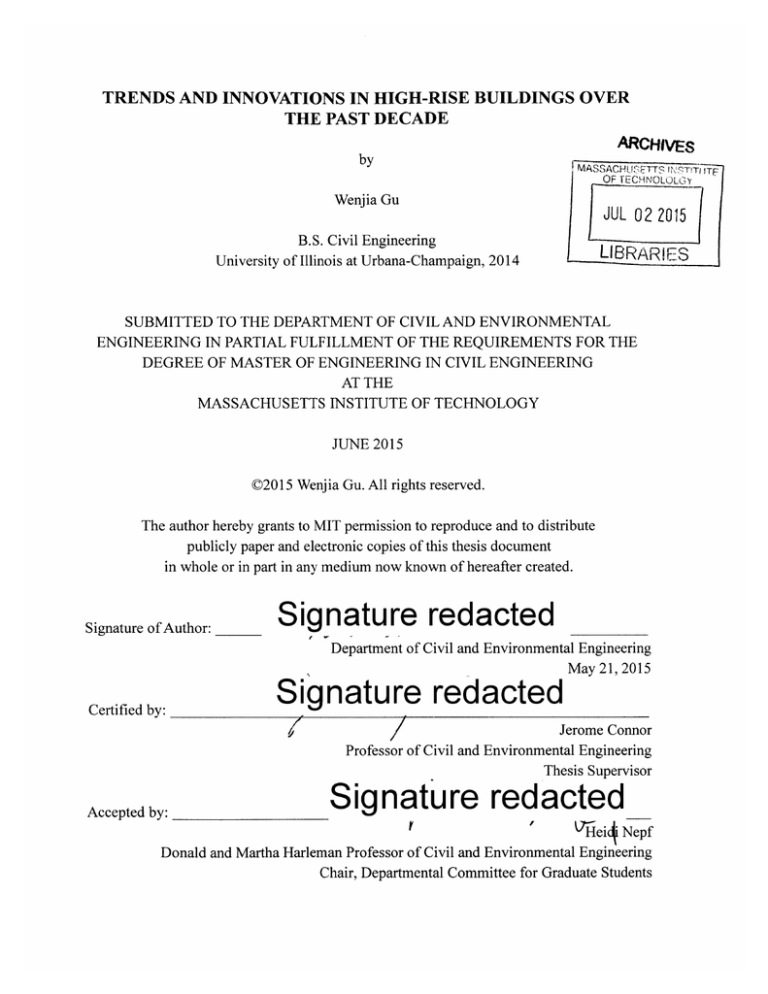

TRENDS AND INNOVATIONS IN HIGH-RISE BUILDINGS OVER

THE PAST DECADE

ARCHIVES

by

1

MASSACM I

OF 1*KCHN0L0LGY

Wenjia Gu

B.S. Civil Engineering

University of Illinois at Urbana-Champaign, 2014

JUL 02 2015

LIBRAR IES

SUBMITTED TO THE DEPARTMENT OF CIVIL AND ENVIRONMENTAL

ENGINEERING IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE

DEGREE OF MASTER OF ENGINEERING IN CIVIL ENGINEERING

AT THE

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

JUNE 2015

C2015 Wenjia Gu. All rights reserved.

The author hereby grants to MIT permission to reproduce and to distribute

publicly paper and electronic copies of this thesis document

in whole or in part in any medium now known of hereafter created.

Signature of Author:

Signature redacted

Department of Civil and Environmental Engineering

May 21, 2015

Signature redacted

(

Certified by:

Accepted b v:

Jerome Connor

Professor of Civil and Environmental Engineering

Thesis Supervisor

Signature redacted

?'Hei4 Nepf

Donald and Martha Harleman Professor of Civil and Environmental Engineering

Chair, Departmental Committee for Graduate Students

TT

1 ;r

TRENDS AND INNOVATIONS IN HIGH-RISE BUILDINGS OVER

THE PAST DECADE

by

Wenjia Gu

Submitted to the Department of Civil and

Environmental Engineering on May 21, 2015 in

Partial Fulfillment of the Degree Requirements for

Master of Engineering in Civil and Environmental Engineering

ABSTRACT

Over the past decade, high-rise buildings in the world are both booming in quantity and

expanding in height. One of the most important reasons driven the achievement is the

continuously evolvement of structural systems. In this paper, previous classifications of

structural systems are summarized and different types of structural systems are introduced.

Besides the structural systems, innovations in other aspects of today's design of high-rise

buildings including damping systems, construction techniques, elevator systems as well as

sustainability are presented and discussed.

To better understand current high-rise buildings, information about buildings above 200

meter completed within recent ten years and the current 100 tallest building in the world is

collected and analyzed. Structural systems of worldwide 100 tallest buildings are discussed,

from which trends are found. Data shows that tubular systems are in vast majority in recent

high-rise building designs and an increasing number of buildings are using concrete and

composite materials instead of steel. Developments in structural systems also reduce

structures' dependence on auxiliary damping devices. Additionally, sustainability has been

given more and more consideration.

Thesis Supervisor: Jerome Connor

Title: Professor of Civil and Environmental Engineering

3

4

TABLE OF CONTENTS

1. IN TRO D U C TIO N .................................................................................

7

2. HIGH-RISE BUILDINGS .........................................................................

9

2.1 D efinition ......................................................................................

3.

9

2 .2 Facts ...........................................................................................

. 10

2 .3 Lo ad s ............................................................................................

. 13

STRUCTURAL SYSTEMS ......................................................................

15

3.1 Previous Classifications ...................................................................

15

3.2 Different Types of Structural Systems ....................................................

18

3.2.1

R igid Fram e ...........................................................................

18

3.2.2

Core and outrigger ................................................................

20

3.2.3

Framed Tube ......................................................................

22

3.2.4

Trussed Tube ......................................................................

23

3.2.5

T ube in tube ...........................................................................

25

3.2.6

Bundled system ......................................................................

26

4. INNOVATIONS IN HIGH-RISE BUILDGINS ............................................

28

4.1 Damping Systems .........................................................................

28

4.2 Construction Techniques .................................................................

30

4.3 E levator System s ..............................................................................

32

5

TABLE OF CONTENTS

4.4 Sustainability .................................................................................

35

5. ANALYSIS OF CURRENT HIGH-RISE BUILDINGS ....................................

37

5.1 Structural System s ...........................................................................

37

5.2 Construction Materials .......................................................................

39

5.3 Sustainability ..............................................................................

40

6. CASE STUDY OF BURJ KHALIFA ...........................................................

42

7. CONCLUSION .................................................................................

47

Al. REFERENCES

....................................................

A2. 100 TALLEST BUILINGS IN THE WORLD BY 2015 ................................

