OHS Self-audit Questionnaire Introduction

advertisement

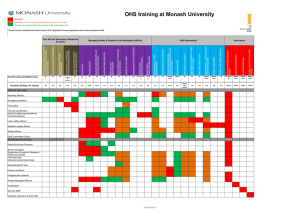

OHS Self-audit Questionnaire AS/NZS 4801 OHSAS 18001 OHS20309 SAI Global Introduction This self-audit questionnaire is based on mandatory elements of the Monash University OHS Management System (OHSMS) and the implementation and monitoring requirements of OHS Standards OHSAS 18001:2007 & AS/NZ 4801:2001. The purpose of this self-auditing tool is for each area to assess their own level of implementation of the OHSMS and to develop corrective actions to ensure continual improvement of health and safety at a local level. The OHS Self-audit questionnaire must be completed annually by each academic/administrative unit. How to use 1. 2. ALL AREAS must complete: Section A: General OHS Management requirements [Q1 – Q52] Areas that use laboratories, studios or workshops in their teaching, research or work activities should complete: Section B if they use machinery or equipment [Q53 - Q60] Section C if they use chemicals [Q61 – Q76] Section D if they use gas cylinders [Q77 – Q80] Section E if they use lasers [Q81 – Q86] Section F if they use radioactive substances, sources and apparatus [Q87– Q 97] Section G if they use biological substances [Q98 – Q102] Section H if they use animals [Q103 – Q106] 3. All OHS documents mentioned in this questionnaire are available from the Occupational Health and Safety unit website located at www.monash.edu.au/ohs/topics/index.html. A list of OHS Consultants/Advisors for all university areas is available at: www.monash.edu.au/ohs/contacts/ohs-branch.html. Details Organisational Unit: Date: Audited by: Signature/s: Safety Officer: Signature: Head of Unit: Signature: Self Audit Questionnaire, v7 Date of first issue: June 2005 Responsible Officer: Manager, OHS Date of last review: January 2015 Page 1 of 14/01/2015 A. General OHS Management Requirements OHS Planning Q1. Does your unit have a current Occupational Health and Safety plan? Yes No Q2. Is a dedicated budget allocated for OHS programs? Yes No Yes No The Monash University Health and Safety Committee requires that each Faculty/Division creates an annual plan to ensure OHS is integrated into planning and to enable continuous improvement by aligning areas with the Monash University OHS Management System. Senior Management must provide adequate budgetary resources to ensure the unit's OHS objectives can be met. Roles and Responsibilities Q3. Is there a Safety Officer appointed for the unit? Please name: The safety officer forms an important link between Occupational Health and Safety, the unit's management group, staff and students. They are the employer’s representative(s) in relation to the Victorian OHS Act 2004, s. 73 (2). The safety officer is the head of unit's nominee for health and safety matters within the unit and assumes a critical role in ensuring OHS is managed in a proactive manner. In the absence of an appointed safety officer, the relevant head of academic/administrative unit assumes the responsibilities of the safety officer (Section 5.3 of 'OHS Roles, Committees and Responsibilities'). Q4. Is there a Health and Safety Representative elected for the designated work group (DWG) to which the unit belongs? Yes No Yes No Please name: Q5. Has a First Aid Coordinator been appointed to your unit? Please name: Self Audit Questionnaire, v7 Date of first issue: June 2005 A health and safety representative is an employee representative who has been elected by the staff in the designated work group to represent their health and safety interests using the procedures outlined in the Monash University 'Procedures for health and safety issue resolution'. A health and safety representative represents all staff in a DWG and is an elected position defined under the Victorian OHS Act 2004. The statutory powers of health and safety representatives are outlined in Division 5, Part 7, of the Act and include: the right to direct work to cease where there is an immediate threat to the health and safety of any person; the right to inspect any part of the workplace at which a member of the DWG works, at any time giving reasonable notice to the relevant unit head and immediately in the event of an incident or hazardous situation; and the right to be consulted, if practicable, on any proposed changes in the workplace that may affect the health and safety of staff. Please note: There is no obligation to elect a health and safety represetatvie if the members of the DWG do not feel one is required. First aid coordinators act as the focal point for communication between first aiders in the work area and OH&S. First Aid Coordinator responsibilities are outlined in Section 5.4.3 of OHS Roles, Committees and Responsibilities'. Responsible Officer: Manager, OHS Date of last review: January 2015 Page 2 of 14/01/2015 Q6. Has a building warden been appointed for all buildings in which your unit is located? Yes No OHS responsibilities of the building warden are outlined in OHS Roles, Committees and Responsibilities' Please name: Building Address: Q7. Please name: Building Address: Have specific OHS