the most preferred form of composting in conjunction with vermicomposting or open pit composting (Ali 2004).

TATA Power Company has a corporate housing colony in Mumbai which utilizes pit composting (Ali 2004). The company hired a waste picker co-operative to collect waste form the 520 households on site, sort the waste, sell recyclables, and compost the organic fraction in shallow beds. It provides jobs to 18 wastepickers and 2 supervisors. The compost is utilized on campus as it's not up to nutrient requirements to sell to the public.

The urban poor tend to benefit from such initiatives as they can outcompete private contractors with better services.

While there are advantages to decentralized composting, there are still aspects that prevent it from reaching its full potential.

There was a severe lack of documentation regarding mass balance flow and financial figures as mentioned above with Vermigold (Zurbrugg et al. 2004). When Drescher and Zurbrugg interviewed employees, nobody knew who the customer was. The market segment hadn't been identified. The only exception was Terra Firma from Bangalore because they marketed their compost through a large fertilizer distribution company. Therefore, a marketing strategy first needs to be developed to identify the appropriate customer bases and then to assess how best to generate demand for the compost product. Otherwise, partnerships should be formed with companies that already have established customer networks and supply chains.

23

If companies had better documentation they could improve relations with municipal authorities and open for possibility for additional assistance either in the form of land usage with low rent or education programs. The role of the municipal authorities would be to lead appropriate organic waste management, to remove rejected material from decentralized compost operations, and to assist in marketing activities.

Case Study 2 Composting as a Social Business Enterprise in India

M.K. Bhalerao was from the city of Saoner in the state of Maharashtra (Ali 2004). After retiring, he identified a need to deal with the waste dumping ground near the outskirts of town. The dump site was both an odor issue and health hazard, polluting the surrounding waters. He decided to start a social enterprise of composting and named it Krishi Udyog (Amol's Society

Business). The purpose was four-fold:

1. Improve the environment

2. Provide occupations to a large number of unemployed in the area

3. Improve the fertility of his and neighboring farmers' lands

4. Occupy himself profitably in his retirement

His brand was dubbed Bhoosampda. Unfortunately, while he figured out how to create the compost and negotiate a contract with the municipality authorities, he had difficulty selling his product to other farmers. Inorganic fertilizers demonstrated results very quickly and it is immediately obvious if they were not used. As discussed earlier, while compost is more sustainable and long-lasting, the results of the compost may take three to four years to emerge

(Ali 2004). Since many Indian farmers own small plots of land and live from harvest- toharvest, they can't afford to wait for so long.

Bhalerao had to employ multiple tactics to promote his compost brand Bhoosampda over Excel

Limited, his main compost competitor. First, Bhalerao priced his product to half (Rs2224/ton) that of Excel's (6354/ton). Second, he focused his market on the local market, within Nagpur and the neighboring districts. Third, he employed sales agents to help him sell Bhoosampda and awarded them 20% of sales as commission. Fourth, he focused on excellent customer service: free home delivery and cash discounts for prompt payment.

He is currently looking to increase his sales through a partnership with a bigger company in the agricultural supplies market. The goal is to sell the compost through their network of farmers.

Case Study 3 - Composting in Dhaka Bangladesh

Waste Concern is an NGO that strives to improve solid waste management in Dhaka. They have been establishing composting plants in Dhaka. They currently process 3 tons of compost a week and so have focused classified their primary customers into two categories.

24

"

Individuals, such as middle-class households with gardens.

Selling price: To1O/kg (equivalent to Rs8.19/kg)

* Commercial entities, such as private chemical fertilizer processing companies.

Selling price: To2/kg (equivalent to Rsl.64/kg)

In Bangladesh, farmers can charge a premium if their produce is grown with organic farming methods. So there is an incentive to purchase the product. One challenge is the investment required, because in the first year, farmers might have to buy an extra-large quantity of compost to restore the soils structure.