6

48

50

1. INTRODUCTION

Over the past decade, high-rise buildings are both booming in quantity and

expanding in height over the whole world. The number of constructed buildings above 200

meters is increasing every year and the height of the world's tallest building has been raised

from 508 meters in the year 2004 to 828 meters now. Some of the many reasons leading to

this phenomenon include an expanding real estate market that emerges from the steadily

growing global economy, providing investors and contractors with more and more

opportunities, as well as the implicit competitions between countries, metropolitan areas,

and cities to attract more global spotlight.

To fulfill the request of taller and taller buildings, engineers keep working on the

optimization of structural systems to improve the structure's resistance over the load acting

on it. Several studies have discussed the performance of different structural systems from

different perspectives. Over the past decade, a number of high-rise buildings have adopted

integrated structural systems that combined two or more basic structural systems, and

innovative systems such as buttress core system can also be seen in completed buildings.

Besides the aspect of the structural system, structural material also plays an important role in

improving the structural stability and efficiency of the building.

Another important factor that helps pushing the limit of the height of buildings is the

development of construction techniques. With the help of high-tech construction equipment,

concrete can be pumped to a much higher distance than ever, even for high strength concrete.

7

Innovative construction methods also shortened the construction time so that for the owner

the cost of developing a new high-rise building could be reduced.

Other considerations for the design of high-rise buildings including the damping

system, fire design and emergency egress also have some changes over the past decade.

Nonstructural factors such as sustainability of the building are given more and more

importance now.

Information about the 100 tallest completed buildings in the world has been

collected. By studying the structural system as well as other properties of these 100

buildings, the current structural design trends can be found and comparisons between

theoretical analysis and actual can be discussed, which will help engineers break the record

of the most attractive high-rise building.

8

2. HIGH-RISE BUILDINGS

2.1 Definition

Before looking into the design trends and the innovations behind the increasing

number of high-rise buildings over the past decade, it is important to define what high-rise

buildings mean and what makes them different from other structures.

A tall building is referred as a multi-story structure in which most occupants depend

on elevators to reach their destinations. The most prominent tall buildings are called

high-rise buildings in most countries (Challinger, 2008). Although these terms do not have

internationally agreed definitions, a high-rise building, however, can be defined as follows:

According to the Council of Tall Buildings and Urban Habitat, a high-rise building

is "a building whose height creates different conditions in the design, construction, and use

than those that exist in common buildings of a certain region and period".

"Any structure where the height can have a serious impact on evacuation" (The

International Conference on Fire Safety in High-Rise Buildings).

"For most purposes, the cut-off point for high-rise buildings is around seven stories.

Sometimes, seven stories or higher define a high-rise, and sometimes the definition is more

than seven stories. Sometimes, the definition is stated in terms of linear height (feet or

meters) rather than stories. " (Hall, 2007)

Besides what is listed above, another important feature of a high-rise building is that

it is the lateral load not the gravity load that governs the design of the structure. Lateral loads,

9

including wind load and earthquakes, are crucial for high-rise buildings and can be resisted

efficiently by choosing appropriate structural systems. The exact height above which a

building can be defined as a high-rise building is specified by codes of the particular area

where the building is standing.

2.2 Facts

As a representative of the development in high-rise buildings, the record of the tallest

building in the world keeps being broken over the past decade. The 508-meter Taipei 101

Tower (Figure 1) which was opened on the last day of 2014 kept its title as the world's

tallest building for a mere six years before the Bun Khalifa (Figure 2), standing at nearly

830 meters above the ground, stole its glory in the year of 2010. Yet once again, this glory

will be overshadowed in the near future by the 1000-meter-tall Saudi Arabia's new

landmark, the, which is under construction now (Figure 3).

Figure 1: Taipei 101.

10

Figure 2: Bur Khalifa.

Figure 3: Kingdom Tower.

At the same time, the number of high-rise buildings completed is also increasing

each year. Information about buildings that are over 200 meters completed each year from

2005 to 2015 is collected and analyzed. Results show that the number of completed

buildings over 200 meters is basically increasing over time, and the average height of these

buildings is increasing as well. As Figure 4 shows, the number of such buildings completed

in 2014 is three times that in 2005, and the number of buildings above 200 meters is

expected to double by the end of 2015. For the height of completed buildings, as Figure 5

indicates, the average height of all buildings that are above 200 meters completed in the year

-

of 2015 is nearly 50% more than that in the year 2005. It is raised by almost 100 meters

from 213 meters to 303 meters.

200

t84

180

160

140

120

100

807

80

2

.

40

20

: 0

Year of Completion

Figure 4: Number of completed buildings above 200m each year.

11

350

e

300

250

m

200

-150

100

50

0

Year of Completion

Figure 5: Average height of completed buildings above 200m each year.

For the current 100 tallest buildings in the world, as can be seen in Figure 6, there

are only 28 buildings were completed before the year of 2005. As much as 72 buildings

were completed within the past ten years. Researches in this paper are focused on these 72

high-rise buildings.

" Number of buildings

completed between

2005-2015

" Number of buildings

completed before

2005

Figure 6: Completion time of the 100 tallest buildings in the world.

12

2.3 Loads

The structural design of buildings is governed by all the loads that are acting on

them. A standing structure is supposed to experience loads from two aspects - gravity loads

and lateral loads.

Gravity loads are forces acting vertically on the structure such as the self-weight of

the building, so they are the same for high-rise buildings and low-rise buildings unless the

force will be larger at the bottom of high-rise buildings because of the accumulation of loads

over height.

Lateral loads including wind loads and earthquakes, on the other hand, are crucial

for the design of high-rise buildings. Wind loads will increase as the height of the buildings

rises, and they act as pressures on the structure. Therefore, for buildings over certain height,

there will be large lateral loads acting on it due to the wind. Besides the force resulted along

the direction of the wind, dynamic effects of the wind should also be considered. The

structure will also experience motion perpendicular to the direction of the wind, which is

generated by the formation of vortex shedding acting on alternation sides of the structure.

The maximum displacement in the lateral direction generally occurs in the along-wind

direction, while the peak accelerations of the structure occur in the cross-wind direction.

The earthquake is another important factor to consider in the design of high-rise

buildings because of the intense vibration. This will result in the internal forces within the

structure. To reduce the influence of earthquakes on the structure, the structure is supposed

13

to be as ductile as possible to avoid failure, and dampers are usually implemented in the

structure.

