OHS CORRECTIVE ACTION PROCEDURE TABLE OF CONTENTS

advertisement

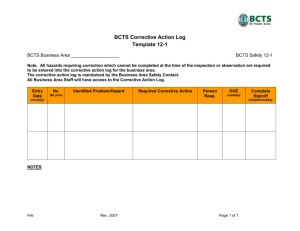

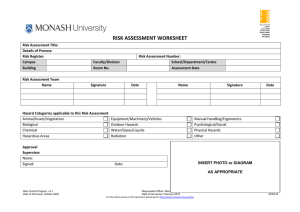

n.pdf OHS CORRECTIVE ACTION PROCEDURE AS/NZS 4801 OHSAS 18001 OHS20309 SAI Global November 2013 TABLE OF CONTENTS 1. PURPOSE .................................................................................................................................. 2 2. SCOPE ....................................................................................................................................... 2 3. ABBREVIATIONS ...................................................................................................................... 2 4. DEFINITIONS ............................................................................................................................. 2 4.1 4.2 4.3 4.4 5. STAKEHOLDERS ................................................................................................................................................... 2 SPECIFIC RESPONSIBILITIES ................................................................................................. 2 5.1 5.2 5.3 6. ACTION SEQUENCE .............................................................................................................................................. 2 CORRECTIVE ACTION............................................................................................................................................ 2 CORRECTIVE ACTION REGISTER ......................................................................................................................... 2 HEAD OF ACADEMIC/ADMINISTRATIVE UNITS (PERSON IN CONTROL OF A WORKPLACE) .............................................. 2 SAFETY OFFICERS AND SPECIALITY OFFICERS ...................................................................................................... 3 STAKEHOLDERS ................................................................................................................................................... 3 CORRECTIVE ACTION PROCEDURE .......................................................................................3 6.1 6.2 6.3 6.4 6.5 6.6 NEW ACTION IDENTIFIED ....................................................................................................................................... 3 CONSULTATION PROCESS .................................................................................................................................. 3 CORRECTIVE ACTION MANAGEMENT .................................................................................................................... 4 ACTION SEQUENCE CLOSE-OUT .......................................................................................................................... 4 REPORTING ......................................................................................................................................................... 4 CORRECTIVE ACTION REVIEW ................................................................................................................................ 4 7. RECORDS .....................................................................................................................................6 8. TOOLS ........................................................................................................................................ 6 8.1 9. REFERENCES ..............................................................................................................................6 9.1 9.2 9.3 9.4 10. CORRECTIVE ACTION REGISTER TEMPLATE .......................................................................................................... 6 LEGISLATION ....................................................................................................................................................... 6 AUSTRALIAN STANDARDS .................................................................................................................................. 6 MONASH UNIVERSITY PROCEDURES THAT CREATE CORRECTIVE ACTIONS ................................................................ 6 MONASH UNIVERSITY OHS DOCUMENTS ............................................................................................................... 