Waste Concern has chosen to partner with MAP Agro, a commercial entity, to market their product. They purchase 300 tons of compost every month from Waste Concern The compost is blended with their chemical fertilizer and resold. Although Waste Concern could have made higher profits by selling the compost themselves, they no longer have to be concerned about marketing. MAP Agro also made it clear they intended to ramp up their order 10 times the present amount. Waste Concern was able to elevate their brand through the credibility of a well-established company. Being able to focus on just making compost allows Waste Concern to focus all their resources on compost production.

3.5 Challenges and Limitations of Compost

Starting a compost enterprise has its challenges. Finding land to start operations can be particularly difficult especially in densely populated cities. In many areas, land is a shortage and thus the compost company needs to work in conjunction with the authorities to justify land for business rather than housing area for the poor. The location should be sited near collection areas and near landfill site (for dumping waste). The transportation costs, available labor, and cost of land need to be optimized.

As stated in Case Study 1, enterprises need to have the support of the municipality and the public. While there is some public awareness regarding solid waste issues, the public is reluctant to perform any actions such as presorting (Kakar and Kakar 2007). If there was separation between organic and inorganic waste at the household level, then the quality of compost could be greatly improved with higher nutrients and fewer contaminant concerns with glass and plastics.

Additionally, there is the challenge of collection of revenues. In Muzaffarnagar for A2Z Group, only 30% of the households pay their Rs per month fee for door-to-door waste collection

(Aggarwal 2014) because they do not perceive the benefits of taking away a material that is considered worthless. In general, waste collection firms have to rely on subsidies from the local city government to break even.

Saha et al. (2010) performed an assessment of municipal solid waste compost quality with feedstocks from 29 Indian cities. It was shown that that they have normal pH and electrical

25

conductivity. Unfortunately, compost produced from cities tended to have lower nitrogen and phosphorus contents compared to compost with feedstock from rural areas. Heavy metals content in compost from larger city feedstock is even more problematic. The cities with larger populations (over 1 million individuals) had 86% more zinc, 155% more copper, 194% more cadmium, 105% more lead, and 43% more nickel, and 132% more chromium compared to smaller cities.

Saha et al. (2010) found that partial segregation did not improve the quality of compost with regard to fertilizer characteristics and heavy metals. In 1985, the Fertilizer (Control) Order was promulgated which defined the quality control protocol for compost. Saha et al. (2010) determined that the majority of compost samples conformed to the following promulgated compost requirements with the following: bulk density, pH, electrical conductivity, total nitrogen, and C:N ratio. Unfortunately, the compost samples were not up to par with total organic carbon, total phosphorus, and total potassium requirements. Thus, very few composting samples were high enough quality to market and distribute.

Finally, it is difficult to find a good dependable labor force. Places that work with waste are stigmatized (Ali 2004); therefore the turnover rate for waste laborers are relatively high

(Chaunhan 2015). In Bangladesh, Rouse found that waste workers would lie to their friends about where they worked. The composting plant would be referred to as "office" or "fertilizer factory".

26

Chapter 4

Observations and Data Collection

4.1 Interviews of Farmers at Agricultural Fair

During January 2015, interviews were conducted with the assistance from Shri-Ram Group of

College, located in Muzaffarnagar, Uttar Pradesh (UP). Muzaffarnagar is known as the Sugar

Bowl of India since it has 11 sugar mills and 4,000 small units that produce jaggery (Jai 2013).

The area is in the upper Ganga-Yamuna doab region and has fertile soil. It is considered one of the most developed and prosperous cities of UP (Jai 2013).

There are numerous farmers in the area that supply the sugar mills of Muzaffarnagar.

According to Dr. Ashwani Kumar from the Shri-Ram Group, these farmers are split up geographically by the government so that they know which sugar mill to send their sugar cane harvest to every year. It was these farmers that I reached out to. Shri Ram College kindly provided space to work from and also translators. Dr. Kumar was our primary translator due to his bioscience background and also his experience as farmer as well. With Dr. Kumar and Dr.