14

3. STRUCTURAL SYSTEMS

The maximum height that a building can achieve is dependent on the ability of its

structure to resist loads that are acting on it. The development of the structural system is a

continuously evolving process. Since 1960 before which the predominant type of structural

system was conventional rigid frame, the emergence of tubular systems, core and outrigger

systems has helped to raise the height of buildings. Over the past decade, new developments

in structural systems such as diagrid systems and buttressed core systems have been applied

to the design of many high-rise buildings and showed satisfying performance in the

resistance of gravity and lateral loads.

3.1 Previous Classifications

In 1969, Fazlur Rahman Khan classified structural systems for high-rise buildings

relating to their heights with considerations for efficiency in the form of "Heights for

Structural Systems" diagrams for the first time (Khan, 1969). Later, these diagrams were

upgraded by way of modifications (Khan, 1972, 1973). He developed these schemes for both

steel and concrete buildings as can be seen in Figure 7. Feasible structural systems,

according to him, are rigid frames, shear walls, interactive frame-shear wall combinations,

belt trusses, framed tubes, trussed tubes, tube-in-tube systems and other tubular systems.

15

140

130

I

I

710

90

so

0

.5

z

40

30

Q?

RO

78

I

20

F

I

70

I

60-

qI

40

I

I

E

0

i

30

F.

6)

20

-0

U,

10

I

.I--

-

a

i-S

. . .

. . . .

. . .

.

50

0

Figure 7: Classificationof high-rise building structuralsystems by F.R.Khan

(above: steel; below: concrete).

Another classification of the structural system of high-rise building was developed

in 2007 by Mir M. Ali. This classification is based on lateral load-resisting capabilities. He

divided structural systems of high-rise buildings into two broad categories: interior

structures and exterior structures, which was based on the distribution of the components of

16

ME

the primary lateral load-resisting system over the buildings as shown in Figure 8 (Ali, 2007).

A system is categorized as an interior structure when the major part of the lateral load

resisting system is located within the interior of the building. Likewise, if the major part of

the lateral loading-resisting systems is located at the perimeter of the buildings, this system

is categorized as an exterior structure.

160

U

140

120

60 0

Z0

I

20

t

M

<

[II111

Frnm

Concrete

Steel

Sheor Wa

Steel Hfnged

Rlome

Broced

+

Frames-

Concee

Shear Wd

Se ald

+

Conciee

Faed

Frames

FAmI

Conrte

Shea Wal

+

410

Oumgg.r

Stucul

Ccncaele

FCrume

17

I

IO

XM7

CCIO 9

Focanod

t

Foslmwo

o

eTLO

lute

COMCOMO

S"0 a"M ecil>91o0n a"@

Imed

OP0080

Ae

*

koncw

SLOP %WO

tue

tue

tune Ametun

cam

Ongo

e fto 20. i

uNXMOa

Ae

TOMe

FarnX

Figure 8: Classificationof high-risebuildingstructuralsystems by Mir A. Ali (above: interior

structures; below: exterior structures)

3.2 Different Types of Structural Systems

3.2.1 Rigid Frame

The rigid frame structure, also called moment-resisting frame structure, is the most

basic type of framing systems. It consists of horizontal (girders) and vertical (columns)

members that are connected through rigid connections at the joint (Figure 9). Such framing

systems resist loads primarily through the flexural stiffness of the structural members. The

size of columns is mainly controlled by the gravity load, while the size of girders is

controlled by the requirements of lateral sway of the building as well as the vertical

deflection under dead and live loads. Because of the need for space in high-rise buildings,

the number of columns should be minimized, which increases the span of girders. Therefore,

18

the size of girders will be increased to ensure the stability of the structure. Additionally, as

the height of buildings increases, bending rigidity of both girders and columns should be

increased to reduce the lateral deflection. Besides, the expense of the moment-resisting

connections is really high. Therefore, the rigid frame would be an efficient structural system

for buildings under 30 stories (Kowalczyk, Sinn, & Kilmister, 1995).

Connections must be

capable of resisting

bending moments

Deformed shape

Bending moment diagram

Figure 9: Rigidframe.

19

3.2.2 Core and Outrigger

The core and outrigger system is another common structural system in high-rise

buildings. The vertical core elements mostly consist of concrete shear walls or braced

system to resist lateral loads. The outriggers are generally in the form of trusses in steel

structures, or walls in concrete structures, which extend on both sides from the central core

connecting the core to the perimeter of the building. The existence of outriggers can reduce

the overturning moment in the core and can transfer the reduced moment to the outer

elements as shown in Figure 10 (Taranath, 1998).

Shear wall or

braced frame

core

Column

20

Outrigger

truss

connected

directly

to core

_F

Moment in core with

--

+

\outrigger

Leeward

columns in

compression

bracing

\.--Moment in core without

outrigger bracing

Windward

columns in

tension

Figure10: Core and outriggersystem.

Belt trusses are often combined in core and outrigger systems to distribute the

tensile and compressive forces to a large number of exterior frame columns, which are

located at the perimeter of the structure. Belt trusses also help in minimizing differential

elongation and shortening of columns. In the design of existing high-rise buildings,

outriggers are also supported by mega-columns in the exterior perimeter of the structure.

Some other advantages of the core and outrigger system includes that the exterior

column spacing can satisfy more aesthetic and functional requirements. For the aspect of

construction, the exterior framing system consists of simple beams and columns and does

not require moment-resisting connections as in rigid frame system, which is beneficial to the

construction process.

The core and outrigger system may be formed in any combination of steel, concrete

21

and composite construction. Because of the structural benefits of this system and the

advantages listed above, the core and outrigger system has been very popular over the past

decade.

3.2.3 Framed Tube

The framed tube system is the most basic tubular system in high-rise buildings.

The tubular system expresses the concept that a building can be designed as a

hollow cantilever perpendicular to the ground to resist lateral loads by designing it. In the

simplest framed tube system, the exterior perimeter of the structure consists of closely

spaced columns that are tied together with deep spandrel beams through moment

connections (Figure 11).

Closely spaced columns

I

:b

Figure 11: Framed tube system.

22

For a framed tube under lateral loads, the corner columns experience the largest

axial forces, and forces are distributed non-linearly along the direction parallel to wind and

perpendicular to wind. This is because the axial forces in the middle columns of the frame

lag behind that in the corner columns because that the structure acts like a hollow tube

instead of a solid one. This phenomenon is called the shear lag effect, as shown in Figure 12.

In the design of framed tube system, the optimal purpose if to limit the shear lag effect.

Cosrmpive

Figure 12: Shear lag effect.

3.2.4 Trussed Tube

The trussed tube is a variation of the framed tube system. By adding large truss

elements around the perimeter of the tube system, the bending stiffness of the structure can

be increased, and the number of exterior columns can be decreased. The truss elements can

also transfer some of the gravity loads acting as inclined column. At the same time, the

23

diagonals of a trussed tube connected to the joints of columns and beams effectively

eliminate the effects of shear lag around the structure. Therefore, the space of columns in the

perimeter of the building can be arranged more widely and the sizes of spandrel beams and

columns can be designed smaller than the framed tubes (Khan, 1967).