responsibilities been included in the position descriptions, engagement profile or performance development plan of staff with the following safety roles: Q8. To ensure the safety personnel have their roles appropriately recognised and rewarded, the role/duties should be reflected in their position description, engagement profile or performance management documentation. OHS roles in position descriptions (pdf 108kb) Biosafety officers Building wardens Yes No First aiders and first aid coordinators Health and safety representatives Yes Yes Yes Yes Yes Yes No No No No No No Yes No Laser safety officers Mental Health First Aider Radiation safety officers Safety officers Have specific OHS responsibilities been included in the position descriptions, engagement profile or performance development plan of supervisory and management staff? Senior management Supervisors Safety personnel must also be provided with appropriate training to carry out their responsibilities; this also must be added to the relevant section of the Monash HR performance management documentation. OHS responsibilities, accountabilities and obligations of managers and supervisors or both academic and professional staff are outlined in OHS roles in position descriptions (pdf 108kb). Yes No Yes No Communication and Consultation: How is OHS communicated across your area? Q9. Is OHS a standing agenda item at all work area meetings? Yes No Q10. Are staff and students in your area notified of local OHS committee meetings? Yes No Yes No Q11. Do staff and students receive requests for agenda items for OHS committee meetings? Self Audit Questionnaire, v7 Date of first issue: June 2005 A clear demonstration of the incorporation of OHS as a core management responsibility is the active inclusion of OHS as a regular agenda item at meetings. OHS Communication Procedure In each area of the University, health and safety issues are managed by a local OHS committee. OHS committees are chaired by a senior academic or professional staff equivalent and include representatives from the various work groups within the area. OHS committees are required to meet at least quarterly. Their main responsibility is to provide a consultative forum for the discussion, resolution and implementation of OHS issues and the formulation of local practices that promote OHS within their area. OHS committee meetings are a forum for discussion of OHS issues, notice of each meeting must be circulated to the staff and students in the area, requesting agenda Responsible Officer: Manager, OHS Date of last review: January 2015 Page 3 of 14/01/2015 items and/or issues for discussion. Items submitted must be included on the agenda of the next meeting and the proposer invited to the meeting for the discussion of the item. Q12. Are minutes of OHS meetings made accessible to all staff and students? Q13. Are the following documents displayed on work area notice boards? Q14. Monash University OHS policy Health & safety issue resolution procedural flowchart? Lists of first aiders & emergency wardens? “If you are injured” poster from the Victorian WorkCover Authority (VWA)? Name and contact details of HSR (if applicable) and Other local Safety personnel Does your work area follow the Monash University OHS procedures for consultation? Yes No Minutes of meetings must be kept and made accessible to all staff and postgraduate students (e.g. copies on safety notice boards, in the lunch room, circulated electronically and/or on a website). To promote general awareness of OHS across the University, all units are to display the current OHS policy within the work area. Staff and/or student noticeboards or safety specific noticeboards are promoted as the best place to display the OHS policy. Section 6.4 OHS Communication Procedure Yes Yes Yes Yes No No No No Yes Yes No No Displaying the “If you are injured at work” poster is a requirement of the Accident Compensation Act 1985 s.101. Copies can be obtained from the Occupational Health and Safety Unit. Yes No In accordance with the Victorian OHS Act 2004 s. 35(1), staff must be consulted: during risk management; when making decisions regarding facilities related to welfare, e.g. toilets, first aid; during development of OHS policies and procedures; when changes are proposed to the workplace, new buildings and renovations, machinery/equipment, substances, processes and other things used in the workplace or the work performed that may affect the health and safety of staff. The OHS issue resolution flowchart is on Page 3, Section 5 of the linked procedure. The Monash University 'Procedures for OHS consultation' outline consultation procedures to be followed by units. Units must also develop internal procedures to ensure that staff are involved in the risk management process. OHS Induction Q15. Do all staff complete the online Monash Safety induction? Yes No Q16. Do all HDR students complete the online Monash Safety induction? Yes No OHS induction at Monash University is split into two mandatory programs - the online general induction and the local area induction. On commencement, all new staff and HDR students