Sachin Pol's help, we were able to identify the agricultural fair as a prime location to locate farmers.

Through interviews, we came to the understanding that while all farmers interviewed knew about compost made from MSW, many chose to use cow manure instead. We also learned that cost of a product was not the only factor that farmers took into account. By far the most important factor when selecting fertilizers was quality of the product. Farmers were attracted to one brand IFFCO in particular because they got results with it and thus earned their brand loyalty.

According to the director of the agricultural center, the agricultural fair draws around 1000-1500 farmers from the surrounding area per event. It is located within a federally run agricultural center, also referred to as KVK. The agricultural center provides multiple services, including honey extraction, pesticide/herbicide research and development, sample herb gardens, vermicomposting demonstrations, and a soil testing facility.

27

The soil testing facility was an area of particular interest for this work because this was where farmers found out whether they needed fertilizers and if so, which types. We learned from the soils laboratory director that the testing was done for free (not the case for every soils testing laboratory around the country) and once the soil deficiency was diagnosed, specific chemical fertilizers would be recommended. Recommendations would extend so far as to the particular brand of the chemical.

Three farmers were interviewed at the KVK. They were asked about the primary crops grown, farm plot size, and what kinds and in what quantities of chemical fertilizers they were using.

There were varying measurements for the plot sizes: bigha, hectare, and acre. Refer to

Appendix B. Bigha was one of the most common units of measurement for the area of land, but the actual precise measurement varied considerably, depending on where you were located.

According to Dr. Kumar, in UP, 5 bigha equaled to 1 acre and 1 hectare equaled to 6.2 bigha.

The farmers interviewed had range of farm sizes from 7 bigha to 100 bigha.

Based on those I spoke to while at the agricultural fair, compost is a well-known product. In fact, many farmers actually use a home-made version also known as Farm Yard Manure (FYM).

It is made from raw cow dung that has been placed in a sand pit for 3 months and allowed to ferment. It is not supplemented, so there is only 5-10% nutritional value leftover after the fermentation phase according to Dr. Kumar (Appendix A notes). All interviewed farmers did use FYM but seemed to do it more out of habit and/or tradition than actual growth effectiveness.

Of all the farmers interviewed at the agriculture fair, all of them used chemical fertilizer. The dominant brand mentioned for the various chemicals was government-manufactured IFFCO.

The reason provided by the farmers was that the IFFCO chemicals provided by the government from are relatively inexpensive and have good results. Additionally, its government ties lend credibility to its quality. The other brands recognized by the interviewed farmers were was

KRIBHCO and IPL (Indian Potash Limited). The interviewed farmers all indicated a strong preference towards IFFCO; they would only purchase KRIBHCO if IFFCO was out of supply or did not supply the particular fertilizer type. There were also locally produced chemicals but the farmers were not aware of any brand names. The chemical source would only be referred to the generic label, "local market".

The specific kinds of fertilizers used were a consistent cocktail of chemicals. Urea, potash, DAP, and NPK were the most common, but there was also mention of single phosphate fertilizer.

Refer to Appendix B for the fertilizer usage amounts and pricing. It was not clear if the chemical lists provided were exhaustive. The farmers would always seem to remember more when prompted by either the translator or the farmers who were bystanders observing in the interview.

28

Regarding payments, farmers were normally required to pay up front in cash for fertilizer.

Initially, I hypothesized that there would be a purchase plan to pay off the compost in installments so that farmers could pay in increments, leveling out their cash flow.

It is interesting to note that according to the soils laboratory director, the leading soil nutrient deficiency is potassium, which can be mitigated with the use of potassium sulphate, K2SO4. Yet none of the interviewed farmers stated that they used any sort of potassium supplement to improve crop yields. Other common deficiencies were iron and zinc for sugar cane and sulfur for rice. Again, these were not chemicals that farmers seemed to purchase or use regularly.