Innovative structural systems over the past decade include diagrid systems and

hexagrid systems (Figure 13). The difference between conventional trussed tube structures

and the diagrid system is that almost all conventional vertical columns can be eliminated for

diagrid structures. This is because the diagonal members in diagrid structural systems can

carry both gravity loads and lateral loads through their triangulated configuration (Panchal

and Patel, 2014). The hexagrid system, also called beehive system, is another evolutionary

structural system in the design of high-rise buildings. In addition to eliminating perimeter

columns, another noticeable advantage of the hexagrid systems is that each structural

element can be optimized. This is a relatively new idea and more exploration is required for

the implement of this structural system in the design of high-rise buildings (Askarinejad,

2012).

Z

Z

N

N/

NZ

NZ

4 N

I

Figure 13: Trussed tube systems (Left: conventional trussed tube; middle: diagridsystem;

24

right: hexagrid system).

3.2.5 Tube in Tube

The tube in tube system uses the core to resist part of the lateral loads in order to

enhance the stiffness of the tubular systems. This structural system consists of an outer tube

in the perimeter and a core tube inside the structure. The core tube inside could be made of a

framed tube, a trussed tube or a solid tube holding elevators and other services. The floor

system connecting the core and the exterior tube transfers the lateral loads to both systems,

while the exterior tube system carries more loads because its greater structural stiffness

(S.R.S.Kuman and A.R.S. Kuman, 2014).

The tube in tube system is flexible in materials because the two tube systems can be

constructed using completely different materials. Current designs of high-rise buildings

combine concrete shear wall core with outer steel framed tube, which is an efficient system

in resisting of different types of loads and has been widely implemented. Figure 14 shows

the floor plan of a typical tube in tube structure, which is the China Trade Center, located in

Beijing, China. The structure of this building consists of a concrete core and the exterior

steel framed tube.

25

Figure 14: Floorplan of typical tube in tube system.

3.2.6 Bundled system

The bundled tube structural systems in a combination of several individual tubes

connected together to act as a single unit. The structural stiffness of the building is notably

increased. In this system, the shear lad effect in the flanges is largely reduced by the

existence of the internal webs. The bundled tube system also allows wider column spacing

in the tubular walls, and the stress in columns is distributed more evenly than that in a single

tube system.

One of the most typical bundled tube systems is the 110-story Willis Tower

completed in 1974 which was also the first buildings using such systems. There are nine

steel framed tubes in total bundled at the bottom of the buildings and they are terminated in

different heights as Figure 15 shows. Such structural system provides the high-rise building

with new possible appearance instead of the simple boxlike shape.

26

D

110

90

Section D-D

66

Section C- C

50

30

Section 8 B

A

Section A-A

Figure 15: Structuralsystem of Willis Tower.

One innovative structural system using the bundled form over the past decade is the

buttressed core system, which was implemented in the design of Burj Khalifa. The most

important factor of this system is a tripod-shape structure in which a strong concrete core in

the center anchors three structural elements arranged around it. The structure of Burj Khalifa

will be discussed more in the case study section later.

27

4. INNOVA TIONS IN HIGH-RISE B UILD GINS

4.1 Damping Systems

As the evolution of structural systems and development in construction materials

especially high-strength concrete, the weight of the high-rise building has been decreased

considerably than that of earlier ones. Lighter structures reduce cost as well as the

construction time. However, they may cause serious structural motion problem due to the

wind load. An implement of damping systems will help control the structural motion.

Damper can reduce not only the amount of lateral displacement but also the acceleration of

the structure. Structures with more damping can reduce the magnitude of vibration and

dissipate the vibration more quickly (Moon, 2005).

Damping system can be divided into two categories, passive damping systems and

active damping systems. Passive damping systems have fixed properties and they do not

need energy to perform as intended, while active damping systems do need energy input

serving as actuators to modify the damping system properties under different load cases.

Therefore, active damping systems are more efficient than passive systems. However,

passive damping systems are more commonly used in high-rise buildings because of the cost

and reliability.

Passive damping systems can be further divided into two subcategories, auxiliary

mass systems to generate counteracting forces such as tuned mass dampers (TMD) and

tuned liquid dampers (TLD), and energy dissipating materials based systems such as viscous

28

dampers and visco-elastic dampers.

Active damping systems are a more advanced form of performance driven

technologies, which is the tendency of today's high-rise building design. Examples include

active mass dampers (AMD) and active variable stiffness devices (AVSD). Different types

of auxiliary damping systems are summarized in Figure 16 (Connor, 2003).

Tuned Mass Dampers ( TMD)

Tuned Lquid Dampers (TLD)

Vicus Dampers_

Passive System

Viscoelassk Dampers

Hysteretic Dampers

Fricton Dampers

-Etem4Aagne

Dampers

Active Mass Dampers (AMD)

Acive

System

Acive Various Stifless (AVS) Devices

Figure 16: Various types of auxiliary dampingsystems.

However, it is noticeable that as the continuously evolvement of structural systems

more and more high-rise buildings do not need additional damping systems anymore. The

property of the structure itself is sufficient to protect the building from vibrations due to

29

wind. Such structural factors that will help decrease the dependence of high-rise buildings

on auxiliary damping systems include bundled systems, twisted shape of the building and

opening at the top, as shown in Figure 17. Trump Tower, which is located in Chicago,

implemented no additional damping systems. The stiffness and weight of the building,

combined with the asymmetric setbacks, laterally support and stabilize the tower ad

minimize perceptible motion.

Figure17: Buildings using geometries to reduce reliance on auxiliary dampingsystems (left

1 &2: bundled systems; middle: opening at top; right 1 &2: twisted shapes).

4.2 Construction Techniques

While structural engineers managed to find a plan for buildings to rise out of the

ground theoretically or experimentally, it still remains a challenge for contractor to actually

30

build it. As the height of high-rise buildings increases, so does the challenge contractors face.

Construction teams not only have to erect steel and concrete members, they also have to do

it precisely, safely, time and cost efficiently and environmentally friendly. Therefore,

construction techniques have to be developed.

Being time efficient not only means that the building can open to public sooner, but

also means lower construction cost. An innovation applied in the construction of the Shard

in London is the top-down construction method. It allowed the first 23 stories of the

concrete core and much of the surrounding tower to be built before the basement had been

fully excavated. This technique was a world first and saved four months time and a huge

amount of budget on the complex program.