must receive an OHS induction outlining key safety and emergency information and OHS training available (see 'OHS induction and training at Monash University)'. Q17. Do you check that trades contractors engaged through a BEIMS request have completed the online Monash Contractor Safety induction? Self Audit Questionnaire, v7 Date of first issue: June 2005 Yes No The Monash Safety Induction is available on line for use by all units in the induction of new staff and HDR students. The program aims to provide staff with a brief overview of OHS policies, procedures and practices at Monash and a basic understanding of their own OHS responsibilities. New staff and HDR students should complete the program, as well as being advised of the health and safety aspects of their work, including local OHS procedures, within the first few days of their arrival. All Contractors are required to complete the Facilities and Services Contractor Induction prior to commencing work and register their on-site attendance (signing in) & departure Responsible Officer: Manager, OHS Date of last review: January 2015 Page 4 of 14/01/2015 Q18. When trades contractors arrive in your area, you must ensure they have the Contractor sticker label displayed. Do all staff complete a local OHS induction that has been developed in accordance with the OHS Local Induction procedure? (signing out) at the Facilities and Services kiosk. Contractors are required to wear the contractor’s registration sticker issued at the kiosk. Yes No Q19. Do all HDR students complete a local OHS induction that has been developed in accordance with the OHS Local Induction procedure? Yes No Q20. Do all visitors complete a local OHS induction that has been developed in accordance with the OHS Local Induction procedure? Yes No Q21. Do all contractors complete a local OHS induction that has been developed in accordance with the OHS Local Induction procedure? Yes No Q22. During induction are training needs identified? Yes No And safety issues associated with the work area discussed? Yes No Yes No As part of the induction process, new staff members and HDR students must be provided with a local OHS induction which covers local procedures and information such as equipment manuals, safety manual(s) and safe work instructions for equipment. As staff commence their work, they should be instructed in the use of new procedures, processes and equipment by their supervisor. Records of OHS inductions and receipt of OHS information must be maintained in the unit. OHS training needs must be identified for staff and students working/studying in their area. Training Q23. Q24. Do you have a system to identify OHS training requirements for all staff and students? Have all staff with safety roles (including managers and supervisors) and students undertaken all required OHS training in the last 3 years? Yes No The Staff Development Unit coordinates centralised training courses for staff (see 'OHS induction and training at Monash' and the 'OHS Training Guide'). In addition, the individual OHS training needs of units can be determined through discussions with local safety officers, by contacting the Staff Development Unit or OHS Consultant/ Advisor responsible for your area. A Training Record form can be used to record local training and is provided at the OH&S web site. On a regular basis, OHS training undertaken by staff and students in the unit should be reviewed against the unit's OHS requirements in order to organise any additional training required. Guidance on determining OHS training requirements is provided in the OHS training guide, available on the OH&S website. Emergency preparedness Q25. Do you have a 333 Emergency procedures booklet by every phone in your unit? Yes No http://www.monash.edu.au/ohs/topics/emergencies-evacuations.html (This is not applicable to areas located in hospitals) Self Audit Questionnaire, v7 Date of first issue: June 2005 Responsible Officer: Manager, OHS Date of last review: January 2015 Page 5 of 14/01/2015 Have evacuation trials been conducted across all the buildings in which the unit is located as required? Yes No The Monash University OHS Committee requires that either one or two practise evacuations (depending on building type) are held in Monash University buildings each year to ensure that all occupants are aware of emergency procedures Q26. Has Occupational Health and Safety been informed of evacuations conducted? Yes No Q27. Is an up to date contact list of trained first aid staff available in all relevant public areas? Yes No Q28. Has a first aid assessment been completed for the unit as required by the Monash University 'Procedures for first aid'? Has a copy of the first aid assessment been forwarded to the Occupational Health Team? Yes No Yes No Q30. Is the assessment less than 3 years old? Yes No Q31. Does your unit have a defibrillator? Yes No Following each evacuation, a copy of the 'Record of building evacuation form' must be forwarded to the local OHS committee and to the OHS Consultant/Advisor by the building warden. The building warden must also keep a copy of the form. Occupational