4.2 Interview of A2Z Compost Users

In addition to interviewing the farmers at the agricultural fair, I was able to speak to farmers who actually purchased MSW compost from A2Z or were planning to. Most of them had already used the product for 5-6 years. They provided a juxtaposition to the farmers who exclusively used chemicals and occasionally home-made FYM. These interviewed farmers originated came from the same region, Punjab, which is known to be a fertile area of India.

They moved to Muzaffarnagar because they could buy more land in Muzaffarnagar than in

Punjab.

Based on interviews, I was able to determine that this group of farmers was using MSW compost largely due to the influence of an enthusiastic advocate. This particular farmer was persuaded during a seminar conducted at a government approved agricultural fair. A2Z offered an introductory discount for those who were willing to try out the compost, Rs1250/10 bags. This farmer accepted the introductory offer, and after noticing improved results, he persuaded his son and then neighboring farmers to try out the product as well. It is important to note that the advocate was a strong, leading figure in the community who also owned the largest plot of land among those that I interviewed. Due to his respected status, he was able to lend credibility to the compost product.

This was not his first time trying to use compost on his fields. Before the A2Z compost, he had tried out vermicomposting. He stated there were good results but production was stopped because the vermicompost heaps were high maintenance with the constant turning to produce aeration and required a large amount of land that could have been used for additional crops.

Finally, the amount of compost from the process was only enough for personal use in their vegetable and wheat gardens.

In addition to trying out compost, he was also part of a seed program where the government tested alternative strains of various crops. The earnings from the seed program allowed him to be more financially independent than those who relied upon the sugar cane factories as their sole source of income. This created a positive feedback loop that allowed the farmer to be more financially secure than others and thus able to take on more risks.

29

Additional proof of the effectiveness of an enthusiastic advocate was provided by a farmer who was planning on purchasing A2Z compost in the future. His primary crops were rice and wheat, though he also had a dairy that provided plenty of FYM to use on his fields. He initially stated that he was under the impression that the A2Z compost didn't have good results.

Nonetheless due to the excellent feedback and good results that he had witnessed from his neighbor, he was going to try it out now.

Of those who used compost, they all had preference for the compost in loose form. This makes sense since it was less expensive, and they plan on immediately using the compost. Most of the farmers opted to pick up the compost with their own tractors-pulled trailers but there were two who opted for delivery. Compost was purchased two to three times a year depending on the farmers' schedules and were paid in full each time.

In addition to the compost purchases, the interviewed farmers also utilized chemical fertilizers to supplement and boost the overall soil nutrition levels. The most commonly mentioned were urea, potash, zinc, sulfur, and NPK. The list was longer than the chemical list from the agricultural fair but should be unsurprising since the farmers seemed to have more financial leeway because they had larger plot sizes.

I also asked about other compost competitors or other organic options. FYM was also used on the fields since they all had access to cows or a dairy producer who had an excess of cow dung.

Selrich, a private company in Delhi, formerly produced a biofertilizer for which they charged

Rs3000/ton. Unfortunately, production on the biofertilizer stopped; for reasons unknown to the interviewed farmers. Additionally, there was a product called pressed mud. It was locally produced at the sugar cane plants, made from the byproducts of the sugar factory processes.

The farmers described it as very nutritionally rich, and thus a desirable product. On top of that, it was very cost effective being Rs15-20 per quintil, much less expensive than normal fertilizer.

The only reason why it was not a common option was due to its low availability. Thus farmers did not expect it to be routinely available for regular use.

Pesticide and herbicide use was noted in the farmers' responses, but the farmers indicated that since the products were considerably more expensive, they were used sparingly. The particular brand mentioned most often was DuPont Indofyl and it was primarily applied to sugar cane and wheat, which are two of the cash crops grown in the Muzaffarnagar region.