As the development

of construction materials especially the creation of

high-strength concrete, more and more high-rise buildings start to use concrete to construct

the structure. Having more powerful pump means high that high-strength concrete is able be

delivered to high levels at greater speed. The KK100 in Shenzhen set a record of pumping

high-strength C 120 grade concrete to the height of 417 meters.

To guarantee workers' safety, precaution for hazard prevention has to be taken

seriously. During construction of Doosan Haeundae We've the Zenith Tower, to prevent

spalling, which is the explosion that can occur when the concrete is exposed to high

temperatures, contractors built the tower with high strength concrete using a spalling failure

prevention method.

31

To make sure the building is in its upright position, GPS technology has been used

over the past decade. This would not have been possible before satellites and GPS

technologies were mature. The Al Hamra Tower, which is located in Kuwait City, utilized

Leica Geosystems Core Wall Survey Control System, a procedure developed by Leica

Geosystems using GPS observations combined with a precision inclination sensor to provide

reliable coordinated points at the top of the building. Another example is used in the

construction of Almas Tower in Dubai, where vortex shedding suppression devices based on

simple principles were used as temporary measures during the construction stage to prevent

excessive wind induced movement of the spire.

4.3 Elevator Systems

As the height of high-rise building increases rapidly, the upgrade of many of its

accessories is required. One of the developed accessories is the elevator system. For

high-rise buildings, efficient mobility is an absolute necessity. Past elevators are

incompatible with today's super-tall buildings, as they have relatively slow rising and

descending rates, causing much time loss when traveling between high levels; some elevator

shafts are so large in size that they take up much of the level's space; some buildings are so

tall that the steel elevator cables are close to the limit where they can no more carry their

own weight.

During the past decade, various technical advancements are seen in the elevator

32

system of high-rise buildings. One smart design is the double deck elevator (Figure 18). As

the name indicates, the double deck elevator consists of two individual cars attached

together, one on top of the other. Both cars operate in the same elevator shaft. Such a

scheme could increase efficiency dramatically during high traffic periods. During such time,

single elevator would stop at every floor, but the double deck elevator will only stop at every

other floor as one of its cars transport passenger on odd floors and the other transport

passengers on even floors. Besides the improved efficiency in elevator shaft usage, the

operation speed of the elevator has also increased throughout the years. Table 1 below

shows the comparison of elevator speed of some of the world's famous buildings. It can be

seen that the speed has increased in the last few decades. The improvement in elevator speed

is accompanied by more powerful magnetic motors, high-tech air pressure adjustment

systems, and lighter and stronger materials. Finnish manufacturer Kone has developed a

carbon fiber dubbed UltraRopeTM that is seven times lighter than steel cables (Figure 19).

The UltraRopeTM will be used in the 1000-meter-tall Kingdom Tower, Saudi Arabia, which

is under construction.

Currently, engineers are picturing elevator systems that will travel both vertically

but also horizontally. As elevators will carry passengers horizontally, vertical shafts could be

reduced, thus saving floor spaces. ThyssenKrupp is poised to revolutionize elevator power

system by using magnetic drive similar to that seen on a Maglev train. The system will be

the world's first cable-free elevator and counter-weight free.

33

Building

Completion Year

Elevator Speed (m/s)

Chrysler Building, New York City

1930

4.5

Empire State Building, New York City

1931

7.1

Willis Tower, Chicago

1974

8.1

Taipei 101, Taiwan China

2004

16.8

Shanghai Tower, Shanghai

2015

18

CTF Finance Tower, Guangzhou

2016

20 (expected)

Table 1: Comparisonof elevator speed of some of the worlds famous buildings.

Coss,

440.MV *kVWwwM

-of

NWe-

we-IR010

Figure 18: Scheme ofdouble deck elevator

Elevator moving masses (kg)

108600

13900

Steel Cable

UltraRope"

.

Figure 19: Comparisonof traditionalsteel cable to Kone UltraRopeT M

34

4.4 Sustainability

Over the past decades, more and more factors besides structural and constructional

aspects are taken into consideration in the design of high-rise buildings. As global warming

and fossil fuel are becoming increasingly concerned topics, engineers are challenged to put

further effort into designing buildings that are more environmentally friendly. Measures that

care most commonly seen in achieving the sustainability of high-rise buildings can be

categorized into two aspects - constructional and operational.

Constructional sustainability is the measures taken during the construction process.

These measures include purchasing construction materials locally or regionally, thus

reducing total mileage of transportation, which in turn reduced carbon footprint. Another

measure is to reuse and recycle excess materials. In excess of 95% of structural steel was

recycled after the construction of New York Times Building, New York City.

Analogously, operational sustainability indicates the measures taken after the

completion of construction and during its normal operation. One of the most common

measure is the use of double-sided windows or double wall curtains with low-emissivity

coating to improve thermal insulation (Figure 20). Additionally, use of LED lights for

signage will reduce electricity consumption significantly. The Shanghai World Financial

Center features over 7000 LEDs, and the power consumption for its signage is merely 220

KW, which is much lower than even the shorter buildings around it. Buildings by rivers or

seas can reduce energy cost by using river or seawater to cool the buildings. An example is

35

the Trump Tower in Chicago that utilizes water from the Chicago River to cool the building.

The cooling system allows the water to recirculate back to the river. Building in high

sunshine areas can install solar panel to heat water. Bun Khalifa features solar panels that

are capable of heating 140,000 liters of water daily. In cities where pollution is heavy,

buildings have air filtration and circulation system to guarantee occupants breathe clean air.

In recognition of and to promote sustainability in building, the U.S Green Building Council

(USGBS) awards the Leader in Energy and Environmental Design (LEED) certificate to

buildings that are outstanding in sustainability. The certification has four levels - certified,

silver, gold, and platinum. The Taipei 101, which is located in Taipei City, has been

awarded the LEED Platinum certificate and will set the quality and performance benchmark

for super-tall buildings.

Figure 20: Double skinnedfacade curtain wall system.

36

5. ANALYSIS OF CURRENT HIGH-RISE BUILDINGS

To better understand the implement of different structural systems, construction

materials and design critics of high-rise buildings in the actual world, information about

high-rise buildings above 200 meters completed in the past ten years as well as the current

100 tallest buildings in the world has been collected and analyzed.

5.1 Structural Systems

Based on the properties of different types of structural systems which are

introduced in previous section, structural systems of modem high-rise buildings are divided

into seven categories: rigid frames, core and outrigger systems, framed tubes, trussed tubes,

tube in tube systems and bundle systems. The results have been shown in Figure 21 and

Figure 22.

Figure 21 shows the distribution of structural systems of high-rise buildings above

200 meter completed during each period over time. As the figure shows, tube in tube

systems have been more and more used in the design of high-rise buildings, while rigid

frame systems is no more been used within the past five decades.