Health and Safety maintains a record of all evacuations conducted across the University. Summaries of these figures are reported to the quarterly meetings of the Monash University OHS Committee in order to monitor performance against targets set each year. First aiders must be easy to access. Systems that can be used include displaying lists of contact details of first aiders or signs to the locations where first aid is available. These systems must be kept up to date. The 'Procedures for first aid' require that an assessment is undertaken to determine the number and competencies of first aiders required and the number and locations of first aid kits in each area. A first aid assessment form and accompanying 'Guidelines for assessing the number of first aiders required' are provided in the procedures. Examples of completed assessments are provided in the procedures and assistance with the assessment is available from Occupational Health and Safety, who should be sent a copy of the completed assessment. The first aid assessment should be reviewed whenever significant changes occur in the size/layout of the workplace, the number and/or distribution of employees, the hours of work or study or the nature of the hazards and the severity of the risks or at least every 3 years. Section 13.3 'Procedures for first aid' Defibrillator Maintenance Checklist Yes No Yes No All hazards, incidents and accidents involving Monash University staff, students, visitors and contractors or property must be reported, investigated and corrective/preventive action recommended. The Monash University 'Procedures for Hazard and Incident Reporting, Investigation and Recording' set out the actions to be followed. Yes No Workplace safety inspections are planned; systematic appraisals of the workplace which can help identify and resolve hazards before any harmful event takes place. Inspections can also assist work areas to comply with OHS legislation. Q29. Q32. Please name the staff member responsible for maintaining the defibrillator: Have the required 6 monthly defibrillator checklists been completed and records kept? Zoll Defibrillator Checklist Incident reporting Q33. Are all workplace hazards and injuries involving staff, students, visitors and contractors reported and actioned in a timely manner in accordance with the Monash University Procedures for Hazard & Incident reporting, investigation & recording? Workplace inspections Q34. Are two workplace inspections carried out in all of the work areas occupied by the unit each year? Self Audit Questionnaire, v7 Date of first issue: June 2005 Responsible Officer: Manager, OHS Date of last review: January 2015 Page 6 of 14/01/2015 Date of last inspection Q35. Have workplace inspection findings been forwarded to the OH&S unit and added to your corrective actions register? A workplace inspection program is available at the OH&S website. Training in the use of the workplace inspection program is coordinated centrally by the Staff Development Unit or the individual OHS training needs of units can be determined through discussions with local safety officers, by contacting Staff Development or OHS Consultant/ Advisor responsible for your area Yes No Following each round of inspections, copies of the 'Summary of inspections' form, which is provided as part of the workplace inspection program, should be completed and forwarded to the local OHS committee and to Occupational Health and Safety unit. An OHS risk register is a central repository for all OHS risks identified by the unit and for each OHS risk includes an OHS risk ranking based on likelihood and consequence, impact and control strategies (also known as a risk assessment). Once the acceptable level of risk is achieved, the risk assessments should only be reviewed when: • there is a significant change; • a hazard or incident report is generated; or • at least every three years. Risk management Q36. Does your unit have a Risk Register? Yes No Q37. Are all risk assessments reviewed every 3 years? Yes No Q38. Are risk assessments for laboratories, workshops and studios: N/A (i) (ii) Yes No Yes Yes Yes Yes Yes Yes Yes No No No No No No No Q39. based on local procedures include: purchase transport operations system of work maintenance/service/repair/cleaning waste and decommissioning working after hours A Risk Management Program is available to assist with this task. Training in the use of the Risk Management Program is coordinated centrally or can be arranged specifically for your work area by contacting the Staff Development Unit. The Risk Management Program is available to assist with this task The following documents provide further guidance: Working After Hours Off Campus Activities Office Ergonomics High risk occupations (VWA) Are risk assessments for administrative areas: N/A (iii) based on local procedures? (iv) and include: Yes No Training in the use of the Risk Management Program is coordinated centrally or can be arranged specifically for your work area by contacting the Staff Development Unit. The Risk Management Program is available to assist with this task Yes Yes Yes