The A2Z MSW compost product was successfully used by this group of farmers due to their satisfaction with the product effectiveness and price: all the farmers interviewed who were current users of A2Z MSW compost indicated satisfaction and provided positive feedback regarding the product. The only improvement they wanted was to be recognized for growing produce organically. They think it would be a step in the right direction to have some sort of organic food certification. This way they would be able to differentiate from others and also further justify the switch over to exclusively using compost.

30

Refer to Appendix B for summary tables of the interview.

4.3 Interviews of Composting Firms: A2Z Group

The first company visited was A2Z Group in Muzaffarnagar. I was able to interview to the collection, operations, and marketing directors.

4.3.1 Waste Collection Process in Muzaffarnagar

In the morning, waste is collected first household-by-household before being dumped into secondary waste collection sites. By the afternoon, vehicles would be sent out from A2Z facility to collect from the secondary waste sites; these vehicles would typically operate in pairs as a truck and backhoe. The waste is brought in and weighed. Usually at this point the waste has been stripped of its primary valuable recyclables, such as plastic and cardboard, as waste pickers have already gone through them. Therefore the only leftovers are generally organic waste and plastic films and other materials deemed non-recyclable.

4.3.2 Waste Operations Process in Muzaffarnagar

The waste is not separated further before it arrives in the processing facilities. The only separation is done with mechanical rolling sieves, as described by Liu (2015). Based on the size, the facility will transform the waste into either refuse derived fuel (RDF), compost, or unusable

(thus sent to the landfill).

When asked, the A2Z Muzaffarnagar operations director stated that the RDF was actually the preferred form to manufacture (Ahsan 2015). Not only did they sell more RDF, but they also could charge more by weight. This is because there are a lot of industries in Muzaffarnagar

(paper recycling, steel mills, and sugar cane factories as the primary industries) that purchase

RDF as a form of fuel to burn either in loose form or bricks.

Meanwhile, compost demand just wasn't as high since most of the farmers in the area relied upon chemical fertilizer. Additionally, compost was more difficult to store as it took up more room. Therefore, to increase production of compost, there needs to be justifiable reasons.

4.3.3 Marketing Operations in Muzaffarnagar

The marketing director, Sandeep Kumar, said their current marketing approach revolved around demonstrations. They take 10 farmers in a village, preferably with farm plots located near the main roads. They request that 20% of the land would use compost and 80% of the land would use whatever was previously employed (Kumar 2015). The farmers would fertilize 20% of their crops with compost and 80% of their crops with the usual (i.e. chemicals), and the yield

31

results were recorded at the harvest. It turns out that the compost-based crops either did equally well or even better than the standard.

The target villages are located near the A2Z plant. The target is annually implementing the demonstration in 10 villages with 10 farmers each. Additionally the marketing representative takes photographic evidence each time to compare crop yields.

The farmers are not compensated for participation in the MSW compost trials, but they are given discounted compost the introductory pricing described above. I was informed that the success conversion rate to compost was 100% (Kumar 2015).

In Muzaffarnagar, A2Z's customer breakdown are 40% local (e.g. farmers) and 60% commercial

(e.g. retailers). Commercial businesses are more optimal customers since they have a steadier demand (Kumar and Verma 2015). Farmers buy seasonally, tending to purchase compost in the months of September through December.

Receipt books were obtained of sales to farmers during the months of April to September of

2013 (Kumar 2015). While these months were not in the peak season, they were able to provide us with some estimates. I found the average quantity of compost purchased during that time frame was 3.21 MT. While A2Z indicated that compost sold to farmers for Rs3000/MT, the average rate was lower at Rs2326/MT. This indicates that A2Z does not stick to their Rs3000/ton price point for farmers. More than likely there is some flexibility in pricing. Compost can be given out at a discounted rate due to promotion or previously agreed upon terms with a longterm buyer. Overall the total spent on average was Rs7132/visit.