Figure 22 shows the distribution of structural systems of the current worldwide 100

tallest buildings. As can be seen, vast majority of the structural system consist of tubular

systems and core and outrigger systems, in which the tube in tube system has the largest

percentage of 38%.

37

16

14

12

"

10

Bundled system

" Tube in tube

" Trussed tube

-

5*

" Framed tube

6

N Core and outrigger

4,

* Rigid Frame

...

...

2...

Figure 21: Distributionof structuralsystems of buildings over 200m over time.

2%

0 Bundled system

U Tube

intube

8 Trussed tube

a Framed tube

M Core and outrigger

0 Rigid Frame

Figure 22: Distributionof structuralsystems of the current 100 tallest buildings.

Taking the average stories of different types of structural systems of the current 100

tallest buildings in the world, comparison can be conducted with previous theoretical

analysis of structural systems. As Figure 23 shows, bundle system has the highest average

38

number of stories, while core and outrigger system has the lowest average number of stories.

Rigid frame system has the second highest average number of stories, which is quite

different from previous analysis, because of relatively small sample size.

100

90

;

80

70

60

s0

40

30

20

10

0

Core and

outrigger

Tube in

tube

Framed

tube

Trussed

tube

Rigid

Frame

Bundled

system

Figure 23: Average number of stories of different types of structuralsystems.

5.2 Construction Materials

To study the trend of construction materials, information about worldwide 100

tallest buildings in each period is collected. Result is shown in Figure 24.

A steel building is defined as a building where the main vertical and lateral

structural elements and floor systems are constructed from steel. Similarly, a concrete

building is defined as one where the main vertical and lateral structural elements and floor

systems are constructed from concrete. A composite building utilizes a combination of both

steel and concrete acting compositely in the main structural elements. A mixed-structure

39

building is any building that utilizes distinct steel and concrete systems above or below each

other.

As the figure indicates, a high percentage of buildings are using composite materials

in the past few decades. The most common combination is a steel building with a concrete

core. At the same time, the number of buildings using concrete as the construction materials

is increasing as well. One possible reason behind the increasing number of concrete

buildings is the development of high-strength concrete and concrete pumping techniques

which have been discussed previously.

100

* Unknown

75

"

50

Mixed

a Composite

" Concrete

25

" Steel

0

1960

1970 1980 1990 2000 2005

2010 2015

Figure 24: Distributionof construction materials of 100 tallest buildings in each

period.

5.3 Sustainability

Since the matter of sustainability has been given more and more consideration in

recent years, the sustainable design of 72 buildings completed in the past decade that are

40

listed in the current 100 tallest buildings is studied besides the aspects of structural systems

and construction materials. Result is shown in Figure 25.

As the result shows, 43 percent of buildings have considered sustainability in their

design, and most of them are awarded LEED certificates. According to the data collected,

most popular measures of sustainable design of high-rise buildings include double-sided

windows or double curtain walls to provide thermal protection and water recycling and air

filtration systems.

* Number of buildings

considering

sustainability

* Number of buildings

without considering

sustainability

Figure 25: Distribution of buildings consideringsustainability.

41

6. CASE STUDY OF BURJ KHALIFA

At 828 meters, the Burj Khalifa (formerly the Burj Dubai) has 163 stories and is the

world's tallest freestanding structure as well as the world's tallest building (Figure 26).

Construction of the tower began in January 2004 and the structure was topped out in

October 2009. It was officially opened in January 2010. The architectural and engineering

designer of this tower was Skidmore, Owings and Merill (SOM) of Chicago and its primary

contractor is Samsung Engineering and Construction Group of South Korea.

Figure 26: Bur Khalifa.

The structural system of Buj Khalifa is buttressed core system that is mentioned

above. It is designed to efficiently support a super-tall building utilizing a strong central core,

buttressed by its three wings. The vertical structure is tied together at the mechanical floors

through outrigger walls in order to maximize the building's stiffness. It is an inherently

42

stable system in that each wing is buttressed by the other two. The central core provides the

torsional resistance for the building, while the wings provide the shear resistance and

increased moment of inertia. The result is an efficient system where all of the building's

vertical structure is used to resist both gravity and lateral loads (Figure 27).

wing

central core

corridor wall

Figure 27: Typicalfloorplan of Bur Khalifa.

The structural integrity of the building itself can also serve as the damping system.

The building rises to the heavens in several separate stalks, which top out unevenly around

the central spire. This somewhat odd-looking design deflects the wind around the structure

and prevents it from forming organized whirlpools of air current, or vortices, that would

rock the tower from side to side and could even damage the building. The variation of the

tower shape, and width, resulted in wind vortices around the perimeter of the tower that

behaved differently for different shapes at different frequencies, thus disorganizing the

43

interaction of the tower structure with the wind (Figure 28). Over 40 wind tunnel tests were

conducted on Burj Khalifa to examine the effects wind would have on the tower and its

occupants. Engineers determined that no tuned-mass damping was needed.

VM

T~-

PWoo

Lower

Pan

Figure 28: Wind profile aroundBur] Khalifa.

During the construction process, over 45,000 m3 of concrete weighing more than

110,000 tons were used to construct the concrete and steel foundation, which features 192

piles. Each pile is 1 .5m in diameter and 43m long buried more than 50m deep. The

construction of Burj Khalifa's used 330,000 m3 of concrete and 39,000 tons of steel rebar.

Special mixes of concrete are made to withstand the extreme pressure of the massive

building. It was difficult to create a concrete that could withstand both thousands of tons

bearing down on it and high Persian Gulf temperatures that can reach 50 0C (122 0F). To

44

combat this problem, the concrete was not poured during the day. Instead, it was poured at

night when the air is cooler and the humidity is higher, and during the summer months ice

was added to the mixture. In November 2007, the highest reinforced concrete core walls

were pumped using 80 MPa concrete from ground level to the height of 606 meters, which

broke the previous pumping record of 470m in the Taipei 101.

At the aspect of elevator systems, eight escalators and 57 elevators were installed in

Burj Khalifa, of which two are double-deck elevators used exclusively for the travel to the

observation deck. Engineers of Bun Khalifa considered triple deck elevators at first, but the

final design called for double deck elevators. With the rising and descending speed up to

1Om/s, these are the world's fastest double-deck elevators. The elevator system of this tower

is also awarded as the longest travel distance elevator in the world that is 504 meters, and the

world's highest elevator which lands at 638 meters (Otis, 2010).