Yes Yes No No No No No The following documents provide further guidance: Yes No Ergonomics/Manual Handling Travel to other campuses Off-campus activities including urban, rural and international Working After-Hours Workload (additional resources provided during busy periods e.g. grant writing, exam periods, end of financial year) Self Audit Questionnaire, v7 Date of first issue: June 2005 A Risk Management Program is available to assist with this task. Working After Hours Off Campus Activities Office Ergonomics High risk occupations (VWA) Responsible Officer: Manager, OHS Date of last review: January 2015 Page 7 of 14/01/2015 Q40. Possible encounters with high-risk behaviour by individuals (e.g. Client-based services, distressed students). When selecting your risk controls do you use the hierarchy of controls? Yes No The hierarchy of control ranks risk control measures in decreasing order of desirability and effectiveness. These are: • Elimination – Remove the hazard • Substitution – Exchange the hazard for a lesser one • Isolation – Separate people from the hazard • Engineering controls – Use physical barriers to control the hazard • Administrative controls – Provide information, training and procedures to ensure that people can manage the hazard appropriately • Personal Protective Equipment (PPE) – Last layer of defence to stop people from being exposed to the hazard. Q41. Have all relevant staff and students been consulted for each risk assessment? supervisor of the area; personal undertaking the task; safety officer of the area; health and safety representative of the area; and External organisation or subject matter expert (when appropriate). Yes Yes Yes Yes Yes No No No No No In accordance with the Victorian OHS Act 2004 s. 35(1), staff must be consulted: during risk management; when making decisions regarding facilities related to welfare, e.g. toilets, first aid; during development of OHS policies and procedures; When changes are proposed to the workplace, machinery/equipment, substances, processes and other things used in the workplace or the work performed that may affect the health and safety of staff. Q42. Have safe work procedures/instructions (e.g. posters and notices, safe operating procedures, laboratory manuals) been developed where required? Yes No Safe work instructions provide essential information to ensure staff and students perform tasks safely. These instructions also assist in the training and orientation of new staff and students in the hazards of the tasks to be performed, as well as providing them with the rules and procedures necessary to ensure that they can perform their work in a safe manner. 'Guidelines for the development of safe work instructions' are available from the OH&S website, which provide a template and guidance for the content and format of safe work instructions. Q43. Are local procedures in use for staff and students working alone, at night or weekends? Yes No The 'OHS after-hours procedures' outline a range of strategies for controlling the risks associated with staff and students who find it necessary to work alone after hours or at weekends. Local procedures should be developed and communicated to all staff and students. Yes No A corrective actions register (CAR) is a record of all corrective actions resulting from audit findings, hazard and incidents, building evacuation reports, workplace inspections and risk management and risk control review. Corrective actions Q44. Does your unit have a Corrective Actions Register (CAR)? Self Audit Questionnaire, v7 Date of first issue: June 2005 Responsible Officer: Manager, OHS Date of last review: January 2015 Page 8 of 14/01/2015 Q45. Does the CAR include corrective actions from the following sources? Q46. Once hazards and issues are identified, corrective actions can be established which should be preventive in nature. Responsibility for completing the corrective actions can then be assigned and time frames for the completion of each action agreed upon and recorded. CAR actions can then be reviewed and closed out. Yes Yes Yes Yes Yes Yes Yes No No No No No No No Yes No Yes No OHS Corrective Action Procedure Yes No To ensure the safety of electrical equipment, each academic/administrative unit is responsible for: Ensuring that electrical equipment is inspected, tested and tagged as outlined in OHS information sheet No. 33: Inspection, testing, tagging & repair of electrical equipment; Withdrawing failed or faulty equipment from service; and Maintaining records of testing Yes No The Wellbeing@ Monash Champion role contributes to building a healthier Monash community by promoting and providing input into the Wellbeing at Monash Program. The role is outlined in http://www.monash.edu.au/ohs/wellbeing/wellbeing-champions.html Does your unit have a wellbeing program/initiative in place? Yes No Wellbeing programs and services http://www.monash.edu.au/ohs/wellbeing/ Please list (e.g. SWAP, Mindfulness, Healthy Catering): 1. OHS Internal, external and accreditation audits OHS Self-audit questionnaire Hazard and incident investigation Monitoring and review of OHS Plans Review of risk management controls Workplace Inspections Building evacuations OHS Committee actions arising Are all corrective actions closed out within the agreed timeframes? Electrical safety Q47. Has electrical equipment been tested and tagged according to OHS requirements? Wellbeing@Monash Q48. Is there someone responsible for coordinating wellbeing programs in your unit? Name of person responsible: Q49. 