Marketing to the commercial sector seemed simpler. A2Z Group would send half a kilogram sample of compost to the company and the company would analyze the sample for the requisite nutrients that has been promulgated by the federal government. If they are satisfied with the results, they can put in orders that could be shipped in bulk or bagged. Compost producers form contracts which delineate a minimum level of production; therefore, the compost producer can guarantee certain amounts of income and demand.

A2Z Group would like to expand to customers such as nurseries, school and kitchen gardens, but do not currently have specific strategies for how to approach these potential customer groups (Kumar 2015). As of now, they demonstrate the product in a public setting, most likely a seminar. The interested individuals can obtain half a kilogram at a discounted price of Rs20 to use in their personal gardens. If they like the results from the compost, they can order more over the phone to be directly delivered to their homes. Unlike chemical fertilizers, A2Z does not have middlemen or supply chains. Instead, everything is shipped directly from them to the customer or the customer picks it up on site.

32

4.3.4 Overall A2Z Marketing Strategies

In Indore, I interviewed the head Director of A2Z marketing, Rohit Chaunhan. He was able to provide descriptions of all the A2Z plant operations with a focus on their marketing efforts.

A2Z annual plant incoming waste levels are as follows (Chaunhan 2015):

* Kanpur: 1500 MT

* Punjab:

* Indore Narache:

* Varanasi:

* Aligarh & Moradad:

* Muzaffarnagar:

* Fatehpur:

1000 MT

600 MT

600 MT

220 MT

120 MT

55 MT

According to their mass balance sheet, about 18% of the waste will be transformed into compost

(Ahsan 2015).

The A2Z compost selling season is mid-March to the end of the June and then a follow-up from,

October through December (Chaunhan 2015). This is in part due to the seasons in India. Rainy season is from July to September and operations slow down during this time. I was able to obtain another data set for the compost sold in Indore from December 2014 to January 2015.

The average quantity of compost sold was 8.2 MT and the rate was Rs2756/MT. The average total spent Rs11504/visit.

A2Z struggles with balancing revenue and costs. Diesel costs are a predominant concern as they can make up approximately 50% of any A2Z plant's budget. Also the municipal board expects to receive "compensation" for each ton received. In the Indore area, it's estimated to be around Rs2l/ton. Cost of production is estimated to be around Rs1400/MT; of that amount, about 13% or Rs180 comes from segregation costs.

The director is planning to implement a presorting program since A2Z had just recently won contracts to collect the waste from 2 of the 4 zones of Indore as well as processing all of it.

Residents will be asked to sort their waste into two bins. It is anticipated to take 6 months to a year to implement. The possible incentives include waiving the user charges or some sort of recognition award.

With mounting costs, A2Z is looking to diversify further to enhance their business. The RDF products at their Indore location are marketed as PVC pipe material along with road filler (also called fluff). They are planning on building waste to energy plant and promote energy collection through incineration of their waste. They also are studying the potential of anaerobic digestion to derive methane from their organic wastes.

33

When asked how to better compete with chemical fertilizer and further promote compost, the marketing director stated that obtaining a subsidy for compost from the Ministry of Fertilizer would make compost more economically viable for farmers. For the farmers, A2Z charges

Rs3500/MT for bagged compost and Rs3000/MT for loose compost. From there with transportation and packing of material, the cost goes up to Rs5400/MT. Therefore, if the government could subsidize Rs3000/MT, the final price of Rs2400/MT would be a far more persuasive and competitive price.

4.4 Interviews of Composting Firms: Sanpurn(e)arth

Sanpurn(e)arth is a firm that develops environmental waste management solutions for their clients. They are located in Mumbai, which is a mostly centralized solid waste collection system. Instead, Sanpurn(e)arth favors a decentralized approach where waste is handled locally since petrol is a very expensive resource. For example, campuses and corporate offices could treat their wastes on site.

Their business model revolves around design and/or management of waste systems. For example, they would first create the blueprints for a biogas facility, supervise the building process, and then operate and maintain the facility.