Burj Khalifa is also considered as a sustainable building. Solar panels are capable of

heating 140000 liters of water daily. A special performance glazing glass with low

emissivity provides the tower with advanced thermal protection. Due to its significant height,

the building is able to utilize ventilation from where air temperature is cooler and humidity

is relatively lower. When air is drawn in at the top of the building, it requires less energy for

air conditioning, ventilation, and dehumidification system. LED modules used for signage

throughout to ensure reliable low maintenance lighting with low energy consumption.

Additionally, Burj Khalifa has one of the largest condensate recovery systems in the world.

45

Collecting water from air conditioning condensate discharge prevents it from entering the

wastewater stream and reduces the need for municipal potable water (Burj Khalifa,

CTBUH).

46

7. CONCLUSION

Over the past decade, both the number of high-rise buildings and the average height

of high-rise buildings have increased rapidly. Continuously evolving structural systems

creates opportunities for structures to be more efficient. Other developments in construction

techniques, accessory systems as well as structural materials have enabled the structure to

actually stand taller and taller.

Based on the study of recent high-rise buildings and the current 100 tallest buildings

in the world, following trends can be summarized: By the year of 2015, tubular structures

are in vast majority of the structural systems in recent high-rise buildings, in which tube in

tube system is the most popular one and has been applied in the design of a large number of

high-rise buildings. Advancements in structural systems also help to reduce buildings'

dependence on auxiliary damping devices. For structural materials, there is an increasing

trend to use concrete and composite materials to construct the structure. Additionally,

sustainability has been given more consideration in modem high-rise building designs.

47

Al. REFERENCES

Ali, Mir M.; Moon, Kyoung Sun (2007). "Structural Developments in Tall Buildings:

Current Trends and Future Prospects". ArchitecturalScience Review 50 (3): 205-223.

Ali, M.M. (2001). "Art of the Skyscraper: The Genius of Fazlur Khan". New York: Rizzoli.

Askarinejad,

P. (2012). "Beehive

(Hexagrid):

Innovative

Structural

System

of Tall

Buildings". Council on Tall Buildings and Urban Habitat.

Baker, W. F. (2001). "Structural Innovation." Sixth World Congress on Tall Buildings and

Urban Habitat. Melbourne, Australia.

Challinger, D. "From the Ground Up: Security for Tall Buildings CRISP Report".

Alexandria, VA: ASIS Foundation Research Council; 2008.

Connor, J.J. (2003). Introductionto StructuralMotion Control.

Hall, Jr JR (2005). "High-Rise Building Fires". Quincy, MA: National Fire Protection

Association.

Khan, F.R. (1967). "The John Hancock Center". Civil Engineering, 37(10), 3 8-42.

Khan, F.R. (1969).

"Recent structural systems in steel for high-rise buildings". In

Proceedings of the British Constructional Steelwork Association Conference on Steel in

Architecture. London: British Constructional Steelwork Association.

Khan, F.R. (1972). "Influence of design criteria on selection of structural systems for tall

buildings". In Proceedings of the Canadian Structural Engineering Conference. Toronto:

Canadian Steel Industries Construction Council, 1-15.

Khan, F.R. (1973). "Evolution of structural systems for high-rise buildings in steel and

concrete". In J. Kozak (Ed.), Tall Buildings in the Middle and East Europe: Proceedings

of the 10th Regional Conference on Tall Buildings-Planning, Design and Construction.

Bratislava: Czechoslovak Scientific and Technical Association.

Kumar,

S.R.S.;

Kumar,

A.R.A.. "Advanced

structural

forms". Design

of

Steel

Structures. Indian Institute of Technology Madras.

Moon, K. (2005). "Dynamic Interrelationship between Technology and Architecture in Tall

Buildings". Unpublished PhD Dissertation, Massachusetts Institute of Technology.

48

Otis (2010). "Burj Khalifa, the world's tallest building, inaugurated: Global press and first

deck".

observation

to

elevators

Otis

ride

visitors

<http://www.otis.com/_layouts/ProjectNewsPopup.aspx?ID= 1 3&siteURL=http://www.ot

is.com/site/in/pages/OtisNews.aspx> (May 20, 2015)

Panchal, N.B.; Patel,V.R. (2014). "Diagrid structural system: strategies to reduce lateral

forces on high-rise buildings". InternationalJournal of Research in Engineering and

Technology, Volume: 03 Issue: 04

Schueller, W. (1986). High-Rise Building Structure (2nd ed). Malabar, Florida: Krieger.

Taranath, B. S. (1998). Steel, Concrete, & Composite Design of Tall Buildings. Second

Edition. McGraw-Hill. New York, NY.

49

A2. 100 TA LLEST BUILINGS IN THE WORLD BY 2015

Building Name

City

Height

(m)

Floors

Completed

Material

1

Buj Khalifa

Dubai (AE)

828

163

2010

steel/concrete

2

Shanghai Tower

Shanghai (CN)

632

128

2015

composite

Mecca (SA)

601

120

2012

steel/concrete

541.3

94

2014

composite

Taipei (TW)

508

101

2004

composite

Shanghai (CN)

492

101

2008

composite

Hong Kong (CN)

484

108

2010

composite

451.9

88

1998

composite

451.9

88

1998

composite

#

3

Makkah Royal Clock

Tower Hotel

4

One World Trade Center

5

TAIPEI 101

6 6 Shanghai World Financial

New York

City (US)

Center

International Commerce

Centre

7

8

Petronas Tower

1

_____Lumpur

9

Petronas Tower 2

Kuala

(MY)

Kuala

(MY)

_____Lumpur

10

Zifeng Tower

Nanjing (CN)

450

66

2010

composite

11

Willis Tower

Chicago (US)

442.1

108

1974

steel

12

KK100

Shenzhen (CN)

441.8

100

2011

composite

Guangzhou (CN)

438.6

103

2010

composite

13

13 Guangzhou Intemnational

Cnter

Finance Center

14

Marina 101

Dubai (AE)

426.5

101

2015

concrete

15

432 Park Avenue

New York (US)

425.5

88

2015

concrete

Chicago (US)

423.2

98

2009

concrete

16

16 Trump International Hotel

ter

& Tower

17

Jin Mao Tower

Shanghai (CN)

420.5

88

1999

composite

18

Princess Tower

Dubai (AE)

413.4

101

2012

steel/concrete

19

Al Hamra Tower

Kuwait City (KW)

412.6

80

2011

concrete

Two International Finance

20

Centre

Hong Kong (CN)

412

88

2003

composite

21

23 Marina

Dubai (AE)

392.4

88

2012

concrete

22

CITIC Plaza

Guangzhou (CN)

390.2

80

1996

concrete

23

Capital Market Authority

Tower

Riyadh (SA)

385

76

2015

composite

24

Shun Hing Square

Shenzhen (CN)