2. 3. Records & Document Management Q50. Are locally created OHS procedures and guidelines controlled in accordance with Monash University OHS Management system requirements? And include: Date Created Author Self Audit Questionnaire, v7 Date of first issue: June 2005 Local area OHS documentation is created when the central OHS Management System policies, procedures and guidelines are not specific enough for the process to be implemented at the local level. Yes Yes No No Responsible Officer: Manager, OHS Date of last review: January 2015 Page 9 of 14/01/2015 Date of next review Filename/ storage location of document Reference to the central OHS Management System guidance document the procedure is based on. Yes Yes Yes No No No Local OHS documentation should be developed in accordance with Monash University’s central endorsed policies and procedures to ensure a consistent method of managing health and safety throughout the organisation. Regular review of local documents should occur to ensure consistency with the OHS Management System. All locally produced OHS documentation should be approved by the local OHS Committee to ensure best practice consultation requirements are met. OHS Records Management Procedure Q51. Are locally created OHS procedures approved and endorsed by the local OHS committee? Yes No Q52. Are local records kept in accordance with the OHS Management System record management requirement? Yes No Yes No 'Use, design and modification of machinery and equipment at Monash University' provides guidance to staff, students, visitors and contractors who use machinery/equipment at Monash University. B. Machinery or Equipment Q53. Does your unit use machinery/equipment (other than personal computers and office equipment)? If no, skip to Section C Q54. Does your unit have a plant register? Yes No Q55. Do you have a maintenance schedule for plant? Yes No The OHS Regulations 2007 require that risk management is undertaken on processes that use machinery and equipment in workshops, laboratories and studios to identify and assess the risks associated with the machinery/equipment and to ensure that effective measures to eliminate or reduce the risk of injury are adopted http://www.monash.edu.au/ohs/topics/machine-equipment-safety.html Q56. Are electrical high voltage equipment protected by RCD or lock out mechanisms? Yes No http://www.monash.edu.au/ohs/topics/procedures/isolation-of-equipment.pdf Q57. Is all machinery adequately equipped with guarding and emergency stop capabilities? Yes No http://www.monash.edu.au/ohs/topics/guard-machine-equipment.html Q58. Do certain types of machinery require clearance zones for safe operation? Yes No http://www.monash.edu.au/ohs/topics/machine-equipment-safety.html Q59. Do you supply machinery/equipment to other areas at Monash or outside Monash? Yes No Q60. If you supply machinery/equipment to other areas at Monash or outside Monash, has this been risk managed? Yes If machinery/equipment is sold or supplied to other users, the OHS Regulations 2007 require that risk management is completed on the machinery/equipment and that this information is supplied to the new owner/user. All records associated with the machinery/equipment must also be provided. 'Use, design and modification of machinery and equipment at Monash University' provides guidance for the sale or supply of machinery/equipment. No C. Chemicals Self Audit Questionnaire, v7 Date of first issue: June 2005 Responsible Officer: Manager, OHS Date of last review: January 2015 Page 10 of 14/01/2015 Q61. Does your unit use chemicals, e.g. for work procedures, cleaning, teaching, research, preparation of materials? Yes No 'Using chemicals at Monash University' provides guidance to staff, students, visitors and contractors who use chemicals at Monash University. If no, skip to Section D Q62. Do you have a chemical register for: Laboratories And external storage areas Yes Yes No No 'Using chemicals at Monash University' (Section 10.1.1) All areas must maintain a chemical register, which includes: A list of all chemicals currently in use, and Either a hard copy or access to an electronic copy of the Material Safety Data Sheet (MSDS) for each chemical Q63. Are local procedures in place for unattended chemical reactions? Yes No The risks associated with unattended reactions must be assessed using the Monash University Risk Management Program and strategies developed to reduce or eliminate identified risks. This includes testing of systems before use, implementation of fail safe systems, signage and notification to Security staff. Q64. Q65. Does your unit use any scheduled carcinogens? Is there a procedure for storage and handling of scheduled carcinogens? Yes