6 DOCUMENT HISTORY .................................................................................................................7 Corrective Action Procedure, v3 Date of first issue: August 2007 Responsible Officer: Manager, OH&S Date of last review: November 2013 Page 1 of 7 Date of next review: 2016 31/10/2013 1. PURPOSE This document sets out the processes to be used for corrective action at Monash University in accordance with the Occupational Health and Safety Act (2004) and associated regulations and with Standards AS/NZS 4801:2001 Occupational Health & Safety Management Systems – specifications with guidance for use and OHSAS 18001:2007 Occupational Health & Safety Management Systems – requirements. Corrective action must be undertaken to meet the objective of the Occupational Health and Safety Act (2004) to eliminate, at the source, risks to the health, safety or welfare of employees and other person at work. 2. SCOPE The processes described apply to all activities conducted on Australian campuses of Monash University. 3. ABBREVIATIONS CAR HSR OHS OH&S 4. Corrective Actions Register Health and Safety Representative Occupational health and safety Monash Occupational Health & Safety DEFINITIONS A comprehensive list of definitions is provided in the Definitions Tool. Definitions specific to this procedure are as follows. 4.1 ACTION SEQUENCE A designated set of steps designed to implement a solution identified as part of a corrective action. 4.2 CORRECTIVE ACTION Corrective action (inclusive of preventive action) is an action taken to correct a health and safety related problem or potential problem, and to prevent, so far as is practicable, a recurrence. A corrective action must have an assigned responsible party, have been consulted upon with key stakeholders, have a specific solution identified and have an agreed timeframe for implementation. 4.3 CORRECTIVE ACTION REGISTER Corrective Action Register (CAR) is a record of all corrective actions that have been agreed upon and/or undertaken within a designated area. A template is available Monash University OHS website: from the Corrective-actions-register 4.4 STAKEHOLDERS Stakeholders include any individual (staff, student, contractor or visitor) who is affected by a hazard which requires controlling. 5. SPECIFIC RESPONSIBILITIES A comprehensive list of OHS responsibilities is provided in the document OHS Roles, Committees and Responsibilities Procedure. A summary of the specific responsibilities relevant to this procedure is provided below. 5.1 HEAD OF ACADEMIC/ADMINISTRATIVE UNITS (PERSON IN CONTROL OF A WORKPLACE) A head of academic/administrative unit has the overall responsibility for ensuring that every corrective action is fully implemented by an action sequence within an agreed time frame. They may delegate this responsibility to a management representative who is authorised to approve changes to a workplace. This is Corrective Action Procedure, v3 Date of first issue: August 2007 Responsible Officer: Manager, OH&S Date of last review: November 2013 Page 2 of 7 Date of next review: 2016 31/10/2013 commonly a manager or deputy head. 5.2 SAFETY OFFICERS AND SPECIALITY OFFICERS Safety officers may only act on corrective actions when instructed by a head of academic/administrative unit (or delegate) or if they have been authorized as delegate to approve changes to a workplace. They must be included in the consultation process. 5.3 STAKEHOLDERS Stakeholders are responsible for participating in the consultation process for all relevant actions being considered. Stakeholders are not responsible for ensuring that an action is undertaken. 6. CORRECTIVE ACTION PROCEDURE 6.1 NEW ACTION IDENTIFIED Process associated with the following procedures may identify occupational health and safety issues that will require corrective action: • Hazard and incident reporting, investigation and recording (pdf 147kb) • OHS Audit Procedure (pdf 124kb) • Emergency Preparedness • Risk management program (pdf 385kb) • OHS roles, committees and responsibilities procedure (pdf 153kb) – Specifically committees • OHS management system implementation procedure – Specifically OHS plans 6.2 CONSULTATION PROCESS When an issue has been identified that requires action, the consultation process must initiated. 6.2.1 The resolution of an issue must be assigned to a responsible party who is either the head of academic/administrative unit or their delegate. In a situation where multiple responsible parties are identified (e.g. multiple organizational units involved), agreement must be reached on whom the most appropriate party is. A head of academic/administrative unit may assign a delegate. 