384

69

1996

composite

50

25

Eton Place Dalian Tower 1

Dalian (CN)

383.1

80

2015

composite

26

Burj Mohammed Bin

Rashid Tower

Abu Dhabi (AE)

381.2

88

2014

concrete

27

Empire State Building

New York

City (US)

381

102

1931

steel

28

Elite Residence

Dubai (AE)

380.5

87

2012

concrete

29

Central Plaza

Hong Kong (CN)

373.9

78

1992

Moscow (RU)

373.7

95

2015

Concrete

Federation Towers

Vostok Tower

31

Bank of China Tower

Hong Kong (CN)

367.4

72

1990

composite

32

Bank of America Tower

New York (US)

365.8

55

2009

composite

33

Almas Tower

Dubai (AE)

360

68

2008

concrete

34

JW Marriott Marquis

Hotel Dubai Tower 1

Dubai (AE)

355.4

82

2012

concrete

35

JW Marriott Marquis

Hotel Dubai Tower 2

Dubai (AE)

355.4

82

2013

concrete

36

Emirates Tower One

Dubai (AE)

354.6

54

2000

composite

37

OKO - South Tower

Moscow (RU)

353.6

85

2015

concrete

38

The Torch

Dubai (AE)

352

86

2011

concrete

Shenyang (CN)

350.6

68

2015

composite

-

30

39

Forum 66 Tower

1

concrete

40

The Pinnacle

Guangzhou (CN)

350.3

60

2012

concrete

41

T & C Tower

Kaohsiung (TW)

347.5

85

1997

composite

42

Aon Center

Chicago (US)

346.3

83

1973

steel

43

The Center

Hong Kong (CN)

346

73

1998

steel

44

John Hancock Center

Chicago (US)

343.7

100

1969

steel

45

ADNOC Headquarters

Abu Dhabi (AE)

342

76

2015

concrete

Dubai (AE)

342

76

2015

steel/concrete

Wuxi (CN)

339

68

2014

composite

World

Chongqing

Cnr

F in

Chongqing (CN)

338.9

72

2015

composite

Mercury City Tower

Moscow (RU)

338.8

75

2013

concrete

Tianjin (CN)

S

C

336.9

3

2011

composite

Shanghai (CN)

333.3

75

6

60

2006

concrete

Ahmed Abdul Rahim Al

46

Aed

Wuxi International

Finnaioal

47

48

49

50

51

Tb wer

Attar Tower

Finance Square______________

48

Financial Center

50 Tianjin World Financial

Center

P

Shimao International Plaza

51

52

Rose Rayhaan by Rotana

Dubai (AE)

333

71

2007

composite

53

Minsheng Bank Building

Wuhan (CN)

331

68

2008

steel

54

China World Tower

Beijing (CN)

330

74

2010

composite

Hanoi (VN)

328.6

72

2012

concrete

55

Keangnam Hanoi

Landmark Tower

56

Longxi International Hotel

Jiangyin (CN)

328

72

2011

composite

57

Al Yaqoob Tower

Dubai (AE)

328

69

2013

concrete

58

Wuxi Suning Plaza

Wuxi (CN)

328

68

2014

composite

1

59

The Index

Dubai (AE)

326

80

2010

concrete

60

The Landmark

Abu Dhabi (AE)

324

72

2013

concrete

61

Deji Plaza

Nanjing (CN)

324

62

2013

composite

Yantai (CN)

323

59

2015

composite

62

Yantai Shimao No. 1 The

Harbour

63

QI Tower

Gold Coast (AU)

322.5

78

2005

concrete

64

Wenzhou Trade Center

Wenzhou (CN)

321.9

68

2011

concrete

65

Burj Al Arab

Dubai (AE)

321

56

1999

composite

66

Nina Tower

Hong Kong (CN)

320.4

80

2006

concrete

67

Chrysler Building

New York

City (US)

318.9

77

1930

steel

68

New York Times Tower

318.8

52

2007

steel

Wuhu (CN)

318

66

2015

composite

69

Riverside Century Plaza

Main Tower

New York

City (US)

70

HHHR Tower

Dubai (AE)

317.6

72

2010

concrete

71

Bank of America Plaza

Atlanta (US)

311.8

55

1992

composite

72

Moi Center Tower A

Shenyang (CN)

311

75

2014

composite

73

U.S. Bank Tower

Los Angeles (US)

310.3

73

1990

steel

74

Menara Telekom

310

55

2001

concrete

75

Ocean Heights

Dubai (AE)

310

83

2010

concrete

76

Pearl River Tower

Guangzhou (CN)

309.4

71

2013

composite

77

Fortune Center

Guangzhou (CN)

309.4

73

2015

composite

78

Emirates Tower Two

Dubai (AE)

309

56

2000

concrete

79

Burj Rafal

Riyadh (SA)

307.9

68

2014

concrete

Tower

Chicago (US)

Chi (U)

306.9

306.9

60

60

1989

1989

Cayan Tower

Dubai (AE)

306.4

73

2013

80

81

52

The Franklin - North

Kuala

Lumpur (MY)

composite

composte

concrete

82

One57

New York (US)

306.4

75

2014

steel/concrete

83

East Pacific Center Tower

A

Shenzhen (CN)

306

85

2013

concrete

84

The Shard

London (GB)

306

73

2013

composite

85

JPMorgan Chase Tower

Houston (US)

305.4

75

1982

composite

86

Etihad Towers T2

Abu Dhabi (AE)

305.3

80

2011

concrete

Incheon (KR)

305

68

2011

composite

Bangkok (TH)

304

85

1997

concrete

Wuxi (CN)

303.8

68

2014

composite

87

Northeast Asia Trade

t

e

Tower

r

88

Baiyoke Tower II

89

Wuxi Maoye City

Marriott Hotel

-

90

Two Prudential Plaza

Chicago (US)

303.3

64

1990

concrete

91

Shenzhcn Changcheng

Center

Shenzhen (CN)

303

61

2014

composite

92

Greenland Puli Center

Jinan (CN)

303

60

2015

composite

93

Leatop Plaza

Guangzhou (CN)

302.7

64

2012

composite

94

Wells Fargo Plaza

Houston (US)

302.4

71

1983

steel

95

Kingdom Centre

Riyadh (SA)

302.3

41

2002

steel/concrete

96

The Address

Dubai (AE)

302.2

63

2008

concrete

Moscow (RU)

301.8

76

2010

concrete

97

Capital City Moscow

Tower

98

Aspire Tower

Doha (QA)

300

36

2007

composite

99

Arraya Tower

Kuwait City (KW)

300

60

2009

concrete

Busan (KR)

300

80

2011

concrete

Doosan Haeundae We've

100

the Zen

We

the Zenith Tower A

53