Yes No No Specific requirements for the use of scheduled carcinogen substances are included in the OHS Regulations 2007. To ensure that units comply with these requirements, they are asked to notify Occupational Health and Safety of any use of a scheduled carcinogen, a list of which is provided by the Victorian WorkCover Authority. Q66. Do you supply chemical substances to other areas at Monash or outside Monash? Do you supply a MSDS for the chemical substances you supply? Are chemicals stored according to Monash University storage limits for dangerous goods? Do you have a process for labelling stored (including fridges and freezers) and decanted chemicals? Yes No It is a legislative requirement for the manufacturer or importer to supply a copy of the MSDS for each chemical to the end user. Yes Yes No No Yes No All containers of chemicals or chemical waste must be labelled clearly. The General chemical storage guidelines available at the OH&S web site and in poster form provide an overview of storage of all chemicals in laboratory/studio/workshop areas www.monash.edu.au/ohs/topics/chemical-safety.html. Q70. Are the dangerous goods storage cabinets functioning according to the manufacturing standards? Yes No Q71. Is there a procedure for managing chemical waste? Yes No The OHS Regulations 2007 and Dangerous Goods (Storage & Handling) Regulations 2000 require that risk management is undertaken for the use, storage and handling of chemicals to identify and assess the risks associated with the chemicals and to ensure that effective measures to eliminate or reduce the risk of injury are adopted. Chemical Waste Disposal Q72. Do you have a procedure for purchasing, handling and storage of scheduled poisons? Yes No Purchase and Storage of Scheduled Poisons Q73. Are your fume cupboards tested annually? Yes No Q74. Is there a process for the use of fume hoods? Yes No The Australian Standard AS/NZS 2243.8 - 2006 Safety in Laboratories - Fume Cupboards requires fume cupboards to have their performance tested on a regular basis. Testing of the face velocity together with smoke testing should occur on an annual basis. Use of local exhaust ventilation systems: fume cupboards Q67. Q68. Q69. Self Audit Questionnaire, v7 Date of first issue: June 2005 http://www.monash.edu.au/ohs/topics/dangerous-goods-storage.pdf Responsible Officer: Manager, OHS Date of last review: January 2015 Page 11 of 14/01/2015 Q75. Q76. Do you have procedures for the management of spills? Is there a process for regular testing of safety showers? Yes Yes No No http://www.monash.edu.au/ohs/forms/spill-kits-laboratories.pdf All safety showers and eyewash facilities must be regularly flushed and checked to ensure they are fully functional. This function is centrally managed by Facilities and Services Phone: 9902 0222 Email: facilities.services.clayton@monash.edu D. Gas cylinders Q77. Does your unit use gas cylinders? Yes No Yes No Yes No Yes No If no, skip to Section D Q78. Are all gas cylinders controlled by your unit 'in use'? Q79. Is there a procedure for the storage and handling of gas cylinders? Q80. Are gas cylinders stored according to Monash University guidelines? ‘In Use’ refers to a pressurised gas cylinder currently in use. E.g. An in use cylinder may include one that is fitted with a regulator and connected to associated equipment. All gas cylinders in the University must be properly restrained, whether in use, being stored or being transported - this includes "empty" cylinders. Cylinders being stored or in use will be secured to a fixed structure. Where possible, cylinders be stored in, and used from secure locations outside of buildings. Refer to Australian Standard 43321995 The storage and handling of gases in cylinders and Australian Standard 2243.101993 Safety in Laboratories Part 10: Storage of chemicals for more detailed guidance on safe storage of gas cylinders used in laboratories. E. Lasers Q81. Does your unit use lasers that are class 3R, 3B or 4? Yes No Laser safety - OHS information sheet Yes No A laser safety officer is required for all class 3B and 4 lasers and class 3R laser that emit in the non-visible spectrum. If no to the question above, skip to Section F Q82. Has your unit appointed a laser safety officer? Please name: Q83. Does your unit have an established system for local training on your class 3R, 3B or 4 lasers? Yes No All users of class 3R, 3B or 4 lasers must undergo training in their safe operation and correct use of laser safe eyewear. Q84. Does your unit have an established system for authorisation of users of class 3R, 3B or 4 lasers? Yes No A system for authorisation of users is recommended for user of class 3R, 3B and 4 lasers. Q85. Does your unit have a system to control access to 3B or 4 class lasers? (door interlocks, emission indicators) Yes No Interlocks are required for class 3B and 4 systems. Emission indicators are required for all class 3B and 4 lasers and class 3R laser that emit in the non-visible spectrum. Self Audit Questionnaire, v7 Date of first issue: June 2005 Responsible Officer: Manager, OHS Date of last review: January 2015 Page 12 of 14/01/2015 Q86. Does your unit require laser eye exams for students and staff that work with 3B or 4 class lasers? Yes No Laser eye examinations are recommended for user of class 3B and 4 lasers. 