6.2.2 Consultation with key stakeholders must occur for all corrective actions. Stakeholders must include, where applicable; a head of academic/administrative unit or approved delegate, area or activity head, relevant supervisors, the designated work group’s HSR and/or any staff, students, contractors or visitors undertaking work or located near work area. OHS chairpersons, safety officers and any other specialty safety roles, Monash University OH&S and/or external consultants may be included in consultation if requested or required. Stakeholders must agree upon: • what is the problem • what potential solutions are available and which of these is the preferred option • what time frame for this action is reasonable • who is responsible for resolving the matter 6.2.3 If agreement on any of these elements cannot be reached, escalation of the responsible party must follow the Health and Safety Issue Resolution Procedure. Corrective Action Procedure, v3 Date of first issue: August 2007 Responsible Officer: Manager, OH&S Date of last review: November 2013 Page 3 of 7 Date of next review: 2016 31/10/2013 6.2.4 6.3 6.4 6.5 Once agreement has been reached; the problem, the preferred option, the agreed timeframe and the responsible party, must be recorded in a Corrective Actions Register (CAR) and the status recorded as “Open”. CORRECTIVE ACTION MANAGEMENT 6.3.1 A responsible party must create an action sequence to complete all aspects of an “Open” corrective action. Guidance on creating and implementing action sequences can be found in the Guideline for implementing corrective actions (to be implemented). 6.3.2 The head of academic/administrative unit or delegate must either complete the action sequence or assign agreed actions to suitable staff, students, contractors and/or visitors. 6.3.3 Responsibility for the completion of an action plan remains with the head of academic/administrative unit or delegate. The head of academic/administrative unit or delegate must review progress against each action plan until the action sequence is completed or the agreed time frame has lapsed. ACTION SEQUENCE CLOSE-OUT 6.4.1 Head of academic/administrative unit or delegated must ensure that each corrective action has been closed-out. Upon completion, stakeholders must be notified of the completion (e.g. via email or phone message) and the status of the action must be recorded in a CAR as “Closed: Completed”. 6.4.2 Where an action was not achievable due to a change of circumstances (e.g. lack of resources), the status shall be recorded as “Closed: Incomplete” in a CAR and consultation on a new action must be initiated. When a new corrective action has been created, this action must be linked with the previous incomplete action within a CAR. REPORTING All entries in the CAR that have recently changed status must be reported to relevant the local OHS committee and/or suitable staff meeting. 6.6 CORRECTIVE ACTION REVIEW All entries in the CAR shall be reviewed regularly by the head of academic/administrative unit or delegate (at least quarterly) and the outcome of the the local OHS committee. review reported to Corrective Action Procedure, v3 Date of first issue: August 2007 Responsible Officer: Manager, OH&S Date of last review: November 2013 Page 4 of 7 Date of next review: 2016 31/10/2013 Corrective Action Procedure, v3 Date of first issue: August 2007 Responsible Officer: Manager, OH&S Date of last review: November 2013 Page 5 of 7 Date of next review: 2016 31/10/2013 7. 8. RECORDS Record to be kept by Records To be kept for: Academic/administrative unit Records of corrective actions including complete and/or incomplete actions 5 years TOOLS 8.1 CORRECTIVE ACTION REGISTER TEMPLATE (http://www.monash.edu.au/ohs/forms/index) 9. REFERENCES 9.1 LEGISLATION Occupational Health and Safety Act 2004 (Vic) Occupational Health and Safety Regulations 2007 (Vic) 9.2 AUSTRALIAN STANDARDS AS/NZS 4801:2001 Occupational Health & Safety Management Systems – specifications with guidance for use. OHSAS 18001:2007 Occupational Health & Safety Management Systems – requirements. 9.3 MONASH UNIVERSITY PROCEDURES THAT CREATE CORRECTIVE ACTIONS (http://www.monash.edu.au/ohs/) Hazard and incident reporting, investigation and recording (pdf 147kb) OHS Audit Procedure (pdf 124kb) Emergency Preparedness Risk management program (pdf 385kb) OHS roles, committees and responsibilities procedure (pdf 153kb) – Specifically committees OHS management system implementation procedure – Specifically OHS plans 9.4 MONASH UNIVERSITY OHS DOCUMENTS (http://www.monash.edu.au/ohs/) Guideline for implementing corrective actions (to be implemented) Health and Safety Issue Resolution Procedure. Corrective Action Procedure, v3 Date of first issue: August 2007 Responsible Officer: Manager, OH&S Date of last review: November 2013 Page 6 of 7 Date of next review: 2016 31/10/2013 10. DOCUMENT HISTORY Version number 2 3 Date of Issue Changes made to document February 2011 February 2013 OHS Corrective Action Procedure, v2 1. Deleted old summary table; 2. Added responsibilities section; 3. Added procedural section in section 6; 4. Added flowchart as a visual representation of section 6; 5. Refined definitions section; 6. Added document history section; and 7. Added Tool section Corrective Action Register Template. Corrective Action Procedure, v3 Date of first issue: August 2007 Responsible Officer: Manager, OH&S Date of last review: November 2013 Page 7 of 7 Date of next review: 2016 31/10/2013