They work in conjunction with the NGO, SMS (Stree Mukbi Sanghatana, translated to Women

Liberation Organization). This is a self-help group for female waste pickers and gives them a voice for collective bargaining. One of Sanpurn(e)arth's primary goals is the employment of waste pickers. Children unfortunately also comprise a large percentage of the waste pickers.

Aside from biogas, they also perform vermicomposting in batches. We visited a compost pit while on the campus of the Tata Institute of Social Sciences (TISS). The feedstock is primarily leaves, garden waste, and other yard waste. The compost produced does not go off-campus.

Instead it is used for gardens and landscaping. Therefore, they have a guaranteed consumer of their end product.

Their focus is not selling product. It's about servicing the client. They find clients through networks. They focus on non-profits and those who partner with SMS or other NGOs. Most of their projects actually come to them looking for zero waste solutions or waste audits. The ultimate vision is to change the way waste management is run while being environmentally friendly and engaging the informal sector (i.e. waste pickers).

4.5 Interviews of Composting Firms: EcoFil

EcoFil operates a waste processing facility similar to those operated by A2Z Group. They were started 18 years back in 1997 through investors from the USA and Singapore. The core business was initially water and wastewater, but they have since expanded into MSW, opening up a

34

plant in Navi Mumbai in 2012. Their feedstock is heavily organic due to the presence of a nearby vegetable marketplace. With 180 vehicles going through their weigh station on a day-today basis, they process an average of 500 metric tons a day. Their waste is classified as 60-65% organic with 25% as compostable and 5-7% recyclable (Kumar and Verma 2015).

They produce 3 products from the waste: compost, RDF, and plastic granules. Compost is their main money maker, selling 60-100 tons per day. They place heavy focus on forming contracts with various retailers such as KRIBHCO, RCF, DPAC, and Tata Chemical. With Tata Chemical, they recently signed a 3-year contract in January 2015.

To sell in Maharashtra, there are different rules to follow compared to Uttar Pradesh. The state issues a marketing license to the firm, enforcing a singular price for all customers. Therefore retailers will check the product, then for the marketing license, and sign a co-marketing permission contract. This allows the reselling rights. The whole process takes around 1 month to complete.

EcoFil has the following contractual agreements for minimum purchases with the following retailers:

* KRIBHCO:

* Tata Chemical:

* Other clients' average:

10,000 MT/year

5,000 MT/year

20-25,000 MT/year

I was informed by Kumar and Verma (2015) that there were two seasons of interest:

" Kharif: May-September, the rainy season o Crops Grown: Onions, Sugar Cane, Rice, and Wheat o Tend to receive more plastic in waste

" Rabi: November-March o Crops Grown: Cotton, Mangoes, Other fruits, and Grapes o Tend to receive more organic matter from the nearby vegetable market

The demand for compost is higher during Kharif season but as discussed by Liu (2015), compost production drops substantially, up to 50% during this season. Thus, EcoFil has to manufacture and store compost in anticipation of the rainy season, around 3000-4000 metric tons.

Other customer groups that EcoFil sells to include the local horticulture, nurseries, and farmers.

They can sell around 5 to 10 tons of compost per customer.

EcoFil has similar concerns as A2Z with regard to staying in business. EcoFil's main source of income is the sales of compost and RDF. Unlike the A2Z Group, EcoFil does not receive a tipping fee. In other words, they do not receive money per tonnage of waste received. This is because they do not collect the waste themselves. It is delivered by another firm that has the tender to collect waste around the city of Mumbai.

35

Kumar and Verna (2015) project that the waste received will increase as Mumbai's population continues to grow. As of 2012, they estimated the city population to be 8-10 lakhs and it's projected to grow to 15 lakhs (Note: lakh is an Indian unit equivalent to 100,000). Therefore, they anticipate increasing compost production in the future as they are unable to keep up with the current demand for compost. They have little to no compost stored on site at any given time except on Sundays (they don't ship out on that day) and during the rainy season.