'Using ionising radiation at Monash University’ provides guidance to staff, students, visitors and contractors who use ionising radiation at Monash University. F. Radiation Q87. Does your unit have or use unsealed sources? Yes No Q88. Does your unit have or use sealed sources? Yes No Q89. Does your unit have or use X-ray units? Yes No If no to all of the Qs above, skip to Section G Q90. Have you notified Occupational Health and Safety of all radioactive sources in use? Yes No Q91. Has your unit appointed a radiation safety officer (RSO)? Yes No Yes No For radiation safety officers (RSO) - Monash University All sealed sources, sealed source apparatus and X-ray units must be registered with the Department of Human Services via Occupational Health and Safety. When purchasing these items, the RSO of the area should contact the RPO for assistance with the registration process. Ionising Radiation: Source Purchase and Licensing Procedures Please name. Q92. Has your unit appointed a deputy radiation safety officer? The University Radiation Protection Officer at Occupational Health and Safety is responsible for facilitating the University’s compliance with the Radiation Act 2005, assisted by Radiation Safety Officers in each area where radiation is used. The Radiation Protection Officer can be contacted at Occupational Health and Safety on Ext. 51016 or via ohshelpline@monash.edu. Areas that use radioactive substances, sources and/or apparatus must appoint a radiation safety officer (RSO) and a deputy radiation safety officer (if required) to assist staff and students with radiation matters. Please name. Q93. Are radioactive sources and apparatus registered as required under the Radiation Act 2005? Yes No Q94. Does your unit have a purchasing procedure for radioactive substances, sources and apparatus to ensure the appropriate licenses are in place before purchasing? Yes No Q95. Does your unit have a system to monitor staff and student exposure to ionising radiation (e.g. personal radiation monitoring badges)? Yes No ‘Ionising radiation dosimetry procedures’ provides information and guidance on these requirements. Q96. Does your unit have a system to control access to radioactive sources and X-ray units, e.g. locked cupboards or laboratory, log books, etc.? Yes No Q97. Does your unit have established procedures for the disposal of radioactive waste that it generates? Yes No Access to radioactive sources and X-ray units must be limited to those provided with information and training in their use. Appropriate access control methods include locking laboratories, locking cupboards, signage and/or the use of log books to ensure that only authorised radiation users are accessing equipment. Disposal of Radioative Waste Procedure Self Audit Questionnaire, v7 Date of first issue: June 2005 Responsible Officer: Manager, OHS Date of last review: January 2015 Page 13 of 14/01/2015 G. Biologicals Does your unit use biological substances, e.g. human blood, bodily fluids or tissues, microorganisms, animal blood or tissues, cultured cells, biological products derived from cells, microorganisms or animals? Yes No 'Using biologicals and animals at Monash University' provides guidance to staff, students, visitors and contractors who use biologicals and animals at Monash University. If no, skip to Section H Q98. Has your unit appointed a biosafety officer? Yes No Areas that use biological substances must appoint a biosafety officer. Q99. Q100. Please name: Please provide the date of your latest OGTR Audit. Have all corrective actions from this audit been implemented? Yes No OHS Corrective Action Procedure Q101. Have immunisation requirements been identified? Yes No Procedures for Immunisation Work Related Immunisation Requirements for Monash University Staff and Students H. Animals Q102. Do staff in your unit use or have contact with animals during their work, teaching or research? Yes No 'Using biologicals and animals at Monash University' provides guidance to staff, students, visitors and contractors who use biologicals and animals at Monash University. Fit testing is required to be conducted for all staff/students that are required to wear respiratory protection in line with AS/NZS 1715:2009 Selection, use and maintenance of respiratory equipment. If no, you have completed this review. Q103. If your work requires you to wear a mask, have you been 'fit tested' (for an appropriate mask)? Yes No Q104. Have the appropriate health surveillance measures been identified? (e.g. lung function testing) Have immunisation requirements been identified? Yes No Yes No Q105. Health Surveillance Procedure Procedures for Immunisation Work Related Immunisation Requirements for Monash University Staff and Students You have now completed this audit. Self Audit Questionnaire, v7 Date of first issue: June 2005 Responsible Officer: Manager, OHS Date of last review: January 2015 Page 14 of 14/01/2015